ralph

Registered User-

Posts

73 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by ralph

-

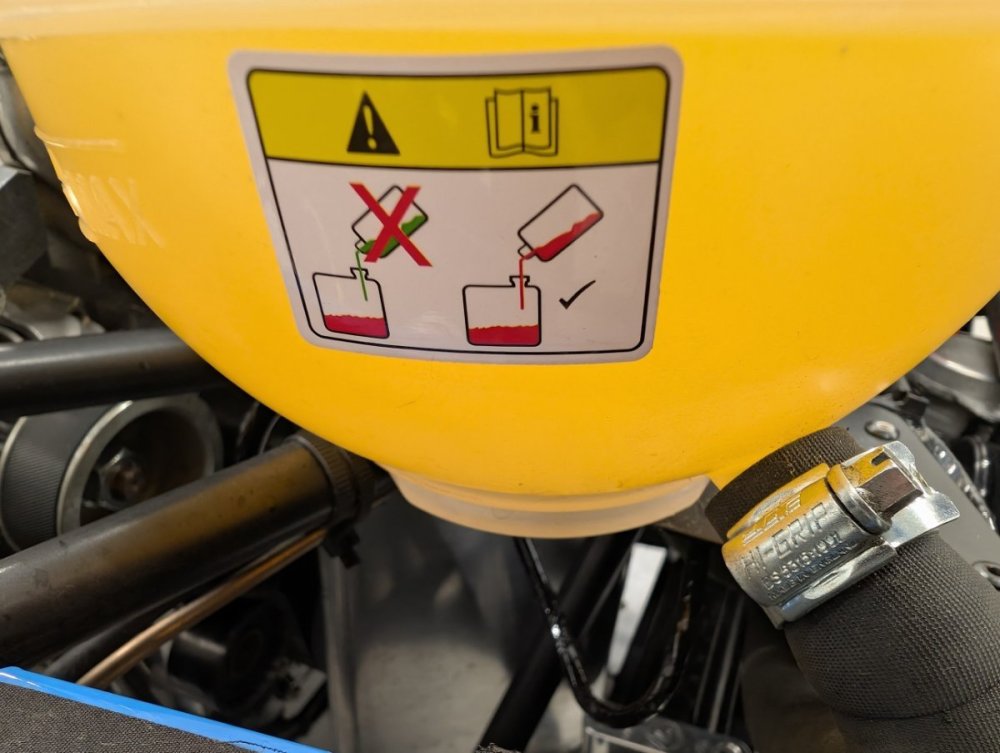

Just adding my $0.02 re:coolant here, in lieu of a new thread. I put a 420R together a couple years ago, and decided to cheap out on coolant, expecting to swap it in a year, and the cheapest I found was green. I missed the fine print about coolant types, and later noticed that the convenient color coding does not obviate the need to read the fine print -- i.e. "blue" isn't silicate-free glycol in all cases (i.e. US/UK/EU/JAPAC coolant color standards are not necessarily the same). Anyway, long story short, I put in conventional/legacy green stuff, and just got through fixing that problem with a series of flushes (to @MV8 point that you can't just drain and refill, unless you have a gantry crane that can hang the car upside down or something). Flushing ritual went a bit like this: drained what i could (with rear of the car elevated), added prestone clean/flush w/distilled water and ran for 10min, then went through a series of 5 drains and refills with just distilled water, elevating the rear at drain time, and the front a fill time -- basically, until what comes out of the car is mostly clear. Attached is a pic of the build-up in my heater circuit after just 18mo/5kmi, and the sticker on the reservoir that very clearly indicates that putting green things in there (esp. mixing) is a no-no, and RTFM is advised. Final fill was the new Ford *Yellow* (P-OAT) concentrate diluted to ~40% plus 5oz of Redline Water Wetter. Would love opinions from the readership here on that fill formula...not thrilled with the idea of spending another day dancing around the car with water bottles, but less thrilled about having my radiator shit itself. Is Ford's yellow/P-OAT the new hotness coolness? What do folks run at the track - non-glycol stuff?...just distilled water and water wetter?...

-

Another option for reference: Lithium battery saves a few pounds at a relatively high position in the car's center of gravity, and provides plenty of Amps. I've heard some caveats about using Li, both because of how they charge and how they spit out voltage, but have had no issues. I did put the Banner back on during troubleshooting an initial engine start issue, but that turned out to be the disconnect switch being miswired at the factory. Because the battery is so much smaller, foam blocks and zip-ties were employed for fitment -- ghetto, but hasn't budged. I have a connector cable for a battery charger on the second (rear) pair of terminals, but rarely use it unless the car will sit for a while (I do use the disconnect switch routinely, just as a habit).

-

ECU is locked (stock Caterham -- so I don't even think I can view what map is loaded). CC just told me that I should see 4.62v/site=0.0 (descending toward WOT) on Easimap. I'm unconvinced. What makes the most sense with what I've read an observed on the car is that the software is inverting the the voltage (5v system, TPS will read a high value at idle, Easimap will show 5v minus that value); as @sltous showed above, a MM probe on the middle wire of my TPS (with the other to ground) reads 4.60v - the inversion is real. Not to mention, if my TPS voltage was aimed the wrong way, I would not expect the motor to behave well under load at higher rpms, where it is happily hoovering fuel and melting the rear tires. I've gotten some great insights from Andy at PGM, and will likely be rewarding him with the purchase of an unlocked 9M4 with a slightly tweaked version of the RBTB config Caterham uses. Really don't like the element of suspense/mystery in this story, and, besides, what could possibly go wrong if I have more access and control?!! On the tach subplot, I may look at raising to 1PPR, since my tach now reads high, by roughly 2x -- still no rational explanation for why this would be necessary, still draws suspicion to the ECU config.... @KnifeySpoony (et al.) any recommendations for bay area local dyno tuning shops?

-

AIUI, those numbers should correlate only in that they are two slices of the 5.0v available; they shouldn't be remotely similar. If your Easimap numbers are more in the 0.30-0.50v range, this is starting to look like the smoking gun -- maybe I do have some sort of mapping/config issue with the ECU, but it's probably not the voltage inversion...that appears to be by design and I'll confirm with a MM on the TPS. Will update here when I've had a chance to push the TPS back to site=0.0 at idle and re-do the aperture and flow meter checks.

-

CC confirms idle should be site=0.0, so I've cranked the TPS too far. They also said the dip switch gymnastics on the tach is normal, but I still don't see why/how. Working theory is that the imbalance of airflow between the barrel sets (1/2 was 2x 3/4) was a bigger factor in causing rough idle than TPS position. I'll focus on dialing that in better and drop my TPS voltage down to whatever gets me just barely at site=0.0. (I think this was around 0.42v as read by Easimap). I have an inquiry into CC to confirm that TPS voltage ascending as reported by Easimap is indeed normal, and the concern about the voltage path being inverted is actually spurious. For anyone on thread who has fiddled with roller barrels, I'd love to hear confirmation as to TPS voltage start point and direction as measured via Easimap vs. multimeter probes on the TPS itself.

-

From CC, no, just kind of a shrug so far. From SBD, I got a similar kind of non-answer restating that for RBTB the voltage is inverted by S/W; for absence of doubt, when you talk about your setup being at 4.62v, is that the voltage value from Easimap, or from a multimeter on the actual TPS leads themselves?...If the latter, I'm going to have a good laugh and go the probe route in future calibration attempts. SBD also told me to follow the instructions that came with the ECU...what instructions? (not laughing) To your earlier suggestion about just turning the TPS until the engine behaves, I suppose there are two problems with that: as noted before, mapping should correlate with TPS site position (so if I roll that too high at idle, I'm fairly certain this will screw up my mapping...it does backfire a lot like it's on the rich side), but the other that occurred to me after snapping my stock TPS is that if the site position is too high, I may run the risk of exceeding the rotation limit of the TPS barrel with the pedal to the floor, which would not be a good thing -- floored WOT and the TPS barrel snaps?...no thanks. I'm starting to wonder if maybe I've been overcorrecting this the entire time, making the engine run way too rich, and buggering up the mapping with way too high a site position. My assumption was if I want higher rpm at idle, I need higher voltage (as read by Easimap, which shows voltage ascending as throttle opens). I'll keep fiddling with it and report back here once I get it working properly...

-

tach: all dip switches off except #8, and the tach seems to behave (down to .5ppr vs 2ppr) idle: cold idle is still not a thing at all, but the engine warmed up will idle stably at .50v/2.9site (which seems pretty off, imo)

-

CC responded and advised that I just drop the first two dip switches on the tach (to reduce PPR) -- seems a bit ham-handed, but I'll give it a go -- also, still no explanation for why this particular variable would change from 9a4 to 9m4 (which are supposed to be able to run with equivalent configs -- begs the question as to exactly what config I was shipped). Hopefully this sorts the tach. As for TPS/mapping, turns out, I'm the first customer to use a 9m4 with RBTB, and since their R&D is essentially customer funded, there we are: tabula rasa. The working theories don't make sense to me (i.e. if the voltage *should* start high and descend as throttle opens, how I'm I able to drive this thing with WOT approaching redline and have the engine basically going gangbusters?). It is certainly starting to look like the 9m4 they shipped has a bogus config, but as to what the right one is...that seems a very open question. Again the symptoms are: very low idle even well past site 0 (2.9) on the TPS, and engine won't stay running when cold, plus a bit of backfiring when backing off the throttle quickly (to me that reads: too rich, but maybe it's normal rbtb behavior?).

-

I paid use tax in full (~$5200) at the DMV shortly after completing the build (approx. 6-7mo after receiving the crates). If the CDTFA wants to charge me interest on the 6-7mo delay, I have no quarrel with that, and will happily pay it. What they are asking me to do is pay tax I've already paid (plus a year's interest), which is not right, IMO.

-

If you've dealt (or are dealing) with registering a Caterham in California, read on... (I'm dropping this in build threads since that's where it's likely to reach folks who may have opinions on it and/or might benefit from being aware of it -- not technically a build thing...more a bureaucratic thing.) Just got notice from the State of California (CDTFA) requesting that I pay use tax (with a year's worth of interest). They had reached out a couple months after my crates arrived, and I had explained (I thought successfully) to the agent that the reason I wasn't paying use tax as part of the import process was that I would be paying it upon registering with the DMV. In this second notice, the situation is characterized as my "claim for exemption has been denied"...which I think is a bit off from the actual situation -- I'm not claiming an exemption per se, but rather pointing out that I have in fact payed use tax, and would prefer to not have to pay it twice. I've sent them all relevant paperwork (though the DMV record of 'fees paid' doesn't specifically mention "use tax"), and am waiting on a reply. I'm guessing that with such a low volume of the particular scenario (sb100/SPCNS) involved, the CDTFA folks are confused by it, and just see someone importing car parts (which would be subject to use tax at the time of import). Has anyone gone through this contention as part of registering their Caterham in CA?...any suggestions?

-

re: tach removal...duh!...yeah, that's super easy -- my dip switches are: 1,2,8 on (which sounds right from what I've read) re: TPS, will try that, but doesn't increasing site position mess with the overall map?...doesn't it expect something close to "0.0" at idle? re: redline, dunno...tach is still on drugs...haven't hit the rev limiter, so there's that; I definitely like the noise this thing makes now, and more so the response/pull (laggy/weak with the plenum) ...if I can't fix the tach thing with dip switches, I'm probably going to have to get the ECU reflashed, which is beyond annoying at this point.

-

Ah, so in theory, with a mirror, I could set the dipswitches without removing the tach....still not sure how to remove it....not seeing those 'thumb nuts' others are talking about. Notwithstanding the tach being on crack and the idle being low/rough, I've managed a couple spirited blats in the SC mtns, and find that a slight nudge of the throttle at a stop will keep the low idle from being a problem. I drive with a shoeless right foot, so I can finesse it with my small toes without too much trouble. For anyone following the idle metrics, I'm at .45v/site=1.7, and it's still acting like it's at 500rpm. I might try going a bit past 6mm on the idle screw and try to get a voltage at site 0.0 that works. I'm assuming that you want idle at 0.0 for the rest of the map to make sense. All that said, this engine now pulls like a slingshot once revs are north of 1.5k or so, and it has no trouble eating as much gas as you can feed it (plenum setup bogged a bit). Passing folks is a breeze, and I feel a vague whiff of contrition knowing my exhaust pipe is aimed at the driver I'm passing -- sorry, not sorry...

-

If I read the related threads correctly, I need to flip some dip-switches in my tach to get it to agree with the ECU (1,2,8 should be on...implying there's something with the crank/pulley ratio (i.e. 2 pulses, not 4)). Thing is, everything else I read about the tach suggests I may have a different tach (see pic, no wrench-free nuts to detach evident).

-

Idle is low-rpm and rough (not quite as rough as when cyl#1 was dead). As far as sync goes, I'll use a flow meter before I start fiddling with bleed screws, and, as you observed, they do seem aligned well within the pairs (I could see the balance screw working loose and making things interesting between the 1,2 pair and the 3,4 pair, but, based on the drill blank used to measure the 6mm, 1=2 and 3=4). Pull's great once I'm up around what I'm guessing is 2krpm, revs great from what I think is 1krpm -- in general it's way more responsive and doesn't bog the way the plenum setup did. Also seems like less finesse/precision is required in what you do with the throttle when letting out the clutch in first (peeve of mine with the stock setup). Glad to hear the tach is an easy fix, just a little annoyed (though not surprised) that this sounds like something that should have been specified in non-existent instructions. I have not heard that the tach would need to be adjusted, and the 9m4 (per SBD) has exactly the same pinout as the 9a4, so I'm not sure what's different...sending different voltage to the tach?...this spooks me a bit.

-

Still struggling with idle, will crank the TPS past site 0.0 and see if that helps, and will tune the barrels via bleed screws. Also, my tach appears to have lost its marbles: registers ~400rpm at idle (which may not be too far off -- definitely too low still), but sweeping up through the revs, it never really gets much past 1100 or so... no word yet from CC on what the idle voltage should be on the 9m4 with rbtb...wonder if i got the wrong map...

-

...something more like .42v at .07 seems to work!...I'm guessing there are actual target numbers for the 9M4, but only Mr. MBE knows for sure... Idle's a little rough, but throttle is more responsive off the line, and holy crap those horns howl...my new favorite sound. will do some fine tuning with an anemometer and might play around with the voltage some more. Pretty stoked to have this thing back on the road; just need to salvage my chainsaw surgery on the bonnet somehow...

-

Got these from a friend with a cosworth: resting voltage V_Initial_New = 0.36v resting throttle site Throttle_Site_Initial_New = 0.0 peak voltage V_Final_New = 3.5v peak throttle site Throttle_Site_Final_New = 14.2 ...since I can actually reach this voltage range with my setup, going to try that and see what happens. The 9M4 is certainly hot off the presses -- vacuum of experience/opinions on it so far...

-

Anyone happen to know if TPS voltage handling is different on the 9M4? According to Easimap, I have from .27v to 4.25v available ascending as the throttle opens. Everything I read about this setup suggests starting at 4.62v (which doesn't appear in the full range of motion of my TPS) and descending as the throttle opens. I would be ready to suspect the TPS (supposedly compatible knock-off: https://www.amazon.com/dp/B08SJ4L8T7?psc=1&ref=ppx_yo2ov_dt_b_product_details), except that doesn't make sense to me...irrespective of what voltages are available, I can't change the direction voltage goes as the barrels open -- clockwise is still clockwise, regardless of the position the TPS is in. Ideas? (have asked CC...will report)...

-

@fastg this setup (on an otherwise stock duratec in a 420R): https://caterhamparts.co.uk/other/3768-engine-upgrade-kit-r400-210bhp-to-220bhp.html @KnifeySpoony thanks for the offer, but I've got one showing up tomorrow; I do need to return your coil sub-loom...will figure something out in the next couple weeks...

-

For MAF, had to cut a grommet, and also threw an o ring under the screw to keep it even and leak free. Have ordered replacement tps, and will figure out its rotation range *before* installing it this time.

-

was feeling pretty good about progress here until my TPS snapped...will see if I can find one locally...

-

Milled the tensioner down (much easier than I expected), threw a shorter m8 in there, and things are nominally assembled now. To-do: - TPS installation and calibration (which looks 90degrees off, I'm hoping it's safe to rotate it) - bonnet cutting! (sans template...will measure 5 times, cut 3 times...or something...wish me luck...)

-

Ok, some progress. My 1/2 barrel appears to have been assembled incorrectly at the factory, with the spring being mounted to the next screw clockwise from the idle screw bracket...shouldn't be there, should be on the next screw after that. Moved it, and can get from 6mm to WOT without issue....on to the tensioner...

-

I pulled the barrels off and screwed them into a board (sprung and joined, as on the block), and I think I found the contention, but I'm not sure what to do about it. The idle screw stop (which is mounted on the 3/4 unit) is hitting the spring on the 1/2 unit. This explains why it only happens when they are joined, and also why the problem starts with the barrels sticking open (hitting the spring in the unwind/close direction), but then stopping full open as it hits the spring again going the other way. The "slightly progressive" feel of of the contention is explained by the fact that the idle stop is angled (the more you turn it, the more metal is in the way). Question is, why is it like this, and what can I do about it. Do I have the wrong parts (as @MV8 suggests, maybe the sprung assembly is simply not designed to be this close together?)?...do I grind down the idle stop? (probably not, since the idle screw is pretty close to the edge of it)...do I move the attach point of the spring on the 1/2 unit? (seems the least invasive, but I'm not sure the geometry works, and I have no idea what happens when I undo one of those screws). 1min video of me demonstrating the contention: https://www.dropbox.com/scl/fi/071ixhfa595pq94v7l10k/rbtb-contention.mp4?rlkey=6kge0zcaxkruqvvllr29hl4qw&dl=0 Asking CC and dealers, but suggestions are welcome...

-

@MV8 they are definitely designed to be mated such that one assembly is supplying spring tension against the throttle cable, and the other is supplying spring tension against that one. @KnifeySpoony I dabbed some rtv in the silicone noodle grooves so they stay put. As to the 'wrong way around' theory, I'm definitely open to that, just not making sense of the physics with these parts as I see them. One thing I should have noted earlier is that, at rest without being conjoined, the barrels are a tad open, and I'm rolling the barrels 180 degrees to get them into a position where there is plenty of spring tension to get them to close all the way. There's no mention of this in the manual, and it develops enough tension that handling these things is a little scary (hence screwdriver handles, vs. fingers). If that doesn't track with what other RBTB installers recall, then I'm 100% doing that bit wrong...I just can't see another way it would work -- if their at-rest position is open, it's not (and cannot) open all the way, which is just another version of the same problem. I think this will remain confusing until I shoot some video of the assemblies separated and joined. Seems like if I do that, someone here is bound to catch my error...