-

Posts

2,093 -

Joined

-

Last visited

Personal Information

-

Location

Houston

-

Interests

7s

-

Occupation

If I told you, I'd have to buy you a drink

-

Se7en

1996 Caterham Xflow Live Axle

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

IamScotticus started following The Passing of John Lodge , custom shift knob , Swan neck wing for Seven and 4 others

-

I'll give $20 + shipping

-

More sprung weight in the back is good. Watch the wear on those A arm bushes

-

Xflow full length Cats traditionally used a left wing that was made higher on the bottom edge to allow the exhaust to pass under. The only reason I'm going with a side tip now is because the replacement wing I have doesn't have the clearance. I would rather not cut a hole. We shall see how it goes. I may find ear muffs sufficient.

-

Thanks for onShape and send cut send. DRS is?

-

I see that. Another wheel reinvention I have is to run a 4-2 dual internal baffled straight pipes all the way back, or to two very narrow cigar glass packs and dual tips. It's not proper 7, its Shelby Daytona. but I would like that very much.

-

My problem with these can shape mufflers is if the lip is lower than the chassis one is at risk of it getting caught and ripping off. This is what happened to me. The muffler also took the rear fender (wing 🇬🇧) off. Stupid mistake I made I will try to not repeat with a can too low. Currently exploring motorcycle mufflers as many are smaller 1.75" for 1600 Xflow.

-

Is there a website for these Walkers?

-

I believe that is the intent. Signal is signal regardless of the application? Petrol guage is in the description. Funny, I discovered this menton on the L7C site from a poster who was giving everyone his plans for a breadboard DIY copy of the device because the Spiyda is too pricey. I was smart like that, once.

-

for miss-matching bits Spiyda Gauge Wizard https://spiyda.com/gauge-electronics/the-gauge-wizard.html

-

Tracsport T9 Semi Helical Gearskit Options

IamScotticus replied to PJJackson's topic in General Sevens Discussion

OP (Original Poster), you may be perfectly correct in your estimate, as this is a very small car. It shouldn't be difficult to locate a noise. But the diff is hard mounted to the frame and noise will be transmitted all through the car. Noise location can be tricky. I have a pickup that soon after new, developed what I was sure was a front end clunk. Thats exactly where the noise came from. Thank gawd for internet research. It was the rear bed U bolts on the leaf springs had slackened and loosened with break-in. It is a very common occurrence with trucks. Internet sleuthing will reveal that on a differential, worn pinion shaft bearings and loss of preload is a common cause of the noise you are have, when you have it. I only suggest this so you don't rule it out chasing something else. OP, It would be a major pita, but can you separate the diff enough to check the pinion for float? If this is measurable in situ, as well as oil level and condition? you should be able to leave the drive shaft connected. You may be able to leave the diff attached and try sliding the shaft with your hands. Any slack can be narrowed to u-joints or pinion end float. Then check for pinion float. The pinion bearing preload is something that can ease with time creating a slack that only makes noise from contact with the back side of the gears and bearings. I am not a professional mechanic, just an annoying amateur. -

I think Cat is backing the wrong Horse.

-

Tracsport T9 Semi Helical Gearskit Options

IamScotticus replied to PJJackson's topic in General Sevens Discussion

I've read a lot of love for the RedLine MTL. But are we sure it's the box and not the diff? A 1st gear job is something I'd like to do in my T9. Looking for kits on this side. Any offers? -

One of the best Texas registrations one can get with a 25+yo car is the "antique" plate. This allows 5 years between Renewals and no inspections. Its cheap too. The caviat is the car cannot be a daily or pleasure driver. The only permitted road driving is enroute to or from an exhibition like a car show or parade. I have been thinking that I could qualify for this because everywhere I stop becomes a car show. Any parking space is an exhibition. I'm a one car parade, everyone is gawking and taking pictures. Should I push my luck with the constabulary? It wouldn't be an issue if the registration weren't abused, but it is.

-

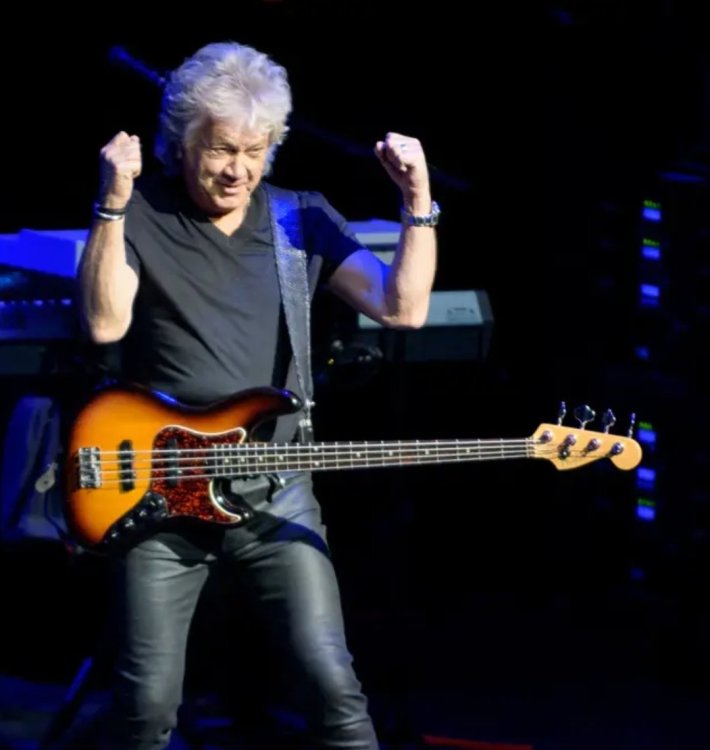

If Rock N Roll had a back bone, I think John Lodge would be one. Unwavering devotee of Buddy Holly and the Fender Precision bass that he never put down for another guitar, left us Oct 10, 2025 unceremoniously but peacefully In Naples Florida. Comming off of 20 dates in late 2024, straight into 33 dates in 2025 ending on Aug 7, you would think John, at 82, was just taking a rest. Never mind the raucous hits, Lodge penned and cut the best melodies of those Moody tunes. Hayward made great contributions, but Lodge, Pinder and Thomas brought on the Astral plains and psychedelics like nobody else but the Beatles and Hawkwind. A hard sell after the early 70s, all that hippie acid trip pixie dust would die off eventually. But it would be John's writing that would keep the Moodys on the radio into the 80s. A true 60s rock troubadour to the end. That's what I think anyway. A veteran cosmic rocker

-

- 2

-

-

-

Photo of your car you took today

IamScotticus replied to Xhilr8n's topic in General Sevens Discussion

Looks like the 1/24 Tamiya kit. Kudos to whoever got those guage decals on. It's difficult to get spray paint between the front flares and upper body. Almost have to hand paint. I haven’t seen one of those monkeys in years.