-

Posts

347 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by DanM

-

Had another hour spare so quickly nipped into the garage. Decided to do one more panel, which will be the last for now. Now, I'm just waiting for my tube straightener to arrive and I'll be back on the fuel and brake lines again. Hopefully much wiser and prepared!

-

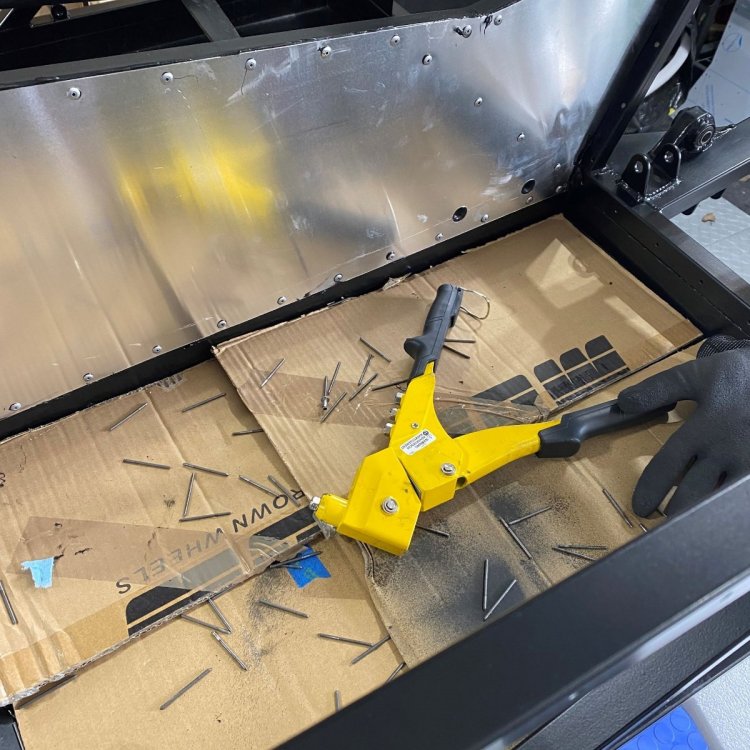

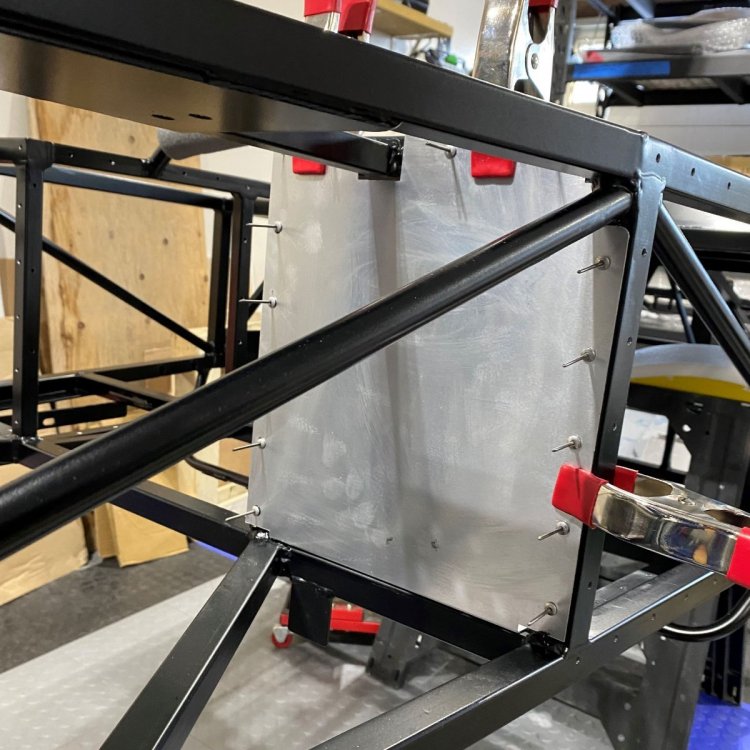

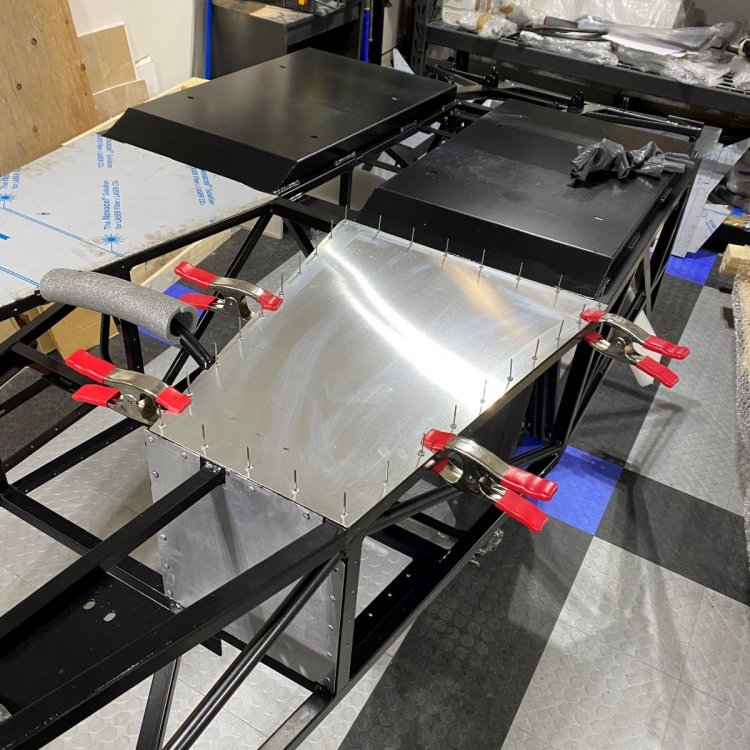

A bit more paneling. With my 10 min pedal box job turning into an afternoon of grinding and painting, I decided to go back to basic, basic stuff....Like riveting a few more panels. Dwayne Johnson eat your heart out! I'm trying to maintain as much access as possible to make installing the sound deadener a bit easier so I focused on the DS tunnel, scuttle and seat back panels. My hands were so numb that I struggled to get the Aluminum wrapper off! Final piece for today, originally by choice, but after I pinched my chest muscle in the riveter as I was leaning into it, it was game over for me! 😬 Now sitting on the couch in pain, but with a big smile on my face. Feels nice to make a little more progress.🍻

-

Thanks for the tips @MV8. I will definitely keep them in mind when I get back to the pipes!

-

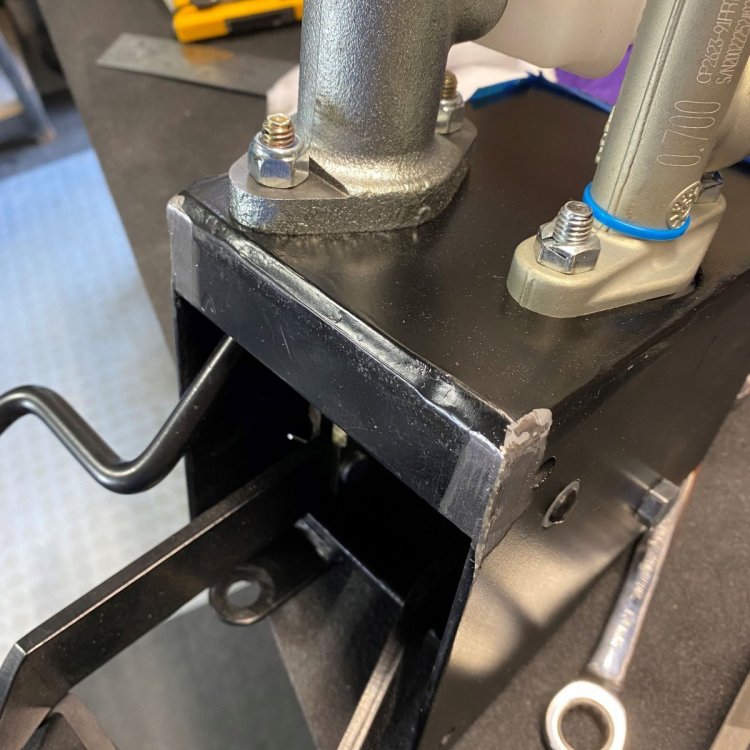

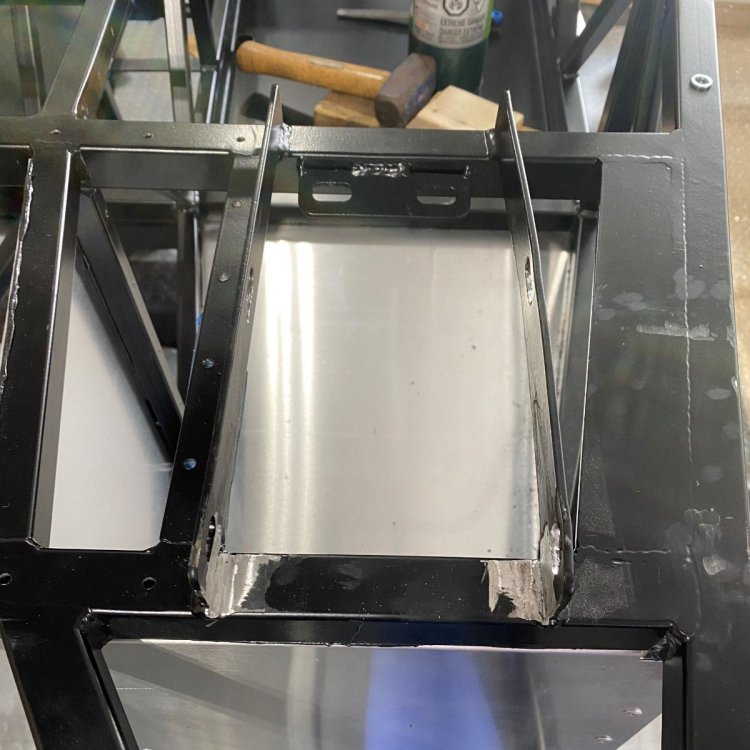

Two steps forward and and One step back.... As the title suggests things haven't quite gone as I planned recently so I had to take some time away from the build, get rid of my frustration and rethink my plan. After a semi successful attempt at running the fuel lines, followed by a good practice bubble flare on a piece of offcut, all was looking good for salvaging my install. Unfortunately, when it came to the real pipes the bends must have been too close to the flaring tool for it to get a good hold and neither flare came out well enough to keep! A new coiled length of fuel pipe was ordered from the local parts store and while I was at it I also bought a roll of Nicop brake pipe. I'm hedging my bets here and figured I might as well prepare myself for a similar experience with the brake line! After week or two away from it all, I decided to get back in the garage this weekend and tackle some simple tasks to get my head back into it..... Pedal box Install Did I say simple task? lol! what a joke! The pedal box sits atop the foot well between two steel rails, and is secured with four M6 bolts. A simple install that I could check off the list in about 10 mins right?!.........wrong! I started by cleaning out the nut threads with a tap....all good so far! Then when I presented the pedal box to the car, the "COVID" chassis struck again. The two attachment rails are positioned a bit too close together and the welds were quite large. The result, I couldn't fit the pedal box between them. Not only that, but the bolt slots on the sides didn't line up with the pedal box either.... At this point the chassis was upside down, so I decided to flip it over to get a better look. After a short stint with some "tools of persuasion" I had to resort to the dremel and start removing material. First from the rails... and then from the pedal box. Finally, after what seemed like an eternity of fettling, grinding and drilling, it was in and after a couple of coats of paint on the bare metal it was done!

-

Lol At first glance I thought that was a Ford Coyote!!

-

Nice job!!! I wasn’t expecting something that well planned and executed!!

-

@MPG I was wondering if anyone had installed a skid plate instead of shortening the sump. If you have a photo would you consider sharing it with me?

-

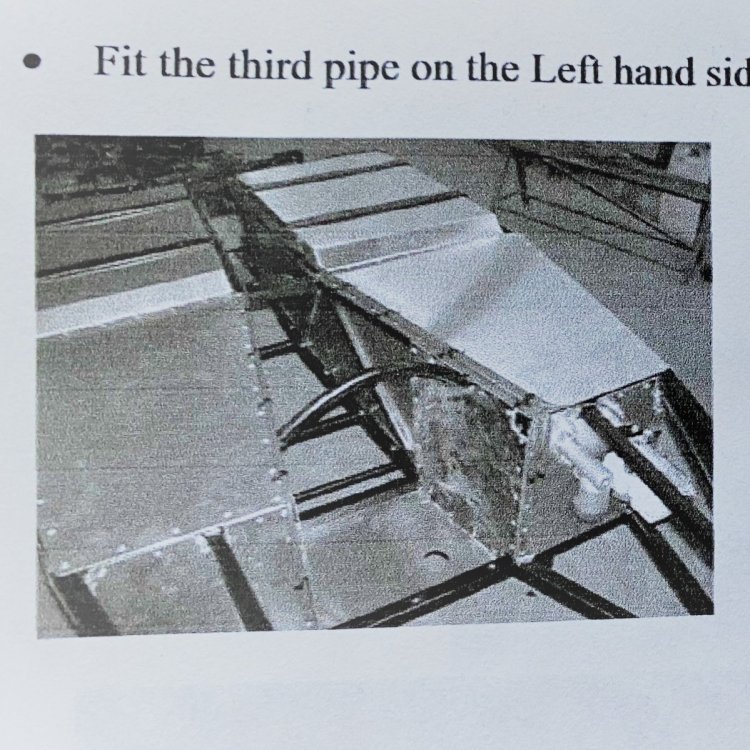

@JohnCh Hey John, It could be a Miata thing! Here is a picture from the the build manual I am following -Published 2006. You'll notice the manual is for a RHD car!

-

@fastg Hey Graham, I thought that too initially, but all the Westfields seem to have the same routing. They are certainly exposed to stones etc., but anything bigger like a curbs would have taken out the oil pan long before the lines! lol

-

What else is new?... Well, in the fall when I was inspecting my engine, I noticed a fair amount of exhaust valve burn. Instead of replacing the valves with stock I decided to upgrade to some Supertech high performance valves and springs from Fab9 tuning in Michigan. After months of waiting they finally came through! Happy Days, I can now reassemble the engine and claim back some valuable real estate in the garage.

-

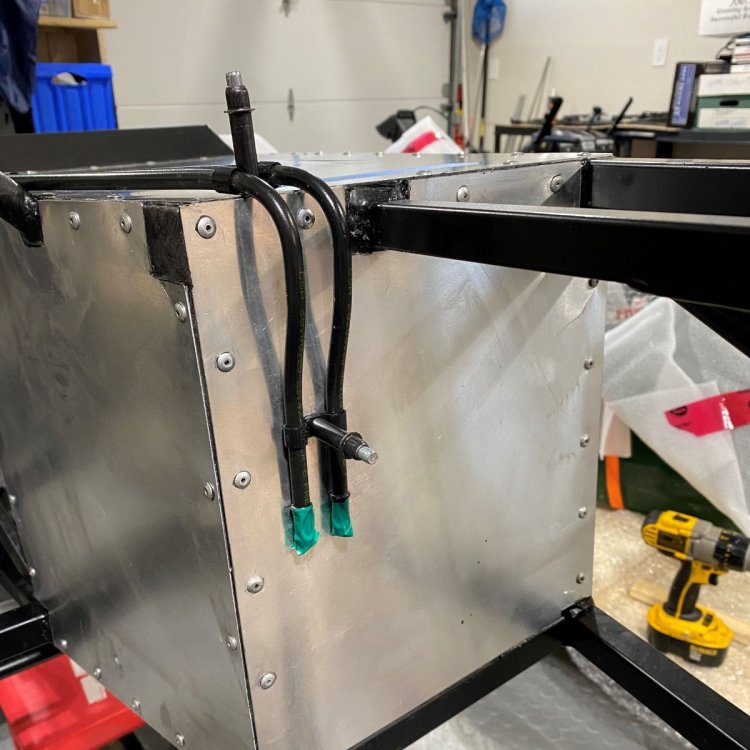

Fuel Lines Not much to report again this week, we decided to book a last minute winter getaway to Mexico for some winter sun. OMG it felt so good to have some warmth for a change! In my last post I had started to run the fuel lines lines on the chassis. Running and bending lines is completely new to me so I have been really taking my time (Perhaps too much) to get them neat. I bought this pipe bender at Canadian Tire and it seems to be working great so far. I also had to try and figure out how and where I was going to terminate them at the rear to compensate for the new brackets that Westfield have introduced to the SDV chassis. I the end, the decision was made for me when I tried to put two bends too close together and the pipe broke....I quite liked the way it turned out so I cut the other pipe short as well....I like symmetry! I still have a few clips to add but at least its a start.

-

Thanks for the complements gents.

-

For those interested in seeing what I actually ended up doing, here is a link to some pictures on my build thread.

-

So it's been a few weeks since my last update. I'd like to say that I made a lot of progress, but as many of you have experienced yourselves, "real life" has got in the way of quality garage time. First there was the trucker protest in Ottawa which put a real downer on things, then the family came down with a touch of the Omicron, followed by general fatigue from everything the the winter has thrown at us this year. It's been a real "F'er". I made a deal with myself that garage time was for when I was feeling a good vibe. I didn't want any negative memories associated with my build. So what have I done..... Well, I spent some time tidying up the dodgy powder coat patches and then filling in some of the floor pan joints with sealant (Thanks @BobMet, I got the idea from your thread 🍻). Next, I spent some time on the pedal box modification. I talked a bit about this in my "Tech Talk" thread and finally got around to doing something. As you know I had an issue with my handbrake bracket and had to have a new one welded on. Well, by coincidence my welder also owned a metal signage company and was equipped with CNC cutting machines and the like. He was able to fabricate and tack on a new faceplate for my pedal box to the Flyin' Miata spec for a very reasonable price. Here's the before... After.... Painted (With Rustoleum Universal All Surface Paint - Satin black and reassembled Finally, I made a start on the fuel lines..... but that's a story for another day!!

-

Thanks @fastg, it is a "push on" connector for a rubber fuel hose with hose clamp.

-

I have been installing the fuel lines on my Westfield SDV and unfortunately messed up my very last bend. I have managed to salvage the line but I need to put a new flare on the end. Can anyone tell me what sort of flare this is and if there is a tool available to make it? Thanks

-

Ooh! a package!!! I love getting goodies in the mail!! My Schroth Westfield harnesses have arrived. I figured there would be a long lead time for these due to the low volumes and the Pandemic so I placed the order in August 2021. Happy Days! Perry Auto Laval (Montreal) is my nearest Schroth distributor and they were great to deal with!

-

Hi @IamScotticus. I reached out to POR-15 directly with my question and here is their response. Hope you find it useful! My Question: "I have a powder coated chassis and there are areas where the powder coat layer is not very thick. Can I paint POR-15 Rust Preventative Coating over the powder coat? If so, what prep do I need to do?" Their Response: "Yes, you will have to lightly sand or scuff the area then use our Cleaner Degreaser before applying the POR-15."

-

@RosteriI think you have hit the mark.....It says best before 31 March 2022!!!

-

A couple more panels today and more mess as I squeezed in to the engine bay to do one of the tunnel foot panels. This time I opened up the nozzle a bit more and preheated the Sikaflex over one of our floor vents (Thanks for the tip @Kitcat). I still found it hard work but definitely easier than yesterday. Another thing I learned today is that about 18 hours after applying the Sikaflex it is strong enough to hold and pull away from the rivet heads and panel. From now on I won't be in such a rush the wipe of the over spill, I'll let it cure a little and then clean up without the stickiness.

-

@MPG Yeah!! That was lesson number 5!!! I had to open the garage door before locking up for the night, the fumes were intense!!

-

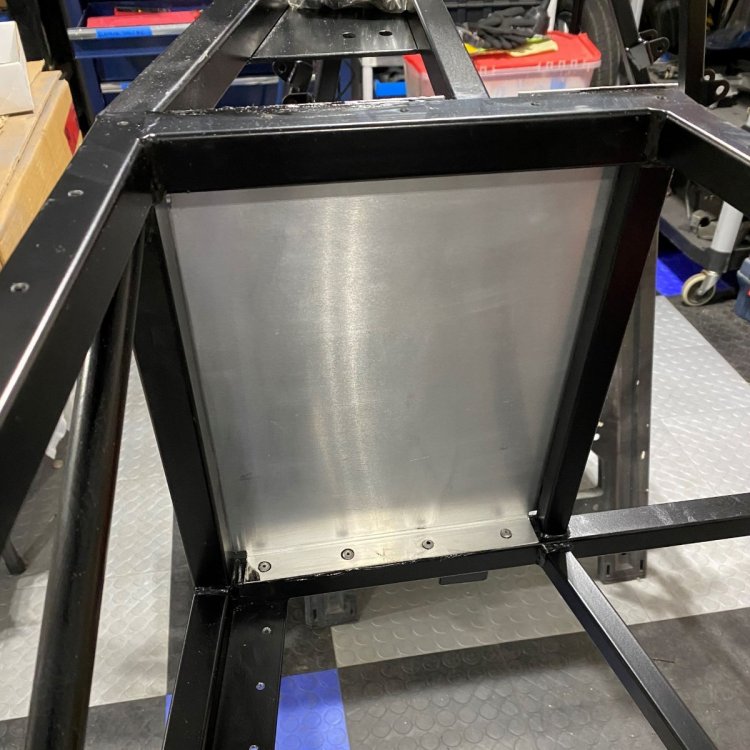

Panel Install This afternoon I made a brief start on the footwell panels. I started by removing the protective film, "de-gooing" and then rechecked each one for fit. Some of them still had a bit of de-burring to do, so I took care of that before opening my amazon package of Sikaflex 221. I'll use this instead of the multipurpose silicone sealant provided in the kit. First panels on were the footwell firewalls. I know, I know, I should invest in a pneumatic rivet gun......... The last panel of the day was the PS floor. Things I learned from my first 2 hours of panel install. 1. Sikaflex. amazing stuff, but no matter how careful you are and how much attention you pay, this S**t gets everywhere. I also found it hard to squeeze out. Perhaps the hole was a bit too small!? 2. How to pull apart, clear and re-assemble a rivet gun that has just chewed up the mandrel on the second rivet you have ever installed. 3. I will have hands and arms like Samson by the end of this!! 4. Did I mention how Sikaflex gets everywhere.......i'm still cleaning the orange strap on my watch!

-

@lg2k Thanks for the photos. This gives me a better idea of where things go and what the clearances are.

-

So while I scratch my head and try to figure out the new fuel line routing I decided to start protecting my chassis rails with cavity wax, before sealing and riveting the floor panels. I ended up using 3M cavity wax and gave it a good spray through each of the rivet holes to ensure good coverage. I just did the floor pans and footwells for now but will complete the rest of the chassis over the weekend.

-

So, news from Manik (Westfield). Apparently the extra brackets have been standard on the Westfield Miata for some time now. Unfortunately, the build manual has not been updated to reflect this, so if anyone out there has build one with the new layout would you be able share some pictures of your fuel line routing? :-)