-

Posts

553 -

Joined

-

Yes, my VX is a later "LN" (low noise) model. Swindon ported and flowed GM heads with the water galleries tube lined to prevent the leaky head issues associated with the non-CosCast heads. It was tough to find CosCast round tooth engines from 1994 on. All the later Swindon saloon car and F3 engines were LN, although most were retrofitted with round tooth belt path components. I believe the round tooth version was thought to be better for RPM north of 8K. Good idea to check that filter thread.

-

Some confusion exists on the C20XE oil system because they were installed in cars with an oil cooler sandwich plate. There is an additional relief valve built into the sandwich plate Maybe this allows the use of unprotected filters? Alternatively, this may be just to protect the oil cooler. I'm not sure as I've never seen a sandwich plate in the wild. Most of the engine builders simply binned the plates as added weight and moved on. You may want to contact SBD or QED and talk to guys that would know all this stuff.

-

bsimon started following TPS (reliable...) , Vauxhall 2L xe Oil filter question , What Diff Oil To Use?? 1999 Caterham Super Seven and 4 others

-

Be real careful choosing the filter. there are two different filter threads on C20XE engines associated with Caterham. The standard thread for Opel, Holden, Vauxhall, Daewoo C20s is 18M-1.5. Caterham replaced the filter nipple on most cars with a 3/4-16 thread, BUT NOT ALL. If the engine is a Swindon build, all bets are off as to which thread you might have. 3/4-16 filters can loosen and drop free of the M18-1.5 nipple. If the nipple measures less than .708" diameter, it's the metric one. -Bob

-

I went out to the shed and looked through my box of spares. The diff really looks like an AP Suretrac. Early in the video you can see pry slots next to the left bearing. Quaife doesn't have pry slots. The turned surface later in the video shows an unbroken smooth surface. Quaife has 5 or 6 drain holes that you would see progressing by in the video. Caterham offered AP Suretrac upgrade during the period of time that the K engines were used. It may have been standard fare for the fancier K models like R400 and such. Suretac is a cam and pawl "Chicklet" style ATB device, very similar to the cam and pawl unit that Hewland used in FT200 and other gearboxes, only more advanced and complicated. Very good strong devices unless you are contemplating outlandish HP levels. The only other diff might be an original Ford viscous limited slip. I've never seen one in the wild, so I'm not sure what they look like.

-

Pat, Did some measurements. Clutch housing to ground is 3.25". Front of wet sump to ground calculates out to 3" Dry sump is 4.75" at front scavenge well/bump. Looking at my old CC wet sump, there are no drag marks on the fins. AFAIK, I never struck it. Could be just good luck though...

-

I'll go out to the shed and measure the clearance tomorrow. By comparing the height of the Pace dry sump pan to the old CC wet pan, we should be able to get some adjusted numbers. Measure the clearance on your car from the bottom of the clutch housing to the tarmac so we're talking on the same wavelength.

-

I would have to go measure actual clearance. I did drive my car with a wet sump for many years with no ill effects. The CC wet sump really doesn't stick below the clutch housing that far. About the same clearance as a Cosworth dry sumped Duratec. Flywheel/clutch housing strikes are more likely than grounding the sump. I run 205/50-15 and 225/50-15 tyres. (23" OD) 205/55-16 tyres are nearly 25" in diameter. Keeping the foam insert in the wet sump current is important. Surge is minimal on the roadway, but longer sweeps on the track can lead to the usual wet sump surging issues.

-

'Tis the (upgrade) season! What are you doing?

bsimon replied to JohnCh's topic in General Sevens Discussion

-

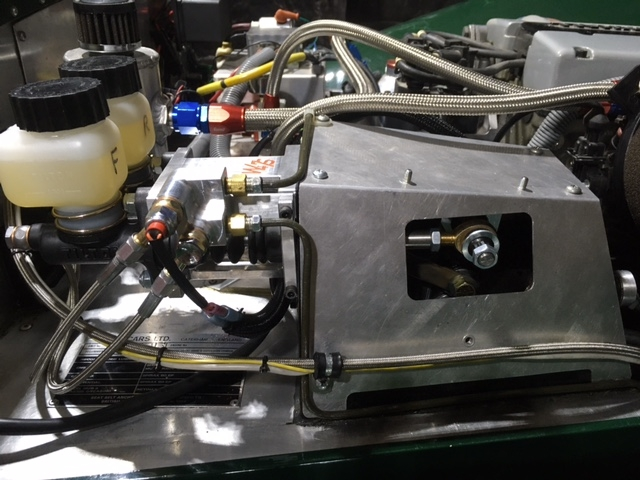

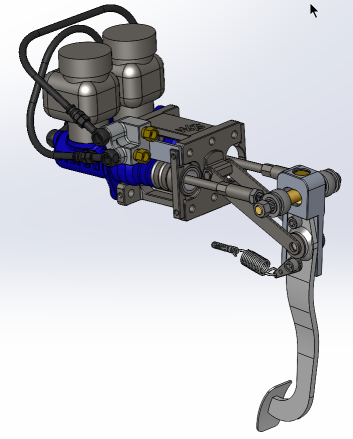

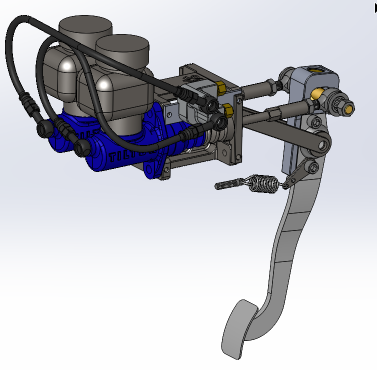

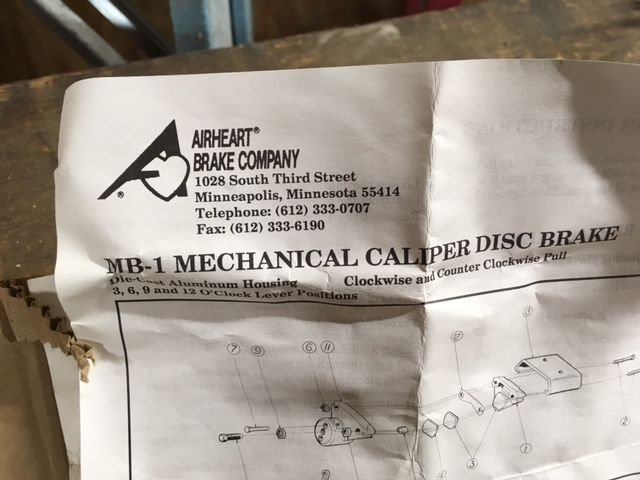

Here's what Caterham supplied with the uprated AP rear brakes. I don't think they are HPC specific, however the brake handle will be LHD or RHD. (RHD shown) The uprated brakes in this era usually have an yellow and silver enameled "Caterham" badge centred on the outer cylinder of the calipers. The parking calipers are alloy Airheart go kart parts. Right and Left The calipers and brackets are fairly light weight but most didn't install unless they were in a legal situation as you are. For example; I use an 8" bit of 2X4 as a parking brake.

-

Can't help you with octane. When I lived in Colorado, I would go to marinas and boat docks to get alky-free petrol. Watercraft and E10-15 don't go good together, so marine suppliers won't even sell it. If all else fails, you can separate the alcohol from petrol by mixing with tap water and draining the water after it settles. I used an inverted VP jug on a plant stand. The alky bonds to the water and settles to the bottom (top) of the jug and can be drained away. 1 quart or more of water to 5 USG of petrol. Here in Wyoming, we can buy alcohol-free petrol at about half the stations in town. Lots of boats, mowers, and motorized toys 'round these parts...

-

TPS = throttle position sensor ITB = individual throttle body

-

I'll post a picture in a day or so when I get time. The adapter is for the Jenvey 51mm tapered style throttle bodies, not the Weber conversion style. The mount may work on the Weber style TBs, but I'm not sure.

-

1995 : BMW : 318I : 1.8L 1796cc L4 M42 AIRTEX / WELLS Part # 5S5022 {#13631726591, TPS4129} BECK/ARNLEY Part # 1580864 STANDARD MOTOR PRODUCTS Part # TH317 {Intermotor} Very reliable and similar electrical specs to the Colvern TPS. I got tired of replacing the Colvern about 20 years ago and engineered this swap. The Colvern's failure mode is to open circuit at the most inopportune time. The potentiometer wiper leaf loses it's tension and no longer contacts the carbon sector reliably. You will need to make an adapter for this to work. Also a female 3 pin Junior Power Minitimer connector will have to be installed on your pigtail. Adapter drawings attached. BMW 318I to Colvern TPS adaptor.pdf

-

The crank sensor is Standard Motor Products PC439 or Motaquip VRC116. Saab 9000 1994-1998. Saab part# 4227203 Might save a few bucks sourcing it at Rock Auto or Vato Zone... For future reference, starter is Saab 9000 as well.

-

Two schools on the crank bolt. Original is a one-time use stretch bolt. (available from the usual Vaux, Holden, Opel, Daihatsu sources) SBD and other builders use a grade 12.9 socket head cap screw. Getting the bolt out with the engine in the chassis is quite difficult. I can't recall the exact torque, but it's enough to turn the car over or rip out the motor mounts. I couldn't budge mine with an impact wrench. I built a torque bar that bolts to the damper and rests on the floor. Good luck!