-

Posts

147 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by anduril3019

-

Sorry if I missed this part of the discussion, but which tubes are we talking about here, and how are they being accessed? If doing repairs or building from scratch, there is access, but on a finished frame there aren't any open ended tubes. Are holes being drilled then capped? Are rivet holes being used? If spraying through small holes, it doesn't seem like you'd actually be getting good coverage on the interior.

-

Sent you a DM

-

Interesting. Mine does have longer runners, not sure if it's an issue or not. I've also seen the center support cutout. DCOE slides right on the studs, no problem.

-

I've got one that I think is correct, but I'm not 100% sure. The person I got it from said it was from a 2L pinto, but I think it's from a 1600 X-Flow. From what I can find online, the Pinto has 2 bolts between the center ports, this has 1. A few measurements are below. If anyone else knows how to positively ID it, let me know. The 2 outside mounting holes are at 14 7/16" Runner spacing is 3 7/8", 3 5/8", 3 7/8"

-

Here are a few other sources: https://www.merlinmotorsport.co.uk/s/suspension-steering/alloy-hubs-and-bearings/alloy-hubs https://www.spitbits.com/store/ALUMINUM-FRONT-HUB-P6467.aspx

-

If you are going to blast the valve cover, make sure the interior is sealed with plywood or something. The media, especially glass or sand, can embed in the aluminum and later be released from heat and oil. Nasty stuff you don't want circulating in your engine.

-

For anyone who was doubting the authenticity, now it's confirmed as a "Super" 7!

-

I’ll 2nd that. I was going to ask the same thing! Looks like a coffee can lid or something like that.

-

The screen name is a Lord of the Rings reference. Anduril, or The Flame of the West, is the sword wielded by Aragorn in The Return of the King. A fitting name for a defense company.

-

Elan wheels with hubcaps is a good look on an S2. My original post said 4" PCD for Triumph, corrected to 3 3/4" which is what your Standard axle and Elan wheels should be.

-

Those wheels look like Ford Anglia, or early Cortina. But the chassis is too early for a Ford rear axle, and the front drum brakes are going to be Triumph PCD, which is 3 3/4", and typical for Lotus. Ford PCD is 4 1/4". Steel wheels in either PCD are not too hard to find, I've even seen steel Lotus wheels for sale occasionally. But you'll need to decide what to do at both ends depending on the parts you have and what direction you want to go. Keep the drum brakes, or upgrade to period discs? Keep the Triumph front hubs and use a Triumph rear axle? A few more variations you could go with. Here's a '69 Cortina GT wheel for comparison, slightly wider, but not by much! (4 1/2" I think)

-

Yes, good advice! I haven't yet decided if I want to go with a concentric. For those with concentrics, any recommendations for or against various brands or models?

-

Jumping ahead a little... Frame core is tacked up, but I've been avoiding the curved pieces: dash hoop, cockpit sides, and rear hoops. I shopped around a little, thinking I could get a local shop to do them, but had a hard time finding someone who would bend just a few tubes, and do it for an unreasonably low cost (Locost?). So, I used a cheapo pipe bender from eBay, along with my own super precision bending fixtures . It worked out surprisingly well, I'm happy with it. Took a few tries to figure out the amount of spring-back. I tried to get the rear hoops and dash hoop each bent as one piece, but couldn't quite nail the width without burning through too much tube stock through trial and error, so I finally settled for a 2 piece dash hoop and 3 piece rear hoops. I was striving for a nice elegant arch to the dash, and the top rear hoop is gently curved in profile to blend with the cockpit sides.

-

You're partially right. Things are further along than the current posts suggest, but still a long way from completion. I started the thread retroactively and am playing catch-up to current status. And now back to our regularly scheduled program...

-

It's MIG. I don't have access to a TIG, so may braze (without a gas fluxer) some smaller items that may be hard for me to MIG, like tabs and brackets. I'll see how the MIG goes on smaller stuff.

-

I actually considered the RX7 axle and almost bought one I found on Craigslist. In the end, I did have access to a Cortina axle, and wanted to stick with the Ford bolt pattern.

-

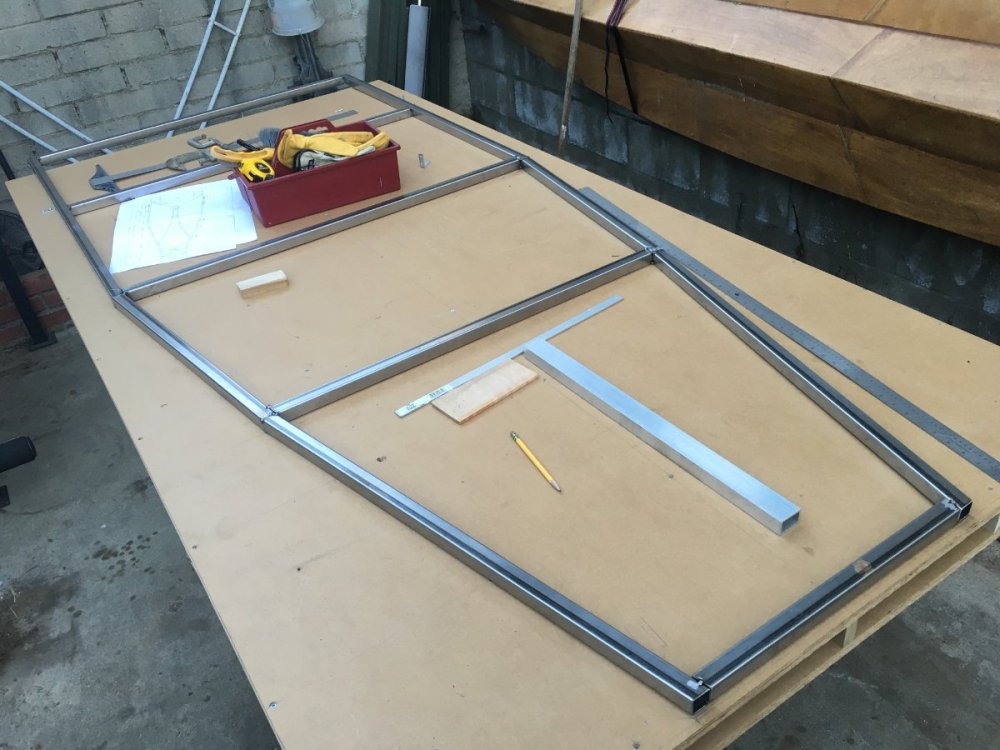

Build Table and First Tubes Table is built from 3/4" MDO and 1 x 2 poplar ribs. It lives outside, the MDO has held up surprisingly well and the surface is nice to work on. Not much rain to worry about in California, but it did get caught uncovered in a couple of storms and still remained flat through the crucial build stages. It's about 2 years old now and has about an 1/8" droop over its length, but is still usable as a level work surface. On hindsight, I'd make the section taller, but it's worked well as is. After a lot of planning, the first few tubes have gone in place.

-

I'm interested if you're selling. Sent you a message.

-

Well, I was more like a serf in the Kingdom of Bean. But, to be fair, he was a benevolent monarch.

-

Thanks for the tip! I've spent a bit of time there and locostusa.com, as well as some of the UK sites. I'm playing catch-up on the build log here, I'm actually quite a bit further along than my posts imply. Chassis is pretty complete and tack welded. Currently finishing up welding and moving on to suspension pick-up points. Should have posts caught up over the next few weeks.

-

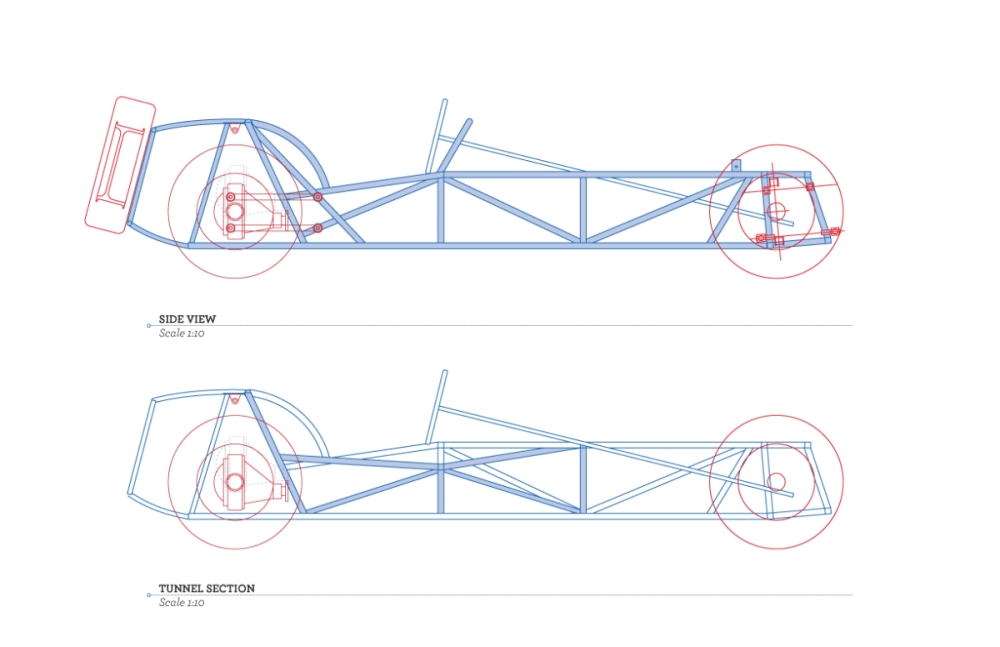

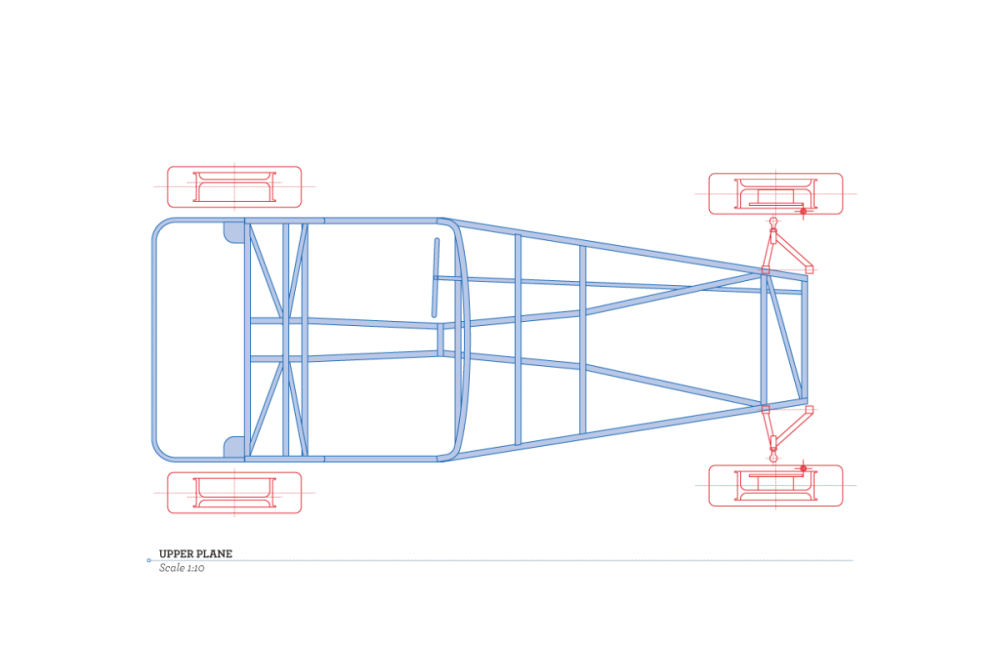

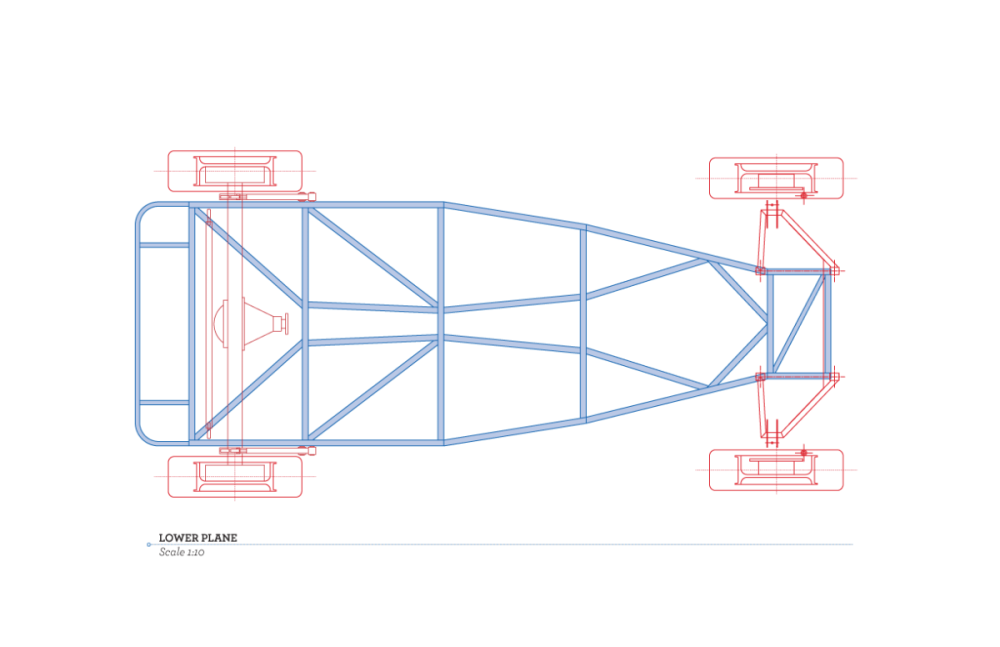

Design intent is for a somewhat traditional build, styled similar to Series 2/3 Sevens from the mid to late 60s. Engine: Cortina pre crossflow, tuned as budget allows. Mainly want to get it on the road! Transmission: Cortina or Pinto 4 speed, standard ratios. Have both, not sure which I'll use yet. Front Suspension: Triumph uprights, Lotus lower wishbones, custom upper wishbones, anti-roll bar, Triumph steering rack. (Wishbones courtesy of Xtra Special Sevens) Rear Suspension: Cortina axle, trailing arms, Panhard bar. Wheels/Tires: Cortina GT, steel, 13 x 4.5, 175/70-13. Frame design is a hybrid of the plans, mods, and specs floating around online. Stretched a little so I can fit "comfortably."

-

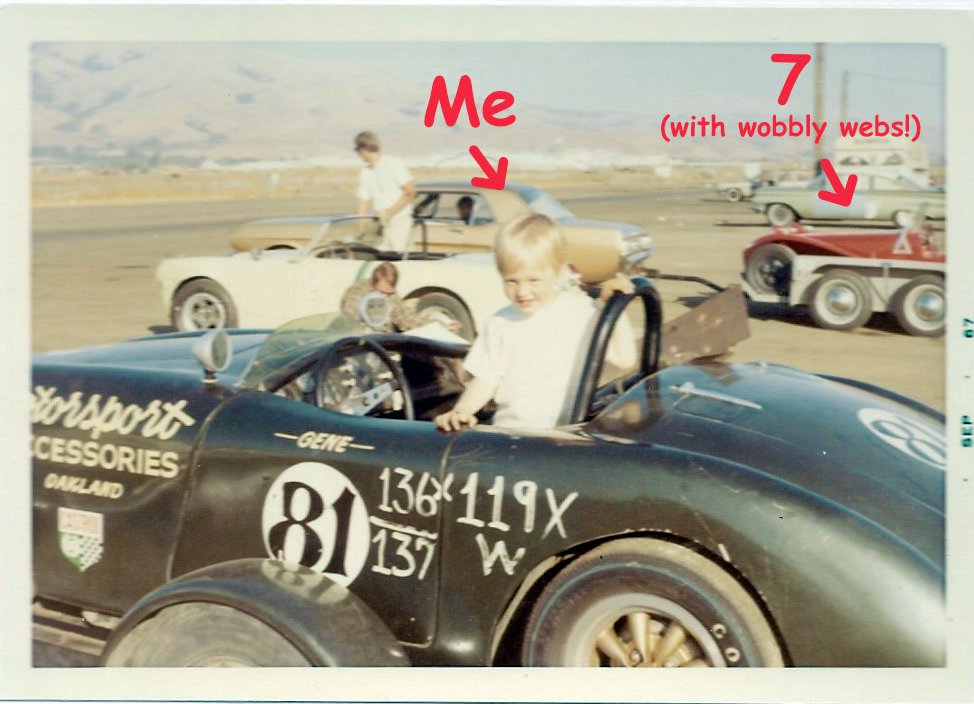

I think he passed those math skills on to me. I started an engineering degree but gave up on the math pretty quick. 81 times 136 divided by 137 times 119x over W equals... Multiple drivers sharing a car for SCCA driver school.

-

Ha! Yeah, looking at the photos, it is definitely the tiny Turner. Not to be confused with Tina Turner.

-

I've been gleaning here for a long time, so time to start a build log. (Semi-parallel thread over at locostusa.com) Some quick history. My dad raced a Turner 950S in the late 60s early 70s, from when I was around 2 to 12 years old. The Turner was awesome and unique its class (sadly, it came to an untimely demise), but even as a kid, I couldn't help noticing these weird cars that I couldn't quite figure out always lurking in the background. To my young eyes they kind of looked like a formula car, kind of like an MG TD, kind of like a squished Model A, and they seemed to be everywhere! They looked fast, fun, and completely useless. I knew I would have to have one someday... Fast forward to college, I ended up getting into Cortinas by accident (literally by accident, but that's another story). That eventually led to me working for Dave Bean in Santa Barbara for a little while and firmly established my love for all things Lotus and English Ford. Still no 7, though) Fast forward another pile of years and jobs, and one of my kids wanted to spend the summer building a go-kart from scratch, not a race kart, just something to impress his friends and annoy the neighbors with. While building that, I taught him a little bit about 7s and some kit cars I was thinking about building "someday." Wise-guy that he is, he said, "Why someday?" After running through the excuses (work, family, money, time, space, priorities, etc.), we decided to just go for it. After all, we built a go-kart, right!? How hard could a 7 be? I can't find the thread, but not too long ago, someone was asking on one of the forums here whether they should build or buy. Someone answered that if you go the build route, be prepared for it to take about 10 years, and cost around $20,000. I've got to say, that's proving to be pretty accurate. It can certainly be done faster and cheaper, but I'm building to my taste and having fun in the process. A timeline goal is to get it done while my dad can still take it for a spin. It's going slow, due to work and a side business that's threatening to turn into a full-time gig (more excuses), so posts may be few and far between, but I'll keep them coming as I make progress. Special thanks to many here who have supplied parts for the project through sale, trade, and donation! You may see them turn up here and live again. Sorry for the long intro, actual build log coming soon!

-

ABC Fire extinguisher "corrosive problem" with aluminum

anduril3019 replied to Vovchandr's topic in General Tech

As stated above, it kind of comes down to priorities, especially with safety equipment. A roll bar's first purpose is to prevent/reduce injury in a roll over situation, If it can also be designed to increase chassis stiffness, great! A harness is also meant to first prevent/reduce injury in an accident, if it can also improve your driving by keeping you from flopping around, great! Likewise, a fire extinguisher/system has a primary purpose of extinguishing fire, preventing loss of life, preventing further property damage, preventing spreading of the fire, etc. If it can do all those things and be non-corrosive, great! So, just letting it burn kind of misses the bigger point I'd say, but he gets extra points for drama!