TEM

Registered User-

Posts

222 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by TEM

-

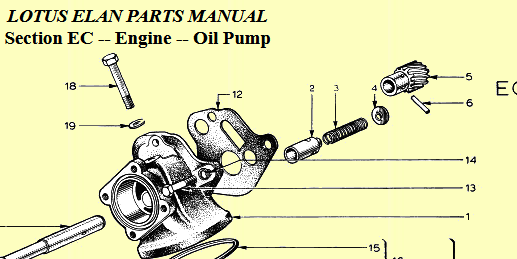

By the way, The pump pressure relief valve was installed correctly. it just doesn't look like the picture in the parts manual.

-

I have been driving it locally with no problem but fear another prolonged drive. Checked all of my local parts stores and none had appropriate hose. I have a speed shop nearby that I will check tomorrow. Does anyone know the fitting size needed to convert the hose from barb to Aeroquip style thread on? I'm leaning towards Startlite hose. Without taking the fittings off I don't know if the sandwich plate uses AN, NPT or something else. And I really don't want to break the lines just to find out but will if no one knows.

-

Pump was removed and inspected. Nothing out of sorts. There is a little wear as expected but no big deep scratches, gouges, or broke pieces. No debris and the gears rotate freely. I did clean out the sandwich plate when this first occurred along with blowing out the oil cooler and all external lines. Nothing was found. I packed the pump with Vaseline and put it all back together again. I filled all the hoses with oil in an attempt to eliminate as much air as possible. Pulled the plugs and cranked 5-10 seconds but no oil pressure. I squired some oil in the spark plug plug holes and cranked a few more seconds and saw the needle move to about 5psi. Now that is was getting some oil pressure I decided to crank away. After what seemed like a frightening amount of time on the starter, the oil pressure started to rise and topped out at just under 65psi. I started the engine and all seems to be back to normal. I'm still worried about these poor quality hoses so I plan to replace. Does anyone have suggestions? Just a better quality hose on my existing barbed fittings or Aeroquip style hoses?

-

New hose but still no pressure. Opened the oil cooler lines and the oil pressure gauge port and cranked the engine (no plugs so higher cranking speed). No oil out any port. I will pull the pump again and see if there is anything amiss.

-

Oil flows freely with filter canister removed. I removed both oil cooler hoses and found a ruptured return hose. The outside casing of the hose had a small slit in it near the filter end hose clamp. It was close enough to the end of the hose that I could feel a hole on the inside of the hose with a small screwdriver. I don't know why this hose failed. It's a new hose. Outside marking says 300psi fuel hose. I have a spare hose of the same material that I will use temporarily until I can procure a higher quality hose. I will put a new hose on and try to build pressure again.

-

Breather is atmospheric. No oil out the breather pipe. I'll check the oil pressure gauge. That might shed light on the no oil pressure but not the oil leak that emptied the oil pan. MV8, good suggestion. I'll take off the filter canister to see if I'm getting any flow.

-

First thing I did was to clean the engine bay, add oil, and spin the engine on the starter. No oil leak and no oil pressure. I suspected a collapsed oil filter so pulled the filter and then the oil pump to see if the pump was damaged. I am not saying the relief is the cause just noticed that it may have been installed backwards. Perhaps the pressure increased, regulator did not open, and oil pushed past the filter seals. Don't know, just putting observations out there in case it rings a bell with someone.

-

When I pulled the oil pump the pressure relief valve plunger was facing the engine. This appears opposite from the parts manual. Certainly makes it a lot easier to install. I can't imagine holding that retainer disc in place while applying pressure and installing the bolts.

-

MV8: All hoses are new. I pulled and inspected each and there is no sign of wear, cuts, or rupture. I pulled and inspected the oil pump gears and there is no obstruction. No broken roll pin. I will look into the cooler more today. Dave W: Good suggestion on blowing back through the oil gauge port. Jb: I did this yesterday and I got no oil pressure and there was no oil leak???????????????? Do I have an oil leak AND a bad pump?

-

Next issue in the saga. After about a 40 mile run at 50mph, the oil pressure suddenly dropped from about 45 psi to 0. I shut off the engine quickly and coasted to a stop. A long trail of oil followed the car. Oil was everywhere inside of the engine bay from the radiator to the battery tray. There are no ruptured hoses, hole in the block or other obvious signs of failure. I pulled the oil pump and oil filter (new 40 miles ago) and all look good. No debris or any sign of pump, filter, or seal failure. I checked the oil pressure gauge line and engine fitting. No blockages. I changed the oil filter and found that I put the spring on the top of the filter instead of the bottom. Not sure if that has any impact on my issue. I topped up the oil then started the engine for a few seconds - no oil pressure. Car has a remote oil cooler.

-

MV8, Pre-Xflow's install the rope seal into a grove in the oil pan, separate from the bearing. And from experience, it's a real pain to change with the engine in the car. The rope seal was no problem as that is fitted into the pan on the bench. The issues I had were trying the keep the cork pan gaskets in the right place, especially in the rear, and trying to reinstall the front seal while installing the pan at the same time. Removing the engine is easier and less frustrating. New, soaked seal was installed and I cut the ends proud by 1/8". This seemed to do the trick. No oil leaks after a 20 mile run. If a new leak forms, I'll switch to Best Gasket or similar alternative. Old seal with 5 miles on it. Was leaking at the upper right hand corner. Leaving the seal proud by 1/16" was not enough and oil leaked past the gap

-

Hi Joe, I sent you a PM.

-

Yes, very helpful, thank you. I did not soak the rope seal before installing. Will give that a try tomorrow. Hopefully, 5 miles is not enough to burn/harden the dry seal. Apparently, cutting them longer (1/8 vs 1/32) also helps.

-

Did about 5 miles today and noticed a pretty good oil leak coming from what I think is the new rope seal I installed. This seal was a little tricky to install since it hadn't take a shape yet so wanted to move all over the place. I thought I had it in correctly but apparently not. I'll have to drop the pan again tomorrow and see what up. if anyone see anything else in this picture, or has some trick to install this seal, please let me know.

-

New head gasket is in. First startup my heart sank as I saw the white smoke from the exhaust again. But I let it run and it clear up. Probably just some residual coolant in the exhaust pipes. Car now runs well no signs of white smoke.

-

Thanks Joe, that's very kind of you and much appreciated.

-

I discussed this head gasket with Ken prior to ordering to confirm it was correct for this engine. Interesting that your water passages look completely different from the DBE gasket. I guess the size of the passages isn't all that critical.

-

I've got to trust what DBE sent was correct. They know their stuff. I'll try it and if it fails, I have experience changing it and will probably go with a Fel Pro next time. Eventually,next year maybe, I'll pull the engine and do a full rebuild.

-

Perhaps my original is not correct and the new one is. The pictures on-line of pre-Xflow gaskets all look different. From Fel-pro to Burton. And none match either of mine.

-

The center holes between #2&3 on the old gasket had one large and one small hole. The new gasket has two small holes. So keeping it as is would change the flow balance.

-

The good news is that the Head Gasket arrived. The bad news is it doesn't match the old one. The water passage holes are different. The passages between the cylinders on the old gasket are all small on top and all big on the bottom. The new one has all small holes on the bottom and two large holes on top. The passages between 1& and 3&4 I think are OK as they sum up to the same area. Should I open up one of the holes between 2&3, or is it OK as is? The bottom right hand corner of the new gasket has a round hole instead of a triangle. I assume this is OK.

-

Yes, that document specifically references the 1340cc Seven with flat top piston. The flat heads had a 10:1 compression ratio. I can't imagine what my engine is with the protrusion. possible cause of the head gasket failure?!

-

Thanks Senc, that would definitely explain my situation.

-

I understand that there are a lot of replacement piston profiles out there, my question was what was original? I have found very few non-original parts on this car so different pistons would be worth noting. Were the pistons changed or did someone over skim the block and head? No problems, just knowledge. Yes, I plan to use the same size spacer on all plugs.

-

Measured the all the bits and there is indeed a potential 0.03" interference between the spark plugs and pistons. It was interesting to learn that the threads start at different locations on both the spark plugs and the head. So, you get a very random orientation of the electrode. The 0.03" interference can be obtained by mixing and matching the plugs and holes to get an electrode into the most disadvantaged position. I had two 9/16" spacers of different thicknesses and the thicker one eliminated the interference, giving 0.005" of clearance. I was wondering how this could have happened if the spark plugs are correct. I have noted in many documents a reference to flat top pistons on these early Sevens and the few picture I could find seem to show a flat type of piston. But, if you look at my pictures, my pistons have a "D" shape protrusion on the top. Is it possible these pistons were replaced with "taller" pistons? There are very few picture out there to go by.