rdhunt1

Registered User-

Posts

53 -

Joined

Personal Information

-

Location

SE Wisconsin

-

Interests

Cool toys! Racing vintage motorcycles and sidecar

-

Occupation

Engineer for API Heat Transfer

-

Se7en

Caterham

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Love the chart! Common manifold or not the different positions and respective causes is great info to have. Thank you!

-

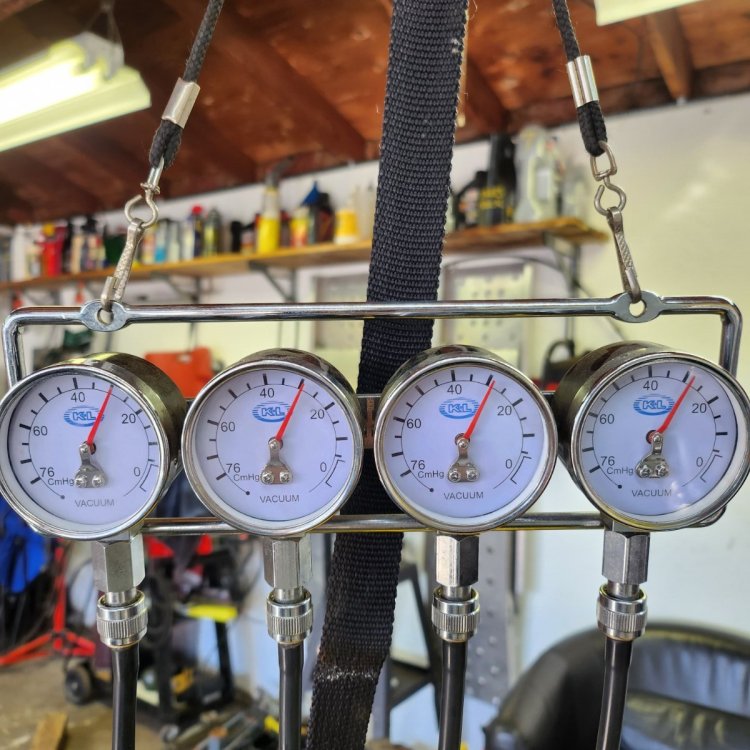

Jb, Yessir... correct on the dampening action. The small collar right before the hose leading to the carb allows damping of the intake pulse. Played with it a bit, but eventually brought it down to about a needles width of movement and continued tuning from there. Prompting my original question was seeing some vac gauges that have colored areas that indicate good, bad, etc. More particularly, one gauge had an area indicated for late ignition timing. Knowing I have my lucas/aldon with a whopping 12 degrees of advance, turned up to about 22 degrees base for an all in around 34 and wondering how much of an effect it had on my readings.

-

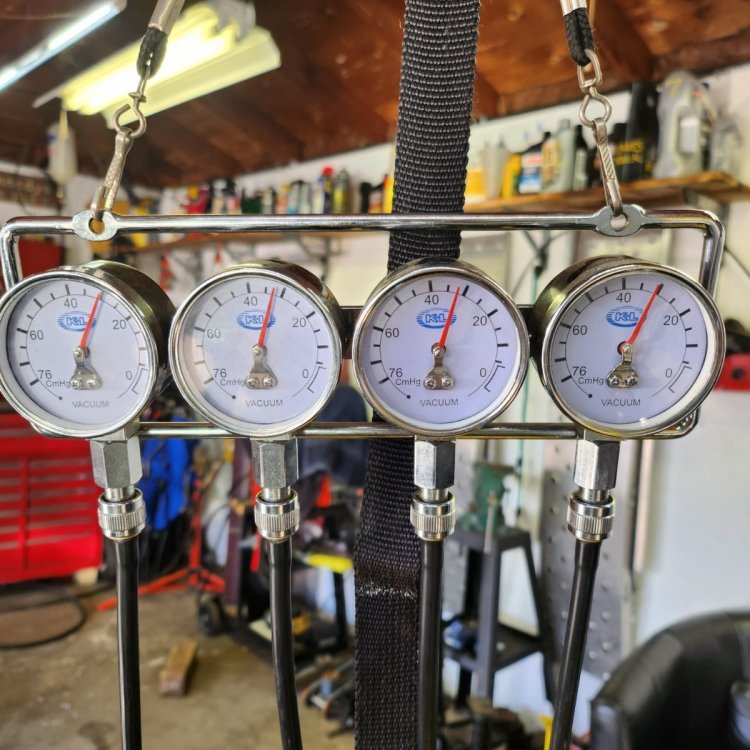

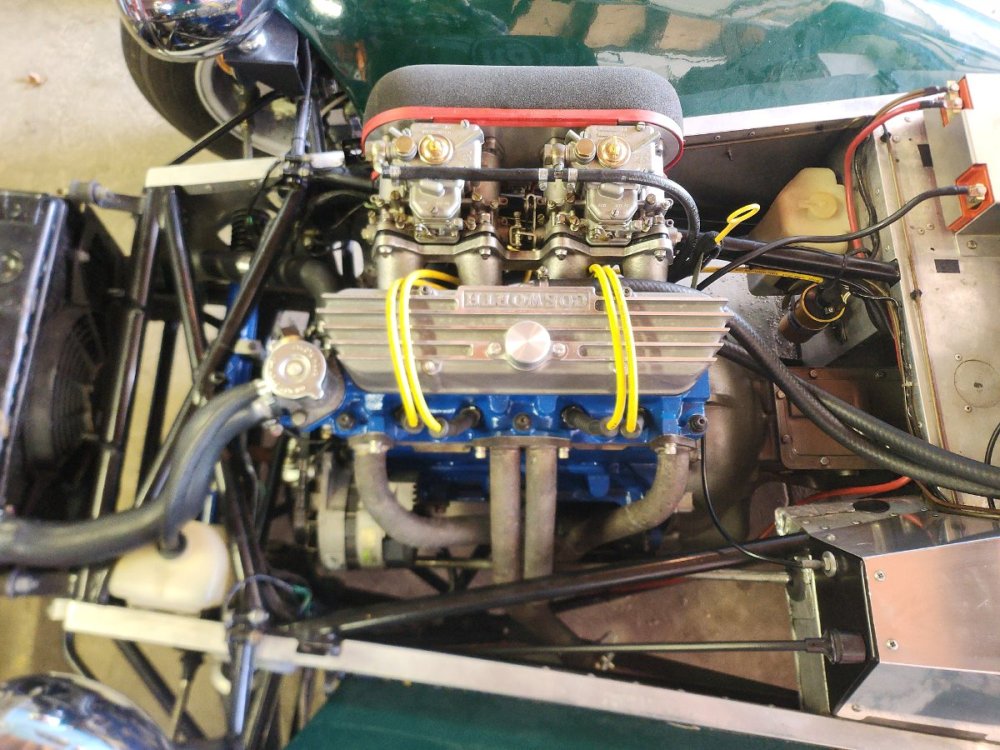

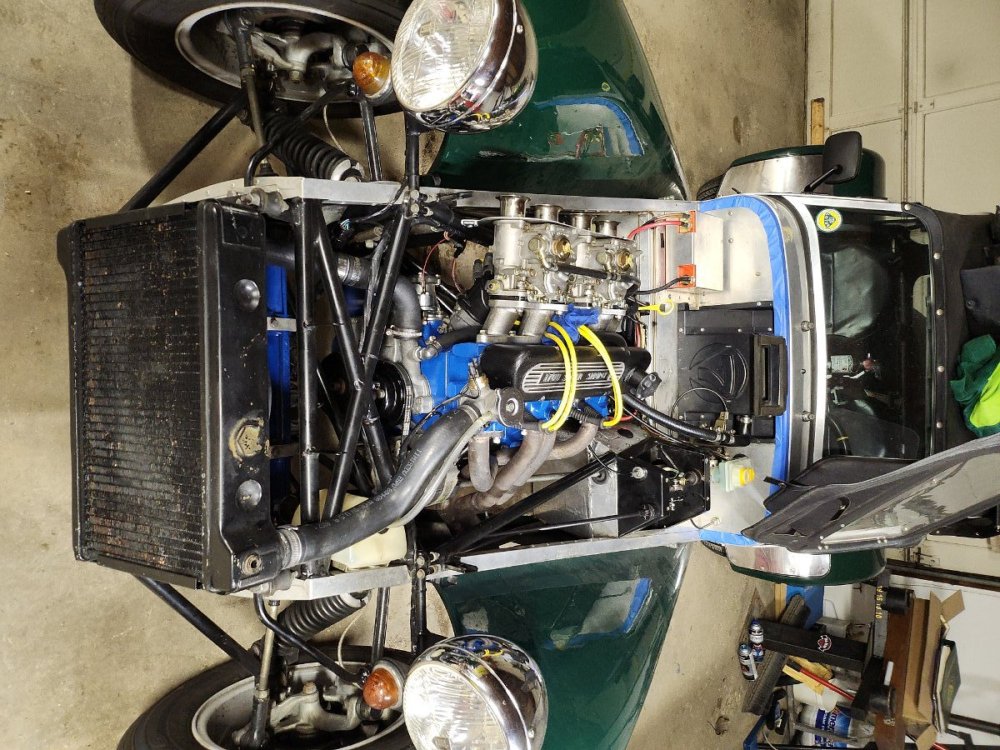

Does anyone have any manifold vacuum data for a 1700 supersprint crossflow on 40's? Maybe this isn't even relative since choke size and cam choice will likely put these all over the map. BUT... With the ever-decreasing temps up here in wisconsin, I decided to try some larger idle jets. After installing i went about resetting idle mixture and checking balance on the carbs for good measure. I got pretty darned close with my old unisyn and using my timing light as an engine bay tach. Feeling like being overly anal I went and borrowed the four gauges you see here. This first pic is at 1000rpm with balance by the unisyn, and tuning idle mixture by rpm. So then i set about playing with the gauges installed. And although there is some distortion due to the angle the picture was taken, I ended up with pretty identical. After all this i wondered if these numbers 30cm or 300mmhg were considered correct, logical, or typical for a crossflow. Vacuum was taken from the small plug right next to the idle mixture and progression hole cap. Anybody have input? Thanks Ryan

-

Oh, and camping with a 7! Spent the weekend at Blackhawk Farms Raceway during their annual AHRMA event. Used to race with AHRMA and just wanted to go and hang out. 7's camp just fine! Brought a cover for the 7 to keep it warm and dry during the overnight.

-

-

Not much else has gone on with the 7. Still trying to have the aluminum professionally polished. in the meantime I brought a 1951 pontiac chieftain back to life for a long time friend. In storage for 27 years and she now enjoys him (ponchovilla) as a substitute daily down in st Louis! i am currently waking up a 74 alfa gtv2000 for another good friend. Yanked from about 19 years in storage. It is up and running on its original Spica injection and has just become a really good driver as cold and snow are coming to wisconsin.

-

Been driving... A lot! Love my 7! All around wisconsin, towed down to Tennessee, Illinois... as long as I don't have to spend hours screaming along the interstate I'm in. I have been keeping my eyes open for a random type 9 to fall in my lap but it just hasn't happened yet. I did absolutely find the cause of oil that was getting flung around the tunnel and drooling into my floorboards. The cap installed on the trans yoke was loose enough that oil behind it would would fling out. Suprising, but true. High temp metal epoxy has 100% fixed that issue.

-

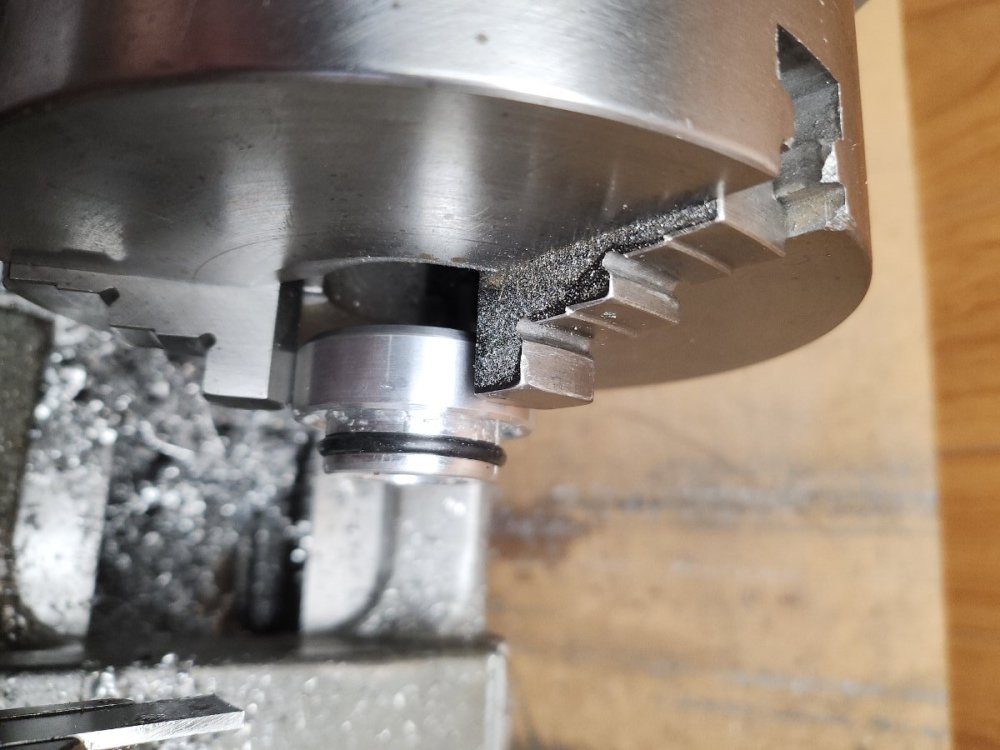

Spent money. Then made a little billet o-ringed cap. Was going to knurl the outside edge but my knurling bit is too big and hits the chuck.

-

-

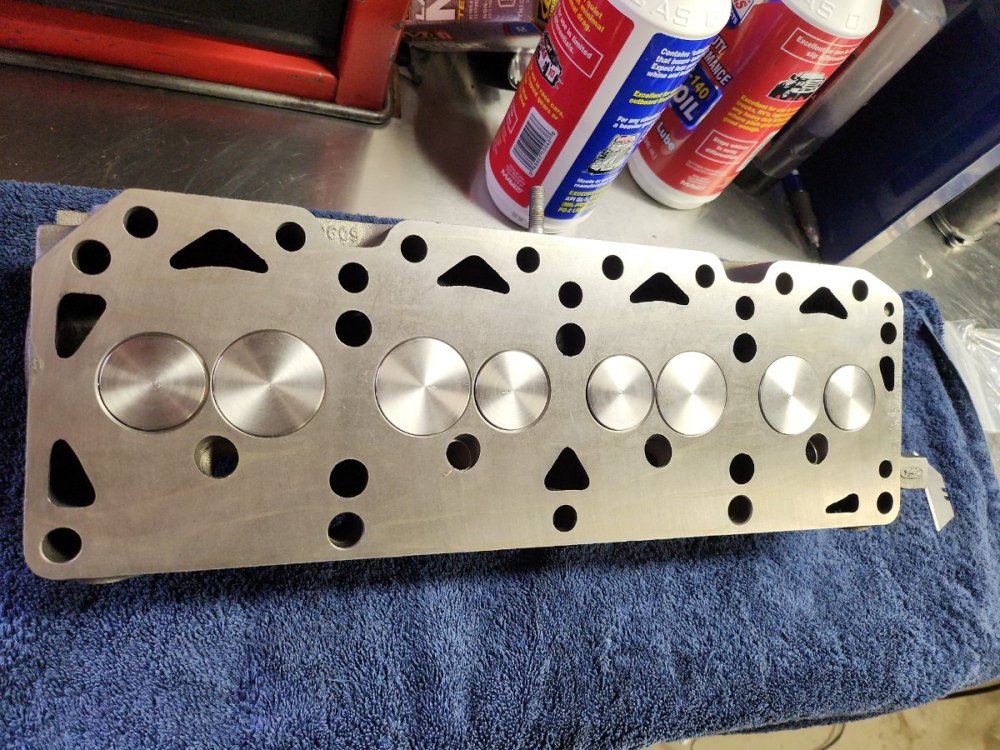

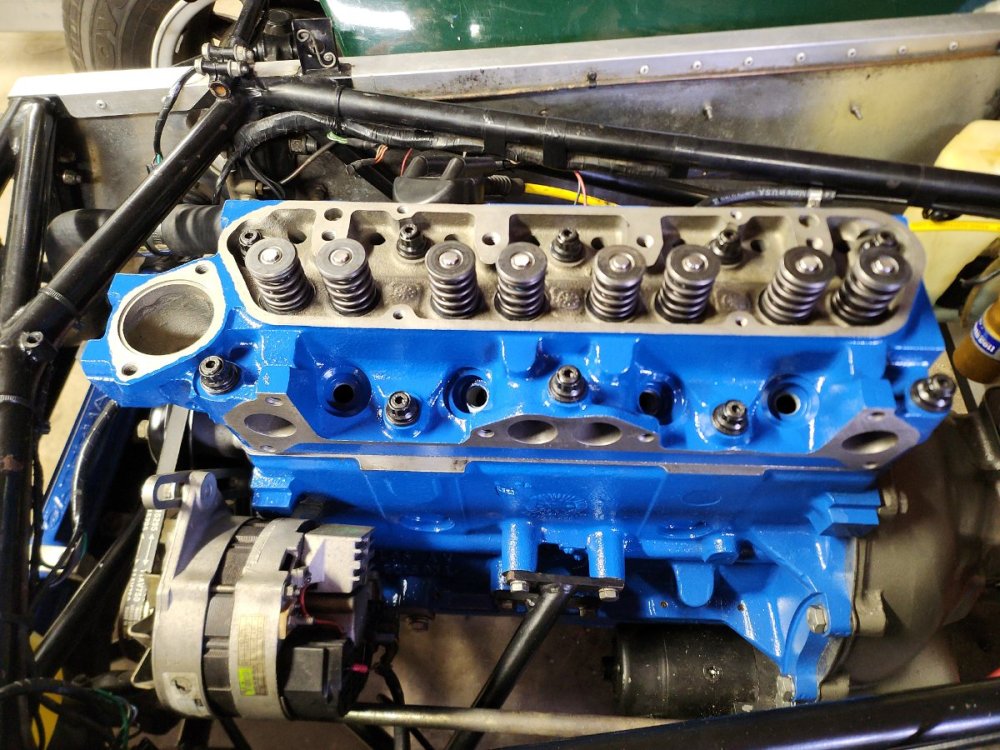

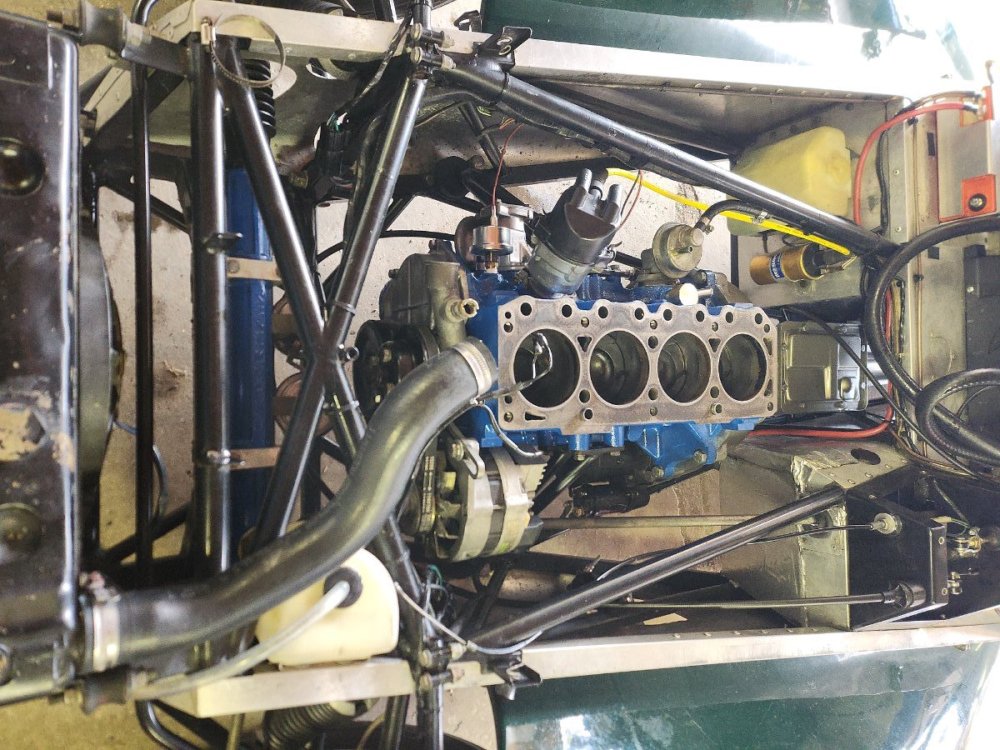

Head is supposed to be returned tomorrow! Engine and trans look, and are, worlds better for having come out of the car. Excited to get it back running. I do still have the lucas/aldon distributor with the pertronix points replacement that is running mechanical advance. Sounds like 34° max advance is pretty common. Recommendations?

-

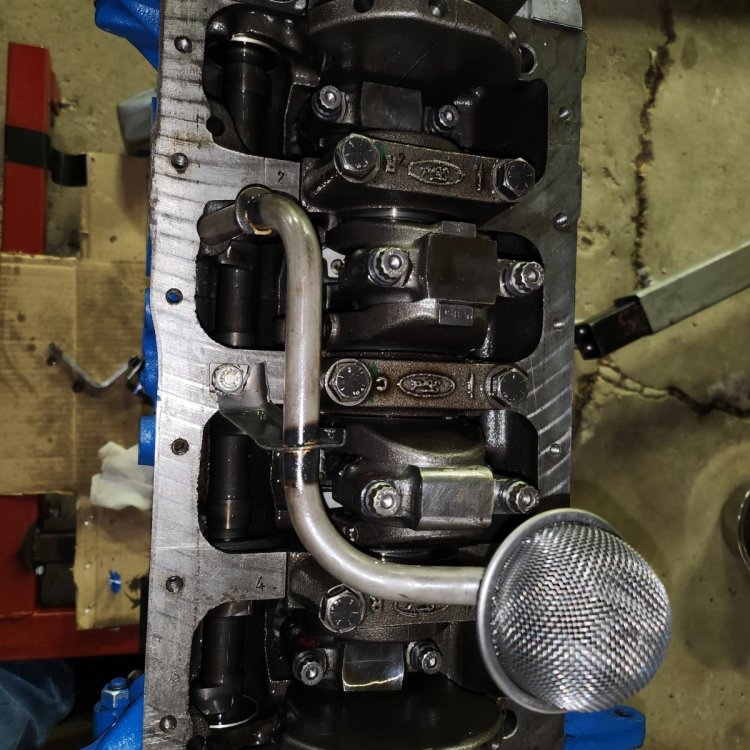

Definitely not a dry sump. Only reason for the ARP even in this low torque application is the strength of the original bolts. My differential carrier bearing bolts did stretch and would not pull to the correct torque. If those oe bolts could do that, so could my rod bolts. Entirely possible that new OE diff bolts would have been fine ( just like the rod bolts) but, well...I just wanted ARP's. Reassembly is going well. Trans and engine will reunite tomorrow. Still waiting on the head from the machine shop.

-

Rosteri- that's beautiful! Very well done! I think I have successfully remagnetized the oe speedo. Similar to magnetized a screwdriver, I used very strong magnets to remagnetize the rotor. Thankfully i believe the oe would magnetize to saturation, so i am not sure it can be overdone. Previously it read about 35 mph when it should have been 76. At the same rpm ( fed via cable from my lathe) it now reads about 75 mph. I will get it in the car and validate with a gps before rolling the bezel back on. While I tried very hard to get the needle back in the identical position it may be a mph off.

-

Exactly! At 16k miles the bores are excellent. Crosshatch still very visible as I would expect. Pulled a piston to check wear and any ringland issues but they still look new. Thought about aftermarket pistons just because but didn't. Lots of parts from burtons. They have gotten them to my door here in Wisconsin in about 5 days each order. Extremely fast service. Stripped the oil pan last night as it will be going ford blue as well. New main seals installed, and i like seeing that they both have been upgraded to dual lip seals. Cometic front and rear gaskets appear to be very nice rubber over aluminum. I did make a new bellhousing to tailshaft gasket. The burton part is just like oem and is like a thin brown paper bag. While I know this is common ( my 67 Enfield has some) I am going for reliably leak free. The oem gasket is .006" and my thinnest good quality material is .018". I can't find any instance where the additional .012" will be an issue. The tolerances of the whole trans just aren't that tight! ARP bolts on the rods...just cuz i can, and when I did the diff years back I found the carrier bolts were stretching and wouldn't torque properly. ARP studs also replacing the head bolts.

-

Also believe I have fixed the speedo by remagnetizing the rotor. It has always read low. About half. Rolled the bezel off, disassembled, and spun in the lathe at a known rpm. Definitely not correct. Appearantly the rotors are magnetized to saturation so I tried to get them remagnetized with some good quality magnets. It's seems to have worked perfectly!! I think I am within 1 mph of what it 'should' be and that could be needle placement...i tried to get it back to the identical spot. I am waiting to test in the car against gps before reinstalling the bezel.