ok7

Club Member-

Posts

19 -

Joined

-

Last visited

Personal Information

-

Location

Oklahoma

-

Se7en

Brunton Stalker

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

That fuel line was one of the first things to go! That raidator has been replaced and new puller fan located behind. It took quite a bit of effort to model and have a raidator built to fit, but I think it was well worth it. The shrouded puller fan should be more efficient also.

-

yes, a retirement project. I've had it about a year, 2005 Stalker, fifth maybe sixth owner unfinished.... and a bit of a mess. I’ve spent most of my time sorting the engine. Just starting to think about the chassis and body work. The picture is car on trailer ready to come home...

-

I don’t have the part, just pictures where they were used. I think I will be able to fabricate one from aluminum, just wanted to find one for ease…..

-

When I used google lens to search, many images from airplanes came up, but nothing quite like what I'm looking for.

-

ok7 started following Stalker upgrade to LS engine and Tkx transmission and Name that part!

-

Does anyone know what this part is called? I been searching and don't know what to use for key words. THANKS IN ADVANCE

-

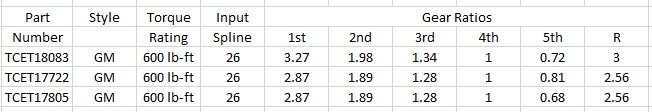

I was not familiar with the TKX transmissions, quick research and they seem well suited for this application. I saw your clutch choice earlier. What bellhousing did you use? Which ratios?

-

Searya, I am considering a 3800 V6 swap to LS in a Stalker and working through the details. So, I’m finding this thread particularly interesting. Would you share your radiator dimensions, and fan make/model? Also I can assist in drawing, and can cut your alternator bracket from mild steel, let me know if I can be of assistance.

-

Styrofoam mockup. 16h x 20w x 3thick would not quite fit without chamfering the corners. the top is almost touching, the bottom has at least 1" clearance, sides maybe 1/2". I's going to be very difficult at this size to place the fan behind. I've got it resting on the top cross bar. and out at the bottom. to clearance the lower A-arm bolt. Not really fond of this arrangement. But do like the way this size fills the space. More to come....

-

Champion tank looks really thin. do you have any pictures of the back side?

-

I'm under the impression that the expansion tank needs some flow to assist in bleeding air from points that might capture air. I can see the top of there radiator as having potential to capture air. That said a port near the top could be incorporated to evacuate air while filling the system.

-

So originally, I was going to use a simple over flow tank. The coolant water outlet (near firewall) is the highest point of the cooling system. My plan WAS to put a filler like this on the engine outlet, and use an overflow catch can. Been reading, and working on a NEW PLAN to use a pressurized expansion tank. A port near top of radiator, a second in the filler (above) I'm a little confused on how to plumb the expansion tank return line. It seems like the expansion tank return line needs some vacuum / suction. It also sems like this may be a delicate balance. Maybe just the restriction in the small diameter of the supply lines balance everything out... I'm a little unclear. The heater core and plumbing have been removed and ports freeze plugged. So going to need to find an alternate point to plumb the return line. Also unclear if the expansion tank has to be the highest point of the system? If not there are lots of options. If it does, then the fire wall is probably the best option. Guidance would be much appreciated!

-

I took some measurements yesterday. I measured in the yellow plane thinking that a slight angle would give the largest height. allowing for some clearance (about 1/2 to 1") on all sides 16" high 20" wide. My plan is to go get some rigid foam board insulation sheathing and cut a 16x20x? block to test fit. After studying the inside shape of the hood, I doubt that knocking off the corners is really going to allow any gains in size. Again hoping test fit of foam board will tell. Looking at fans, there are a lot of 16" ones. I've feelin that radiator needs to be at least 16" tall. Reading about fans, the round fans do not take advantage of the full area of the radiator. I would really like to build sheet metal duct and mount the fan behind the radiator. This may be a real challenge with the tube frame basically in the same space... but I think something like this would work. I also find this radiator interesting in that it is a double pass and inlet and outlet are on the same side. My engine was originally transvers mounted, so both water pump inlet and outlet at back of the block are on the driver's side.

-

I had found Griffin Radiators. They have some measuring instructions and a form to get a quote. I may use rough measurements to get some idea of cost. Thanks!

-

this may work, but on initial consideration I think that it will need the top corners "knocked off" but wont know till I make a template

-

not ready to start on that puzzle yet! I have several concerns about spaces used... I will add this to my "list"... THANK YOU