ralph

Registered User-

Posts

73 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by ralph

-

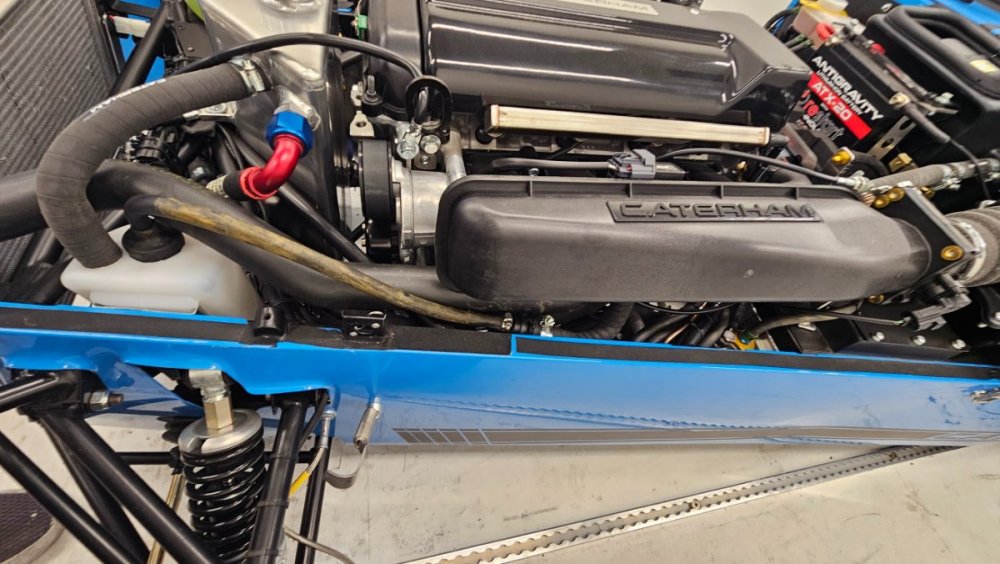

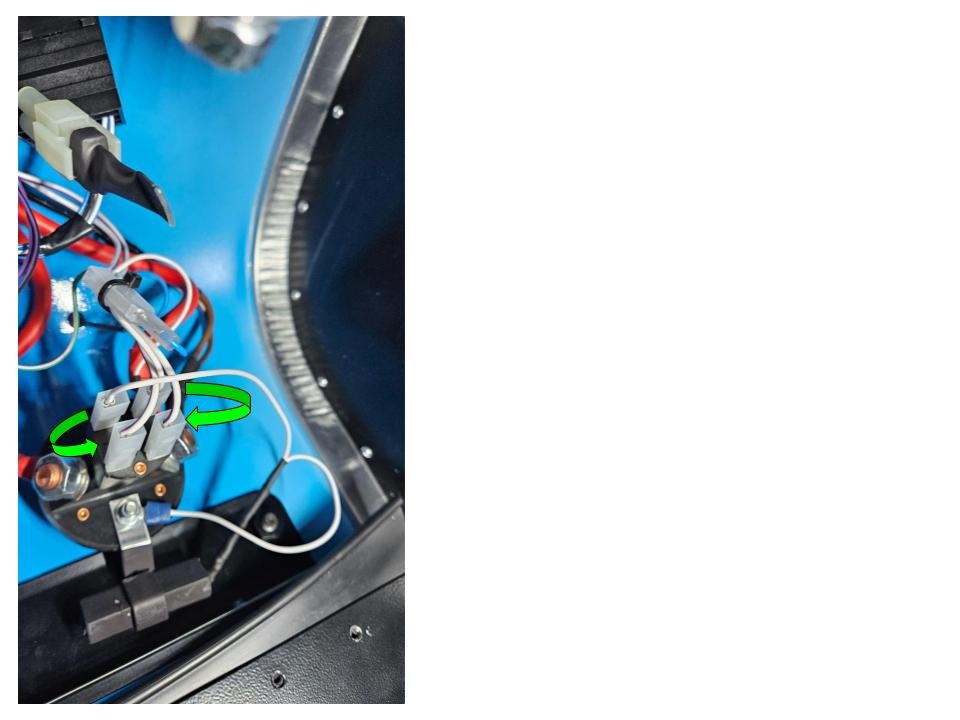

Mine's pointed the same direction (arrows point to plenum, which is the desired flow direction). Pinching the hose on the catch tank side of the PCV restored normal idle pointing to a vacuum leak upstream (catch tank cap has a hole in it -- plugged the hole, so now the system is more "closed" than previously, but I haven't tested it yet). @MV8 re:pressure/vacuum I thought positive crankcase pressure and negative intake pressure (vacuum) would both push/pull against the PCV spring to open the valve...so, I'm confused there as to why intake vacuum would need to exceed crankcase pressure -- they're both opening the valve, no? Also, if there is a breather/inlet on my crankcase, I'm not finding it...looks like it's just one line from the rearward part of the crankcase to the sump tank.

-

The PCV itself is one of these (cheapest I could find): https://www.summitracing.com/parts/URO-016453 ...and working left to right in the admittedly subpar photo here, you've got the stock catch-tank cap and hose, with the hose pulled through so an inch or two is still in the bottle (definitely keep the end away from the bottom so the vacuum doesn't draw spillover oil into the plenum), the other end hose-clamped onto the inlet of the PCV (which has directional markings) just under the plenum on the left, and since the outlet barb is small, there's a section of smaller hose to allow the stock caterham hose (spare bit unused in build) to be cinched down over both, while the other end fits snugly to the hole in the plenum that comes with a blanking hose cap of sorts clamped onto it. As with most of my build, this is solid B- quality work. Modesty prevents me from showing pics of the other side where I wrapped the headers in fiberglass jackets with all the finesse and aesthetic sensibility of a 2yr old putting their toys to bed in a blankie. In my defense, both these mods are function-before-form, so, style points are inapplicable, IMO... The fiberglass header wrap lets off a bit of smoke at first (I assume they use some kind of light oil during manufacture to get it through whatever sort of loom weaves the stuff), so I had some words with the CHP this morning about why I was driving a car with no license plate that had smoke drifting out from the bonnet gills. After inspecting the paperwork, the officer asked to see the VIN on the chassis, and I will admit to being more than a little apprehensive about pulling the bonnet off, but all was good. He agreed that the car was better off at Laguna, and thanked me for following the process by the numbers. BAR ref (virtual) appt on 8/23...

-

@KillerB (and anyone else with opinions), I put a PCV on and my idle is way higher now. Theories?... No ill effects to power or rev-ability so far (if anything, it requires less clutch finesse off the line now). Will throw the stupidly-overpriced ECU cable on it and see what the numbers are, maybe back the idle screw down a bit since I raised it above the target TPS voltage before. Related: is it possible that US cars get an ECU with mapping appropriate to having a PCV present?

-

I more or less followed these: https://bauerltd.com/the-magical-sb100-registering-your-car-in-california/ ...best advice I got in the process is to make sure that the actual DMV clerk you are dealing with is familiar with SB100, or they are liable to get it wrong; this could be a simple matter of tenure in the job (Santa Cruz DMV has some folks who I swear have been there since I moved here in the 80s). The guy behind the desk handling my case was newish, and a bit of a deer in headlights at first, and I was about to escalate when a coworker overheard the exchange and said "oh, SB100?....I got this...". I was nervous about getting the SPCNS sequence number (not because they would run out -- they don't, nowadays -- but because something might be amiss with the paperwork); I was able to get verbal confirmation on the same trip to the DMV where I filed for it and paid use tax (DMV clerk called the mothership, told me I was #2023095). In short, I wouldn't be afraid to escalate if the person helping you seems to be improvising, and the call to confirm the sequence number assignment is a perfectly reasonable request to make (IMO). There's a few things you have to get right (e.g. have two separate receipts -- one for power-train and another for all else -- if you have only one, that's not good), but they mostly involve things you don't do....like make any mark of any kind on the CHP form (don't even sign it), or populate fields like "Model Year" on any of the forms (in fact, anything you aren't 100% on, probably leave blank and work it out with the DMV folks). For that matter, there are few details in the process notes here that are no-ops here -- e.g. the CHP didn't assign a new VIN for me (used the one scratched into the chassis rail), and lights/brake inspection was not requested. Best of luck! -r

-

BTW, I got my sequence cert three days after bitching about it here. Maybe the DMV reads these threads? ;-)

-

Yeah, 84 used to be part of my recreational bike loop (leftover from my one lap with this oddball hoon crew: http://www.docwong.com/st-clinc/); my non-17 commute route was empire->alba->hwy9, with 35, 84, stage rd, pescadero, etc. being more of a weekend thing). I'm strictly track-only bike-wise now -- everyone's going more or less the same direction, no one's texting, eating a bagel, putting on make-up, etc., so I find it less aggravating, maybe even safer. Been that way since 2012 when I lost an argument with a coworker's subaru at 7th and brannan in SF, and had to say goodbye to my shifter toe. Ironic, I suppose, that after 20+ crashless years of commuting over hwy17, I'm knocked over at low speed in the city. As it happens, it's probably been 10+yrs since I've spent much time on these roads, hence my surprise at stuff like brake zone markers, great pavement condition on the north end of 9, etc....that's new (to me, anyway)...

-

@KillerBI thought about the PCV -- had a 1970 Europa that had a fake one (plugged w/silicon, but as long as you didn't take it apart it would pass visual (pre-exemption for '75 and prior)). Got any specifics/pics?...is that something you slapped on prior to the appt, or did you have to go back?...or? @KnifeySpoony I've driven up to Alice's a couple times and may make a habit of it. I like taking Empire up out of SC, cutting over to 9 on Alba or Felton/Empire, then up 35; the north bit of 9 is nice too. There's some nice twisties throughout, and, if I'm not mistaken, 35 has braking zones marked (?!!)...between that, the 100octane race gas in Saratoga, and the bmw M flag on the mailbox just south of Alice's, there's very little pretense that this particular chunk of silicon valley isn't for the hoons...#Nerdburgring

-

When did you get your cert?... Relative to paying use tax etc?...I was told a couple weeks, and it's been a month...

-

yeah, that's me alright. I do have a temp operating permit through Sept, and I'm sequence number 95 ('I am not a number...'), but I don't have the actual sequence number paper yet, so haven't been able to visit the BAR ref...

-

Can confirm: motor runs!! Thanks to all for tips/pointers on this.

-

I may have this sorted. After swapping the WP / W wires at the battery disconnect, I'm now seeing 12v at the injectors. Simple mis-wire at the factory. This is as maddening as it is cathartic, so...on brand, I guess...

-

At the moment, I have no easy way to transport the car (the trailer the crates came in is too big for anything I can tow with), but on the off chance that I find a way to move it, any recommendations in the Santa Cruz area? Greg Solow's shop can find their way around Morgans pretty well, and they used to work on my old 1970 Europa back in the day (though I recall Greg would go into something resembling a Tourette's fugue when I'd show up -- that europa was highly customized, and not in a good way...come to think of it, electrical issues abounded, and were exceedingly difficult to troubleshoot because the first/prior owner had rewired the whole thing with a single spool of one color wire...this should be cake, comparatively...)

-

I may have made some progress narrowing this down. Looking for what's in common with all injectors and plugs, there's the white/purple wire. It doesn't go to the ECU, AFAICT, it goes to a relay. If I test voltage from the back of the engine loom connector from an injector's red wire to the white/purple on the loom connector, I see .23v. If I leave the test lead on that red wire and move the white purple to the fuse where it appears to terminate, I see 12v. This makes me think that there's something funky with the relays/fuses/wiring thereof, and all this poking around with the loom and ECU connectors was off base.

-

I think this is a good call, and probably what Rich was driving at in our many exchanges on the topic. I did do continuity checks from the ECU connector, and ruled out wiring issues in that path; as you observed, the female side of the ECU connector could show good continuity, but if the barrels unseat when connected to the ECU itself, those results are spurious. The weird part is it's not one sensor, it's all plugs/injectors getting fractional voltage; it's not obvious to me how one or two loose barrels could do this. I'll pick that apart that connector today. RE: battery, completely agree, but leaving things stock for now until I isolate the fault(s). Glad to hear your build went well. Thanks, Brian!

-

Theories are thinning out....anyone in the bay area have a known working standard spec 420 ECU sitting around?...

-

if by "conjunction" you mean in parallel as suggested above, yeah, I wasn't going to do that. I have ample current to crank the engine and unequal voltage batteries in parallel is a general no-no. I would think that as separate supplies (one for the ECU, one for the starter, etc.) that would be ok, but I'm not finding info on how to separately power the ECU. It's suggested in several places (including SBD's docs), but I'm not sure how to do it.

-

I have 2x4awg on ground and stock hot side (with battery disconnect); I suppose I could upsize the +. Worth noting here (caveats re:lithium notwithstanding) that with the ATX installed all voltage readings, including cranking, were higher. Might be hairsplitting, but if 9v is nominal for ECU function and the meter read of 9.5v is considered marginal (since it's not instantaneous and may not capture the initial drop when cranking starts), if 10.5v or so (more what I was seeing with the ATX) isn't considered marginal, I should be good cable-wise, yeah?

-

Based on this commentary regarding 'bad crank tooth pattern' being expected on first/last engine rotations (since they are partial), I'm going to bet that the wiring isn't swapped: https://www.sbdmotorsport.co.uk/app/uploads/2020/11/Helpful_hints_when_starting_your_engine.pdf

-

Flipped the polarity on the crank sensor with a couple clips and some safety wire. No more "bad tooth pattern alerts", but also no engine start, so I'm not sure that's anything definitive.

-

Good to know re:ATX-20; I'm leaning toward keeping it. Easimap shows ~13v before cranking, drops to ~9.5v, whilst meter shows 13v/10.5v respectively. In the course of trying to ferret this out, I added a second ground cable (so stock one from bellhousing to chassis bolt hole, and another from an m8 hole on the left front of the engine block to the top sump tank bolt. ECU plug is seated well. Nothing visibly amiss at sensor plug, main loom coupler or ECU connector.

-

Hey, all. I'm working on the last few build tasks for a 420R kit, and while the posts I've read regarding these symptoms seem to point to the crank sensor, I thought I'd lob my experience out to this forum for opinions. Symptoms: Good: engine cranks like crazy fuel pump is getting fuel to the rail fine Bad: no fuel in engine (so injectors not opening at all -- I 'burped' the air out of the fuel line by disconnecting it at the rail) no spark Weird: obdc reports a myriad of sensor faults inconsistently, but with themes suggesting low voltage in the ECU control plane, including occasionally reporting more explicitly "<foo> sensor low" or even "low system voltage" after a lot of cranking. I think some of these could be explained as downstream symptoms -- e.g. baro pressure will be low if the engine isn't firing, right? MBE985 cable -> easimap6 reports "Bad crank tooth pattern"...which seems a bit more on point, but I'm not sure what to do about it apart from replacing the sensor I've checked continuity back to the ECU for all plug, injector and crank sensor wires; all checks out, correct pin assignments, etc. There's a sub-plot here that I'm very curious about: the use of lithium batteries. Originally, I'd swapped out the stock Banner lead/acid for an Antigravity ATX-20 (680CCA/20Ah). Then I found this: https://sbdmotorsport.co.uk/wp-content/uploads/2022/05/Helpful-hints-Battery-Voltage-Issues.pdf and immediately reverted to stock, thinking I'd found the smoking gun. No dice. The idea that the starter could starve the ECU voltage-wise made some sense, and I noted that while the CCA metric for the ATX battery is more than adequate, the Ah rating was 2/3 of the stock battery (less overall energy stored), so the SBD article looked like a plausible root cause was indeed the lithium battery....that is, until I borrowed an MBE985 cable from a friend with an ATX-12 (480CCA/16Ah) happily powering his caterham without issues. To me this suggests that the SBD caveat is probably spot-on for grossly underpowered lithium batteries, but maybe not for the ATX-20. Until I get this engine running, my plan is to leave the stock battery in place, just to have one less variable, but I'm interested in hearing other folks' opinions on lithium options like the ATX-20. Apart from the expense, there shouldn't really be any drawbacks, AIUI. As to the current impasse with getting the engine running, I'm going to fiddle with the crank sensor a bit, but apart from the ECU itself, or power to it, I'm kind of out of ideas...

-

As it turns out, I had it level enough I didn't lose much oil (maybe ~2oz), and the propshaft fitment wasn't too gnarly. I did yank a couple things off the front of the motor so I could scoot it forward more to make room for it. The beastly part was getting alignment on the gearbox mount bracket -- there was a 0% chance of all four chassis screws fitting, so dremeled a bit of metal out of the bracket, and aligning the 'business' bolts to get them to actually thread required some brute force prybar tactics, but the motor is in. If I had to do this again, I think I'd arrange my build space so I could follow the standard sequence (motor/gearbox, then propshaft, then diff), but this way did work in the end. The manual is ambiguous and/or wrong about several things, so in that sense this step was like any other. The adventure continues...

-

I'm about to attempt an engine install with the diff and propshaft already in place (i.e. out of sequence w/manual). I notice you mentioned spilling gearbox oil (I'm assuming this is from uncapping the gearbox to connect the prop shaft), and I'm wondering if I shouldn't just tip the engine up and dump a bunch out, add it back after the propshaft is in). If you had it to do over again, would that seem like a prudent step?