-

Posts

257 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by Yoram

-

Hello All, It's been a very long break for several reasons -- one was a detour for some unscheduled work on our Volvo XC70 (future Yellowjacket tow car...), which got deeper than desired. That part is done (I hope...). The other was due to my new decision to change (again) the build sequence. Instead of, as planned originally, proceeding next with the wings, I decided to first complete a DIY wheel alignment, while the wings are not in the way. I also decided to come up with my own alignment method using generic and inexpensive hardware. Generating the concept, procuring the bits, putting them together, tweaking them and evolving the process took quite a bit of time. I have completed this interesting and labor intensive step now, and the car is aligned to my satisfaction. The next several posts will document the method, equipment and results. I'll have them split primarily due to pic file size limits and to make it easier to post and read.

-

Seats Installed the standard (non-race) seats after torquing the suspension joints but before the ride height change and re-torquing. This required access to the front bolt of the radius link with the seats in. Please see previous post. Both seats are identical. The fore-aft adjustment works (within its limited range) and with my 5' 9" frame I actually moved the seat forward a notch to comfortably reach the pedals. Several tips: a) remove the bottom cushion for the installation (it comes off and goes back in easily) b) lay the lap belts (in a 4 or 6 point harness) pointing forward along the floor, place the seat on the floor, then pull the belts up on the outsides onto the seat to clear the rails and allow the rails full contact with floor c) use a spherical tip hex bit (H6), or a U-joint adapter on top of the hex bit, with long extension for the rear bolts and the fore-aft adjustment all the way forward; this is the most tedious part d) no problem installing the seats with the car on the ground (as I have) however it's more convenient to have it on jack stands e) keep the protective plastic covers on until completion of build, just make sure to cut out the bottom so it does not get caught between the rails and floor It was really fun to sit in behind the wheel for the first time, feel the pedals, wiggle the steering wheel and adjust the belts to fit!! Cheers!

-

Suspension Torquing, Ride Height and Cross-Weight - Conclusion!! (now really) I ended my post of Aug 2nd with a concern about the proper trade-off between rear rebound travel vs ground clearance. In subsequent consultation with Josh Robbins of Rocky Mountain Caterham he recommended loaded ride heights of 148 front, 163 rear (with 14" wheels) -- 10mm lower than where I ended up on Aug 2nd... As always, I took his recommendation, but implementation required quite a bit of work... These were the main steps: 1. Untorque all suspension bushing joints and roll the car back and forth to settle the suspension 2. Lower the ride heights to the new targets and adjust the cross weight to 50% while periodically re-settling the suspension 3. Unload the ballast from loaded to Curb and again re-settle the suspension 4. Torque the suspension 5. Reload the ballast and re-settle the suspension 6. Final ride height and cross weight adjustment Here is the final (current) status. Here are some tips and lessons learned: Need to balance handling, ground clearance and ride quality. Increasing ride height reduces rebound travel. On an 360S S3 with 14" wheels, recommended ride heights are 148mm front, 163mm rear. This results in near 50mm rear rebound travel in loaded condition Pre-set coil-overs: For the above condition, set all 4 coil-overs so that 10-15mm thread protrudes above the spring platform/nut before assembly into car; saves a lot of work on the car Lubricate the coil-over platform thread (I used WD40) to prevent the threaded sleeve from turning with the platform/nut 80-90mm C-spanner with round peg works well. Need a second spanner or a conical punch to tighten the jam nut against the main nut To adjust rear coil overs and to torque radius link rear bolts under load need to jack up under the deDion A-frame bushing and remove wheels; nearly impossible to adjust with wheels and on the ground The thread pitch of the coil-over height adjustment is 2mm. This results in 1mm length change per 1/2 turn or 3 one-hole steps, which at rear equals the ride height change. In front, due to the coil-over ~45 deg tilt, 1mm ride height change requires about 1/3 turn or 2 one-hole steps Protect the lower spring coils and adjacent body surfaces and suspension parts with masking tape to prevent scuffing with the C-spanner or conical punch Measuring ride height is tricky and can be inaccurate and unrepeatable without special equipment, which I don't have. I may add in here later my clunky and time consuming (but repeatable) method... Bathroom scales (min. 500lb capacity rear) are very accurate and repeatable (compared same weight readings between scales and repeated measurements on same scales) -- less than 1 lb (<0.3%) variation. Need to make sure they are shimmed horizontal, not rocking, and tire patches are reasonably close to centers To torque the radius link front bushing with the seats installed, a stubby 8mm allen key (short leg <25mm) can provide counter-torque on the inside if the seat is pushed "all the way" forward Preload in the suspension bushings, when torqued at Curb, contributes ~2mm to the ride height in loaded condition (vs. untorqued). The car is now off my "scales frame" and back on jack stands. Next quick post will be about installing the seats. Then on to rear wings... Cheers!

-

Was thinking of something along the same lines but you nailed it!

-

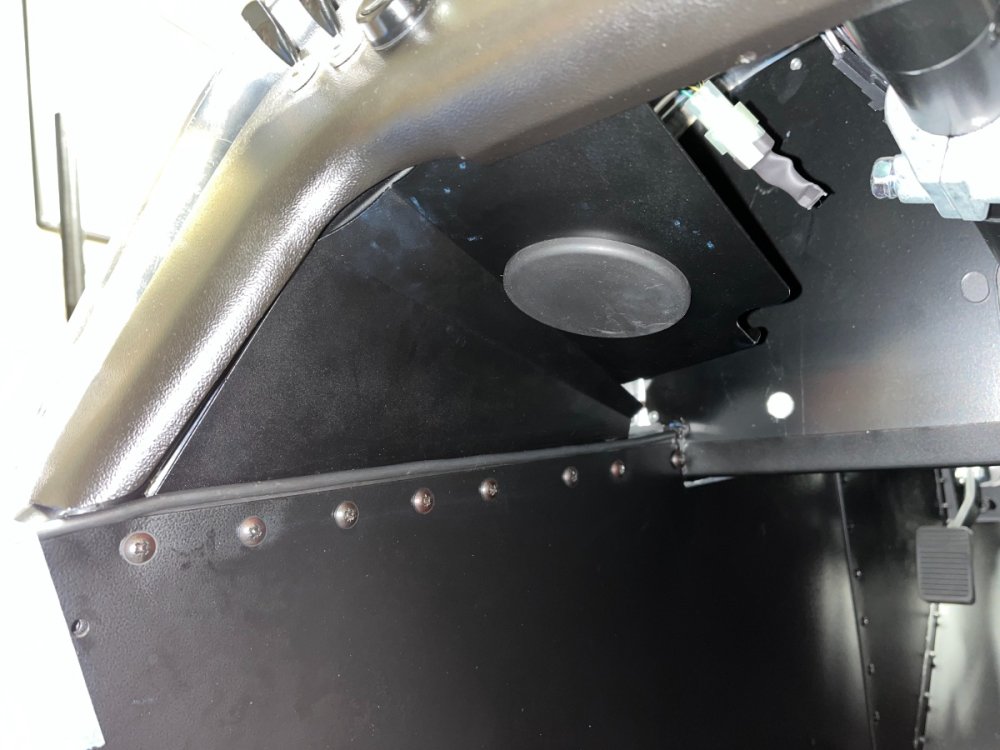

Heater-Delete Blanking Plate and Grommet My kit came with the cockpit heater which I decided to delete. Theoretically there is a Caterham blanking plate to cover the heater opening in the "firewall" however it is currently unavailable with no time estimate. So I decided to fabricate my own from a 0.025" sheet of aluminum and bought 5' of a small U-channel rubber seal and M5-0.8x16 stainless steel screws. Had extra SS nyloc nuts and washers on hand from my wing stay attachments (subject of a future post). Used the heater as a pattern and cut the sheet with a small jig saw. After drilling I rubbed it with a fine Scoth Brite pad and WD40. Used the existing holes in the firewall and added one at top center for stiffness. Also used a short aluminum U profile to clamp the plate on the inside at bottom center without drilling another hole in the firewall. Used leftover length of rubber seal on the edges of the aluminum profile and along the top edge of the opening to prevent buzzing. One should also plug the heater cable hole on the driver's side of the firewall. I wanted a 1/2" (ID) blanking grommet which turned out to be more difficult and expensive to procure than one might think. Cheapest I could find was a 2-pack on Amazon for over $6.... It is visible below near right bottom corner: View under the dash: Aug 21 2023 edit: Added an external center rib (similar to the one I had installed behind the dash) to better clamp the plate to the "firewall" without "membraning" it. This is helpful if you want to avoid drilling a hole at the bottom center of the firewall (access is difficult). Instead, the two ribs clamp at the bottom on the firewall with the lower bolt passing through the heater opening. I used 3 flat washers between the inner rib and the plate to force the plate to sit flat. The ribs are out of a 1/2"x1/2" aluminum U (really I_I ) channel. A bit OCD I guess... Next post: Seats. Cheers!

-

Torquing, Ride Height and Cross-Weight -- Complications and Conclusion (?) A bit of a delay catching up here, sorry. This one will be tedious for demonstrative and empathy soliciting purposes... Torquing: Following the status reported in the last post, I unloaded the "payload" part of the ballast and left only the ballast representing "curb" -- "ready to drive" with 1/2 tank of gas and no one in the car. I then rolled the car back and forth several time to settle the suspension and finally torqued all suspension bushing bolts. Torqued all connections per values in IKEA guide. This was pretty straightforward except for: a) Upper wishbone: Torque wrench access to both bolts and nuts is difficult. Both front and rear bushing joints required torquing the bolts, not the nuts; the front using a 2" torque extension for the torque wrench (and adjusting the torque setting), and the rear using a U-joint adapter and long extension, in both cases using an open wrench for counter-torque on the nuts. b) RH lower wishbone rear bushing: This is a Grade 10.9 M12-1.75 joint. For some unknown reason two "tall" (15mm total height, 12mm hex height) nyloc nuts supplied in the kit stripped while attempting to torque. All three other lower wishbone connections torqued fine with seemingly identical nuts. Don't ask me why there were extra nuts in the kit... I examined the bolt and it looked OK but wasn't sure of the correct pitch. To confirm the pitch and the bolt condition I bought a regular M12-1.75 nut at Ace hardware and tried torquing it to spec. It torqued fine! I am hoping to get a replacement nut from RMC. The cheapest way I found to get a tall M12-1.75 Grade 10.9 nyloc is to order a batch of 50 from Grainger... so for now I have the standard temporary nut torqued at the rear RH lower position. Ride Height and Cross Weight: Now came time to load back to "loaded" condition and finalize the ride heights and cross-weight. I did this and reached the target settings -- 50% cross weight, max ride height in front (as high as the adjustable coil-overs will go), and 15mm higher at the rear. ....here it comes... All looked peachy so the next step was simply to tighten the jam nuts under the platform nuts on the coil-overs. I unloaded the rest of the ballast, raised the car back on jack stands and removed the wheels, as simultaneous access to both coil-over nuts, especially at the rear, is impossible with the car on the ground. I used a C-spanner on the jam nut, and a conical punch on the main nut for counter-torque. Well... As I was turning the LR jam nut to raise it to meet the main nut (the spring platform) I realized, too late, that instead of the jam nut rising, the spring platform was lowering!! The threaded sleeve was turning with the jam nut and acting like a screw jack. The LR height and the cross weight settings were lost!! To pour salt on the wounds, now I could not unjam the jam nut from the bottom end of the threaded sleeve on the car... ....and clawing our way back... I jacked up the rear onto chassis stands, dismounted the coil-over from the car and unjammed it holding the flats at the bottom of the sleeve in a vise. Re-installed the coil-over confirming the jam nut and spring platform both rotate freely on the threaded sleeve. Dropped the car back on its wheels in preparation for a cross-weight redo... Assembled back the scales frame (which I had disassembled and put away...), placed and leveled the scales again, and filled up the containers (which I had emptied and put away...) with 300 lb of fresh water.... First loaded the car back to "curb" condition, rolled it back and forth, jacked up under the deDion tube, removed the LR wheel and and torqued the coil-over connections. Then dropped the car back on the wheels, loaded it to "loaded" condition, rolled it back and forth and onto the frame, and adjusted again the LR coil-over height to reach CW = 50%. While turning the LR spring platform I noted that threaded sleeve tends to rotate with it; fortunately only part of the time or slower... This was very time consuming and maybe the most frustrating episode of the build. But it's done. Here are the results: The ride height values seem quite good, and the rear-front height delta and the cross-weight values are right on target. Rebound Travel Concern: However, during this exercise I also measured the vertical gap between the bottom of the deDion tube and the top of the chassis rail in loaded condition and in full droop (rebound) when on jack stands. The difference, which is the net rebound travel in loaded condition, is just under 40mm on both left and right sides at the above ride height settings. I am concerned that this is too small and will result in frequent topping (shocks hitting rebound stops) on public roads. The only way to increase it is by lowering the ride height (in front as well to keep the 15mm delta) which of course will hurt ground clearance. Posed the question to Josh at RMC and am inviting any feedback here.

-

Have Corner Weights Got my two extra capacity scales (only 550 lb, not 560... ) for the rear corners. Had to expand the frame a bit to make them fit. Got quite repeatable weight readings. Here are average values and the initial cross weight calculation in loaded condition: Current CW = 50.6%, which is not terrible. Will try to bring to 50% by lowering (=unloading) the LR coil-over, mostly to experience how sensitive it is (how many threads it would take). I do not plan on lowering the RF coil-over at all due to the already very low ground clearance under the Duratec sump. Will repeat this exercise and report after torquing the suspension -- to learn how sensitive the cross weight is to it and to see if it needs further tweaking. Cheers!

-

Yes, I will need to loosen and re-torque the bushing bolts after significant ride height adjustments and settling. You need to start somewhere. I am not guessing. I am simulating and measuring actual weights and ride heights. The weights are known and as close to reality as I want them to be. The ride heights may change in time. I will be monitoring them to decide if they warrant re-torquing. Iteration is a common process in development, as in life...

-

I know that. Rubber creeps and degrades also under static shear load. My plan is to torque the bushings in curb (parked) height as this is the position in which they will spend 98% of their life.

-

Slow progress with weights and ride heights... So... the path still is to first get the ride heights and cross weight adjusted in "loaded" condition. Then unload to "curb" and settle and torque the suspension joints. I raised all four coil-overs to maximum height (recommended starting point for a mostly road use setup with a wet sump Duratec). Lesson learned: Raise the coil-overs to max height before assembling into the car -- much easier... I then loaded the car to "loaded" condition, which for me adds 200 lb driver, 75 lb 1/2 passenger, and 10 lb in trunk over "curb", and rolled it off the frame and back onto the scales. I found that the LR wheel load exceeds the limit of my bathroom scale, and the RH one is barely under 400 lb. I guess I was a bit off in my estimate of the weight distribution... So I searched again on Amazon, this time with the keyword "extra capacity bathroom scale"... Well, they come in 560 lb capacity! I ordered two at $33 each. Another lesson learned... My approximate ride heights in loaded condition are 160 mm front and 175 mm rear, which seem not bad. Next will report corner weights and ride heights in loaded and curb after cross weight adjustment. Pics in loaded condition: Cheers!

-

Because access is more difficult with the wings and seats in place, and wings are vulnerable with all the shuffling and wrenching around them.

-

Correction to Next Sequence After some more nagging thoughts I decided that torquing the suspension joints/bushings should be done at "curb" ride height, which is the target ride height at curb weight (and which Caterham does not specify...). My interpretation of curb weight is empty car with 1/2 tank of gas, ready to be stepped into, started and driven. The reason for this decision is that the bushings on a Seven spend at least 98% of their life in "curb" ride height... (in garage) Therefore, I am now proceeding to load the car as close to "curb" as practical, roll it back and forth, set the ride heights and cross weight under that load, roll it back and forth again, verify the ride heights and cross weight, and torque the suspension joints in that position. This will include simulating the weights and positions of the heavier parts which are not yet installed, such as the exhaust downstream of the header pipes, seats, etc. Then I intend to load it up to "nominal" driving weight -- me, half of my better half (splitting the difference between 1 and 2 up), small bag in the trunk. I will then roll it back and forth again and check and if needed adjust the cross weight one more time to 50%. My OCD has now kicked into overdrive. More soon...

-

Re Spring Settling My plan is to set the ride height up a bit on the high side, maybe 170 mm front and 185 mm rear with target load, and check it after a few hundred miles. I now have my ultra high tech ride height and cross weight adjustment system which I will keep for a while... Will report developments...

-

Bathroom scales work! Back from a few weeks up north. Today was the first test of whether my Amazon bathroom scales will survive the weight of the empty car, and especially the transition when rolling onto the scales. So I crossed my fingers and rolled the car onto the scales, first with the fronts only (dummy scales at back) and then with all four wheels. No issues! All four scales supported the load intact and recorded consistent readings. I rolled the car on and off the scales several times to confirm. Having confirmed that the scales survive, I used my siphon system to shim them to ensure each axle is horizontal: Left front was ~5 mm low -- required 3 vinyl tiles, and left rear was ~7 mm low -- 4 tiles. Current corner weights before any adjustments and without engine oil or coolant, seats, cat+muffler, wings and lights are: LF=270.6, RF=279.2, RR=255.6, LR= 274.0 [lb] Next steps will be to roll the car off the frame, load with ballast, roll back onto the frame, adjust ride height and cross weight, and then torque the suspension joints. Siphon system for leveling the scales: Car off scales: Car on scales: Typical reading: Cheers!

-

Quite surprising. I do not understand this from steel stress-strain characteristics. I don't doubt the settling but am wondering what is the mechanism that causes it. I wonder whether the springs get better seated. Baffling.

-

Thank you for this good info. I'm wondering whether it's the springs or the rubbers (spring seats, top and bottom mounts, etc). My guess would be the latter. Either way, I will get the car set up for ride height and cross-weight and check the settings after some driving and adjust if needed. Cheers!

-

@KnifeySpoony, thank for the tip! For how long do you think (and obviously in static state) ?

-

(Note/apology: I am writing this away from home and am missing some pics which I will add late next week when I'm back. I wanted to use the time that I'm not able build to catch up a bit on documentation.) Prep for coil-over adjustment and suspension torquing I decided that before proceeding with wings, lighting, seats, exhaust and body trim I am going to set the ride height and corner cross weight, and torque all suspension joints at proper ride height. The idea is to maximize access and minimize risk of damaging the wings. I decided that I will try to get this done by myself in my garage at very low cost. In order to perform the ride height and cross weight adjustments one needs individual corner scales defining a plane. Ideally the plane should be exactly horizontal, however it can slope 1-2% longitudinally (typical garage floor slope) with negligible error. It should be horizontal laterally (no sideways tilt). And of course you need 4 scales, capable of measuring the corner weights of a moderately loaded Se7en. Well... a quick search on Amazon shows that a standard bathroom scale sold in the US market is rated for 400 lb... Pretty scary, huh. My 360S with all fluids, my 192 lb and 1/2 tank of gas should weigh about 1480 lb with close to equal weight distribution over the 4 corners. So I ordered 4 identical highly rated scales from Amazon at $20 each. They are a bit under 12" square. And I proceeded to build a frame which will position them on the garage floor at the exact tire patch locations and allow the wheels to roll gently onto them, hopefully without breaking them... Hey, this is R&D - no risk, no fun. All the lumber was repurposed from the rolling frame I had originally built to unload and move the CBU crate. The frame. 2"x10" sections serve here as dummy scales. To simulate load I filled 24 collapsible bags with water ballast -- 10.9 lb each. In addition I will use 2 kitty litter containers filled with water -- 18 lb each. The next challenge will be to level the scales. You need some level-type device to indicate when the tires of the same axle are on a horizontal plane, and ideally also between front and rear. First I borrowed and tried one of those laser levels for hanging pictures etc., but it proved useless. Whenever you level it carefully and then rotate the beam turret sideways, the vials would come out of level. Junk. So I proceeded to rig a simple siphon system with two portable 2' tall 4x4 posts and a ~10' long 3/8" ID clear hose (filled with water) between them. I will post some pics as soon as I'm back home. In order to level the scales I will use 12"x12" vinyl tiles to shim them as needed. Steering wheel + first "Wheels Down"!! It may be symbolic, but on 4th of July the car got to touch the ground for the first time on all 4 wheels! My good friend Mike helped me push it, from the bay in which it had spent all its life on stands, out to the driveway, into the adjacent bay and onto my corner weighing frame. It was surprising and delightful how light and easy it was to push and steer the car (without sitting in it)! The prerequisite for that, and another first, was to install the steering wheel. Interestingly my kit came with the wrong screws (for the quick release wheel which mine does not have), so I had to get the correct ones (three M6x1.0-20 class 10.9 flat-head allen key black oxide) from Ace Hardware. I plan to unscrew them and apply ThreadLocker Blue before taking to the road. Steering wheel on!! The center pad is not mounted for now (Velcro pads). Ace Hardware screws match like magic... Car on the frame with dummy scales. The four real ones can be seen stacked under the hanging level. The next steps will be: 1. Load the car with the water ballast 2. Roll the car off the frame 10-20' to settle the suspension 3. Position and level the scales 4. Roll the car back on the frame and onto the scales ... and assuming none break and all give valid readings: 5. Adjust ride height at all 4 corners, probably to 160 or 170 mm in front, +15 mm in back 6. Adjust the cross-weight to 50% (of which more in one of the next posts) 7. Torque all suspension joints Cheers!!

-

Submarine hose routing, or... Finished Plumbing! (hopefully...) One of the loose ends from my engine plumbing phase has been the routing or securing of the submarine-modine coolant hose in a way that will prevent chafing against the throttle pedal stop bolt and/or contact with the steering shaft. I had left off with zip-tying it to the starter solenoid housing - not a very robust solution. So after some more pondering I decided to try to secure it to the throttle pedal stop bolt with an Adel clamp. Granted, it would attach the middle of the hose to the chassis while both ends are attached to the engine, but I figure there is enough hose length and bends on both sides to ensure no over-constraint. So I proceeded to do this. I used a 1" Adel clamp and a separate M8 nyloc nut on top of the existing jam nut on the throttle pedal stop bolt. Had to enlarge the clamp holes to fit over the bolt - must use a 15mm wide clamp (net metal) to ensure sufficient material around the enlarged holes. The little reinforcing tabs at the clamp ends separated during drilling so I glued them back on with super glue before installing. The installed clamp provides around 1/2" clearance between the hose and the steering shaft and also keeps the hose from touching the sharp left rear corner of the engine block. Installing the clamp requires disconnecting the main upper radiator hose from the head, so it's best done before coolant fill... 1" 15mm wide clamp: Clamp installed (view from below) With this I consider the plumbing phase complete! (until proven otherwise...) Cheers!

-

Handbrake adjustment and cable routing Adjusted handbrake to max 5 detents and verified discs can be rotated by hand in fully released position. After completion of adjustment inspected cable routing. RH (adjuster) cable seems to require no further securing. LH cable required securing with zip-ties to ear on top of diff. Verified routing clear of driveshafts (for now in full rebound only). Cables are too short to secure to the A-frame without excessive bending and tugging. At max pull (5 detents): LH cable from below: ...and from the side: RH cable from below: ... and from the side: Torquing propshaft flange bolts My original plan was to use the handbrake, once adjusted, to provide counter-torque when torquing these bolts. However, this proved not feasible due to not enough brake bite. I suspect this may be due to the pads not being bedded in but it could be that the handbrake alone will not generate sufficient torque. So... I reverted to the time-tested shade-tree mechanic way with a protected pin punch inserted in the propshaft front yoke and reacting against the chassis rail. Well, I guess the shade-tree mechanic process skips padding the pin punch.... Used ThreadLocker Red and torqued the bolts in a cross pattern to 47Nm (per IKEA guide) with a 6" long 8mm spherical hex bit and a drive extension. Applying controlled torque with this long combination extension is not "clean", but as the pics show, there is no clearance for a torque wrench and a short straight hex bit. My upcoming next steps are quite exciting: - Install steering wheel (non-quick-release) - Mount wheels, lower on ground, load up, roll back and forth - Torque suspension bushings - Torque driveshaft nuts - Install seats Back soon... Cheers y'all!

-

Hi All, Took a few weeks break in Michigan (couldn't take the kit with me). Now back at it. Did not mention that I have been working for a while "in the background" on the front wings. They are now ready to install however I will delay that to as late as possible to maximize access and minimize risk of damage. To keep things organized I will report about the entire front wing process in detail when completed. This task turned out trickier than meets the eye. What I will report now is brake + clutch fluid fill and bleed, handbrake adjustment + cable routing, and torquing propshaft flange bolts. Brake + clutch fluid fill and bleed Filled the system with Motul RBF 600 racing brake fluid. After completion of bleed the system took a total of ~540 ml. Started bleeding using a MityVac vaccuum system. For the brakes followed the standard sequence RR, LR, RF, LF. At each front brake bled the inboard bleeder first. Repeated the brake bleed sequence twice, the second time tapping the rear caliper body while bleeding to help move trapped air bubbles per the text manual. However at the end of this attempt the pedal was still soft and bottoming out against what felt like a stop. Realized that I will need to complete the bleed the old fashioned way with a helper to pump the pedal. Clutch pedal feels good (but of course without the engine running it is impossible to confirm whether disengagement/pick up works properly). Resumed and completed the brake bleed successfully with help from my good friend and neighbor Stevie, using the same sequence. Rear brakes took many pump-and-bleed cycles and some more tapping on the calipers with a rubber mallet. Front outboard bleeders took more bleed cycles than the inboard ones. Pedal now is firm and steady with what feels like about 1" of max travel. The MityVac reservoir replenishment bottle is handy and I used it also in the "manual" (pedal) bleed. The vacuum bleeder "kind of" worked on the inboard bleeders of the front brakes but proved useless on the rest. Next Post: Handbrake adjustment and cable routing, and torquing propshaft flange bolts

-

Then you would like these. Very legible and look OEM. At under $11 each and free shipping I think they are well worth it. Wouldn't bother in a regular car with a regular glovebox for the owner's manual...

-

Quick Update: Fuse Box Labels Received and affixed the fuse and relay stickers inside the fuse box cover. I had captured and formatted the images from the online owner's manual on the Caterham site and ordered them from car stickers.com. They are vinyl, good quality, and arrived within less than a week by first class USPS. My "official" next step is brake and clutch fluid fill and bleed, so I can adjust the handbrake and then torque the propshaft flange bolts and the driveshaft nuts. However, I "detoured" to mess further with the throttle pedal stop and to set up the front wings (position, measure, drill). I will fully install the wings only near the end of the build, but in the next posts I plan to share status on these two items to keep current. Otherwise I will have a ~15 day pause in the build due to travel. Cheers!

-

Interior - Part 3 ----- pics to be added ! ---- Tunnel top: Left only the front ~2" of the tunnel horizontal heat insulation in the gear lever area (cut off the rest), and folded it down to act as an air flow deflector. Installed the tunnel top. Drilled and screwed in two purchased #14 black sheet metal screws at bottom rear corners. Tightened handbrake sleeve below the handle as neatly as possible with a zip-tie. I know there are fancier ways to do this but this will work for now. It might resurface as a continuous improvement item... Installed the gear knob Secured with VC-3 thread locking tape (a first use trial) and the supplied set screw. The tunnel top in place. Note the screw at the bottom rear corner. Note sleeve tucked around handbrake lever: Gear knob (color is distorted here - it is a nice light matt gray): Lap harnesses: Installed the lap harnesses with the supplied thin-head bolts (necessary to keep room for the seats). The Buckles go on the tunnel side to prevent banging against the outer panel when released and moved out of the way over the sills. Applied ThreadBlocker Blue and torqued to 40 Nm per the IKEA guide. Steering boss: Used my rack travel center marks to place the boss on the spline as symmetrically as possible with one hole on top to match the steering wheel. No direct torque spec found; Caterham generic for 1/2" UNF is 61 Nm (45 ft lb). Torqued to 40 ft lb (per Josh). Provided counter-torque with a thin adjustable spanner on the flat in the upper section of the steering shaft coupling, and vise-grip as lever. Main remaining interior tasks are seats (after torquing the radius links), steering wheel and rearview mirror. Cheers!

-

Interior - Part 2 Knee trim panels: Knee trim panels are screwed with supplied sheet metal screws onto the upper chassis rails. It helps to hold the rubber piping in place and punch a hole in it before starting the screw, although getting both hands in there is awkward. The LH side panel has a hole for the OBD II port - a bit "out of context" in a 7 but then again so is a Duratec... The hole gets covered with a rubber plug. The panels look different from the drawing in the IKEA guide and initially I did not identify them and thought they were missing. The pic shows the driver's side panel with the plug over the OBD II port. Fuse box cover: The fuse box cover looks even more different from the drawing in the IKEA guide and here again I initially thought it was missing. The reason here is due to the different location and configuration in LHD cars (the guide shows of course only the RHD version). The cover gets wedged and held in place between the front bulkhead/"firewall" and the lower lip of the dash relying on its own springiness. No need to glue velcro strips as shown in the guides. To make identifying fuses and relays handy without the clutter of a cheat sheet or the manual I decided to have stickers of the fuse and relay layout on the inside of the fuse box cover like in many cars. I used the PDF of the owner's manual from the Caterham site and snapped the respective images in good resolution, sized them to fit and uploaded them to carstickers.com. Will post pics once I receive and affix them. The pic shows the fuse box cover in place and the passenger knee trim panel. Riveting: The sills and tunnel rear plate require riveting. I had initially bought an inexpensive pop rivet tool at Harbor Freight and used it to rivet the brake line clips to the De Dion tube and the catch bottle bracket to the chassis. Having tried now to use it again it jammed "permanently" after the second rivet ( after less than 10 rivets in total), so I ordered and got a more expensive one from Blind Rivet Supply. It is a FAR K39, made in Italy (for a change a tool not made in China), and has worked great. The sills required drilling (5/32" cobalt bit) through the rubber piping and the stainless steel sill protectors. Again need to hold the rubber piping in place to ensure it's straight and snug. The tunnel rear plate requires 18 rivets and its pre-drilled holes do not match perfectly the ones pre-drilled in the chassis tubes, so I had to enlarge a couple of them to fit the rivets in. However, I made the mistake of not proceeding to rivet from the center out in a growing star pattern and re-drilling as I go. As a result I got a ripple in the plate which I tried to hammer out with a piece of smooth hardwood. It got smaller but is still there. At this stage I decided to let it be. As Josh says, a character mark that happens in almost all of them... Before.... ... and after riveting the plate: Continued in Part 3...