-

Posts

426 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by JohnK

-

And just when I thought I had ECU tuning figured out. http://www.physorg.com/news/2011-04-laser-revolution-internal-combustion.html

-

Current issue of National Geographic has an article on this - one goal was to get a "fresh" sample of the lava, which is the Earth's magma for a better understanding of what's going on under our feet. These pictures are amazingly revealing.

-

One man's experience: I had over a year's experience tuning engines managed by an ECU: a few V8s and a few Zetecs, all in various states of modification. I used both Engine and load-bearing Chassis dynos. The experience caused me to jump at the opportunity to buy a Se7en that ran an engine whose output was satisfactorily high in stock form; i.e., I wouldn't have to touch the calibration. I'm certain that there are people out there who can calibrate an ECU well, but I am very skeptical that there are very many of them, AND what are the criteria can be used by the owner to evaluate their work. (One client I had had years experience building engines and racing them - and he was very surprised at how far off his tune was and how much the change in performance was when things were adjusted just so that everything was 'reasonable' with respect to ratio and spark.) The number of areas that one has to be knowledgeable in are considerable (electricity, electronics, digital hardware, analog hardware, software behaviour, application behaviour, ... ) above an beyond the question of "what is it that qualifies as a 'good tune' " There are people out there who would confirm that I could arrive at a 'good tune' for their engine, perhaps even a 'very good tune'. But, it is very time consuming, is very difficult, and consequently, very expensive to get it done well. The higher the output of the engine, the more difficult it is to get it right - to give 'good drivability' - and the easier it is to ruin an engine. Tread carefully.

-

Hi Jim, Glad that you found the parts and that they could be made to fit. If more detailed pictures would help, let me know. I do have inboard brakes so the mounting of the calipers will be different but I was pleased to be able to fit the rod-to-cable stay in somewhat tidily. Bet even a used BMW brake handle is gonna be a bit more than one from a Civic. Figure it's so small 'cause its flat? Anyway, happy fabricating.

-

Sounds like that area of your car differs more than a little from mine - I sent the last set of pics in hopes that it might clarify that issue, that you might be able to judge the proportions and positions. Yes, my lever/rachet is hardened and I did cut maybe a couple of inches out of the middle of the lever and resectioned the button rod. Trying to remember the details of the modifications, but from my pics I hoped you could see the relative position of all the bits and hence the mods I made. I remember avoiding changes to the paul/rachet after finding out how hard it was.

-

For what it's worth, the Superformance Cobra replicar uses the same unit - and, just like the S2K, it is quite out of site and I managed to drive a Cobra I was tuning up and down the hwy with the thing on. I sent mine back to TX because it was not only not handy but was big and heavy. Dunno if fabricating the new one really justified all the work but there it is.

-

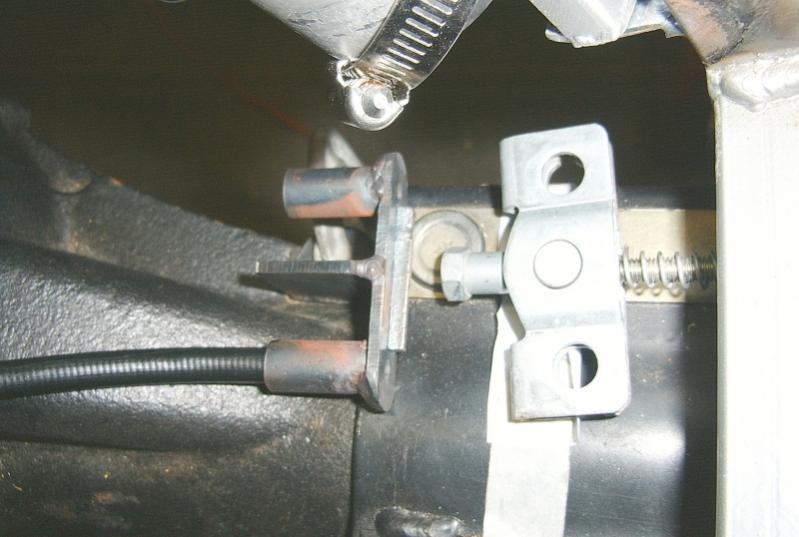

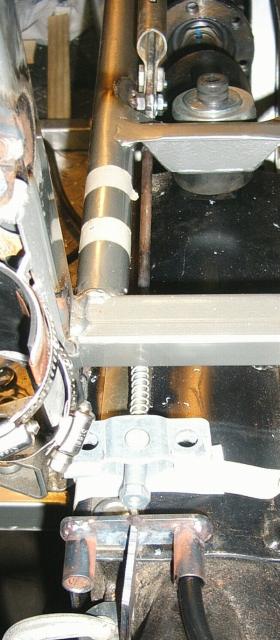

Added pictures to support your assessment - this area is indeed really tight. I wound up carving up what I think is a std Honda Civic or Accord brake lever - the ones I found looked identical to the one in my '94 Civic. Note that bolt heads are shaved and top mounting bolt is welded to frame (blow up handbrake07). Pull rod fitting is similarly tight: made a cable stay from scratch and found that the diff had a flange at just the right place to anchor the stay with a drilled and tapped hole. Getting carried away, I fitted two mechanical calipers - Perhaps there's some sort of 12-step program out there for people like me .

-

Jim, My implementation- Local junkyard, any Honda Civic or Accord handbrake assy, shorten the lever to taste (and toclear the shift lever), couple of small welds to hold things in place, tuck it in on the driver side and route the rod out the back to an assy to secure the cable. Have detailed photos if interested. Almost disappears, 'cept when you're reaching for it, and it's impossible to drive away with the handbrake on.

-

Mondo, Yup, re. the thread you cite, and if you look you'll see a post by me about using a type of precision bolts to reduce the free play that can reduce the pounding due to clearance. I was worried about some sort of incompatibility that I hadn't yet heard of. Chain wax sounds like a good idea - well suited to staying put under severe conditions.

-

Before I order my Koni's, anyone care to comment on why this is so?

-

Whoa - glad you caught that before ....! By the way, what's that spacer all about? I have one maybe 1/2 that height that's cone shaped and aluminum, which I reduced 1/4" in height to fit 13" wheels and also reduced the diameter at the top to prevent the rod end from jamming on it. Anyone know what the practical repercussions are re camber gain as this distance changes?

-

As you consider this change, have you looked at, or are you using bits of the production Subaru setup? There are some pieces that bolt to the fwd part of the diff shown on a parts diagram I have (dealer provided) that look like they'd aid such a re-design. What you describe would be a GREAT help - the diff is such a pain to change with a tunnel rather than a gap to fit through. (Unfortunately, I put hard lines in and would have some work to do to cut that out. I'm certain that all the mental gymnastics involved in figuring out where to run and how to fit things on a Seven prevents Alzheimer's.)

-

You're on the list! It'd be great to have you try out my work on a real live car rather than just a bunch of numbers loaded on a chip. Spring is coming, stay tuned and wish me luck!

-

Chuck and WestTexasS2k, Thanks very much for this info. It means a great deal to me because you both have a lot of practical experience and have been able to assess the results of changes made to the car. I don't anticipate doing autocrossing because I don't think my reflexes are up to a competition that is that intense, but we'll see. I brought that subject up to reinforce the point of what I felt was appropriate gearing, since there were views that running a tall ratio was not a big deal. Chuck, your experience for a setup with 4.11 and 13" wheels is what I was hoping for and then some. I didn't expect that it would still have reach at 141 MPH. The weight I got for my car is something I'm not comfortable with, even though I spent quite a bit of time trying different setups and sequences. And, yes it's with my weight in the driver's seat, a half tank of fuel, and all fluids. I used a lever-divider setup with bathroom scales and could not come up with very consistent readings - I was looking for +/- maybe 10 lbs and got more like 25. The problem I think is due to suspension loading of the corner placement of the scales - even though I was using solid struts in place of shocks, (home-made) slip plates, varying the scales looking for bias, trying different ways of placing the car on the scales, ... I'm tempted to spend the money with Longacre on proper scales but really think the problem is with my procedure. Zakiras Garage is down the street - maybe I'll see if they're up to doing that for a customer. WestTexasS2k, It's good to hear that your experience with steel rotors indicates no problem. Wilwood was really adamant in their advice - maybe they just doin't know about Sevens :-) Perhaps the cast iron will result in a more solid feel - but at least they'll allow me to fit 13" wheels (after I get the short sump and the Accusump fitted). I've done a bunch of things to the car that SHOULD make differences in specific areas. When I finally get everything dialed in (like shocks, ARB rates, brake bias, ...) I'll be looking for people experienced with the base car or at least a Seven to spend some time at the wheel to get some feedback - AFTER I spend some time enjoying the thing after all this work :-) Thanks again very much for giving me (and other Listers who may be just as interested) the benefit of your experience.

-

Bingo! This is the kind of stuff I've needed to see and hear. Thanks all, especially WestTexasS2K's descriptions and Mondo for the picture of the brace, ... and m wirth - your calculator looks like it'd be much easier than having to boot Windoze! See end for notes on gear ratios. WestTexasS2K, when you say "You can swap the diff out for any R160 Subaru diff." is "the diff" MY diff? - as per my concern about my brake setup with all its special bits. I'm a bit weighed down at this point by all the info you've provided, but will consider swapping out the entire diff (changing just the gears SOUNDS a lot safer but I have not done such before). I would like to know if you do have a 4.11 unit available and what you'd sell it for. However, with shipping from TX it may make more sense to source it locally ? Diff mounting. I saw earlier where people had torn out the forward boss - and welded a thick bead around both sides of mine in order to increase the support. As per the attached pic, I do not have a chassis that I can attach a brace to - so I guess it's back to the dwg board. Ideas/suggestions appreciated here. I can see where twist would be a problem, and will change the rear mount material to Urethane. Mondo, et al. - Brakes were the first thing I tackled. Wilwood told me that the steel rotors were for drag race apps only - single hard usage application followed by long cooling off, otherwise they distort over time into a bell shape. Coleman machine has a pretty wide selection of cast iron rotors that they're set up to machine to spec. I spec'd out a set of Wilwood calipers that'd allow me to run Diamond 13" wheels, figured out the caliper piston sizes I needed along with master cyl piston sizes front and rear to give appropriate balance along with force, and figured out the widths and diameters to fit caliper to rotor. We'll see how well balanced it is when it finally gets put into service. What follows is a set of calculations showing the difference in possible acceleration with my current setup and then switching to a 4.11 diff and Hoosier 13" tires. Assuming that more acceleration is better, ... :-) Also, for doing Autocross, WestTexasS2K's observation that a diff ratio as low as 4.44 still allows 2nd gear to go from start to 60 mph makes this a killer combination for this type of sport, and emphasizes how much I need to get rid of my tall ratio diff. Tran. Gear Ratio 1.21 Ring & Pinion Ratio 3.5455 Final Gear Ratio 4.28 Chassis Total Weight (lb) 1725 Drive Line Efficiency 85.0% Engine Torque (lb) 168.0 Engine Torque Per Wheel (lb) 84 LR LR Tire Loaded Radius (in) 12.844 LR Acceleration Force (lb) 286 Possible LR Acceleration (g) 0.166 RR RR Tire Loaded Radius (in) 12.84 RR Acceleration Force (lb) 286 Possible RR Acceleration (g) 0.166 Possible Total Acceleration (g) 0.331 *** ----------------------------------- Tran. Gear Ratio 1.21 Ring & Pinion Ratio 4.11 Final Gear Ratio 4.96 Chassis Total Weight (lb) 1725 Drive Line Efficiency 85.0% Engine Torque (lb) 168.0 Engine Torque Per Wheel (lb) 84 LR LR Tire Loaded Radius (in) 10.85 LR Acceleration Force (lb) 392 Possible LR Acceleration (g) 0.227 RR RR Tire Loaded Radius (in) 10.85 RR Acceleration Force (lb) 392 Possible RR Acceleration (g) 0.227 Possible Total Acceleration (g) 0.455 ***

-

One more thing that really needs to be fixed :-( I tried to ignore this as I was wrestling with other things that seemed a lot more important but it's beginning to be as conspicuous as a sore thumb. My "kit" came with a really tall rear end (11:39, or 1:3.5455). Because my primary goal in putting the "kit" together myself was to see what I could come up with in the handling department, I ignored this, but . . . Someone observed that Sevens spend most their lives between 60 and 80 mph; I've got just lots of HP without having to do anything other than wire up the stock ECU correctly; while I expect to spend time on the street, I really hope to do track days and possibly some SCCA Solo competition; my Racing by the Numbers software makes it really apparent that running tall gearing is awful if you want the car to accelerate 'smartly'; the Honda S2000 drive train comes with a 4.10 dif; . . . Have I missed anything? Is there any conclusion to come to than "It's really stupid to run such a tall rear end! (never mind the question, "How come you were delivered a "kit" with such wrong gearing?") ? As a feeble defense I'll offer that, had I not been doing things like redesigning and figuring out how to fabricate the front suspension so the links wouldn't tear out the R&P when I both turned the steering wheel and an inside wheel happened to hit a bump at the same time, I certainly would have addressed the problem earlier. So, how to proceed? I'll offer that the best approach seems to be to buy a Subaru 4.11 gearset, do the gruntwork of getting the shimming right, and bear the hazard of having to do the shimming over if I don't get it right the first time. I'll support this approach with the following. I know of no way of telling exactly which diff I have, and don't what to find out that there's something subtle that interferes with something else by having the rear end self destruct once assembled, trashing all the special fitting of the one-off pieces. Thus, only replacing the gears, leaving everything else the same, seems like the safest course. (Anyone know how to decode the numbers stamped on the diff - and do they signify anything relevant to this issue?) Another complicating factor is the complexity of the rear suspension. By some great stroke of luck the "kit" came with inboard brakes, which is great in terms of handling and very cool in visual appeal, and it SEEMS in all appearances to actually be correct (he says crossing his fingers - no noise when run up on blocks and especially when the brakes are applied). But this means that the axles, with their welded-on brake rotor flanges on the inner CV joint, have to match the diff - perfectly (one-off machining job ensures that the calipers and rotors are in alignment). I expect that the parts have worn in together, but at this point I wouldn't bet on anything. If I get a used diff and there's any difference in width, some very expensive machining may have to get tossed - not to mention gremlins lurking elsewhere. So new gears seem the safest. Pictures of the assembly provided for the terminally curious. Suggestion, comments, watchouts, . . . polite laughter?

-

That is an amazing piece of research and development. I'd love to see an overview of the control algorithm. Fuzzy logic, maybe? Twobone: And then there's the guy, a really smart, high-achiever*, who bought the Segway company from the inventor, took one of the All-Terrain versions out into the boonies and drove the thing off the side of a cliff killing himself. *I was gonna say "high-roller" but that would have been too far out ;-)

-

Re drawing suspension with a CAD package and trying to figure out how the suspension works: I used a highly-regarded purpose-built suspension geometry product by Wm. C Mitchell called WinGeo3 to attempt to understand my suspension (http://www.mitchellsoftware.com). It allows me not only to see my suspension in multiple perspectives, but how it responds to bump and droop and roll and braking. I can change the length of a link and see the result on Caster, Camber, scrub, ... at a range of roll + ride-height change, ... And an add-on spreadsheet done by a mathematician allows me to determine the spring and roll-bar movements similarly (at 0.5G right turn and 0.2G braking, for example) so I could arrive at the right spring rates given the geometry of the car. However, ... I ALSO learned that really really tiny changes can make big changes in the results that you see, depending on what you're looking at. In the main, it gave me a much much better picture of what my car's doing, but, when it comes to something like getting rid of bump-steer, or minimizing scrub at the expense of camber - well, now I understand why serious race car teams spend millions of dollars on equipment and setups to align their cars to 0.001" values. It was pretty disheartening when I saw how little that three days of work crawling around under the car and measuring x-y-z for over a dozen points to a 1/16" or better bought me. And to add salt to the wound, I remember that I read a long time ago in Allan Staniforth's Competition Car Suspension that scrub, caster and camber all work against one another. There is no 'solution' to the problem of how to dial in the suspension. For even more gloom read what Caterham paid a consultant to do to improve their latest car (http://www.usa7s.com/vb/showthread.php?p=29481#post29481) The only thing anyone can do is measure the car real, real accurately, understand, and if possible measure, how the car is working, then propose a hypothesis as to what should happen when you change something in a particular direction, and then repeat the process. Or you can just buy a Caterham, ensure that it's aligned as the factory said it's supposed to be, hope that nothing's been bent since it left the factory, and the go out and enjoy the damn thing!

-

Lots of questions to answer! Too obsessed? Perhaps... :-) I'm expecting to be on the road this coming Summer. The list of things that have to be done is getting pretty short. A trip to Koni Racing with a list of specs in hand to order the shocks - which will be expensive. Logistics will consume time, like getting a trailer and tow to get to the inspection station, and figuring out where I can test drive it safely. After so much work I don't feel like risking the thing out on the highway without some serious stress testing. And then . . . there's finding a local experienced Seven pilot to spend some time with it to provide an un-biased assessment of the thing, and perhaps some help in dialing in the shocks - hmmm, I wonder how I can accomplish that? ;-) Power: back in my motorcycle days, the word was that you learned on something that handled well but didn't have a lot of power. That way you found out how to go fast by learning to drive - how to get every bit of traction out of your machine and exploit all the momentum you could generate in every corner you went around. Then, when you could afford something that had lots of power, you'd know what to do with it. > danilo Wow 5 years in the making.. Perhaps as much as the whole first year was spent in a deep funk as I found one thing after another that had to be un-done, figured out and then built correctly. After that it went downhill for another stretch when the picture became even more clear :-( >How heavy IS that pesky Honda unit? If I remember correctly, 405 lbs including transmission. I think the lightweight here is the Rover at around 270 lbs for engine and trans - there's a thread on this site on that topic. >Older (pre 2000 my) Saab 2.3 engines, albeit even heavier than an s200.. easily.. out > performs the >Honda.. 300hp & 350 ft lbs is seriously effective.. by any yardstick. Positive manifold pressure will get you that :-) >Dunno.. if one wants that much pig iron in the front of the car though :-). And who was it who said "Add lightness"? >Crossflow engine although not even close to current durability yardsticks is a decent > engine, once balanced and revalved :-) A Madza 2.3 could be a V good substitute IMO. When you're facing the confines of an empty chassis, you find that it's really difficult to find room for everything. The Ford T-9 bellhousing is really narrow, which makes for very tidy packaging. Everyone else's engines have pretty wide ones. >I wouldn't overly worry about state of art unless it's a personal achievment issue... >it's the operator much more than the machine. My feelings exactly. >I've currently been obsessing over getting big enough brakes for my build.. >poring over catalogues and parts lists to see what is possible.. I did that from scratch and it takes some doing. Wilwood can be very helpful. Their selection of calipers is huge, and they have pedals and master cyls - and very good advice if you call them. Also Coleman Machine (Wilwood recommends them) is set up to provide made-to-order rotors and hats - they have quite a selection and are reasonable. Caveat emptor - they can be really sloppy occasionally. Check measurements thoroughly. The tricky part for me was figuring out how to mount the caliper to the upright. I was able to arrive at and implement a complete system that gives balanced front-rear braking, that has real, HD, cast-iron, vented rotors, and that allows running Diamond 13" wheels. It was a lot of work! I started with a (now out of print) copy of Fred Puhn's Brake Handbook >Wife chimes in by saying there is No problem with the OEM S7 brakes .. besides you just don't use >them.. they only slow you down. She DOES know how to drive, and I've heard that before. Maybe going into a corner way too hot and finding out your brakes have faded lets you know you can go a lot faster - after your pulse gets back to normal. Mondo: I replaced my rack when I found that I could not get rid of significant bump steer due to the dimensions of the rack. But, I have to plead considerable ignorance here because I've never driven an Ultralite and am going completely on the numbers I got when attempting to align the car. I hope that as the years go by some other Ultralite owners will have a chance to drive my car to provide a comparison. Perhaps I'll find that the very challenging work of fitting a new rack was largely an academic exercise. As a (very, very good) reference to guide the work, I used what's written in the Woodward Precision Power Steering catalog. Were I wealthy enough to afford what I wanted appearance-wise, I'd look to something like a early 60's Alfa or Maserati sports racing car, and have seldom thought of a Seven in any terms other than what it is like to drive. But still, every time I've been able to walk up to and admire a Lotus 7 or Caterham, or a Bug-eye Sprite, I get this big smile on my face. I think it's some sort of ancestral memory. It's certainly not anything to do with reasoned thought, so I should excuse myself from making any comments as to a particular Seven's appearance. Happy planning danilo.

-

danilo, A wife who races, and does well at it! I'm impressed - and a little envious :-) My interest in (and hopefully not obsession with) understanding how all the bits work together and also understanding how to dial everything in as well as possible comes from relying on Carroll Smith for those understandings. One of his lesson is "It all comes down to tenths." I think that some cars feel amazingly wonderful to drive because some talented people got all the parts to be of an especially optimal and harmonious mix and dialed everything just as it is supposed to be. Kitcat gave me a ride in his ho-hum ordinary Caterham and I was amazed at the combination of agility and the comfort of the ride the car provided. I've seen pictures of Caterhams going around corners on their door handles (metaphorically speaking) and wondered how they could corner so well and yet have so much body roll. Somebody understands what they're doing. The ultralight caught my attention with its IRS (actually I found out that it's adapted from a (gag) strut layout) and drive train. I spent over a year tuning only a few cars with ECUs on a dyno and knew that the stock S2000 would give me better power and especially drivability than anything I could get otherwise - and that I wouldn't have to touch it. The successes people have had with it in the One Lap of America also added to its creds. However I agree with you that "It just doesn't look 'right' ". The engine's too tall and quite heavy - it changes the look and especially the 'sense' of the car with respect to a Lotus or Caterham. Plus, the build (redoing stuff that really had to be redone) has taken too long. And, even though I really have enjoyed all the development work, it would have made much more sense to just by a plain cross-flow engined Caterham from someone and enjoy driving the thing. And, with what I've developed, the only thing that'll really be missing is my having the nervous system of a 23-year old. Good luck with your clone, and watch out for those after-market vendors.

-

Chile, if my source is correct, and Flaming River supposedly pays about USD $35 for each. However, . . . one cred point that I added to my decision to buy an Ulralite "kit" was that the cars had run the One Lap of America, and suffered no chassis and chassis-related failures. I did replace the rack on my car for reasons other than the quality (or lack of it) of the rack. "If it works, ..." You might look at Woodward Precision Power Steering's MR series racks, if you're interested in flexibility (Mosteler and Saleen both run them in their race cars, and the basic unit is the favorite of the soon-to-be mechanical engineers' Formula SAE cars). But this is NOT a bolt-the-thing-in type of job. It took me many weeks to get very quick steering and absolutely ZERO bump-steer. If you don't know what bump-steer is and that it ruins the driver's ability to tell what the car's doing, it would be good to do some reading. The SAAB bits sound like they're worth a look.

-

If you're interested, or curious, I have an unused MG-B aftermarket rack (sold by Flaming River) that I'd love to find a new home for. This is used on the WCM Ultralite.

-

Have you taken into account steering arm Length? Depending on the upright you run, you may use only a small fraction of the rack's stroke. Also, you may beable to shorten the steering arm to quicken the steering.

-

Jim et al, I agree with you about the "looking in the mirror" part; some of our current economic situation has to be due to a wide-spread attitude of "I can do any damn thing I want to". But getting back to the Ethanol problem, Capitalism as an economic system has a lot of really awful properties - like, once a company (like an oil company) establishes itself, if it's a GOOD Capitalist, it will do ANYTHING to keep anyone from hurting its economic position. This means we're pretty much stuck with whatever it is they're selling, and that someone else out there with a really great new solution or insight or idea is gonna get mugged by any company that's threatened by a potential challenge to its business. Kinda makes you feel stuck in the mud when you think about, like, finding some cool way of making your Seven work better.