-

Posts

86 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by CarYenta

-

Car is now PPF'd on the front cone and hood and sides (thanks Seattle Clear Bra!). Since then, it has been raining, and raining, and more raining, but finally found a day to do a little low speed drive around Lake Washington and sit behind slow drivers. The amount of public support for this car is hilarious. I had more than 10 people come talk to me about it. A car with three little kids U-turned and they all came running out staring haha. The mild dampness showed the supreme capability of these wider tires. Tons of traction. I also tried out the roll bar Spa mirror mounts I Macgyvered together with the extra DPR fixings they graciously sent me when I ordered their door brackets. The distance they are away from the car on the normal doors with the DPR mounts I find it very hard to back up in a straight line into a parking spot, and hard to judge rear fender distance to things next to me. In normal cars, the mirrors stick out to the same width as the car or further, and so you get great perspective for backing up. Not so in the 7. So, for the roll bar mount contraptions I made up, I flipped around the L bracket to get more distance. Much easier now! To minimize time spent converting between rain-mode full doors with DPR mounts and sunny day half-doors with cage mounts, I ordered a second set of Spa mirrors, the GT / Le Mans style this time which are a little taller by about 3/4 inch and wider by about 1-1/2 I believe. I also have a set of coilovers being custom designed for the car by MCS. To-do is measure the motion ratios and then remove the bilsteins to find the un-sprung weights.

-

Dash cam mount for my viofo a229 pro installed. Used a quad lock system on the bar so that it can remain there when running the aero screen. https://www.quadlockcase.com/collections/build-your-own?selected=eyJoZWFkIjoiUUxQLTM2MC1MSCIsImJhc2UiOiJRTFAtMzYwLUhDQiJ9 plus a standard quad lock flat face mount. Also have the 1.5" roll cage mount mirror brackets put together with some DPR block nut conversion mounts. The L bracket can be 180 turned to have the mirrors stick out quite far if need be. Next up is applying the ppf from Premier Paint Guard.

-

Haha I probably should make a lessons learned guide once I have the car where I want it to be. I aligned my headlights perfectly at night, and then they worked themselves loose on the drive home and became lazy eyes oops! We don't talk about Fanny 😂

-

Had no fishing wire, razor wire, nor 007 watch-wire on hand. Tried a variety of tools, in the end this puddy knife made short work of the rubber adhesive from the factory. 5 minutes a side pushing / rocking side to side half a width of the puddy knife at a time to get under the adhesive. No knife required. Lots of contact Other side too Time to bend, didn't need more leverage than a thick screwdriver. Bend back down with a spacer, hit it with a hammer while pushing if needed for the rear stays since it's hard to lean on it. Bingo Do for the other 3 Added two bead layers extra Sikaflex 291 on top to make the stays a tad taller to clear the inside of the wing. Thought about cutting some holes to get it lower, but I think it's fine. Once those dried, I added another layer to adhere to the wings and slapped them on. Bing bango Bob's your cousin? I'll add a bunch more from the underside once this dries in place I made the wings slightly more inboard to help reduce side of car debris /things going into my face since the sidewall will stick out just a tad when perfectly centered. Still covers outer tread

-

I think that is the way to go, adding a washer/spacer on the knuckle connections doesn't seem like the greatest idea. Elongating the upper mount hole might work but then isn't centered. 15" I'll keep an eye on that for sure. I thought about this and decided bending would be faster, cheaper, and closer to the OEM scrub radius.

-

Maybe I finally get to buy a welder?? Or does someone sell wing stays for taller tires? I think it's the 50 profile that's killing me, 205/50 circumference is larger than 195/50 oops.

-

Lol thank you! I see I am not very observant, shimming up is not really a thing. Elongate via splicing in additional bar? Looks like 7 mm clearance on the horizontal side

-

My 10 mm wider tires are 15 mm wider 😂 Contacts cycle stay lightly. Otherwise fits great, easy to mount. Should I: 1) shim the cycle stay towards center of car? 2) shim cycle stays up? 3) shim both directions? 4) bend the cycle stay? I'm not sure what the cycle stay holes look like since these were installed already when I received the car. Rears fit as anticipated, slightly more than a 1 finger gap between trailing arm and tire. No the stands are not under the exhaust although it really appears as such! Vs Old

-

Front hub bore is 58.3 mm Orcus wheels are around 63 ish, caliper didn't really fit in there. Will take a center cap off at some point.

-

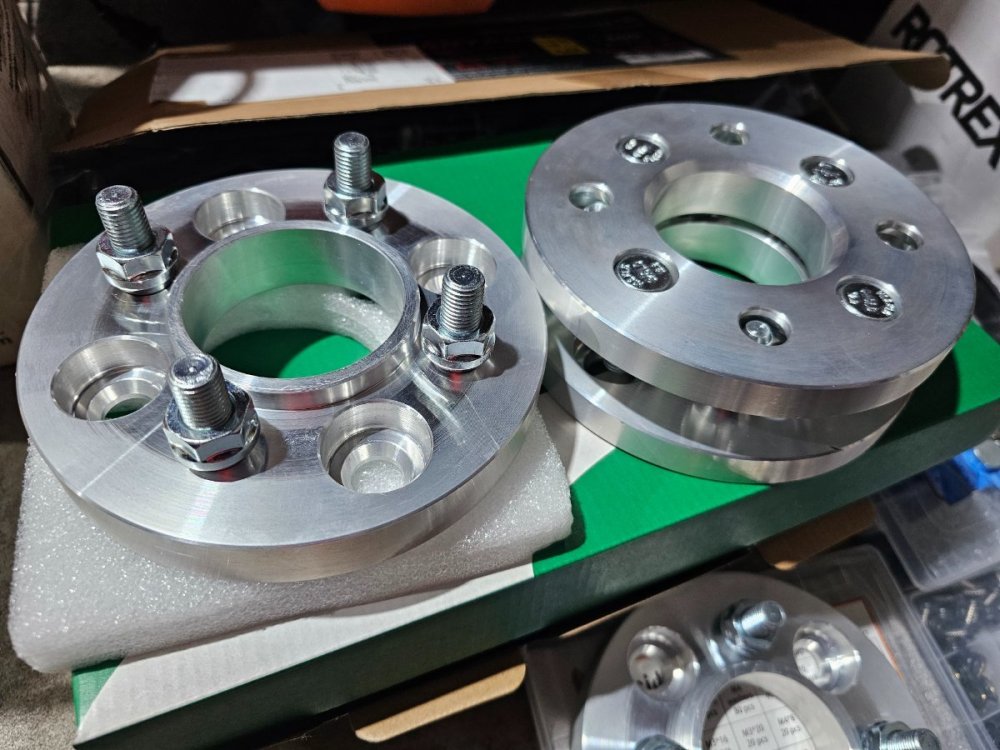

Before. This will only be driven to church 😂 Hoping the tires are stiff enough. The existing dampers are height adjustable only. I think the unsprung weight will be nearly the same as the OEM wheels. I suppose I should do the math... Front 20 mm adapters are 1.3 lb each with nuts. Rear 15 mm adapters are 1.1 lb each with nuts. (I had these flipped on the first post. These weights are according to my really accurate bathroom scale with me + adapter - me without adapter). Front 15x7 wheels are 11.3 lb Rear 15x9 wheels are 12.7 lb Front Conti ECF 205/50 are 19 lb Rear Conti ECF 245/40 are 21 lb (From TireRack) OEM orcus 15x6.5 are 13.0 lb (https://caterhamparts.co.uk/lightweight-15-orcus/7513-65x15-orcus-wheel-anthracite.html) OEM Avon ZZS 195/50-15 are 20.7 lb (https://www.arielmotor.co.uk/product/avon-zzs-tyre/) Therefore, corner weight (new) - (old) = Front: (1.3 + 11.3 + 19) - (13 + 20.7) = -2.1 lb Rear: (1.1 + 12.7 + 21) - (13 + 20.7) = +1.1 lb Good thing the inside has so much room. On cornering, compression should keep the whee at a lot of negative camber. A drift over a speed bump might be the worst case scenario where it would tuck without camber change and maybe hit the fender exterior lip. Would be a shame to have to buy carbon fenders!

-

Based on tire section width differences of the conti extreme contact force in 205/50 and avon zzs in 195/50, the 10 mm clearance should change to ~5 mm clearance to the inside stay. MCS are motion control suspension out of Atlanta: https://www.motioncontrolsuspension.com/buyers-guide/3-way/

-

It's for the science! Am talking with MCS currently about my options. Anybody have total unsprung mass values for front and rear and motion ratios?

-

Only needed to take off about 1 mm for the 4x108 wheel studs to not interfere with the back of the front wheel reliefs. Coated with some zinc antiseize until I get around to painting it off. The wheel adapters have grade 12.9 studs and seem real beefy, whew. What I did find out is: 1) I am terrible at measuring - the rear hub sure is 63 mm, but the front is more like 58! 2) neither the front nor rear OEM orcus wheels have any hub centric ring spacers, so the front wheels from factory are lug centric! The rear may be too, I ordered a calipers so I can measure the hub sizes better and get a ring for the front at least. 3) I think the wheels will fit perfectly. Mounting tires Thursday. If either front or rear are too wide, I will swap to 195/50 and 225/45 which should certainly have enough stretch in them. Thanks discount tire! Front wheel fitment: Rear Lots of room on the inside, will measure once the tire is on but 1-2 fingers-worth At ride height: Will have to see what the stretch looks like with 245's. I don't think they will bulge out much. It's possible on a two-wheel speed bump it could compress enough to contact the fender, we will see! Ride height from top: Compressed only on wheel side, tons of room.

-

Thanks, I agree I don't know what the actual mechanical limits are for these studs, and that more is better. I don't think they are triumph studs. Another calculator showing the min to nominal range is 5.5 mm to 16.5 mm for M12x1.5. Yet another rule of thumb I've seen for M12x1.5 is 6 turns minimum, 12 turns nominal. If my 18 mm is as I tested 12.5 turns, 17 mm is 11.8 turns. I am convincing myself :P

-

Oh nice! Looks like I measured 10 mm but these are M12x1.5 studs most likely, so 12*1.5 = 18 mm, 1 mm short of the 17 mm I'm thinking about. But, using the equation in the link, d = diameter of thread p = pitch of thread thread engagement length = 2 * tensile area / (pi/2 * (d - 0.64952 * p) tensile area = pi/4 * (d - 0.9382 * p)^2 simplify your pi thread engagement length = (d - 0.9382 * p) ^2 / (d - 0.64952 * p) thread engagement length = (12 mm - 0.9382 * 1.5)^2 / (12 mm - 0.64952 * 1.5) = 10.2 mm Which is 0.8 * d as the bare minimum. That is a lot shorter than 1.5 * d which is probably a real-world safer value. Therefore I think 17 mm is good to go.

-

Straightened out my headlights, they were set to UK angle as seen here: Suspension felt good around town, pretty darn smooth at low speeds over terrible roads. On the highway, it's very busy and a bit bouncy. Realized I never actually checked tire pressures and they were at 25-30, brought down to 22 to try that. But that got me thinking that the car felt under-damped on the highway very similar to how my Miata with bilsteins did. Reading online and it seems a common sentiment. The other common sentiment is to buy suspension kits from meteor motorsports. Having been burned with tariffs so much lately I think I'll find a US solution. This leaves Penske, MCS, FOX. Will post some suspension measurements. The wheels: Each front stud has 20 mm of thread engagement for the stock front wheels and the lug nuts took about 12.5 turns to remove. The studs appear to be about 10 mm diameter, so with the 1.5x rule I need 15 mm thread engagement and have 5 mm extra. My front spacer adapters are 20 mm thick and the front studs are 28 mm long. The relief in the back side of the front wheels is much smaller than the rear wheels and is 6 mm. This means 28 - 20 - 6 = 2 mm extra. Since I have 5 extra to play with, I can cut 3 and have 17 mm thread engagement when using the stock front wheels. For the rear, the relief in the back of the wheel is 20 mm, the studs are 32 mm long, and the spacer is 15 mm. 32 - 15 - 20 = -3 mm of gap between the end of the stud and the wheel relief, so it should be ok as-is. Do I have any flawed reasoning to think 17 mm front stud-lug nut engagement is acceptable? Front studs: Engagement via antiseize:

-

Westermann half doors needed some cutting in order to fit. I initially sanded away with a Dremel to see how it would fit, but found out it was best to just make a single straight cut to get around the track day roll cage. As it comes door on left, cut on the right: Another view of the cut: View from top when installed: View from side with two poppers in place, planning to add two more and then add on some edging so I stop scratching the crap out of my roll cage:

-

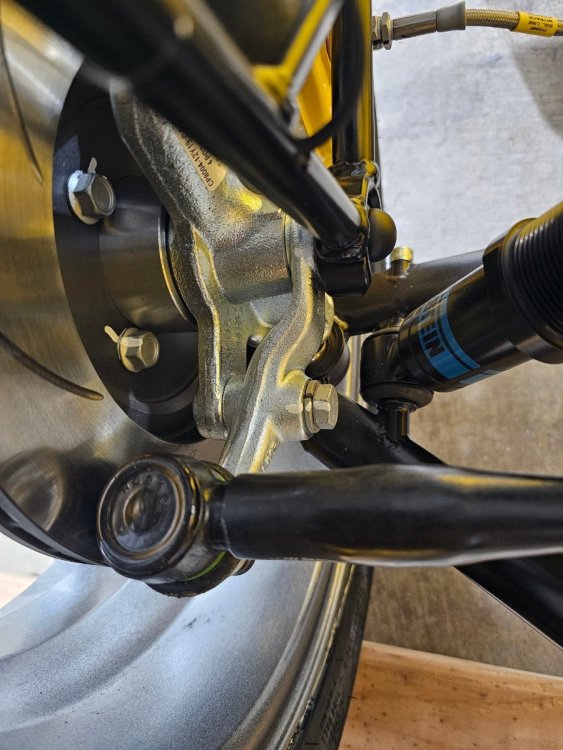

The transition by hand does seem mostly smooth, but it's micron level precision to make it so. I'll verify what the reference values should be. I drove around today to test it out, and it's wild that that -0.01 V difference made it so so much more driveable. I am surprised. I could Seattle hill start with a car right on my butt no problem, no hand brake. For the fuel gauge, it does perform a test sweep at ignition set to run. I hope it's not the tank sensor 😬 going to grab another gauge from Bruce to test first. Another thing I noticed, is how close the tie rod end boots are to the brake calipers. These are going to get burned off the first time I get the brakes up to temperature. What do I do about this?? I see a few other forum posts, one was to add a washer (not sure how that would be safe). FL FR

-

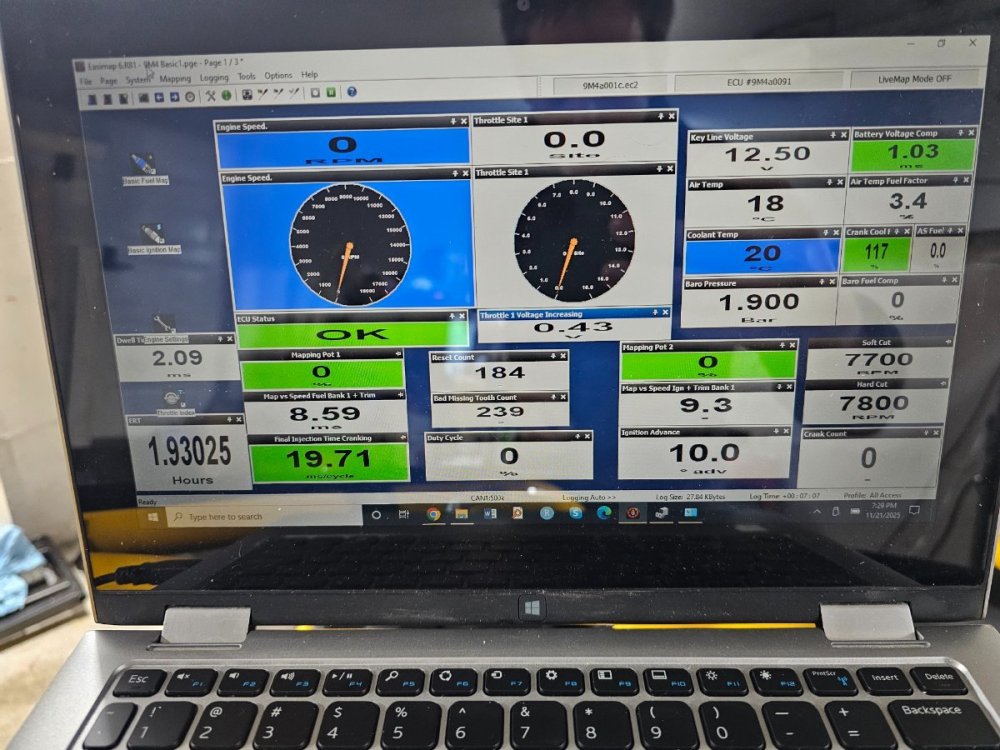

Checked my throttle position sensor voltage - idle was at 0.53 V site 0.0. Site 0.1 starts at 0.54 V. Idle screw completely out (throttle closed) was 0.43 V. Fully open was 3.38 V. It seems like my idle up/down surge repetition is probably something related to thermal expansion and going from 0.53 to 0.54. I set it down to 0.52 V to see if that helps. I did notice that with very, very small throttle actuation, the throttle site value goes up to 1/4 of maximum. This is almost certainly related to the difficulty in small throttle modulations. ---> is there a mod to make the throttle cable actuation more linear at the initial actuation? Like a larger diameter butterfly Build support had me test continuity between green-black and green-black on the fuel gauge dial and fuel gauge connector on the rear left tank side and, it was good. Decided to raise the rear up a little since I was going to take the rear wheels off anyhow to bleed the brakes for the seventh, yes, seventh time trying to get more air out. Went up to 165 mm each side in the rear when loaded with my weight and kept 150 mm in the front.

-

Oh really, so this full droop actually has the shock fully extended already then and increasing ride height only increases spring preload?

-

Fascinating. I took the wheel off to measure the hub bore, so it's easier to see the sunpension also: Is it typical to have the coilovers near minimum height yet only have 10 mm distance from de Dion to side rail at full droop? I was going to raise the rear up 10-20 mm but not anymore! Is the 150 mm ride height not applicable to 620? Also look how long these springs are, 13 inches! ~50 cm end to end on the shock body. And some hub measurements if anyone or future me needs it:

-

I might need to put in slightly shorter studs too, will find out! Can't determine the wheel rear fascia pocket depth. No idea what the contour shape is of the nuts either on the adapter so may need a few parts. An adventure!

-

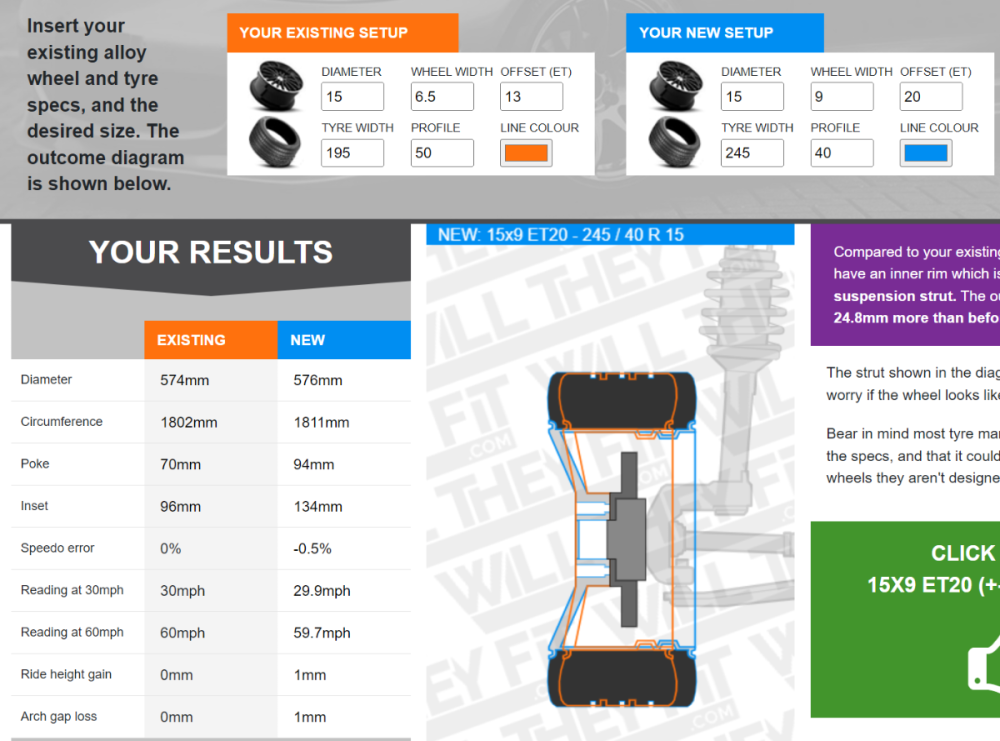

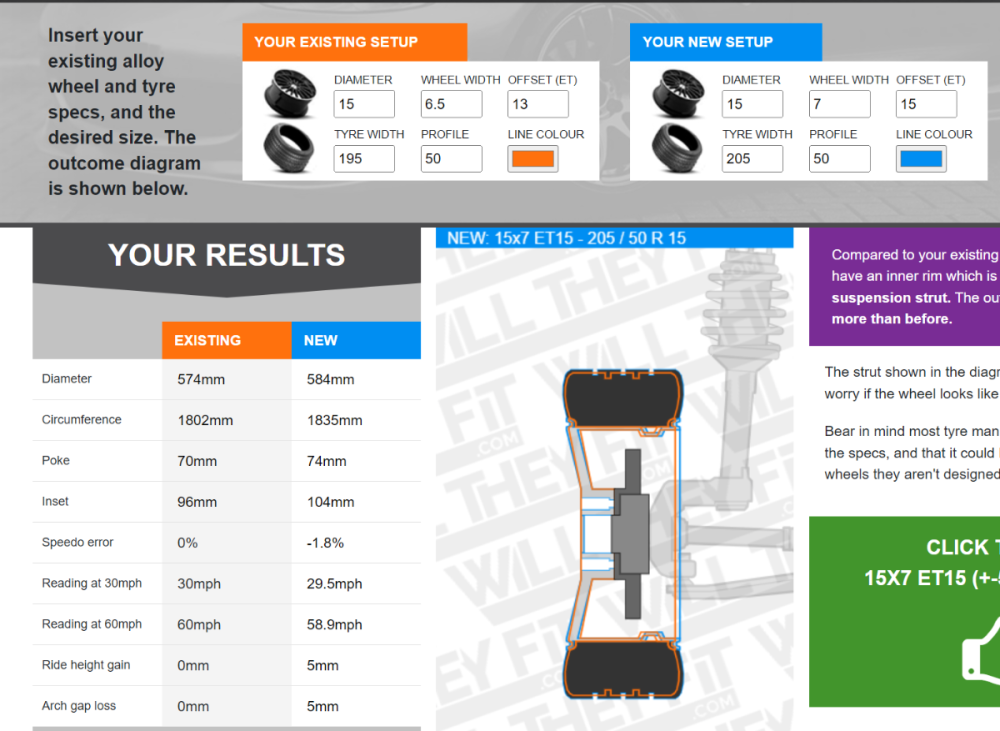

Going for gold (anthracite w/ polished lip actually) since the black friday sale is ridiculously cheap compared to anything custom, and have had a good time with Konig on my miatas: Konig Hyperspec 15x7 et35, cb 73.1, 11.3 lb Konig Hyperspec 15x9 et35, cb 73.1, 12.7 lb Australian Caold converters, 4x108 w/ cb 63.4 to 4x100 w/ cb 73.1 20 mm thickness front, 1.1 lb = effective et15 front for total of 12.4 lb 15 mm thickness rear, 1.5 lb = effective et20 rear for total of 14.2 lb How it will sit compared to the 15x6.5 et13 on the car currently: front: rear:

-

I believe it does not have a watts linkage - this is the right hand side looking forward, there would be a second bar coming off the top of the de dion tube going towards the rear if it had a watts, right?

.gif.362721cf8de6035489da02e000599cbe.gif)

.gif.8975a20aad176db7c2e3de89e398edba.gif)