-

Posts

88 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by mdork

-

While waiting for a few bits needed to install my repeater lights I decided to make some simple protection for the boot skins using a roll of neoprene. May not win any design awards but I’m happy with the result

-

Too late - they’re in. Of course they didn’t fit at all without trimming but wouldn’t expect anything less. 🤣

-

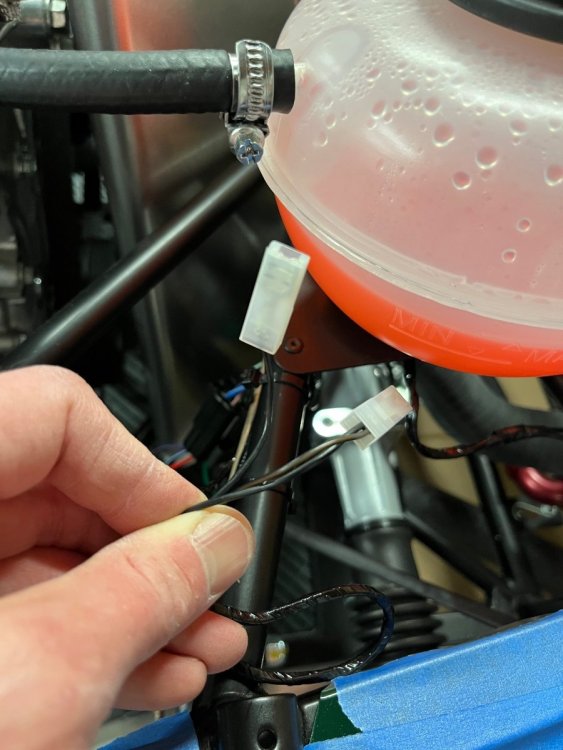

Big day yesterday. Wings are on!! Took some courage to do the fronts but hopefully did ok. Love the new LED lights in the rear but Caterham don’t supply a grommet so will have to harvest one from the supplied set. Got the fuel filler cover and washer bottle in as well. The supplied wiring harness was too short so had to build a little jumper. Will do the repeaters today along with trimming the knee panels to fit. After that it’s off to Bruce before I can do the final few bits. Sadly the weather is horrid this weekend but hopefully will be out for a blat soon!

-

Thanks! Targeting build complete in 8 days. Excited to get the last bits completed and off to Bruce for PBC and some final adjustments.

-

Bruce confirmed those mystery wires connect to nothing. In other news - got the steering wheel in and adjusted. Couldn’t help but do a very slow lap of my street. She feels eager! Will be away from the car for a bit before The Big Push to complete by end of the month.

-

That would explain it 🤣

-

-

Big milestone yesterday - first engine start went beautifully! Learned a few more lessons along the way. Planning to drill the steering wheel today. Possibly tackle the rear fenders as well. IMG_0061.MOV

-

True innovation! There have been many moments of pure mystery during the build so far. All part of the adventure. Just glad I have Bruce nearby to do a post-build check to make sure I didn't make any egregious mistakes. Will make me feel better about putting my kids in the passenger seat.

-

Mega day today - finished plumbing, reinstalled plenum, installed the throttle cable, and got the airbox in. Plumbing is done apart from sorting a ground from the submarine. Seems I'm missing the right nut. My kit was also missing the 5/16" tube to connect the expansion tank breather hose but a trip to local auto parts store got me sorted. Dangerously close to first engine start. Just need to get fluids in, battery acid in + charge, and I should be ready to go. One thing that seemed too easy was the throttle cable. I've read about people needing to bend the pedal quite a bit...mine seemed to fit quite well without any bending. Probably messed it up somehow...we'll find out soon :). Rear fenders are off getting PPF ... terrified to glue the fronts on .... maybe next weekend. I'm determined to finish by the end of the month though I think I've missed the window as far as Seattle weather is concerned.

-

Steering all sorted now. Was a bit of an RTFM moment as I'd not inserted the upper steering shaft in the correct orientation, causing the binding. All back together and torqued. On to the expansion tank next and then go for my PhD in plumbing

-

Yes there is a u-joint - could be the culprit as things worked great till the steering clamp was tightened. Not sure and out of energy for the day. Will try to resolve this week.

-

Steering rack rotated a bit solved the clearance issue. Now the rack seems to be binding. Seems such a simple job but I’m easily stumped. Will have another try later. @Pokey Haven’t done any plumbing yet. Have some good reference diagrams but if I get stuck I’ll let you know

-

Good day today. Rear hubs torqued, dry sump tank in, along with the oh so pretty headers and exhaust. Ran into a bit of a snag with the steering rack as it’s just touching the alternator. Clears the pulley (barely). Not really much to adjust. Anyone else have this problem?

-

Yes a good friend has them on his car (pictured to the left) and the sound is intoxicating. Keeping them happy at low idle seems to be a different challenge. Will probably do it down the road so long as it won't make the car harder to live with as I'd like to drive it often.

-

Removed it during engine install and left it off to have more access. Will add it back along with the airbox once I make some progress on plumbing. Having the plenum removed does make me wonder if going straight to roller-barrel throttle bodies is a good idea but then I think about cutting my bonnet open and I decide I'll just enjoy it how it is for a while

-

-

Love that track. Great video!

-

Thanks - the 41mm socket(s) arrived today and indeed don't fit. Silly me to believe the manual. 42mm socket arrives Thurs. Good tip on torquing - thanks! All part of the adventure. @DemoDan I'm very close to Seattle. Send me a message and we can sort something out

-

Anyone planning to be at the all British event in Kenmore on Sunday? http://wwabfm.com/

-

Got the rear end more or less complete today. Missing the 41mm socket for the hub nuts. Uncle Jeff (Amazon) will bring me one on Tuesday. Then I’ll get the car on the floor and torque the front end before moving on to plumbing. Todays adventure was discovering the lovely lads at Caterham packed 3 M6x80 bolts for the ARB along with 1 M6x75 cap head. They look similar in the bag but of course the short one isn’t up to the task. Thank your chosen deity for Tacoma Screw and their vast selection. Made it before closing and they sent me on my way and at no charge. Funny how a small gesture of good service feels so rare and wonderful. Excited to have my pretend car looking more like a car

-

It’s possible. The old manual says to get within +/- 2mm so if that means the tolerance is 4mm then I’m well within. If it means 2mm then I’m still ok. Think I’ll keep going and have Bruce have a look-see once I’m done.

-

I used “the force” to try and get one more washer in but really what I need is two half washers. Feels snug for now. Hoping to get the rest of the rear end done tomorrow. Haven’t taken too many pics. If you’re bored tomorrow come on by. Maybe too hot and smoky for a blat.

-

More progress on the rear end. De Dion tube is in along with rear dampers, radius arms (used the S holes as the R required drilling carbon panels), and the a-frame. Got within 2mm and calling it centered as there is no way to squeeze another washer in. Woke up in a cold sweat thinking the harness bolts would be too long to fit with the roll bar in place. Managed to get them in by backing out the roll bar a bit (of course I had to do this prior to damper install). Had a bit of a struggle with 1 of 4 bolts but par for the course. They’re in and torqued and not coming out for a long time. If I was doing it over again I’d put the harnesses in (shoulder straps) before fitting the roll bar (I have the track day bar). Life is a bit busy so progress continues to be slow but happy for the experience to last a bit longer.

-

Sounds like we had the same experience. We effectively installed it 2/3rds of the way twice before figuring out a sequence that worked to get all three bolts in. Based on the internet it seems there isn’t one way that works reliably but I’m not planning to do it again either.