Clarko

Registered User-

Posts

62 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by Clarko

-

Wow MV8! very detailed Thankyou so much for the time in explaining that to me. I will start those steps.. and report back. I might be pushed to get that done before I head across to Scotland to check in on my Mum for a couple of weeks. 👍🙏🙏

-

Hi MV8, so here is my latest update: For the first time ever the engine is now running in the car ! I did have a crank trigger welded to the crank pulley and moved the Crank Position Sensor to the front of the engine: Bingo! I do however now have the problem of a nasty noise coming from the starter motor / flywheel area… sounds like a bag of spanners rattling around! I switched the starter motor for another one… Worse! I am open to suggestions on how to diagnose exactly what that might be? I have the three bolts tight? How do I know if it needs shims etc?

-

Hi MV8, I was getting tired of nonsing around with ferrite beads and additional emi shielding, and have decided to go to a Crank pulley mounted trigger wheel to try and get rid of my issue once and for all. So I have some bits and pieces ordered up to make that happen. (Omex reckoned that moving the CPS that far away frm the starter should alleviate any issues 🤞) I will keep you posted, thank you so much for your help 👍🙏

-

Here is a vid I shot yesterday showing voltage drop down to about 11.5 volts cranking so I believe that’s plenty of juice. I am messing about with ferrite beads and adding shielding to the starter motor and CPS cable but am thinking that I should give that up and move to a trigger wheel on the Crankshaft pulley to hopefully put this to bed so that I can move forward with the build 🤷🏻♂️ IMG_3788.mov

-

Brief update: I installed the new starter motor today… and the good news that I got stat sync to come ON… but timing errors still climbing…. So I’m only HALF pregnant! so the new starter has improved things ( throwing off less emi) but I’m still throwing off enough interference to mess with the crank sensor reading ecu? Ill see what Omex suggests but am guessing I need to up my “suppression” game 🤷🏻♂️ IMG_3754.mov

-

Yes one of my favorite expressions Bill! 🤣🤣

-

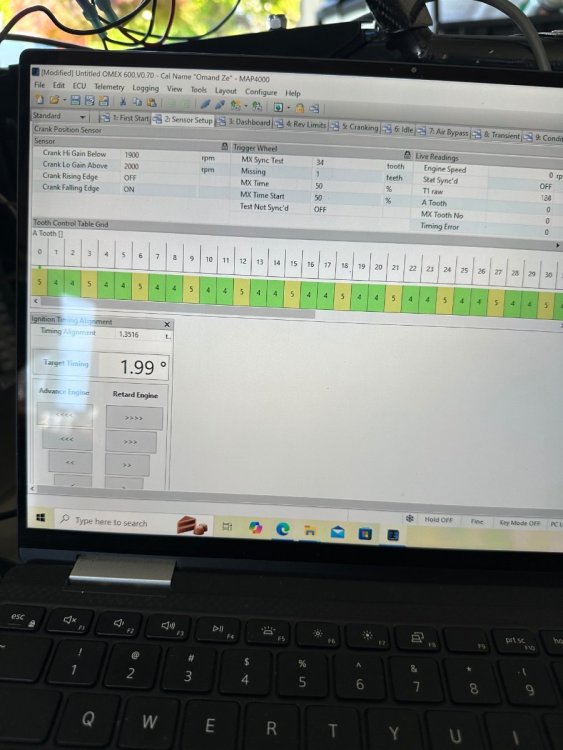

Yes currently using 50 for Mx timing and Mx timing start.. have tried them both down to 20 and up as high as 75. I know some people have had issues with Omex getting sync because air gap between sensor and trigger wheel was too wide which is why I spent an inordinate amount of time adjusting the gap from 1mm to around 0.5 mm now…. And yes have switched polarity on the two wire sensor leads “ just in case” but but no joy. So my current thoughts are: Put in the new starter when it gets here… If no joy there… then connect everything up again and bump down hill to see if everything works… try increasing shielding on crank sensor wire even further and maybe shielding starter motor? Failing that its mounting trigger wheel on from pulley and fabricating a bracket for crank sensor for that… which is a slight pain as no one does a kit for it… ( don’t need to because the engine already has a crank position sensor housing there already

-

Handed across my starter motor to the auto electrical place… They are going to source a different one that fits my application. Now I’m cleaning out my entire fuel system to get rid of 5 years of crud. will keep you guys a breast of progress 🙏

-

A couple of screen shots of the Omex software live readings… also… back in 2020 when I threw in the towel.. I had sent Omex the ecu to test on someone else’s car… and it came back to me as double checked and fully functional… so it is definitely something to do with me! And my setup.

-

Hi just to clarify your first para to make sure we are on same page.. when cranking with starter… the stat sync stays OFF…. My understanding is that is BECAUSE it’s miss counting teeth and that causes the timing errors to keep rising …. So until I get SYNC, it will not produce fuel or spark…. the good news now of course is that we know if we turn the engine over by rolling it down a hill it DOES sync…. we just have to figure out WHY the starter throws the crank sensor for a six so badly!!!! I have Jerry rigged up a home made additional shield for the crank sensor lead (it was already a twisted shielded pair from Omex…. I used tinfoil, then painters tape, then a length of wiring loom and earthed the end of it to battery negative with my two Omex ecu earth wires…. Didn’t work! the search continues.

-

This second vid is with spark plugs IN IMG_3540.mov

-

OK first vid is clutch in and NO spark plugs(fuel pump relay removed) IMG_3538.mov

-

Yes, exactly as above👍 no lambda sensor or shift light. Ford 36-1… no Hall effect jumper on the board installed as of course it is VR crank sensor. I will send those two videos 👍

-

Here is a video(volume up) of me cranking the car… (spark plugs out) stat sync will not go on … So I think that means that the ignition switch IS wired correctly as the ecu IS getting feedback on engine revs from the crank sensor?… but cannot sync and determine TDC? IMG_2927.mov

-

IMG_3453.mov

-

I’ll attach a vid of the bump start Omex screen when bumping it in 2nd gear.. shows exactly what I would like it to show me, but need it to do this with the starter motor spinning too! … I do have to pause to think a moment though about your question regarding does everything in the Omex get power when cranking???let me get back to you on that🧐

-

Hi, Yes third owner of the build… so it’s 22 years old… (I think 2003?) and has never started… Omex 600 with their Race spec loom, Jenvey ITBs… I tore out what was left of the Birkin wiring and started fresh with a 26 circuit off-road circuit by Painless… mostly following Slomoves diagram from back in the day… but there are differences which is why I have not posted it….perhaps worth noting that I am not using a relay between ignition key and solenoid… but that did not seem to excite Omex too much. 🤷🏻♂️

-

Hi Bill yes that works perfectly when bumping the car without starter 👍

-

Hi Bill, thank you for the response. Good point re: the starter… There is a place that I will call on Monday to ask if they can check the starter for Electro magnetic interference… ( it’s actually a new starter.. well 5 years ago it was, but in my new philosophy of leave no stone unturned,) I will try that. Its a brand new battery with tons of juice so that’s not an issue, and of course cranking the engine on the starter is no problem… it’s just the crank f the motor and getting the crank sensor to allow “sync” to switch on meaning it knows where TDC is and will activate fuel and spark. The ignition key thing is an interesting point which I will think about… I DO have a different set up with the stock ignition key that I could try 👍👍🙏

-

-

IMG_3319.mov This is a vid of the earth points I am using: I am running a 4 gauge wire from battery negative post to a bolt that goes through engine mount, sandwich plate into Birkin bell housing. I then have another 4 gauge wire running from a bolt into the block to the chassis frame.. all contact points HAVE had powder coat ground off. so am I missing something obvious? I saw an article about Westfield running battery negative to chassis rather than to engine block (and then presumably another strap block to chassis as well? I saw a Caterham post where they ran BOTH a chassis ground AND an engine ground from Batt negative… I have tried also adding a temporary cable starter motor bolt to batt negative and also a jumper cable from engine bolt to battery negative to see if that made any differences? But no! Seems silly. Any suggestions would be much appreciated. 🙏 Clark

-

Hi MV8, thanks for the response: This is a follow on question from a no-start issue I had 5 years ago… which resulted in me throwing up my hands 5 years ago and giving up on the car…. It had languished under a cover in the garage all that time, until now when I have become re-motivated to get it going…. I will link the old thread in here (if I can figure out how? I will also post the photos you have requested. To answer your basic question.. my ecu manufacturer from the UK (Omex had apparently thousands of Zetec running on Omex ecu’s… their latest conclusion is this: Since I can now get the Crank signal to “sync” properly when bumping it down a hill in second gear (I have not actually tried to start it this way as I need to change 5 year old fuel out of the tank)… but CANNOT get the engine to sync when using the starter, and the software suggests large EMI when starter is used that I therefore have a starter related EMI problem. This NOT my strong point but I can follow instructions pretty. The starter motor was new and it’s the second one that I have put in….. making me think is it possible it’s a grounding issue, or the way I am running my grounds which is why I am reaching out to the collective…. And looking to follow a “ known good” wiring method that works on someone else’s Zetec engined car… obviously a Birkin would be even better…. There is no such thing that I can find of Birkin posting WHERE to attach battery neg to chassis or engine and where to attach engine to chassis etc 🤷🏻♂️ Any help would be appreciated… I BELIEVE I am one step closer to get a first start on this car than I was 5 years ago 🤞

-

Hi All, as I have now diagnosed my non-start issue to being emi interference from the starter motor!… I am trying to to double check best practises for earth wires? Where are you guys running your Battery negative wire? Engine block to chassis? Where? And then do you all have the starter motor as a 3 bolt to just the spacer plate between the Birkin 2000 sump and engine? … any special earthing required from that? Have any of you had issues with Electro Magnetic Interference thrown off by the starter…. I must have done something silly? Or have a starter with a fault? any thoughts would be much appreciated 🙏 Clark

-

Thanks for this, AI at its best…. It’s the first reference I have seen to the shallowness of the trigger wheel that Fidanza attaches to the aluminum flywheel being a possible problem?? I am also back to playing with the air gap by trying to grind down the sensor and also the aluminum “Ford bush”.. crazy part is… the tolerance required by Omex for the air gap is 0.3-0.5 mm. I am trying to work on a plan B… My preference would be NOT to have to drop the engine out (I didn’t put it in so I am a tad intimidated by that) as I understand it EVERYTHING will have to come off that engine again first! Does anyone have a video or reference they can suggest for removing engine from a seven? If I did that then I guess Retroford in the UK for a new bush and lightened steel flywheel? Or open to suggestions? Or a new ecu sourced in North America? any suggestions for that? any other thoughts if you were wearing my shoes? Thankyou to all for your kind responses 🙏