-

Posts

426 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by JohnK

-

"Don't mean to hijack thread (though we are talking about footwells too);" Let me offer that this as information "of general interest": for those building a non-Caterham Se7en it provides some examples on what they might consider, and for those with ur-Se7ens to better understand better that Caterham's been doing some thinking as they updated their models over the years. "John, you have floor mounted pedals so it looks like your footwell black box just needs sealing around the bottom of it." The "hump", as I've heard it called, fits the hang-down pedal assy OK and I used it as-delivered. Fitting the pedal assy is separate from the issues of connecting electrics to the engine and the cable to the throttle. In order to get a reasonable seal I had to add glass to the front of it and build up what it sits on just fwd of the dash. Even so, it was necessary to fill some space due to irregularities and flex, which was done well enough with the 1" urethane foam I found at MSC. From the left, you can see the extension on the front and the strap used to secure it. http://dl.dropbox.com/u/49212285/AnnouncementShots/Heat/h1_Hump_in_place.JPG http://dl.dropbox.com/u/49212285/AnnouncementShots/Heat/h1a_HumpFit_gaps.JPG shows the size of one irregularity filled in and one gap I gave up on, which turned out to be not a problem (so far). Note at the far right I used treated wood to give the lip better support. "What did you do for the throttle cable and are there any other wires/tubes penetrating the black box? . . . Plus the other side of the black footwell box." http://dl.dropbox.com/u/49212285/AnnouncementShots/Heat/h2_Hump_in_place_RightSide.JPG shows all the traffic that runs through the hump. The lowest is the wiring to the rear of the car (lights, fuel gauge sensor and fuel pump power inside Flexo sheathing), the grommet is the engine wiring harness, and the other thing is the throttle cable (Honda, re made from a piece from salvage yard). With some dremel work and a bit more glass I put an opening in that captures the stock grommet giving a perfect seal. The gap at the bottom I gave up on and just stuff with paper towel which seems to work fine beyond being tacky. The single wiring harness connection: based to lots of bad past experiences with wiring and associated problems getting such systems to work without gremlins, I duplicated the Honda schematic exactly as per the Helms manual. The benefit of this is that when removing the engine, all the connections unplug making maintenance a lot simpler. See http://dl.dropbox.com/u/49212285/AnnouncementShots/Heat/h3_UnderHump_ECU_Wiring.JPG Oops! I now see that I routed dash the and the stock ignition switch connections through gaps I cut in the wood hump seat, avoiding extra ports in the hump. "I'd like to see pics around the radiator.I still don't see how it seals between the radiator and the hood itself." Work was inspired, as usual, by Carroll Smith. He gives a very nice explanation of what needs to be accomplished. Paul Snyder also helped pointing out the need for chin sheeting, which makes perfect sense because that's clearly a high pressure area. Smith talks about nozzle and augmenter. The work at the nose was a bit tedious but came out well. Made cardboard pieces and fitted them through the front supported by the radiator since the sheeting, in order to seal properly, sits on the radiator tanks. Given this I could tape the cardboard in place and mark where it intersected with the hood. Then I could figure out how to put the supporting brackets on the hood to which I could attach the sheeting. Given the area between the brackets and the hood, and that GE 100% plumbing silicone is good for 4-500 degrees F this should live a long life and allow me to fix the sheeting if it gets hit by something. With respect to the radiator's top and bottom, I siliconed some tabs on the top of the radiator to seal that part off, and did the bottom with just the urethane foam on the hood. http://dl.dropbox.com/u/49212285/AnnouncementShots/Heat/Ra1_Radiator_sealing.JPG http://dl.dropbox.com/u/49212285/AnnouncementShots/Heat/Ra2_Radiator_sealing_Left.JPG http://dl.dropbox.com/u/49212285/AnnouncementShots/Heat/Ra3_Radiator_sealing_right.JPG Also related to getting flow through the radiator and only the radiator, I put sheeting on the chin so that the flow has to continue for some distance through this area before it dumps out the side port and below the engine. The whole thing is secure because early on in the build I made proper mounts for the radiator. Reid supply handles some really nice and importantly strong shock absorbing mounts called Barry Bond mounts - they rely on rubber trapped in compression such that, even if the rubber is destroyed, the two pieces don't come apart. I welded stout tabs on the chassis and fabricated strong mounts to connect the radiator to these tabs. The time I spent on this paid off since it required me to position the radiator in the most optimal position with respect to the hood. So I not only gained a radiator secured by mounts that were designed to bear its mass but was also solidly positioned and placed with the greatest amount of clearance possible. Hence my sheeting won't be destroyed by a flopping-around radiator. http://dl.dropbox.com/u/49212285/AnnouncementShots/Heat/Ra4_Radiator_mounting.JPG "I do have a vent similar to yours on the driver's side but it's not nearly enough. Perhaps you can start another thread for S2K heat abatement..." Planning on a NACA duct tucked behind the headers. Will post it when I get to it, and hopefully will find another solution or two to go along with it. If I get my nerve up I'll measure the underhood temp just behind the dash to have a reference value. I find that going through an explanation of all this is valuable - it allows me to rethink the work and verify that my design actually makes sense in retrospect (and, of course, expose my thinking and work to anyone who cares to point out how badly I've managed to screw things up! ;-) ).

-

Exhaust sealing stuff: wurth makes an exh joint sealer thats held up well in the 500 miles I've put on it so far - no puttering, hissing sounds that I can detect. Also Flexbar handles a refractory cement that, together with crimp -on band clamps, is holding up on the header-cyl head flange where it's keeping the exh wrap secured.

-

Mondo, I'll get you some pictures.

-

"I was thinking of an opening at the rear of the hood bulge... or a couple vents on the flat portions of the hood (to the sides/rear of bulge) to let the hot air out." I can't convince myself that cutting any openings in the hood wouldn't weaken it, though I'd like to - once I did some work to ensure that where I wanted to cut was a low-pressure area. And then maybe figuring a way of reinforcing the area. I have slackened the side hood hold-downs so there's a bit of a gap between the hood and side panels, and cut some gaps in the wool felt I have where the hood and dash seat - but haven't seen much difference. The gap between the dash and the lower chassis tube dumps heat in my lap. (For those unfamiliar with the S2K, it has no scuttle/firewall - the instruments stick right into the engine bay and all of its heat.) I am seriously planning on finding a grill of some sort - like from a production car's AC system - that seals well and punching a hole in the dashboard. Since I've managed to get through life without acquiring a partner of any kind, blasting a passenger in the face with hot air isn't an issue :-) . Don't know if there's enough space to do the thing shown in the Westfield, and while I think that this is a really nice solution, it doesn't address the exhausting of engine heat from the headers and block and all. See attached AirBox_spaceOccupied.JPG for a space reference re the Westfld solution vs the S2K. Myself, I'd be worried about compromising the integrity of the bonnet were I to add the Westfld/Caterham type vents there. Radiator seal: look at i_Front_right_Low-angle in my set of pics - To either side of the radiator are panels that are mounted on the hood with tabs so the panels can be removed. And also see the attachment NACA_duct-NosePanels which shows the back of those panels and one sealing tab at the top of the radiator. If you want to tackle this job let me know and I'll take some more pictures. When the rad fan comes on, there's quite a bit of air that blows out of the NACA duct. Footwell: Attachments Footwell* and HumpPositioning give an idea of how a person in need of a good 12-step program approaches sealing up the footwell. E.g. if you look you can see bits of a kind of heat-sealing gasket assy I made which traps some polyester felt where the secondary steering column goes through the footwell in order to seal that area up. Also, Lowe's or Home Despot GE plumbing Silicone is good for 400 degrees F and not that expensive - a real bargain. Other insulation came from Summit. They carry a good selection of different types and spell out appropriate uses well. What's not shown in the pic is some 1" thick urethane foam I got from MSC that I put underneath the polyester felt (white at base of hump) that's between the hump and the chassis, and I used a strap with D-rings to hold the hump down. This, especially the urethane, seals up the footwell quite effectively. Also, my wiring harness came with its master grommet intact and I was able to fit it to the hump for a good seal there too. Let me know if you want detail pics of this. Every time I get bummed out trying to construct something that makes the car work like it should I step over an look at my 18 year-old Civic for inspiration. Amazing what you can do with visionary planners and a crew of well trained designers and engineers (and 20 or so years of development)!

-

Your alien might have been a Locust - like a 17-year type, but I think they're white on the inside (full of fat). I'll bet a local college teacher whose area is entomology could ID it for you given the locale, the size and the more obvious bits in the splat. I was on my Ducati years ago and caught a June bug square in the forehead between my goggles and helmet and which, at 60 MPH, made me glad my clip-ons and lean-fwd riding position kept me on the bike . Then later, talking to a biker, he said he was truckin along on his chopper and caught a crow square on his chest - at least he thought it most probably was a crow - said he found himself sliding along on the ground taken clean off his bike with blood and feathers all over his chest (no sissy bar of course).

-

Under-hood heat is a problem. Knowing this beforehand I did a lot of work to eliminate it and succeeded mostly, but I'm concerned that the temperature inside the engine bay is going to shorten the life of the electrical components. Insulation is a good way to protect things, but I think getting the heat OUT of the car is the key and there's not a simple way to do that. Wrapping the exhaust does that, A reverse-NACA duct I put on one panel does dump a lot of heat out of the car, but it could use another on the other side just behind the headers (and making and fitting these is a LOT of work). Someone wrote that Caterham & Birkin louvers on the top rear of the bonnet happen to be in a high pressure area, so while they look like they'd vent really well, they don't. One thing I did which helped the ENGINE was to seal up the area in the nose so that all the air hitting the front of the car goes through the radiator and only the radiator. At Paul Snyder's direction I also covered the chin of the car with sheet that routes the air flow at the nose even better - and out the reverse NACA duct. Details, and you can see http://www.usa7s.com/vb/showthread.php?t=7421: I covered with insulation all the walls in the engine bay, the tunnel, wrapped the exhaust and put a reverse NACA duct on one side of the body (and planning on doing the other side), put some gaps in the joint between the dash and the bonnet. My feet don't get even warm but there's a lot of heat being dumped in my lap. All this tells me it's really hot on the other side of the dash. In my car the bonnet is fiberglass and punching a hole in it would probably weaken it considerably.

-

A serious solution: http://vibrantperformance.com/catalog/index.php?cPath=1022_1125 Also, for shock absorption: http://vibrantperformance.com/catalog/index.php?cPath=1022_1064 Nice selection of bits: http://vibrantperformance.com/catalog/index.php?cPath=1022 These are an amateur fabricators things of beauty :-)

-

A caution - the quicker the steering, the greater the effort req'd, and the more critical the caster setting. Less caster gives you lighter steering effort but at the cost of less directional stability, i.e., more attention is req'd to keep the car going straight on the highway.

-

Mike, A suggestion: Based on years of dealing with people with grossly exaggerated opinions of their talents, and especially people who had years of experience - at turning out bad work and getting away with it, I've found a few outfits I feel comfortable dealing with when I need work done. One of those, which would be at the top of my list, is Zakira's Garage a mile up the street from me (272-2229). These folk have a breath of experience I can't even begin to describe and if you can get on the same page with them, they'll be a very valuable resource. They are extremely competent in terms of turning out good work, and most importantly knowing how to proceed in figuring out what the work that needs to be done is before undertaking it. If you stop by the shop, be prepared for the shock. It's like stepping behind the scenes at the Smithsonian. Best of luck.

-

NPR's All Things Considered did a nice obit. Even mentioning that Peter Brock (at 23!) was the person responsible for the streamlined and tradition-breaking coupe that allowed Shelby to go lots faster than the 250 Ferrari that had been eating the Cobra's lunch, and that Shelby won the Manufacturer's Championship via that piece of work by Brock. Talked with Brock for some time about the engine tuning and theory-practice concerning work I was doing at a shop once several years ago - my task was an aluminum big block 427 shoehorned into a one-off aluminum-bodied Superformance Cobra. A pretty historically interesting combination. At the time I didn't know who he was or what his accomplishments were. He was a very pleasant person. I learned later from an, as usual, excellent article on Peter Brock in Automobile of the contentiousness of Shelby - as noted by the fact that others refer to the "Brock Coupe" while Shelby named it the "Daytona Coupe". Still, any guy who makes such a splash in the industry has to be someone you just never stand in the way of, or expect to stop and listen, much less tending toward social niceties.

-

Squish? As in modeling clay between head and piston to measure clearance at TDC?

-

Try the "Ithaca Lemonade" approach/philosophy - if you have the patience and the money.

-

Getting on to reality, of which I have hardcopy evidence... I spent 10 years doing design and implementation IT work for a "large consumer products corporation headquartered in Cincinnati". One very cold and gloomy day in February 1991 I and 65 other companies that did similar sorts of work for said company got a letter which said "We have decided not to do business with small vendors anymore. Thank you for your past service. Goodbye." I, behind the scenes, let the Enquirer know about this in some detail and, stepping out of the picture, they got an accurate and informative article about the consequences of the company's decision from the information I passed to them. My neighbor owned and ran a construction company. As anyone in small business,especially one that provides service in a seasonal market knows, you need a line of credit to conduct such a business. Stopping by for his yearly loan, my neighbor got told by his bank that they had redefined their criteria for the clients they wanted to do business and he didn't fit. And his business winked out of existence just like the 66 above. I packed up my stuff, went elsewhere and did other things. My neighbor, unfortunately, took it personally and became real bitter. Both companies exercised, what in their judgement, was the best path forward for their success in the marketplace. Now Capitalism is absolutely the most successful economic system - period. However, like any economic system it comes with a collection of bad properties. There are lots of modification that have been made to capitalism as it's done in the US to make it less awful, but sometimes, it's still just awful.

-

Take some solace in that you weren't the one who put the thing together and can pay someone else to deal with the headaches of fixing it. If you built it, then you likely know what the problem might be and suffer the prospect of having to do all that work yourself. And of course, there's no one else to blame.

-

Klasik-69: Even with an exceptional welding machine (way better than I deserve), I'm probably going to do mechanical joining with some sort of sealant. There's so little space and the alignment issues are so critical that the warping you get working with sheet will likely nix anything I'm capable of fabricating. xflow7: apparently some mfg's make a product support line available, but don't bother making sure that those folk give out correct information. They've certainly lost a customer for life over the matter, in spite of the fact that lots of their stuff is good. I've talked to 3M support several times and have gotten engineers, and they've given me lots of their time and made sure I knew what I was working with. In spite of the fact that 3M stuff in general is expensive, it's nowhere near as expensive as all the work I'm going to have to go through as a result of Devcon's misinformation. 1turbofocus: I have now ! :-) Thanks for the link. I chose this route because this car's been an excuse to learn how to do a bunch of development stuff that I'd been turned onto over the years. Fuel cells really do make sense and I'll probably go that route when (if) I get to enjoy the thing on a track. They are a bit expensive and it'll be work finding one that will fit. I'd write a book about my experiences, but Carroll Smith's already done that for all of us. Thanks all.

-

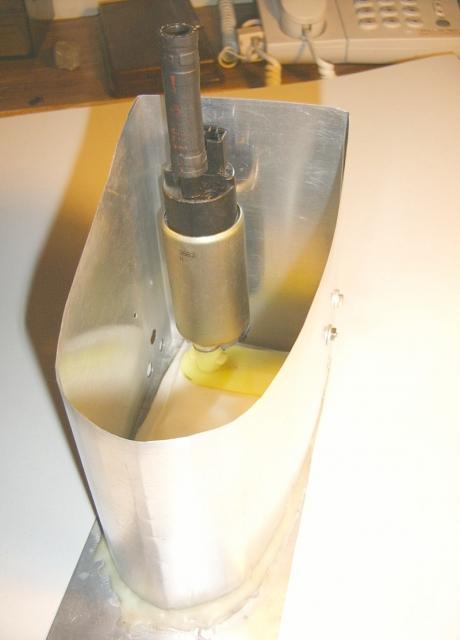

Early on in my build I designed a sump with check valves in it to retain maybe a couple of pints or so of fuel when the fuel level was low and I was cornering. The in-tank pump fitted in the sump and the return line from the fuel rail emptied into the sump. Working with sheet aluminum and having not yet decided to buy my TIG welder, I searched around for a good epoxy to hold the sump together. Devcon assured me that their HP250 High Performance Adhesive would live quite happily under gasoline. I used their mixing nozzle with their cartridge delivery system to ensure proper proportions and mixing. Several years later and finally on the road, things seemed fine, but after tossing the car around a bit and getting to 1/4 tank, it became obvious that the sump wasn't working like I'd hoped. Then, even with a full tank, it began losing pressure sporadically when pulling away from a full stop. Pulling things apart I found that Devcon had lied. The sump parts were all apart, though held in place by the tank foam. I'd put some of their epoxy around the electrics, and as it swelled it may have pulled things apart electrically somehow - not clear at this point exactly how this interrupted its operation, if indeed it did. The Deutsch bulkhead connector seems fine and disassembled with no problems once I cut away the dead epoxy, but I'm going to have Deutsch verify that this application is OK, and perhaps search for a heavier duty solution. And of course, get my welder out and put the sump sheet aluminum together properly. Beware manufacturer's claims!

-

And M Wirth. As I said, size availability is my attraction to NT01s and I should have added that Kitcat, speaking of his experience with RA1s, posted his own experience indicating that "death by cold temperature" didn't occur as predicted by the mfg's warning and that they improved with age, not showing the related "death by heat cycling". I remember someone saying that the NT01s are heavy, but heavier than the RA1s? Anyway, sounds like the NT01s are a pretty safe bet if you want to either swap out the Falkens on your Ultralite, or save some money, or even both! :-)

-

Perhaps. There are enough bits in your reply that map back to what ShiftMaster gave us and what I learned disassembling EEC code looking for the injector vector and MAF table definition, for me to consider that you just might be a perfectly capable tuner. I also realize that figuring out all of this stuff and getting it to work is one thing, but having the technical writing skills to produce a concise description of the work is another, as are the social skills to deal with skepticism. When huge claims are made by a tuner, anyone who has a serious investment in their car can only be expected to be pretty skeptical - being able to answer skeptics is just one part of the job.

-

Hmmm. While Ive not been paying attention to latest EEC configuration, I'd be surprised to learn that they've changed the architecture that fundamentally (although I have heard recently that the turbos use Speed Density because MAF is too difficult to program for the behavior of turbo lag). The real plus of the Ford system has been that it's a parameter-driven algorithm, rather than a table-dependent lookup system. If you modified your Ford, all you had to do was change the values (e.g., in the case of the injector size) or the characteristic table (e.g., in the case of the MAF) in the EEC once you figured out the configuration that you thought would work and the algorithm had the proper values to control the new pieces (of course you had to dis-assemble the code and figure out where everything was specified, and have a means of changing it). But if the algorithm thinks it's feeding fuel through one rate of injector and turns out to be controlling those of another rate not to mention breathing through a different sized MAF, it's hard to imagine it could work at all. Perhaps they figured out how to take "adaptive" to the point where the injector size is not specified? But I'd expect more noise from the EEC folk, not to mention other turner communities, if Ford came up with a completely automatic control mechanism - providing a self-tuning engine.

-

1turbofocus, So there's enough headroom with the stock injectors' #/hour rate for the EEC algorithm to work OK?

-

RA1s don't come in the sizes I'd like, but NT01s do. So the question is, are these two really equivalent, or are the Nitto's just thought to be the same compound. Discount Tire Direct handles Nittos and said specifically they don't handle Toyos 'cause Toyo owns Nitto and there are marketing issues.

-

Amen. There are mechanical issues re marrying parts and then, assuming you have an after market ECU, finding a shop that can deal with a non-standard engine configuration. There's a shortage of folk out there who actually understand what they're doing and it can get really expensive.

-

And THIS is the reason someone like me takes up a life of crime. Pure lust.

-

Steve, and other Superformance S1 owners out there, Mallock, or the guy who builds Mallocks, figured out how to get both the alignment advantages of a live rear axle (tires stay perpendicular to road with no scrub when cornering) and the load transfer advantages of an IRS with parallel A arms (both inside and outside rear wheels have similar traction) when he came up with a linkage that puts the rear roll center very close to the ground rather than at the center of the diff. Superformance implemented his design in their S1. Allan Staniforth shows this in his Competition Car Suspension.

-

Oh heck - I should have initially given a more complete description of what I meant. I was attempting a joke, and my joke was close to the truth! There isn't an "L" sound in the Japanese, Korean, ... languages and when non-native speakers attempt it, it typically comes out as an "R" sound. So instead of my joke of a Japanese Client generating "Rotus" from a mispronunciation of "Lotus", it was a client making a joke, corrupting "Lotus" using the commonly-known the cross-language mispronunciation. And on top of it all, lots of people, not remembering that the name of the rotary engine known as the Wankel, get by calling in a Rotary (Lotus with a Wankel becoming "Rotus"), certainly not knowing that it is of neither Japanese nor English invention. Bizarre.