ralph

Registered User-

Posts

73 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by ralph

-

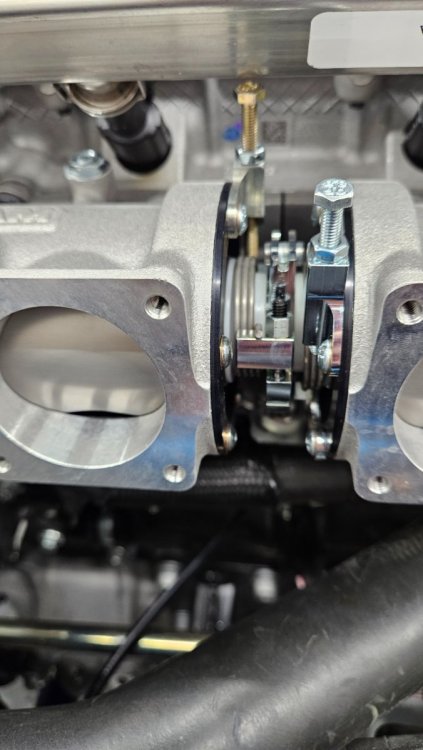

@KnifeySpoony Here's a look at the assembly installed, and, again, I can't see any parts that are actually colliding at the premature stop, but it does look like the spring on the left is pretty tight already for this position (a tad past idle). When the barrels stop, it's less of a sudden percussive stop like two metal parts colliding (which, again I can't see happening anyway), and slightly progressive, more like a spring running out of available slack, which (modulo confirmation bias) seems consistent with the observation of the tight spring on the left....but all that said, I need to take this apart and make sure I understand the spring rotation and just the basics of how these parts come together. At initial mounting, the barrels stay open (??!!), and then after a tap or two on the accelerator, something slips and they drop to idle...maybe something's slipping into the wrong place, maybe a spring is too short...or is on backwards?...maybe, just maybe, I just have no clue what I'm looking at here... Will take it apart again and maybe snap some pics at the various stages...

-

The weirdest thing happened: I got the ECU/RBTB package from Caterham, but there were misfit/missing parts and no useful instructions!!?!!....<rimshot!>...thank you, thank you,...I'll be here every Wednesday night this week...please tip your waitress... But seriously folks...couple relevant points for anyone considering the RBTB upgrade, and a couple questions for anyone who's done it before: Useful instructions: Cosworth build manual appears to be a reasonable source of truth on RBTB assembly: https://dubaipetrolheads.com/biggles/download/CSR260 _Build_Manual.pdf (pgs 28-31)...if there's a better one, I'm all ears... Misfit parts: Easy: mounting nuts were wrong thread pitch (tapped them out to M8/1.25) Impossible: carbon fiber backplate was supposedly redesigned (per CC) to no longer require a belt tensioner mount mod to fit; the one I got does not fit, so that would mean grinding down the tensioner mount, which seems...ghetto...but doable... Missing parts: dzus type quarter-turn connectors for the air filter came with only the male side; maybe this is a blessing in disguise, since dzus type fasteners aren't the greatest for fastening points subject to lots of vibration in otherwise rigid parts...might just throw bolts in there and suffer the extra effort when I have to clean the filter. Assembly snags: Early throttle stop -- I roll the barrels to wide open and keep them there with a pair of screwdriver handles, mate the two spring-loaded sides together, mount the assembly to the studs, put the throttle cable in place, etc., pull the screwdrivers out, tweak the adjustment screws to get them set to idle position with a ~6mm gap, at which point they only open about half-way when attempting to open the throttle, and I can't seem to figure out where the contention is. Anyone had this problem?...or have ideas what might be stopping the rotation (nothing I can see from the outside, and there's really nothing inside that would do it, AFAICT...) No template for slicing the hole in the bonnet...anyone got one?...I can just trace around the air filter and measure where that probably lands with the bonnet in place, but this feels like a measure twice / cut 4-5 times scenario, and I have to believe there's a better way. Also curious to hear from folks who have cut on the small side vs. large side...I'm leaning toward the former (trying to right-size for a tighter fit), but if there's no real advantage to it, maybe it's not worth the extra precision...thoughts? In other news, I have the 9M4 installed (not much to report on that until the new snoot gets sorted out), and I did manage to pick up the more robust coil sub-loom, which from the looks of it, should probably be standard equipment -- it's way beefier -- if anyone was waiting for (either of) these, there is apparently some stock now.

-

For anyone else in ECU limbo, the way my situation resolved may be informative: MBE took a look at my ECU and said "nope"...not worth trying to fix. Guessing they are out of 9A4s, because the ECU I'm getting is a 9M4 (likely part of the delay since those were still being qualified until very recently -- like days, not weeks ago, I think), and, since I left it an open question before, I did indeed opt for the RBTB mapping, and yes, RBTBs just shipped with the ECU. Still poking around for a map to the RBTB upgrade minefield...I see lots of chatter about TPS tweaks... P.S. @KnifeySpoony I haven't forgotten that I still have your coil subloom. Will ping next time I'm driving through the East Bay...

-

I just zip-tied the wires down the roll bar; the zip ties don't really stand out now because I hung a small fire extinguisher on the same rail. I got a light that was wide enough to mount to the existing holes in the bar. The light I got really doesn't want to be installed in pieces (light is secured to the case with screws that are only accessible from the back of the case, which is up against the bar. To mount it in assembled form, I used barrel-nuts with square-head bolts on the inside of the light case (since you can't get a wrench on those to tighten -- with the square head flush up against the edge of the case, the bolts won't turn, and you can just pop an allen key in the barrel-nut side to secure them). Running a wire all the way to the fuse block is probably overkill -- LEDs are pretty low-Watt things that can operate without issue by tapping into one of the existing brake light wire pairs. I don't have pics of the splice for power, but you can use parallel or t-type tap splicers pretty easily -- just have to find the right wires with a multimeter. I chose the parallel type as they are more compact. You can use that wire you ran through the tunnel to put a 139dB Stebel Nautilus air-horn aimed out the back as a retaliatory implement; I mean, that's what *I* would do with that wire... RE: side mirrors, the standard ones that ship with the kit are garbage -- they block more forward view (larger), and show less rearward view (flat, not convex); plus you can't secure them without removing the glass which has about a 2% success rate...the manual might as well say "unpack mirrors, smash with hammer". Get a pair of the convex ones used with the aero screen. As you can see below, they can mount to the windscreen fine, you just lose the ability to swing the doors all the way open unless you get a pair of eccles mounts (which effectively makes the mirror part of the door); I don't mind not swinging the doors all the way open, and prefer the stability of the windscreen frame mount.

-

For builders in CA (I have no clue about SC DMV/reg rules), apparently the law has changed and you are *required* to have a 3rd brake light (top of roll bar being the logical location for it). I can't say this was even mentioned in any of the in-person or photo-based "inspections" of my car, but apparently, that's the expectation now (and it would be nice if CC updated the kits for it). I got a relatively cheap LED bar, mounted it via barrel bolts via existing holes in the roll bar and zip-tied the wires down through the boot to splice them into the left rear taillight -- pretty simple. Regardless where it's a legal requirement, it does seem like a prudent step to avoid being too invisible out there...

-

Same thing happened with my mirrors. "Unclicking" might have worked with some prior version of the mirrors, but it's not a viable option with what they ship now; it just breaks them. The silver lining is those mirrors suck anyway. Convex mirrors will show more while blocking less (particularly with an Eccles mount). I'm using the mirrors designed for the aero scoop and they work fine. Agree this is among the more unforgivably shoddy bits of the kit. Just go fast enough that what's behind you doesn't matter.... -r

-

Congrats!!

-

Fixed the pic - sry, rookie maneuver there.

-

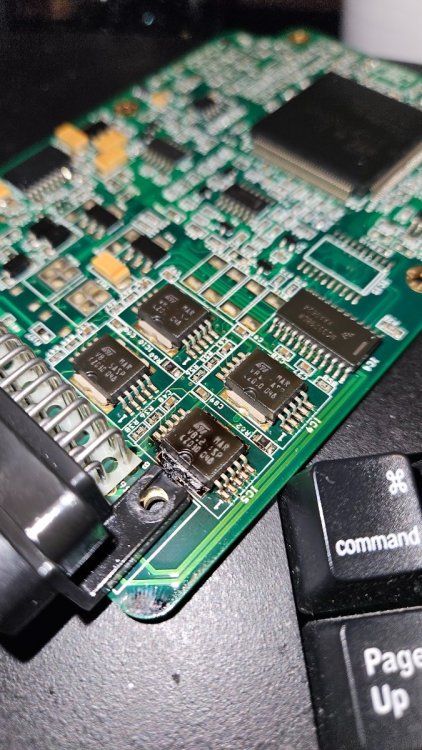

MBE kindly waived the "warranty void if this cover is removed" stipulation and let me take a peak at the ECU board: ...I don't really know what I'm looking at here, but I'm guessing those four chips are the coil drivers, and guessing the fried one is for cyl #1. Waiting for MBE to give me the go/no-go verdict on shipping this (i.e. if it's too fried, they'll just send a replacement; if they deem it fixable, I'll ship it back to them for repair). The only other question that remains is what mapping to get. If I'm going to be waiting a while anyway, I could just throw RBTBs on...

-

Interesting. So, CC still has a pile of these to burn down, my guess. Well, let's hope that supply isn't exhausted before the 9m4 is available... Anyone out there have 420R-duratec/plenum map files for an unlocked ECU?

-

Appreciate the offer. I don't want to do anything that might (be construed as something that could) do any damage or otherwise complicate a clean warranty repair process. I suppose I could kill fuel supply and just dry-crank, so nothing untoward happens to the motor. I see your angle though -- what if, after however many weeks, the newly repaired ECU arrives and presents the same symptoms because I missed something else. Worth considering -- not worth you going out of your way though. Related, I just saw your post re:loaner mbe9a4, so I'm not going to bother with a similar post. I reckon there are just none to be had; sounds like we have a bit of a wait for the 9m4...starting to think that getting an unlocked ECU mapped might be worth a stab...

-

Warranty repair of ECU now underway. Repair, not swap, because MBE doesn't sell this ECU anymore (n.b. MBE9A4 "currently being re-designed"). This could take a while, which is a bit frustrating, given that the weather will turn soon. I would love to get my hands on a stock (plenum, not RBTB) 420R ECU if any owners/dealers out there have one, but so far the only 'spares' I've found have the wrong mapping...

-

Here's my evidence: wet/clean plug (put a new one in, there's no evidence of combustion at all) used ignition coil tester pen to confirm spark on other three cylinders, thought this a bit janky so... pulled the plug and grounded it on the block while turning the engine over - no spark ...identical symptoms with your loaner loom (thanks, btw), and, to be thorough, I remeasured resistance from the ECU connector to each COP lead, and they're all nominal (around 0.6ohm), both with your loom and the original. Per the Rocky Mountain crew, while those coil loom faults are not uncommon, having one develop in 1700mi on a car that isn't doing track laps is pretty weird.

-

Bad coil theory seems to align with symptoms, but so does bad coil driver in the ECU, which Lee (CC) postulated as something he's seen before. RE:testing, I'm admittedly very much a noob at this, but shouldn't the DVM essentially be passive when in DCV mode? I could see that if I had it sending voltage (e.g. measuring resistance) maybe that would cause problems. As for the differential between cylinders, it makes perfect sense that crank position would alter these readings, but I don't think that's a factor here unless my engine happens to stop in exactly the same crank position every time it's shut off; further, while I did notice variance from one cylinder to the next, it was never in the giant increment evident on cyl #1. The thing that's leaning me toward ECU/coil-driver here is that when I did swap the coils on #1/#2, #1 still didn't fire. That was with the original sub-loom so it's possible there was a continuity problem with that wire at the time, but if so, that appears to have fixed itself. In the handful of threads I've read on sub-loom issues, there does seem to be a pattern of longer, more intensive use before the wire-fracturing issues surface -- not something that would surface in ~1700mi of casual driving; that doesn't mean there couldn't have been some temporary impedance factor in how that wire was planted, I suppose...for good measure, I will probably get 3AL080A when it's back in stock.

-

No, but I definitely don't have spark on #1, so I figure I should fix that first. Is there a failure mode where the ECU won't send spark due to some other condition?

-

swapped plug, coil, coil sub-loom, still no spark on cyl #1. #2 seems ok now (?)...back to 3 cylinders...

-

update: swapping in spare coil loom didn't fix it. I actually have good continuity, low resistance on either my loom or the one I borrowed, back to the ECU connector. I had swapped coils 1&2 to see if the problem moved/cleared, and it didn't - more like it spread. I now have *nothing* burning in #1, no spark at all, and intermittent/weak spark in #2. I suspect the injectors are fine since plugs 1&2 are coming out wet, but I'm stymied as to why electrons aren't finding their way through the coils. Car is now 2.5 cylinders...ECU coil driver?

-

Understood re:white/purple->meter->ground confirms 12v supply; thanks. Curious why there would be different voltage across just the #1 cyl' coil pairs...suggests something is different in those wires, and different is probably not good. Will be swapping in a loaner coil sub-loom tonight to see if that's it (odds are, from what I've been reading). I verified continuity at the loom connector, and will take it a step further at the ECU connector. Ordered a set of NOID lights to test the injector side, and I suppose if I do have spark on cyl #1, the next step would be to have a look at that injector.

-

Makes sense. I'm getting batt voltage from positive to ground on all four coil connectors, but I'm only seeing that voltage across the #1 connector leads; the other three have a fraction of 1v across their pairs, which would indicate short affecting #1, right?

-

OMG, yeah, for sure. ping'd you my contact info...

-

I would say it's consistent at idle and partial throttle; since it was running rough, I didn't attempt WOT for fear of damaging the engine. Continuity back to the ECU connector seems fine (white/purple are all effectively the same piece of metal by way of a crimp, and I can see brown white on the back side of the engine loom connector. Coil loom does indeed appear suspect, but I'm not sure how to confirm what bit of it, or if/how to implement a workaround. I would expect a continuity fault to result in no measurable voltage, not more voltage. In my admittedly limited understanding of engine electronics, this seems more like a short (like one of or both of the two #1 coil wires has had insulation fail near another wire it shouldn't be sharing electrons with). Is it expected that there is continuity across all six pins on the engine side of the coil loom connector?...not the case on the ECU side...

-

Noticed some rough running, low power, backfiring on my last lap around Nerdburgring. Infrared thermometer says cyl #1 is cold. Ignition on, motor off, I'm getting 12v across #1's coil connector leads (I think something more like 0.35v is normal -- that's what the other three cylinders show). I should be looking for a short in the #1 coil wires, no?...is there any other reason nominal ignition-on/engine-off voltage across coil connector leads would be different?

-

That's correct. TMK, Caterham does not ship a PCV with dry sump duratec engines; the powertrain installer would have to source (no biggie, it's a <$10 item) and install one (also no biggie -- couple of bits of hose and a couple hoseclamps, maybe a reducer/coupler). For registering cars in CA, the SB100 process is the preferred path, and I'm not sure that's a shorter less complicated/expensive one than registering straight away in MN. I'm out of my depth here, so I won't say more, but, were I in your shoes, I'd investigate both options very thoroughly...(as you say, separate thread)...

-

(disclaimer: I'm not technical either) @rider Yes, PCV = Positive Crankcase Vent, and you may not have one on your car (420R kit doesn't come with one, and your state doesn't require it -- CA does). If you do have one, I'd suggest you remove it. Follow the oil hose out of the crankcase on the top/right/rear of the engine, and you should see it terminate at the sump tank; in the same general direction, you'll see a hose exit the top of the sump tank and go into a plastic catch bottle; from there the cap of the plastic catch bottle has a hose in it that, in the standard set up, goes nowhere (i.e. vents vapor to ambient air, fluids (oil) to ground -- though the latter shouldn't generally happen unless you have way too much oil in the engine and/or the cap hose is too low in the bottle). In the setup that will support getting your car registered in CA, that cap hose has to connect to a one-way pressure actuated check valve (the PCV) which connects to the port in the bottom of the plenum. This 'circuit' is intended to take any crankcase blow-by vapors and feed them back into the engine where they can be burned completely, thus reducing emissions. In other engines, this can work well. In our dry sump Duratecs, on the other hand, it can confuse the ECU (increasing idle, which means more emissions), and can make the engine run rough (also increasing emissions with incomplete burn), and in extreme cases (as in mine, as it happens), can even feed a bit of oil into the air intake, which is most definitely not good for emissions. You could say that the PCV circuit itself is a metaphor for the regulations that mandate it: excess tax revenue (blow-by) is routed through regulatory apparatus (PCV) in a manner that makes the economy run rough and smell bad while more than defeating the intended purpose. You can tack this whole thing onto the epically long list of well-intentioned but hopelessly confused CA environmental regulatory claptrap, but if you want a legit registered car in CA, the PCV has to be there.

-

That makes sense. As far as "proper" PCV setup, while what I have doesn't quite pattern-match the typical setups, I can say that it's a closed system where crankcase blow-by does enter the engine (albeit on the wrong side of the air filter). As many have suggested, the whim/mood of the BAR ref at the time of inspection may play a larger role in this than the technical particulars...we'll see. I sent them pics of what I've got, so if it's totally out of line with their expectations, I figure I'll hear about it before the actual on-site...