-

Posts

257 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by Yoram

-

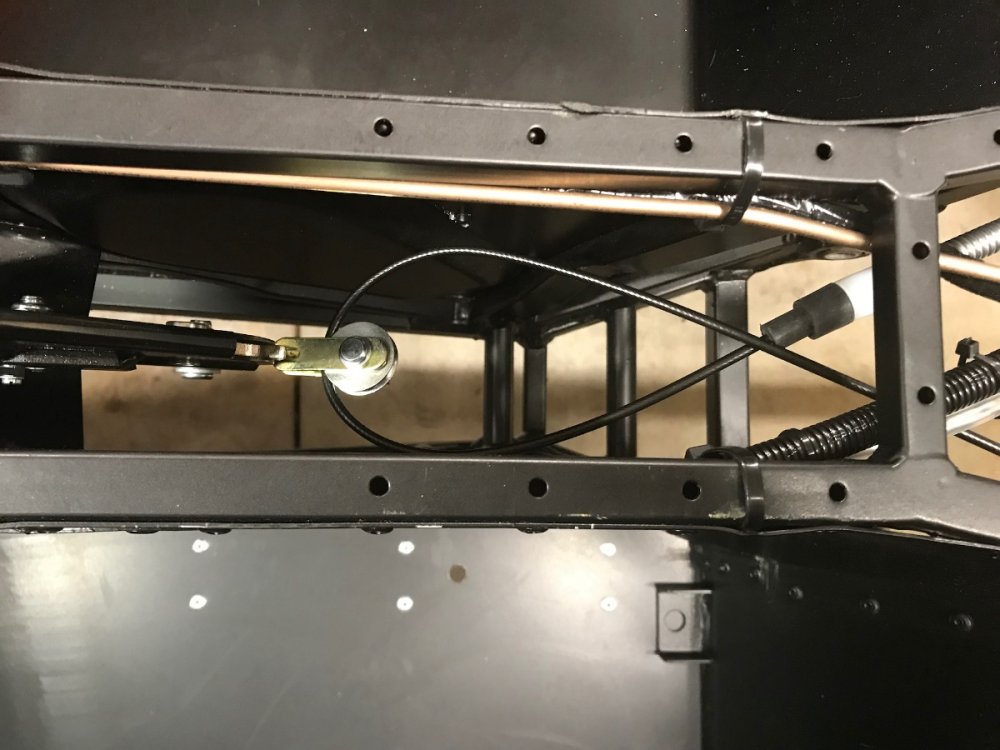

FINALLY, PROGRESS!! Hello All, Sorry for the long hiatus. I've been cleared to resume normal activities in the last week post my back surgery and proceeded to install the diff. I used my floor jack with a wooden cradle to be able to do this solo. First pics show the fixture: Floor jack with the fixture works great for solo installation; needed to loosen rear piece of fixture to raise the diff nose. Following are most of the steps - sorry but this will be tedious...: 1. Loaded propshaft into tunnel. 2. Removed plywood section of trunk floor to improve access to the top mounts and to spray-coat and seal (per tip from Denver); awaiting warmer weather to do this outside. 3. Touched up machined surfaces of diff housing with chassis paint pen. 4. Raised the diff with the floor jack into position, inserted conical punches in all 4 holes and confirmed diff is supported safely without the jack. 5. Routed RH park cable with adjuster below upper mounting to better engage bracket on diff. 6. Ground conical tips on the lower M12 bolts and on the upper 1/2" bolt and repaired the threads with thread dies. Tested the lower bolts to thread OK into the diff "cage". 7. Torqued RH lower bolt all the way (with temporary shims under the head) and measured the total gap on the LH side = 4.4mm. 8. Measured the distances from outside the chassis to the faces of the diff "cage" = 433 LH and 430.5 RH. Equal distances would be 431.75. Calculated required bottom shim stacks as 3.15 LH and 1.25 RH. 9. Installed LH bolt with calculated (~3.2 mm) shim stack, tightened snug and measured RH gap (= target RH shim stack). 10. Loosened LH bolt and installed RH lower bolt with target shim stack. 11. Tightened both lower bolts snug and verified near-equal distances from outside tubes to cage -- checked out at 432 LH & RH (otherwise would need to dismantle and modify the stacks)! 12. Measured the LH and RH gaps at the upper bolt mounts. 13. Inserted the upper bolt -- sub-steps: a) Loosened the lower bolts to allow more play. b) First few attempts to test-insert the upper bolt from the LH side into the LH diff cage hole (w/o shims) failed. c) Supported the rear part of the diff with the floor jack (w/o the fixture) and adjusted to align the LH chassis and diff holes visually as close as possible. d) Reground a much shallower cone at the bolt tip (after verifying sufficient bolt thread length). Test-inserted past the diff cage by hammering via a piece of lumber, then hammered back out and verified thread intact. e) Assembled the LH shim pack per 12 and inserted in gap. Inserted the bolt until it cleared the shims, then began hammering in as above until ~halfway in. f) Lowered and removed the floor jack to prevent over-constraining the diff. g) Assembled the RH shim pack per 12 and inserted in gap; resumed hammering until the bolt got all the way through. h) Checked the exposed bolt thread with thread die, removed the copper grease off the thread with a dab of brake cleaner, and threaded on the locknut. 14. Torqued the bolts: Lower first to 60 lb-ft, then upper to 45 lb-ft (IKEA guide specs). Notes: i. Measured gaps for shims with feeler gage. ii. Used the smaller (3/4" OD) shims except larger ones (7/8" OD) at the lower bolts on the outside facing the chassis. iii. All shims were coated with copper grease to keep together during insertion. iv. Bolts were coated with copper grease except thread engagement areas. v. RH lower and both upper shim stacks were inserted while leveraging with a large flat screwdriver to open the gap a bit (there is some "give" in the mounts). vi. Schnorr rings used under all bolt heads and nut as specified. Lining up the LH upper hole. Upper bolt - ground nose Diff installed - LH view Diff installed - RH view Diff installed - view from trunk (wood floor removed). Next chapter is rear suspension - already started. Hopefully will be able to report progress much quicker than on this one... Cheers!

-

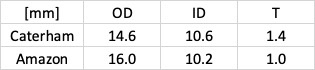

Hi folks, I'm not able yet to make any real progress, however here are two "lite" updates: 1. The world famous copper washer conundrum: I ordered and picked up from O'Reilly what I believe is the Dorman 10-pack that @MV8 mentioned. They call it "BrakeBest Copper Gasket BHH H9453". I guess the part number is the tell tale. The actual measurements are OD=15.7mm, ID=9.8mm, T=1.65mm, and these also match closely with the ones @MV8listed, so this should be it. Unfortunately these don't work because the ID doesn't clear the little ridge on the fitting. So I reinstalled my Amazon washers after annealing and will keep them unless I find something thicker or if they leak. 2. Track rod end: A warranty replacement piece arrived just in time to serve as my #1 Christmas present... It installed with no issues and both sides are now torqued. The next step will be the diff (of course after the propshaft is in the tunnel). I envision asking a few questions about parking brake cable attachments, among other things. Unfortunately this is still a few weeks away. Wishing y'all Happy New Year!

-

Thanks! Per your info 2 mm is the thickness of the original AP washer (which I can't find in my kit), that's why I "spec'ed" it. The ID of the Dorman washer looks like a snug fit which may help keep it in place when installing. 1.63 mm thickness is way better than my Amazon 1.0 mm. Would you need to anneal the Dorman washers before use?

-

Thanks guys for the helpful insights into copper annealing... interesting how we all would zero in and deep dive into a seemingly minor point (but useful if you want to be able to stop using only tire/road friction). So the remaining question I have is does anyone know how I can get (or has to sell) a few copper washers that are 10.2 mm on the ID, 2 mm thick and at least 14.2 mm on the OD? I will conduct another search through the kit but it will need to wait as I'm not supposed to bend or lift for a while. And you can never have too many caliper washers on hand... Merry Christmas!

-

1. Another reason to go with the original 2 mm rather than my 1 mm Amazon thickness. 2. I'm not a copper metallurgist, but why drop into water rather than just cool down naturally? Sounds like hardening rather than annealing?

-

I assume this refers to the handbrake assembly. Genius! Will remember this for similar situations. Thank you!

-

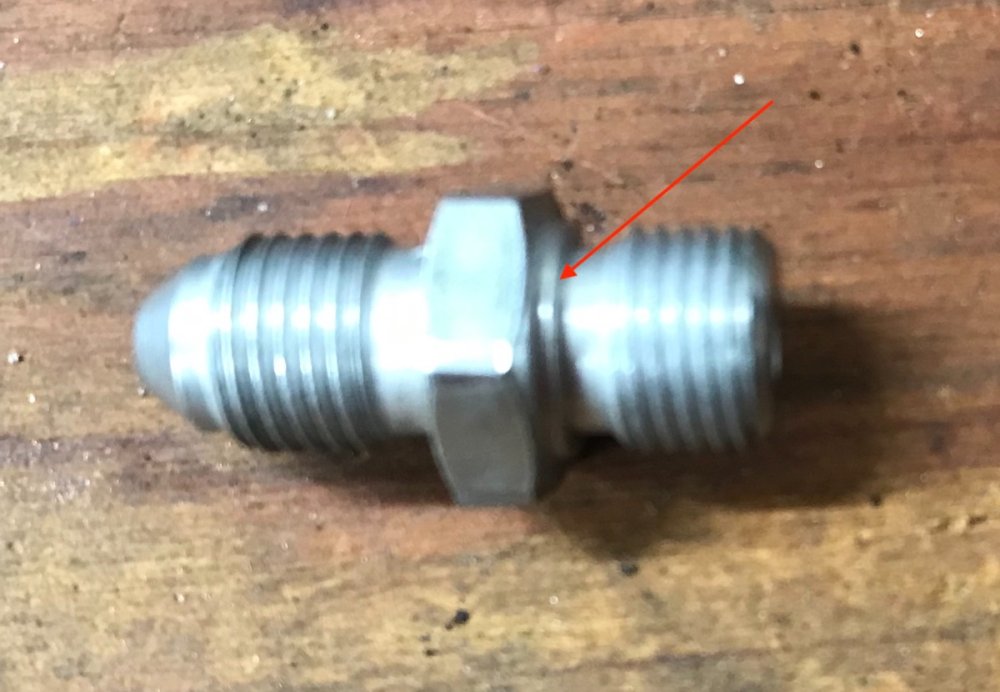

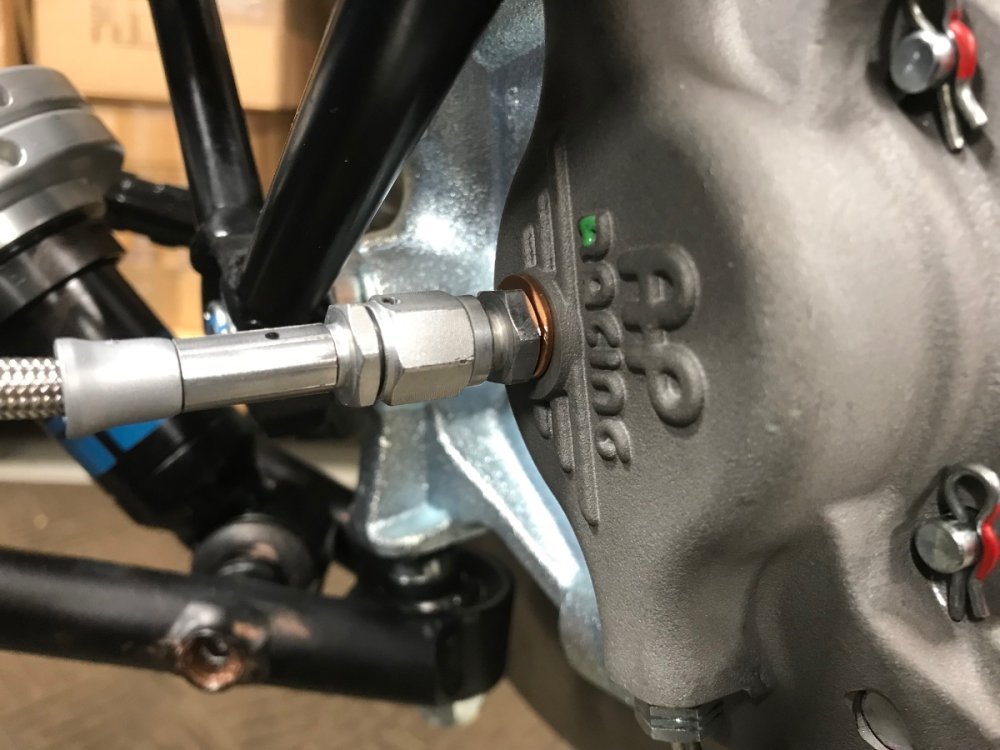

I looked into this some more, following a key pointer from Josh Robbins. The fitting has a small "ridge" on the caliper side between the hex and the neck-down - sorry for the crappy pic. The ridge is supposed to locate the ID of the washer. I measured the diameter of the ridge and it is just about 10.0 mm even. The Amazon washer ID is 10.2 mm, same as the AP one. So... I disassembled both sides and installed carefully a new Amazon washer on each side making sure it is concentric around the ridge. They fit perfectly and sit flat between the hex and the caliper, so the problem is solved. I don't like the 1 mm thickness of the Amazon washer but the height of the ridge is about 0.5 mm or less, so it does not "short" the washer. I will try though to get hold of the AP washers.

-

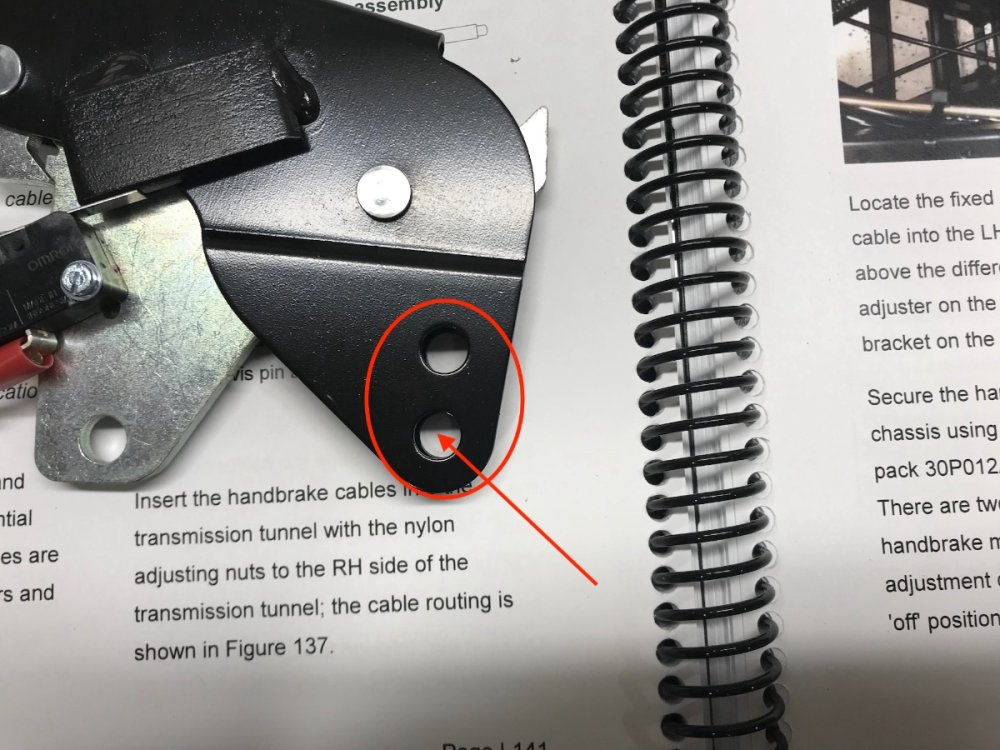

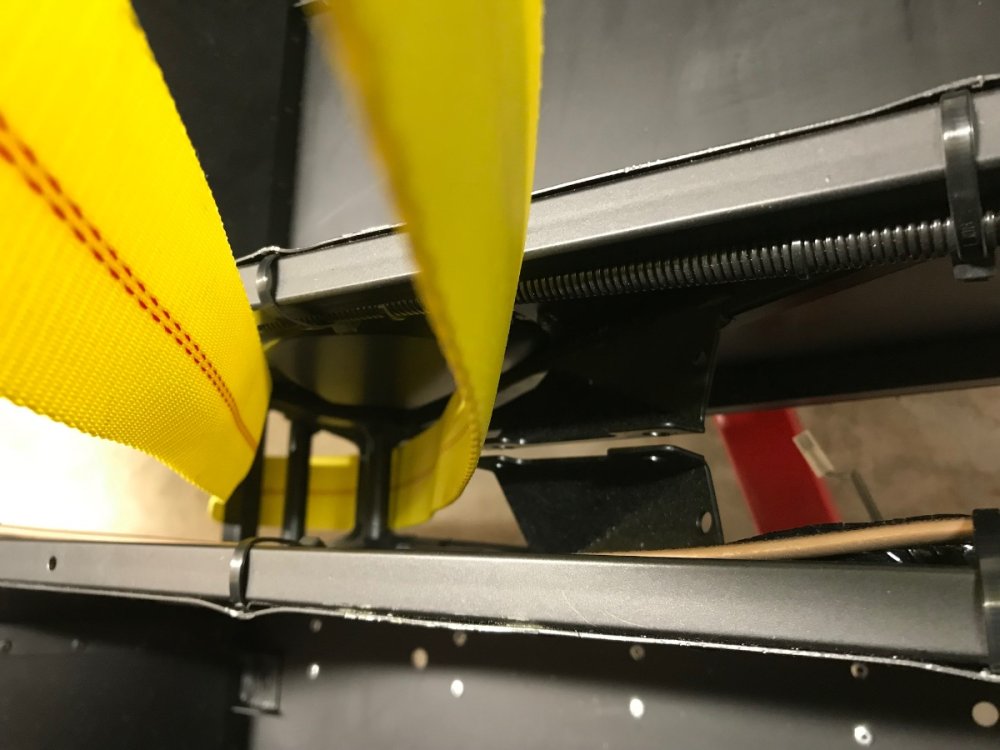

23Dec22 Update Hello folks, This will be a minor one. Not a whole bunch happened since the last update due to my primary garage focus being diverted to post-acquisition repairs and prep of our new(er) schlepping and occasional Yellowjacket towing vehicle, a low mileage 2008 Volvo XC70. That included replacing the rear springs (rust), eliminating a headlight washer plumbing leak, replacing driver side headlight assembly, and (important!) installing a trailer tow bar and wiring kit. All good. Back to Yellowjacket: Heeding Josh Robbins' invaluable advice, I decided to leave the engine-gearbox double marriage (to each other and to the chassis) for once the car can be rolled around the garage. So after adding the front brake lines, I proceeded to install the track day roll-over bar and the handbrake lever assembly, and did some planning for the next step of propshaft and diff. Highs and Lows: Front Brake Lines: First just an obvious tip: To make it easier to line up the fixed brake pipes with the braided hoses I removed the outermost zip ties tying the pipes to the chassis. I also loosened the bolt holding the little brake line manifold to let it "find its place". Tighten it back after "final" bending of the pipes and tightening of the fittings. Yellowjacket has the standard brakes (remarkably fixed calipers nevertheless!); I found in my kit two pairs of slightly different brake hose/caliper "adaptors", both with apparently same thread types/sizes (don't ask me what they are): I decided to use the gray ones as they leave a bit more thread length on either side after tightening. The real issue is with the copper washer between the "adaptor" and caliper. The only pair that came with the kit does not work -- ID too big, OD too small. I found a size that fits a bit better from my Amazon copper washer assortment on hand, but still not optimal (ID still a bit too big, and thickness smaller than the kit one). See the initial eccentric position of the kit washer (before getting discarded) and dimensional comparison: Waiting for more feedback from Denver... Track Day Roll-Over Bar: Y'all know that the upper mount bolts of the rear suspension coil-overs need to come out to insert from below the bolts into the threaded boss of the main hoop. That's part of the reason the roll bar went up now rather than after the rear suspension. The other reason is that it provides a stable rear hoist point should I decide to move the entire incomplete car in the garage with the engine hoist and strap. This went in remarkably easily. The overall dimensional control between the bar and the chassis (in my case) is actually remarkable. But still, here is a lame tip I'm sure most of you figured out: The thread in the boss at the bottom of the main hoop (which takes the bolt from below) may not quite line up with the hole in the chassis. The solution is leverage it to line up by a conical punch from underneath while tightening the smaller flange bolt (see arrow). It will hold the boss aligned and ready for its bolt. Handbrake Lever Assembly: Inserting the two bolts and nuts to secure the lever base/bracket to the tunnel (rearmost couple barely visible at left edge of pic) is a Royal PIA. Make sure to have a few first aid bandaids handy and the garage radio turned up loud. After a bloody fight to insert the bolts, I got each to bite into the nut by holding the nut in vise grips and loosely dangling it to line up with the bolt axis... A diabolical design. I suspect there are cleverer ways to perform this... But here is something that left me speechless: We all recall Sir Colin's decree "No Washer Shall Get A Free Ride", right? Well, I counted 7 (!) washers between the two clevis pins! And clearly that is only because the pins themselves are too long, which compounds gravely the weight penalty. Truly shocking. By the way, my handbrake lever has 2 clevis pin holes, which I hadn't found mentioned anywhere. The advice from Denver is to use the bottom one (quicker action). I suspect the top one is to add lightness... And finally, for now, the most good and bad part: I got my own (not Yellowjacket's) spine nerve passage ground out this morning in outpatient surgery (I offered to bring the Dremel tool to reduce my cost but they declined because they were not sure it was sterile). Seems to have gone quite well but the bad part is there will be no serious build going on for the next 4 weeks, just some light out of order futzing. That sucks. Cheers and Happy Holidays to y'all ! Next update next year. -Yoram

-

Hahaha. Thanks! The bar needed more impact than a mallet could provide... that's why the hard wood....

-

Thank you!! You are welcome to stop by anytime - just let me know. Cold beer is always available even though the admiration will quickly dissipate...

-

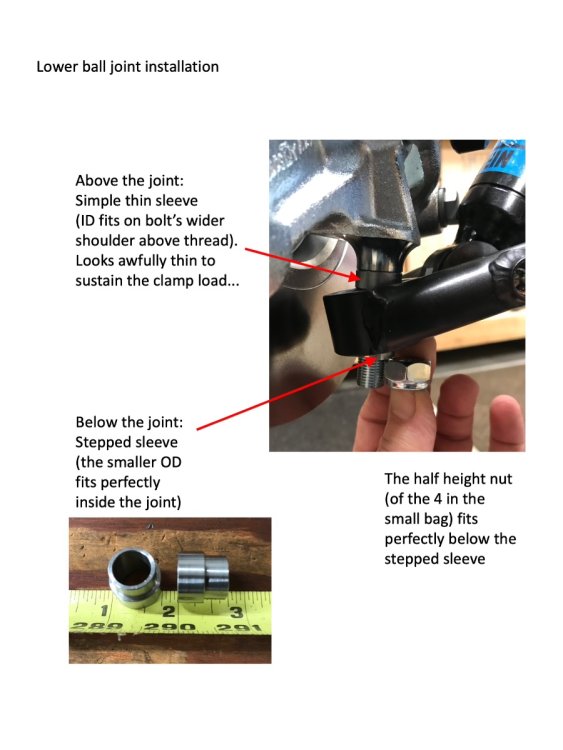

13Dec22 Update Front suspension is complete for this stage with one open issue: LH track rod end ball thread arrived defective and wouldn't let the nut on without the ball spinning. Josh Robbins is facilitating a replacement. For now it is marked on top with a red X. Both sides will be torqued when the good part arrives and gets installed. Also wishbone and coil-over mounts are only hand tight. Joints torqued to specs have yellow paint marks (except... of which later). (why yellow? because my Amazon paint pen set does not include green...) Highlights and lowlights (?) 1. Lower ball joint installation Neither the 2015 Text guide nor the IKEA guide include any reference to the parts in my kit. I guessed and winged it and afterwards it was confirmed to be correct. Here is my documentation... 2. Upper ball joint installation (and wing stays) At first I messed up and installed the nyloc nuts all the way (not torqued) without the wing stays... They are now installed and torqued with ThreadLocker Blue, as are the stub axle nuts, since there were no replacements in the kit. These get marked blue. One of the wing stays needed some gentle twisting in a padded vise to go in. Both need drilling a 1/8" hole for electrical ground. Initially I freaked out a bit until I started drilling and realized it's aluminum... With a drill press and rudimentary fixturing there is no need to drill a thru-hole as suggested in the IKEA guide notes. It's actually a bad idea because if your drill bit is not centered on the diameter you can break it (this happened). Conventional torque wrench access to the upper ball joint nut (with the wing stay...) is impossible, so I rigged an extender with a stubby double 22mm wrench engaging a 22mm hex bit socket (must adjust the torque spec!): 3. Anti roll bar Realizing early on that I will lose a physical fight with the bar, I decided to try leveraging and manipulation... I was able to (kind of) seat both ball ends with the middle of the bar hanging loosely on a couple zip ties off the frame. To pull the bushings/mounts to their positions on the frame I bought four "temporary" long M8x1.25x90 bolts and matching nuts. I threaded the nuts up the bolts and threaded the bolts through the frame into the welded nuts on the mounts, same as you would with the "correct" bolts. To get the bolt to engage with no risk of cross-threading requires padded vise grips to "tilt" the mount on the bushing so it is perpendicular with the bolt. Now you very gradually tighten the new nuts down the bolts, a thread or two at a time, pulling the mounts and the bar towards the frame. Need to make sure each mount stays near parallel to the frame and both have about the same gap from the frame. You eventually get the mounts tightened on the frame without anything breaking or flying off. Now you remove one temporary nut and bolt at a time and replace it with the actual bolt and spring washer (I used the flat washers with the temporary bolts as well). Now the only remaining issue was that the ball end on one side got seated all the way in but the one on the other side (bottom pic) didn't... This was solved by whacking (over a protective piece of hard wood) on the knee of the bar near the problem ball end with a decent size hammer, as if you were trying to straighten the knee. After a few whacks it got the message and went in all the way. This was fun. I hope to make some more progress and post another update before Friday the 23rd, when I'm scheduled for some outpatient back surgery which will ground me for a few weeks. But I will continue lurking around here. Thanks for spending time on my post. Cheers! -Yoram

-

Yes, thanks! Got that tip directly from the Source (Josh Robbins). Also the headlights.

-

08Dec22 Status: Little progress so far due to holiday travel and other distractions. As of tonight the steering rack, front wishbones, headlight brackets and coil-overs are installed. All just hand-tight. A few "lessons": - Lower wishbones: Installing the 2nd pair of washers in the lower wishbone rear bushing position is easier if you temporarily install 4-6 washers on the front bushing bolt and partly tighten it so that it pushes the wishbone back and increases the gap for the washers. - Headlight brackets: Getting the bolt through the second (rear) hole is a struggle. Used a different way on each side, neither one truly uplifting. First way: Observe in which direction the rear hole is off and bend the bracket ears accordingly in a vice with smooth aluminum faces to create a "mild trapezoid". Apply the bending by hand on the bracket boss. Second way: Carefully hammer a conical punch through the rear hole with the bolt partly inserted in the front hole. Easier than the first way. Mask the body and upper wishbone to prevent damage. - Coil-overs: These were surprisingly straightforward. Not sure why the upper bolts come screwed in so tight. - The IVA condoms are useful to contain the bonnet front catches. - Pandora Reggae station helps smooth little kinks. Next step will be front brake corners and anti roll bar, hopefully tomorrow. Cheers!

-

A few more unload pics -- sorry didn't have these handy for the initial post. "Kit Tower" crate on pallet jack barely squeezing under standard 7' garage door. Standard 27" wide pallet jack works for both this and engine crate. CBU crate unload sequence: 1. Winch onto flatbed tow truck: 2. Slide onto rolling frame (all casters must have brakes!): 3. Roll into and position in garage (all casters must swivel!):

-

Thank you, Jimmy!! How cool!! Looks like you squeezed in. shortly before they shut down the Sigma engines... How does it drive?? Beware as I may take you up on it!!

-

Thank you for facilitating this, Carl !! Will post shortly a minimal update...

-

Thank you, Bill!! I will very likely take you up on it!...

-

Thank you, Croc! Yes, although it sounds ambitious to be done by spring... we'll just go with the flow and see where we end up when...

-

Thank you, IamScotticus!. It is just one 20' strap wrapped around the 3 cross tubes at the rear bottom of the tunnel. The resulting "roll axis" passes below the CBU C.G., therefore a helper is needed just to stabilize the CBU to not "roll over", which takes one hand and very little force. A helper is needed anyway for facilitating soft landing on the jack stands, so there is no point in searching for a "stable" but more complicated one-man lifting scheme.

-

Hello All, 1 year and 7 months after placing the order my kit has finally arrived on November 14! The first pic is the configurator rendering of Yellowjacket. As the 1.6L Sigma engine became unavailable during my wait I got a no-cost upgrade to the 2.0L Duratec so my S3 kit changed from a 310S to a 360S. It is now mostly unpacked with the CBU on jack stands. Before going any further I need to pay tribute to the legendary Josh Robbins of Rocky Mountain Caterham who has been holding my hand patiently and helped make the purchase, wait and logistics actually fun! I started a build journal (in a spreadsheet, of course) but was prodded by Josh to post a blog here. Not sure exactly how to do this -- whether just by posting periodic updates on this thread or is there another format. I welcome y'all's feedback and guidance on this, as I know I will at many points along the build itself. Had not had much time beyond unpacking and some organizing and celebrating since the kit's arrival. A couple notes from the unload: a) Delivery was by 53' van, and offload of the CBU crate with the help of a flatbed tow truck onto a home-built rolling frame (with 4 swivel+brake casters and sufficient clearance underneath for subsequent lifting out of the crate by engine hoist). This worked like magic. I need to lay my hands on some pics and possibly video from the unload -- it was pretty cool. Will post them ASAP. b) Offload of the CBU from the crate onto jack stands was very easy with a fully extended 2 Ton engine hoist, a 20' x 2" nylon strap with some quick links and a helping hand to stabilize and guide the CBU. I will post some more pics and details, especially in response to specific questions. I have no timetable or deadline for this process. Only reason to hurry would be to drive the damn thing while I can still get in and out. Cheers to the madness!

-

Thanks, John. Alleviates some of my guilt. BTW, I like the 944 Turbo in your stable. Had a '88 944 Turbo S and it was a far far better car than my '87 911... (hope no Porsche cops around here). -Cheers.

-

Sorry about the double pic. Donno why it happened.

-

!!! I was going to suggest the same thing!! ... but don't have my Seven yet... :-(( Ran it in my '87 911 and in my Holden (Chevy SS), and it is a blast -- so long as you get on it early in the morning, before the Harleys and sightseers.... Also need to wait till spring... Found the enclosed pic and video on the net.

-

:cheers:

-

Re Seven: I do not intend to order the aero screen. My windshield at least initially will always stay on. The base S-Pack comes with removable top and doors. Beautiful car!!! Custom painted wheels? Re Volvo: I consider ours very reliable. By far the lowest total cost of ownership of any car we've owned for decades. It is our workhorse, schlepping dogs, home and garden project stuff, and our long distance cruiser, so if the sunroof does not work or there are some scratches we don't fret. It is great to have a "carefree" car you park anywhere and don't worry about door dings, yet is still tight and refined and full of character. Cheers!