TEM

Registered User-

Posts

222 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by TEM

-

The Dry vacuume bleed is interesting. I will see if it makes a difference.

-

I never really understood the two circlips note in the manual. My one circlip fills the groove. I don't know where the second one is supposed to go. Maybe one was used like your washer.

-

Yes, I set the gap without the spring while wiggling the arm to make sure I had the gap correct. It's a domed nut so the 1/16" is a bit of an approximation. I know I didn't have too much play there because when I added .2" of preload on the arm, the clutch slipped badly to the point of being undriveable.

-

All I did was push the slave cylinder back until the circlip was firm against the mount then adjusted the domed nut to give the appropriate 1/16" gap. If you don't push the slave back then for sure you will have a gap that will limit the stroke.

-

No, I do not have this washer. When adjusting the clutch you are to leave a 1/16" gap between the domed nut and the arm. Does it matter if there is a washer there? I would think that the washer is only there because the circlip is so thin and a washer would provide better contact area with the bell housing. It may also reduce the chance of a rattle. But I don't think it will lead to any stroke reduction. There is a 1/16" gap with and without the washer. I check the Elan parts list (similar design as the Seven) and there is no washer there either.

-

That is the correct formula for a 5/8" master and 3/4" slave. Your results match my previous post. As I mentioned, I remove the slave cylinder from the bell housing and raise it above the master cylinder. I clamp the slave cylinder so that the piston doesn't eject itself and then bleed as normal. This keeps the air pocket at the highest point. I first bench bleed the master.

-

I measured the MC travel both on the bench and in the car with no fluid and I'm getting about 1.36~1.37" of stroke. The pedal is not hitting the firewall or anything else I can see so I assume the MC is bottoming out. I would agree that changing the MC from 0.625 to 0.7 would help if I were able to get full stroke from the MC with everything hydraulically connected. But that's not what I was seeing. Something else must be stopping the stroke. If that is the case then a 0.7" MC will not stroke any further and only serve to make the clutch heavier. But I will check hydraulic stroke again after I rebuild the the slave.

-

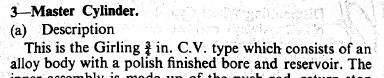

Sorry for the confusion. As I dig deeper into the issue I learn more. When first looking into this, an observation was made that the MC was not going full stroke. Since this MC was recently rebuilt and the observation that the clutch was not fully disengaging, the MC bottoming out was a reasonable hypothesis. Upon removal from the car, the MC was found in good working order and could reach full extension. Therefore, something else must be limiting the stroke. That is where we are today. My pedal setup is show below.

-

MV8 Commenting to your above assumptions. 1)Yes, MC stroke in the car connected hydraulically to the clutch measured 1.04". 2) No, I can't say that I am bottoming out the MC. It could be bottoming out on the clutch. 3) Yes, bench testing the MC yields a stroke of 1.375. I'm not sure how the MC can be pre-loaded. The pedal is free to move before inserting the pin to hold the MC and pedal together. Is it possible that the MC doesn't full retract? Possible. But I can say that I didn't see any movement of the MC rod when removing the MC form the car and motion is smooth on the bench. But, I'll check it when I get the system back together. The release bearing is in contact only when shifting (confirmed visually through the shift fork hole). I Had to cut the slave seal when I accidentally pushed the piston out of the cylinder. I will send pictures when the new seal arrives.

-

Why would you not assume that? The only thing to stop the MC travel is the pedal hitting the firewall or the clutch arm bottoming out in the pressure plate. The odd thing is that when I added the 0.2" preload the car was undrivable due to the clutch slipping. So, the clutch grab point is very high. So, why does the rest of the pedal travel not fully disengage the clutch?

-

I'll be darned, That works well. Thanks

-

Yep. Mine was stuck in there real good too. I used a long screw driver to lever the throwout arm just enough to coerce the piston back in the cylinder. Don't want to do that on the side of the road.

-

I disassembled the carburetors to clean out the old fuel and make sure that everything moved as it should. I performed a basic rebuild and float setting but not to the level of shaft seals and bearings. Interesting note on air leaks. I will be going through these in a lot more detail at a later date. I have seen others discuss seeing the butterflies through the progression hole ports. i have never been able to see them through those tiny holes.

-

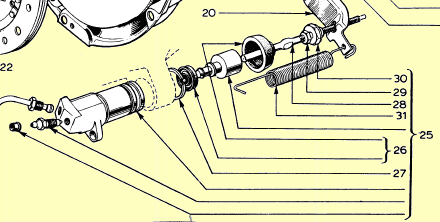

Form the brake section of the Seven manual. I love conflicting information. I have nothing in wring on the clutch MC. Others including a fellow club member with a Seven have said they are using 3/4" MC on the brakes and 5/8" on the clutch. Perhaps the clutch was replaced with a heavier competition clutch and thus the massive pedal force needed with the 3/4" MC. More important to me at the moment is why I'm not getting full stroke from my MC regardless or piston size. I pulled the MC and on the bench, the stroke is perfect at 1.375". put it back in to check stroke with the slave attached but forgot the slave does not have a stop and pushed the piston out of the bore and got it stuck on the pushrod. The seal was sticking half out so I had to cut it off to get the piston back in the bore to dislodge the slave cylinder. I'm dead in the water until I get a new rebuild kit.

-

Yes, I bought a real Girling. Every thing on this car is original so I want to keep it as original as possible. The 3/4" MC is the one I bought new, one of the mounting ears was broken off.

-

Test drive did confirm that 0.2 more inches of throw will allow full disengagement of the clutch. But, the 0.2" of preload also caused the clutch to slip so I will need the full 1.375" of travel from the MC. Time to remove and disassemble.

-

Ignore my previous post. The 100E and 109E throws are completely different! 0.1" does not equal 1.04" According to the 5/8" Girling MC info I found on line, the stroke should be 1.375". A big difference from my 1.04". Substituting this new stroke at the MC would give me 0.96" of stroke at the slave VS 0.715". If my test drive confirms the 0.2" preload solves the problem, I will pull the master and see why I'm not getting the documented stroke length.

-

My DCOE's are -2's also. SN's are 126xx 149xx

-

The manual under the 100E description says that the clutch slave pushrod moves 2.54mm which is 0.1" Assuming the throw is the same on the 100E and 109E transmissions, my 0.715" throw is not enough. More volumetric math shows that a 0.7" MC will give 0.91" of slave throw and a 3/4" MC will give 1.04" of throw. This gives some credence to the 3/4" MC on the clutch theory. However, this assumes the throws are the same. Given that the transmissions are different it's hard to say the throw is the same. I' going to try pre-loading the clutch by 0.2" just to see if a 0.7" MC will do the trick.

-

Camera is garbage. Can't see anything, light source is not strong enough. I'll take a look at the turret. I hadn't thought of that as a possible shifting issue. With the current pedal setup, I have no problem pushing the pedal all the way in. It does not hit the fire wall, but it does bottom out the MC. I use the old/original pushrod on the new MC. I could make a new pedal but am I just masking the problem? The manual calls out 3/4" master for the brakes but there is no mention of size for the clutch.

-

You could be right on the timing number. The manual says that aligning the marks for the 105E give 10BTDC initial advance and the 109E is the same as the 105 but with 1/8" retard. So 4-5BTDC is about right. I have a 109E. I thought I had a 109E block and a 116E head but the 116E casting on the heads were also used on the 109E so I'm convinced I have a standard 109E Cosworth engine with dual 40 DCOE carbs.

-

The issue I am trying to solve is that I have difficulty getting into any gear with the engine running. The car originally came with the clutch and brake MC swapped where the 3/4" master was on the clutch. After rebuilding the masters, I tried the 3/4" on the clutch but it required herculean effort to depress the pedal. I swapped the master to original configuration with the 5/8" master on the clutch pedal. I have no issue with pedal pressure now that I'm using the 5/8" master. I'm now thinking that the previous owner had similar issues so he used the 3/4" master on the clutch to give more throw. His left leg must have been twice the size of his right.

-

Pedal orientation to vertical will be where ever my foot can reach it. I'm at the max length of adjustability on my rod which gives me about 25deg from vertical based on iphone precision. You would have to have really short legs to have 35deg from vertical. Unless your pedal shape if different from mine. Not sure on the the pressure plate type yet. I'll break out the borescope and see if I can discern.

-

Even if there is play in the pedal to master rod linkage, once the slop is taken up, the master will still be pushed to it's max stroke unless the pedal bottoms out on the firewall. I'm short so with the pedal adjusted for me there is no risk of bottoming out the pedal on the firewall. I have very little slop by the way. After careful measurements, I show the following: Master cylinder rod travel = 1.04" Slave rod travel = 0.715" Theoretical volumetric math shows that a 5/8" master with 1.04" travel should yield 0.722" on a 3/4" slave cylinder. 0.715 is pretty darn close to 0.722 so I think I'm getting all the stroke I can.

-

I readjusted the the timing by retarding 1/8" per the manual and that resolved the hard cranking issue. Pulley notch is now centered on the leading edge of the case indicator. Car starts easily and runs but it's not perfect. This will take some sorting which I will do once the car is derivable. Yup, they all go hand in hand. Needed to get timing in the ball park to start the engine. Tried to tune the carbs but engine over heated. When testing overheating by driving, I uncovered the clutch issue. New crank pulley meant readjusting the timing. Eventually I need to get back to carbs. The Ford 109E Cosworth engine came with twin 40 DCOE Weber carbs. I do not know the final drive ratio but I can tell you its very tall.