-

Posts

426 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by JohnK

-

Noticed an article in the December Car & Driver on a prototype Subaru/Toyota sport sedan that C&D seemed to like a lot - particularly with regard to the "engineering comes first" approach used in the development of the car. What caught my eye is that it uses an updated Subaru*+Toyota** 4-cyl engine and 6 speed trans in a front engine - rear drive configuration, and claims 210 HP. When Honda stopped making the S2000 I was afraid that the end of the model would mean that no more such high performance drive train assemblies would be available in an out-of-the-box form. But this Subaru BRZ looks like a winner as a new source of Seven-applicable drive trains. Anyone got an inside line as to the dimensions of the engine and how broad the bell housing is? Definitely something to keep an eye on and fingers crossed over. * FB20 ** D4S dual port and direct-injection technology

-

Croc, Anyone done a comparison with the just-released Nikon Coolpix AW100? Similar price ($320 at Costco), and, among other things, it includes a GPS - which I would need to find my way out of the woods I'd get myself lost in after going off the track ;-)

-

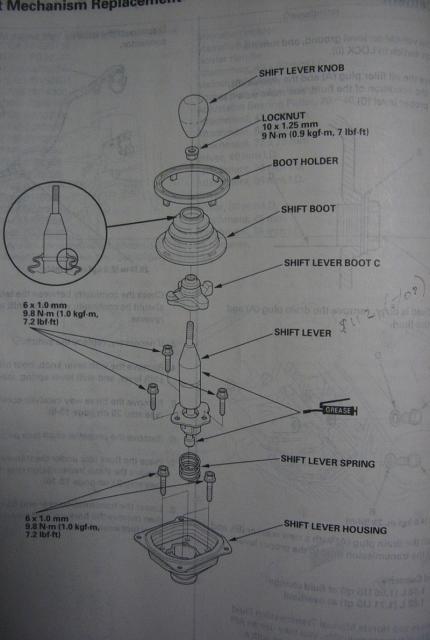

Scott, Here's the entire picture. You can supply the "You are here." arrow to it. Original.jpg is from the Helms manual - the shift lever is what I cut vertically along the fat part in order to expose the shaft to deliver what's shown in What_I_got.jpg. This is shown after I threaded the M10 top with a M1.5 pitch. I turned the knob from a piece of Osage Orange and JBWelded in a nut. I decided that while I was at it I could reposition the lever to be much more ergonomic and cut/sectioned/welded it to give What_I_did.jpg. Also, before I began carving up the shift lever I found that a new one was $112, so recovery of a mess-up on my part would not have been too costly. Food for thought. Shift knobs are really personal touches. I appreciate you interest in getting this "right".

-

M10 & 1.5 is what i used for the shaft+knob, but i had to cut up the stock assy to expose the same shaft that you show and and buy a die to put the threads on the shaft. Your pic looks as if someone pushed a collar on a stock M10 shaft. Maybe it unscrews or can be pried off to expose an M10 shaft? Getting a die square on a shaft isn't as easy as it looks. I decided to cut and weld the shaft to make it easier/faster to get to the shifter - and found no problems doing this. I'll send some pics when i get to my other machine. Original came with a much taller lever which included a bonded bush/coupler that had to be dissected off to expose the primary shaft- looks like someone was in a hurry in your case :-(

-

Oops - thats cycles per MINUTE.

-

One pretty fundamental measure is wheel frequency, which gives you a sportyness figure - 120 cycles per second is reasonable for a seven. This is figured for each corner by dividing the coil rate by the square of the suspension leverage, dividing that value by the sprung weight, taking the sq root of that value and multiplying it by 187.8. After that, things become complicated. An anti-roll bar is a tuning device which is dependent on suspension geometry and weight. Linkages determine what each component does at each instant as the car is under way. Wm.C. Mitchell makes an affordable product called WinGeo3 and a companion product by Rowley will allow you to see the effect (understeer or not) of different roll bars. Overall, there is not "an answer" or a good starting set of specs, and ANY solution involves a lot of compromises bundled into a guess... but its also a lot of fun, esp when things turn out well.

-

I heard a discussion on this commonly-found-on-your-better-aircraft feature, perhaps on Science Friday Talk-of-the-Nation - When they first tried to do one of these, they used a rocket (seems sensible, huh?) but it was too slow to do the job. Current versions use a bomb - quite literally. Think I'll stay with sailplanes.

-

Sean, I agree, and even with the extra moving about, it shouldn't take any more work than the vacuum method - and you get the benefits of the pressure method. The worst problem I have is finding caps to match my M/C reservoirs: my Se7en has Wilwood remotes and a separate, integral, clutch (it must be the same as the plastic ones, I think); and then there's my Civic. 's never simple is it?

-

A power/pressure bleeder not only creates pressure at the master cylinder reservoir, it also adds fluid to the reservoir to prevent the reservoir running dry and air being pushed through the system. As a result the bleeder needs a supply of fresh brake fluid that's sufficient to avoid running dry - erring on the side of caution, this usually involves adding a considerable excess of what could be done by the slower, step-at-a-time vacuum procedure. E.g. my favorite add for one of these units usually appears at the back of Automobile magazine with a young honey announcing "I really love a hard brake pedal!" After you/I get past that, notice that what they're selling is a insecticide sprayer refitted for the purpose - so, considering the size of that container, you must have to add at least several pints to the bottom of the thing - and of course pitch any you don't use. The point of this whole thing is due to the property of brake fluid absorbing water over time, which is why your owner's manual says to change (flush out) your brake system with new fluid every two years - otherwise you face a rusty mess as the years go by and have to replace your calipers and fittings, and ...

-

Bleeding: Power bleeders are a bother, especially since you have to use more fresh fluid and match the fitting on your car's reservior BUT once you get things set up, you get to flush the system much more easily. I have read that the usual method of pulling the fluid from the caliper end may draw air in around the piston seals and introducing air into the line - leaving the pedal spongy - although I've never experienced that myself.

-

Your overall favorite engine for a Lotus 7 variant.

JohnK replied to Ruadhd2's topic in General Tech

Mike, You might think about: There's been some discussion on rear ends in past threads, WestTexas seems to have this area pretty well down with respect to the Subaru diff you're running. If you compare ratios with a performance calculator that gives input HP:gear ratios -> acceleration, I think you'll find that a 4.11 diff may buy you a whole lot more than switching to an engine with a bit more torque, and still give you a very drivable package. Powderbrake runs a 4.57 or some such ratio on the street with his WCM/Ultralite and the S2000 came with a 4.10. -

Broadening the scope a little - I was driving home late one evening a while back on my 250 Ducati Desmo, tucked in doing maybe 80 on an unlit but, fortunately, perfectly straight road. I thought I saw my headlight flicker and before I could sit up, had no light whatsoever. The engine, of course, never missed a beat. I was describing this and its aftermath to some friends later and one remarked; "You know, I've owned German motorcycles and the lights always worked. I've owned British motorcycles and the lights never worked. I've owned Italian motorcycles and ... an Italian motorcycle will lose its lights on a mountain road in the middle of a corner - the Italians have a sense of humor."

-

While this might suggest a poverty of imagination, I'd just buy a Ferrari 458 Italia and spend the rest of my life learning how to drive it well. .... and so that I'd have a place to do that, I'd buy Bridgehampton (It's in such a nice neighborhood).

-

In the 60s I worked at a very hip shop that sold Ducatis (and Norton, Guzzi, Triumph, and BMW). I hung with a guy who was very into Ducatis and had one of my own - a Diana Mk III (5-speed, Red cam) which I tricked out a lot. Friend pursued his passion and, in '71, rode the very first 750 Ducati twin (direct ancestor of the above) in the US from Cincy to Richmond KY, where I was going to grad school. I got to take it out some 20 or so miles from Richmond to Paint Lick and back. Can you say "Country road twisties?" After years on a very quick and super agile single it was a revelation. I think when I die that experience will be fresh in my mind.

-

Certainly is a pretty flashy weapon, but if you're really interested in getting your target with a minimum of work - http://www.physorg.com/news/2010-12-deploys-game-changer-weapon-afghanistan.html

-

Next time I pay my taxes I'll feel proud of what I'm supporting. What an incredible accomplishment.

-

Think I'd have to spend the rest of my life and then some studying history and political "science" to even begin to understand what it's like playing in that arena.

-

Spend some time staring at your tables and thinking about what the state of things is when youre in a range where there is backfiring. At each cell where theres no load/off throttle and revs are maybe 2500 and below, turn off the fuel - also you can advance spark (the leaner the mix, the longer it takes to burn). As it becomes clear to you, you should eventually have a large patch in your tables like this. The point of "max volumetric efficiency" is where you run the least advance, cause thats where a cylinder has the greatest amount of oxygen in it, and THAT allows you to run the greatest amt of fuel --- and that mixture burns faster than anything leaner, which is why thats where your engine makes its highest torque. Properly done, you can make it so that, when youre off throttle, it feels like the engine has died - yet a touch of the throttle gives you instant response. It erie feeling. Ask S1Steve about this behavior. BUT it takes a while to get all the ducks lined up. Good tuning.

-

Pretty impressive on what, to me is an unwieldly piece of equipment. But more akin to what a Seven driver might relate to, see what's out there under "observed trials".

-

Now THAT's (Guinnes) obscene! A dirty mind is a joy forever!

-

Doesn't the property of "progressive breakaway" necessarily diminish as the stickyness of the tire increases?

-

That kind of thing is why people become physicists.

-

If you 're modifying steering, Woodward Precision Power Steering has very useful info on dimensioning a rack, Ackermann, and bump steer - all written up in the on-line catalog. Carroll Smith explains bump-steer adjustments very clearly. However, even though all is well written, getting to the point where you understand what to do is pretty heavy going.

-

I think that's what you call "having a good nervous system".

-

Try http://www.trailerplans.com. this gives a selection of types/configurations, and the step by step plans are done by a PE (an engineer who's certifiied), so what you construct is not likely to fail from some sort of structural weakness.