-

Posts

210 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by SK400

-

I think it should be good and will work. I recently bought and installed a race De Dion tube (only has an extra reinforcement bracket) and no issues. I have a minus 2.5 degree rear camber which may help a bit in full disclosure. I have Apollo 13” rims and other 13” rims. I would not put any rim balance weights on the first 2 inches from the inner face of the rim thought. Worse comes to worse, you can lightly file one of the corners and it should work.

-

Rear uprated ("race") brake upgrade finally done

SK400 replied to KnifeySpoony's topic in General Tech

KnifeySpoony I’m installing the updated rear brake calipers as we speak. I had read and heard from Roger at Meteor not to install a bias valve because it destroyed the brake feel and rather adjust the bias and rear locking risk using different rear pads with lower friction than the RS pagid pads that come with the kit. What are your thoughts? also would you mind showing how you connected the biais valve to your master cylinder? thank you -

Replying to myself since I think I solved it. I had to split the gearbox and engine at the bell housing, insert the gearbox straight into the tunnel, and lower the engine vertically after having removed the serpentine belt and all the various belt pulleys to create clearance. I then managed to align the engine and gearbox, clutch disk splines etc and brought it all together in the car. Torquing the bell housing bolts in place was not too bad. Let’s see how the rest of the build goes ….

-

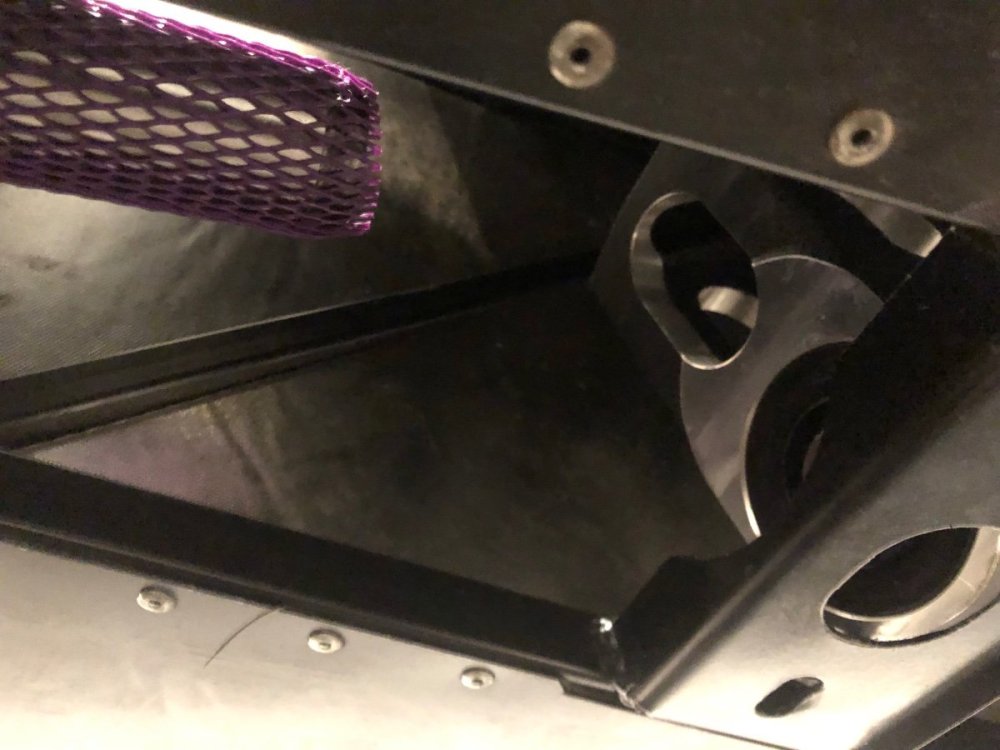

Hello all Has anyone installed a Sadev in an S3, 2013 r400 frame? I used to have a 6 speed caterham gearbox and could pull out and reinstall the engine and gearbox assembly in matter of minutes with no sweat by inclining the engine and the car chassis. I finally received my freshly built Esslinger 2.3l engine, now bolted to a brand new Sadev sequential. I’ve been trying to install the assembly into the car, but to no avail. I’m missing 0.5” of clearance it seems, distance between the rear sensor boss and the end of the gearbox resting on the gearbox mounting plate. I can’t seem to find a way (see pictures). Whats the trick if I may ask? Any help would be much appreciated. I hope I don’t have to modify the frame or gearbox mounting plate. Thanks much Seb

-

I’m in the process of installing. In fact, I’ve been struggling to get the right fittings to connect properly to the bias valve. I assume caterham fittings are ISO bubble connectors. How did you install your bias valve? Next to the driver and cut through the rear copper line or closer to the master cylinder? if the pedal feel firm when the valve is closed, that’s at least a good sign. But I think what you are describing is what Roger at Meteor Motorsport warned me about. I’m trying to install in a way that I can remove valve or change if I don’t like the feel.

-

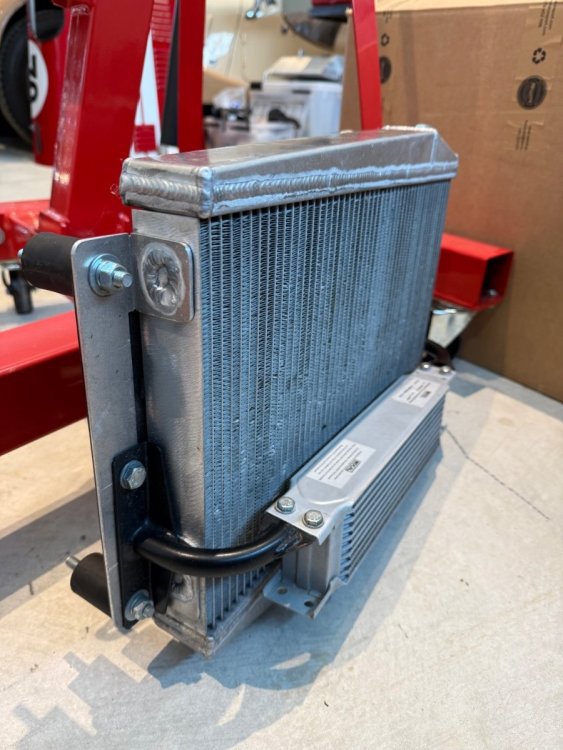

I have a 2013 r400 before they were called 420R but it’s essentially the same thing. The radiator, oil cooler and electric fan combo is in pristine condition, arguably like new. I’m selling it because I replaced it with the slightly larger new radiator model and integrated oil cooler that come with the newer caterhams or the 620r as I was upgrading to the R500 powerplant. Just because. I also have the newer race nose cone to fit the new radiator. attached are the pictures. @vovchandr, let me know if this would work for you.

-

In an effort to clean up my garage, I have a few R400 S3 parts for sale: 1. One R400 Aluminum radiator and one R400 Oil cooler and oil cooler mounting bracket combo, used and very good condition 2. One DeDion Tube in very, used, in very good condition 3. Two DeDion A frames, used, in very good condition 4. A set of rear brake calipers, Ferodo pads and disks, used and good condition 5. a set of Rear De Dion tube aluminum "ears" with negative 1.5 deg camber, used, look like new 6. a set of rear hubs and bearings, used, in very good condition 7. a set of front vented disks for uprated front brakes, used, 0.68" thick vs 0.70" new Let me know if interested. Questions welcome. Please feel free to send me a PM. Thank you.

-

That’s right. We moved a few years ago to Ann Arbor, MI. A great little town and some good local tracks. That’s said, miss the East Coast gang and our more regular days at NJMP or Lime Rock.

-

I’m upgrading my current 2.0l duratec R500 block to a 2.3l and have, as a result, have a few engine parts for sale. I have less than 1500 miles on the parts below and are in perfect conditions, essentially new. Parts for sale - set of R500 Ford Duratec 2.0L model Kent Cams DTEC35 - set of 4 K1 conrods for 2.0L ford duratec and matching King bearings assembled by Danbury Competion engine. - forged crankshaft for 2.0l Duratec, keyed for balancer - caterham factory ÉCU with R500 fuel map loaded - CR500 flywheel, clutch and pressure plate - optional 2.0l block and supertech pistons Questions welcome. PM me if interested. Thank you

-

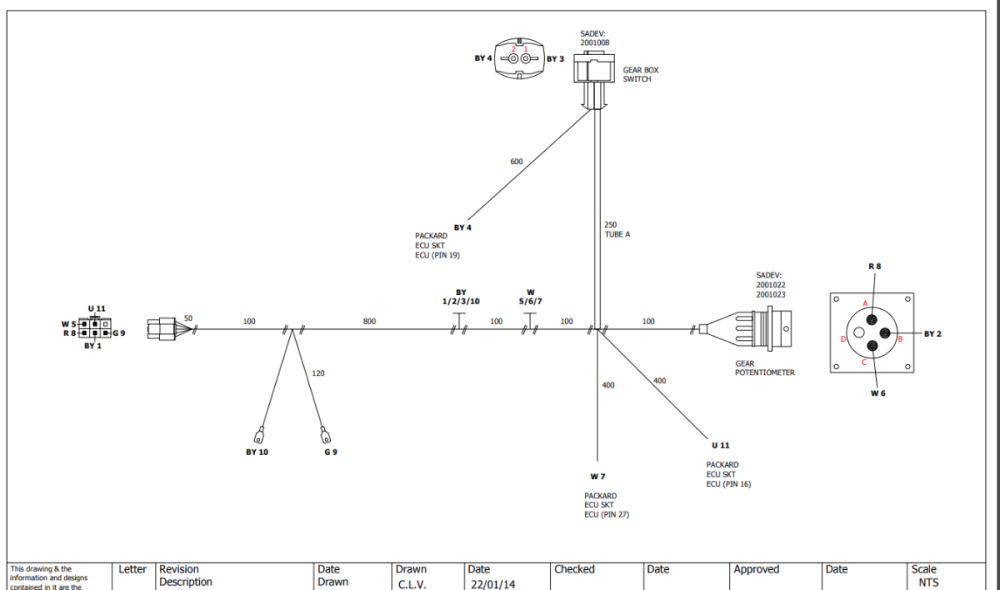

Alright. So on this topic,, BY10 and G9 should connect to “free” flat connectors under the dash. I haven’t looked at it yet but I remember seeing a few available zipped tied connectors in the past when attempting to mess around under with wires under the dash. These should be power. Special thanks toJosh from Rocky Mountain for this guidance. the BY3 and BY4 connector is for flat shift. Will need to connect the various pins to the ECU and may have to pull existing pins out and replace with those. Left is the rear switch. Need to connect the chassis rear green wires to that switch through a Deutsch plug. BUT … it will take a bit of time to see if all of this is working. After some regular engine TLC, I decided to upgrade my engine to a 2.3l with a short block from Esslinger, (just because I can’t let Simon win too easily .. although some of this forum would be quick to add that he would still win if he rode an e-bicycle around the track against most of us). Will keep current 2.3l ported head and valves (well enough for what I want to do) and probably change cams to match displacement aiming at 285 hp and 200 to 210 ft-lb of torque. With the Sadev, on a. s3 chassis, this will be mental enough and suspect that anything more than this will be fighting for traction …. More to come on this on a different thread

-

Thanks a ton Croc. Some useful info in the document. I reached out to SBD to see if they had any insights on the loom and pin connectors. I intent to have "flat shift" functionality programmed so had planned to reach out to Steve at SBD anyway to update the map I made with him. I will circle back when I hear from them.

-

I did not purchase from Caterham directly and perhaps to a fault and paying the “price of figuring things out now”, I decided to buy directly from the UK Sadev distributor (from which I had outstanding service and decent delivery lead times of 3 to 4 months). question for Yellow7 or Croc: do you know how your respective Sadevs are connected to your cars and ECUs? (Orange monster and CatKong) Thank you

-

Sf4018 Yes. My ecu is an MBE9a4 from SBD. Following your logic, it seems that the connector on top of the diagram must be for flat shift signal to ECU. The left connector is for the Shiftec gear indicator. And the flat male BY10 and G9 connectors are for reverse switch. However if that the case, what should I do with the current reverse switch connectors? Splice them with BY10 and G10 to close the circuit?

-

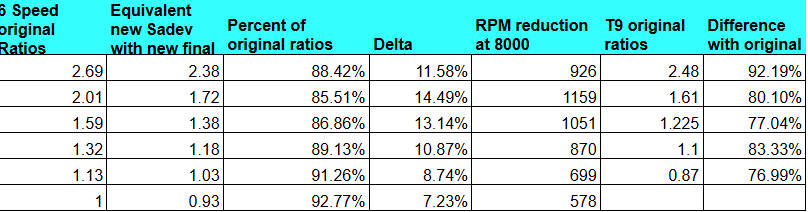

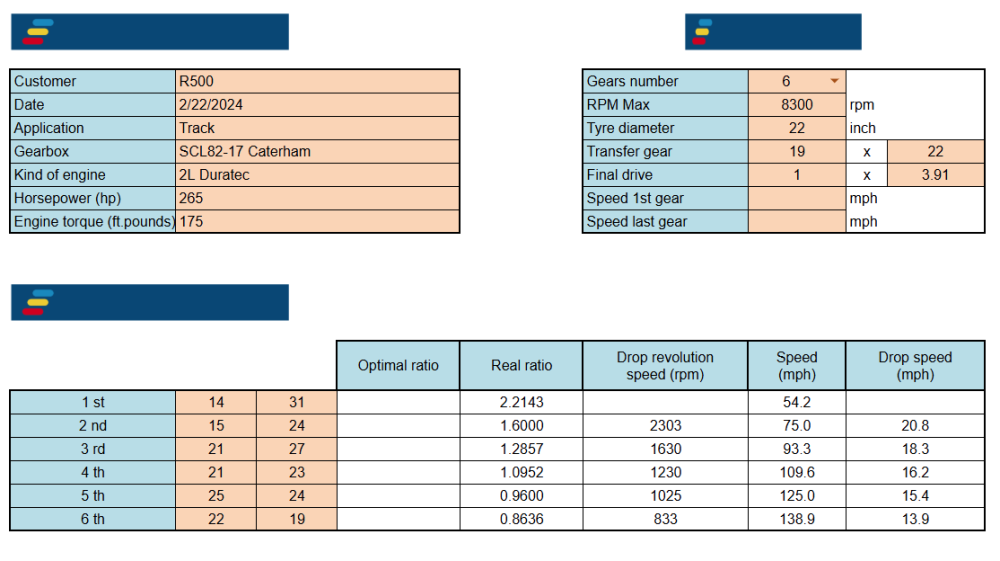

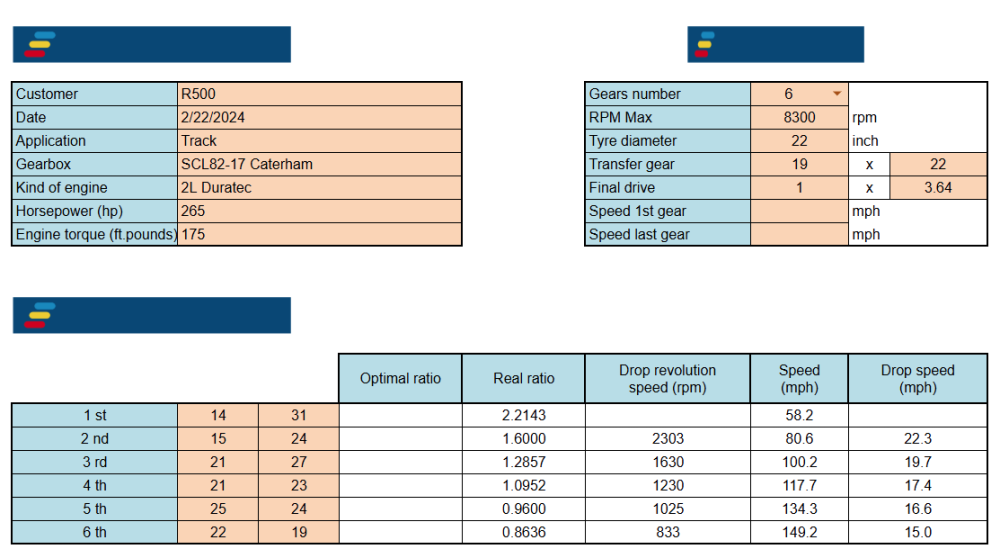

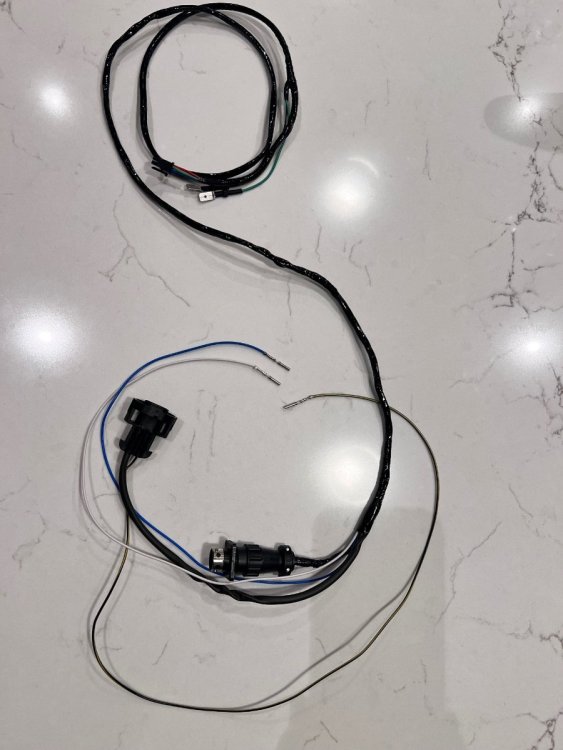

True to form Croc. Missed your salt and pepper! Regarding ratios, I ended up choosing the long Sadev ratio (19x22) transfer gear to give me a few more options and use a bit more the engine torque. I always thought that my 6 speed caterham transmission was a bit too short with 6th speed 1:1 ratio, especially with the new r500 engine that has a bit more torque. I think the 6 speed was best suited for the original zetec r500 not the duratec and as a result, never used 2nd and very rarely 3rd on tracks, spending quick a bit of time changing between gears. With that said, I thought that keeping my original final drive of 3.64 would be much too long for my engine and all the tracks I run inclusive of Gingerman, Mid Ohio, limerock and even the two NJMP tracks. So I opted to change my final drive to 3.91, which I think will strike the perfect balance for my engine, driving style and tracks. Please note that if I had more torque (like that of my red caterham with white stripes nemesis who is on his 5th engine in 2 yrs with a lot more stroke and hence torque than me to compensate for his lack of momentum he carries in corners…) I would have kept the 3.64 ratio. attached are the model output for the 3.64 and 3.91 ratios. In short the 3.91 along with the chosen Sadev ratios will be 10 to 15 percent longer than what I had, which feels right. Going the a 4.1 final drive ratio would bring it in line with my current caterham 6 speed setup. Regarding the wiring loom that I procured from caterham, I have several questions - if the yellow and black wire and connector is for the reverse gear, then why do we have an ECU pin for this function? Not sure why the ECU needs to know I’m selecting reverse but I’m sure I’m missing something important - is the connector with black and tallow for reverse of flat shift input? - the caterham connector is if course different than the connector from the Sadev so need to cut and modify. Okay - there are two leads with flat male terminals: one with green wire and the other with the same yellow and black wire. Where do these wires connect to? The reverse light circuit or something else completely? - does the loom and gear indicator get the power from the ECU pin? Pardon my obvious lack of knowledge on these electrical spaghettis

-

Greetings everyone. It’s been a real while since I’ve written on this forum. About 1.5 years ago, I took my car to autobahn country club in Chicago and unfortunately blew my transmission. After a good 10 yrs of reliable service, the lay shaft of my 6 speed caterham transmission decided to seize and let go, jamming the entire powertrain. I guess my new r500 engine was a bit too much for it. So… it was time and the occasion to refresh the entire car, and finally pulled the trigger on a brand new Sadev sequential gearbox to “finish the job”. The car is now in pieces. Engine is out for some precautionary TLC, differential is out for LSD refresh and final drive ratio change (another project on its own), I’m finally installing the uprated rear AP racing brakes, new dedion tube, new a frame, new bearings front rear etc etc. And I have the gearbox finally after a decent wait. I received the loom to connect the sadev to the ECU and the rest of the car and I admit, I could not find anything online to figure out what wire is what. Attached is a picture of the loom (and the gearbox and the child labor I exploit to work on the car). Any help discerning what goes where and what wire is what would be very helpful. I’ve been guessing and trying to use logic but I could use a bit of expert and friendly advice. thanks in advance.

-

KnifeySpoony Did you install a proportioning valve after all? If so, does it change the pedal feel and travel? I was told by someone to avoid the proportioning valves. I’m asking because I’m considering installing the rear AP racing brake kit from Caterham I had ordered 2 yrs ago and never installed. It comes with Pagid pads and of course the two piston calipers and concerned that I will increase the rear bias more than I’m looking for. Thoughts?

-

Based on your experience, are you then suggesting the Caterham “race” setup? You seem pretty happy with it, are you ?

-

I asked that very question to Simon. He assured me no understeer. I too currently have my rear ARB set at the second hole from its stiffest. Now perfectly balanced. I agree that I may have to get the next level of rear ARB diameter to balance things out.

-

Thanks all for the replies and apologies for the delayed answer back on the forum. KnifeySpoony - correct. After some research I do have the 170 lbs spring in front and progressive in the rear (probably 110 lbs). I think this is the standard Road setup that came with the R400 car when I bought in 2012. I’m quite amazed with the handling and until I started to drive with full slicks and with an R500 spec engine, I could argue that the setup was well sufficient for both road and track. I connected with Simon Rogers from meteor Motorsport in the UK. He recommends a set of Core dampers and track spring setup with 250 lbs in front and 150 lbs in the rear. He suggests that the ARB that I have from stock are sufficient (arguably the front one being a bit too stiff). i think I will pull the trigger and order a set. They come with bright red springs that will match my car quite well. (As the NJMP gang knows, these little things and color coordination matter a lot to me… ). What’s more, I think I’ll save a few more pounds of weight compared to the stock shocks. Curious to know if anyone in the US has already bought and driven with the above mentioned Core spring damper setup. Let me know. thanks all.

-

Winter is here! Which means I’m now shifting gears to maintenance and slight upgrades on the car. I finally plan to install the AP racing brakes (rear) I had ordered several yrs ago and considering changing my shocks / springs to nitron or core systems as I feel the car rolls a bit too much when leaning heavily into curves when using full slicks. With that said, I’m reaching out because I’m trying to find out what spring rates I have on my car right now (and wonder if changing the damper system will indeed improve or not the handling or should I only upgrade the sway bars). Suspension is stock 2012 R400 superlight (wide track) for s3 chassis. Any input or advice would be welcome. Thanks all.

-

Bruce. Good to see your car in pictures. I was your neighbor at eyes on design with the red r400/r500 caterham. Is your car sold? If not, might be someone in Michigan / Ann Arbor who might be interested. (Might). Let us know. Txs.

-

Save The Date - Annual USA7s HPDE at NJMP - September 18-19, 2022

SK400 replied to Croc's topic in General Sevens Discussion

Went to Gingerman, MI, last Saturday to shake the winter cobwebs and get mentally ready for the 2022 season and eventually NJMP in September. Starting to enjoy the new 500 spec engine after SBD fuel mapping session earlier this winter and almost a year of trouble shooting. Don’t want to jinx it but I think slowing getting there. The car is a real pleasure to drive.. sooo strong! A noticeable difference from our 400 spec .. might now have to upgrade the brakes!!! Gingerman was a real challenge to drive. Took me two days to recuperate physically trying to hold on to the beast. Can’t wait to seeing the gang soon.