-

Posts

605 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by Klasik-69

-

Your friend in Austria could easily look up motors on ebay located in the USA. He could also request a shipping quote from those yards that ship on a crate. I would think it would be expensive but if that's the only source for a motor, what's the choice. Ford sells a race prepped 2.0 Liter engine for $5,200 less ECU or harness.

-

You bring up a good point about detonation. The engine and ECU does not have a spark knock sensor so the safety zone isn't there. I've been concerned about that. I burn 93 octane but that is still E10 fuel and thus a few points shy of true 93. I just took some fuel pump pressure readings and its rock steady at 60 psi, +- 2 psi up and down the rpm range. Also, I just got my synchrometer to syncronize the ITB's as required prior to further tuning. They're now dead even. My next move will be to hook up the computer to the Pectel T2 and hope that the system isn't locked. I understand about intellectural property and the need to protect one's tuning skills but it really pisses me off to have a system you purchased be beyond your ability to manipulate. I would never buy another ECU that doesn't allow me the flexibility to adjust as needed. If I have to ditch this one, I believe I'll go to the MSPNP. How is the AFR adjusted by the ECU ? Is it the duration of fuel injection or the timing of the fuel injection, or both ? If anyone knows who its accomplished, clue me in. I'm old school, carbs and distributors, hammer, screwdriver and channel locks, maybe a coat hanger and a hose clamp will make anything run enough to get you home. Now you need a computer science degree or have a 12 year old in the house :ack:

-

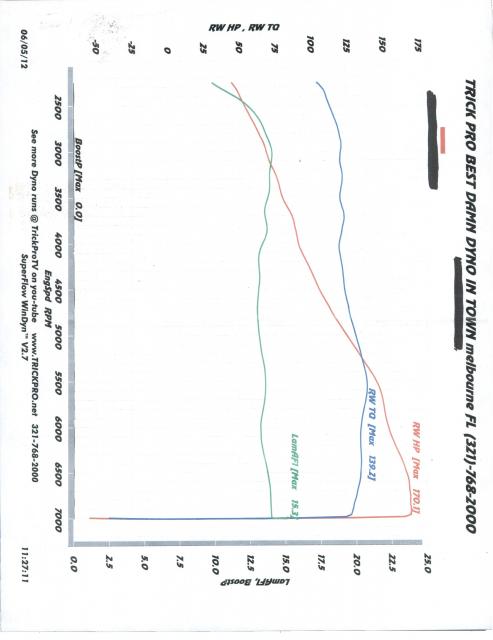

I just ran my 2003 R300 on the dyno to see where I was on power. The engine is the 2.0L Zetec with a claimed 202 crank HP. I tried to attach the dyno sheet on this but the site keeps claiming a database error. However, the dyno sheet shows an AFR reading of around 10.0 at 2500 rpm then climbing up to 14.0 at 3000 rpm, dropping off to around 13.4 with slight ups and downs all the way to 7000 rpm. Torque started at 105 @ 2500 rpm then climbs to around 139.2 @ 5500 rpm for a max. Horsepower at the rear wheels starts at 45 @ 2250 rpm and climbs to 170.1 @ 7000 rpm with a pretty linear climb. What do you guys think of the AFR ratios ? (sorry for the graph being sideways.........I tried to rotate it but wasn't successful)

-

Sorry I didn't get back with you sooner but its as glenntwincam stated. Mine is the Goodyear belt as well.

-

I have a spare belt for my Zetec and when I get over to my shop I'll look it up to give you the part number. It may or may not be the same as yours. Mine is an 04 Zetec motor prepared by Jon @ Caterham USA. Also, you may be aware that most belts have part numbers written on them. However, in the case of serpentine belts, the back of the belts usually ride on an idler pulley or the back of some other pulley which usually burns off the id markers.

-

California registration issues

Klasik-69 replied to WestTexasS2K's topic in General Sevens Discussion

With so many illegals in California, who would notice one itty bitty Lotus ?:rofl: I know, here in Florida, I think our "legal" population is a minority. One store had a sign in the front saying "Se Habla Everything". Good luck with the car. -

Cool article. I'm surprised that he was all that aware of the 7 due to his younger age. I think they gave the driver/writer credits backwards in picture #16 since you're driving and he's riding, and its a right hand drive car. No matter, very cool. You did a good job of promoting this little car.:hurray:

-

Listing was pulled as of this morning.

-

My 2004 Caterham is also somewhat of a pain but less than you encountered. The seat has to be removed to have access to the lap belts and anti-sub belts attachments. Seat rails have allen head bolts on top and nuts and washers underneath. I simply put the allen wrench into the bolt head and worked the nut underneath without issues. The issue I ran into is that the attachment plate for the Caterham belts have a 0.545" hole and most harness have a 0.375" or 0.435" hole to accomodate swivel mounting of the plate. So I had to remove the new harness attachment plates and drill them out, six of them per side. The lap belt attachment is a bolt into a threaded bushing welded to the frame. There isn't a nut to hold onto (Thank God). The anti-sub belts use a nut and bolt attachment and having long arms is a definite plus, or a friend who isn't doing anything at the time. Overall, the process of changing the belts to the new Racequip belts took about 3 hours from beginning to end. I went with Racequip since they have the smoothest camlock design and their belts are the best value. In comparison, the stock Caterham belts were adequate but I would rate them as minimal. Racequip uses 3" webbing for both the shoulder and lap belts, 2" for the anti-sub belts. They are also fexible enough to use with a Hans devise without the need to have them stitched back to a 2" size at the shoulder. And I really like the looks of the red harnesses in the black 7. I also ran into some SCCA issues with the stock Caterham roll bar and its rather minimal attachment so I welded another attachment plate towards the front that utilizes the outside most harness attachment bolt hole. It is very solid now.

-

I believe that most sending units have high resistance at 0 psi and lower resistance as the pressure rises. Good way to find out is to put an ohm meter on the oil pressure plug with the engine off, then start the engine to see where the resistance goes, if it moves at all. If the resistance doesn't move or change between the plug and the engine block (ground) you either have no oil pressure or you have a bad sender. Two bad senders ? I kind of doubt it but its possible. Have you put a mechanical gauge in there to see where you are on actual oil pressure ? I would do that first. You could easily test the sender off the car with a couple of air fittings and an air pressure gauge. Most oil sending units are 1/4 NPT or 3/8 NPT. Get a an appropriate sized tee, screw in your male QD in one branch, the sending unit in another and a gauge in the third tee. Check resistance to ground at 0 psi, then check resistance at 50 psi. Grounding issues can be between the motor and the chassis (doubtful) or the carbon fiber dash and the gauges (more likely). With an ohm meter, you can check the grounding by measuring the resistance between the metal body of the gauge and the car's chassis. If its open or high in resistance, you have a problem and need to fix that. Good luck.

-

Ride height and camber adjustments are two totally different things, although one will affect the other. You wouldn't change the ride height to correct the camber, or vice versa. If you have a Caterham suspension, you would unbolt the top ball joint attachment and separate the upper control arm from the spindle. Then you would screw in or out, depending on whether you want to add or remove negative camber, the ball joint at the control arm. Screwing it out will make the upper control arm longer thus adding positive camber. Do this with the car level from side to side, roll the car back and forth between ajustment to setttle the suspension, then check with a camber gauge to see where your are. Both sides need to be the same unless you're racing on a NASCAR track and always turning left. :bigear: Once you have adjusted the camber to where you want it, you will now need to reset the toe-in alignment since by changing the length of the upper control arm, you have effectively changed the toe. If you change the ride height, do that first before doing any of the other stuff. Any change you make will change other components of the suspension/alignment settings. I use digital levels to measure my camber adjustment and have set mine up for track use at around -2.5. This setting may not be very good for street use since it will wear the inside of the tire more than the outside. If I was setting up for street use only, I may start at around -0.8 and then monitor the tires for signs of uneven wear. On a track, we use a pyrometer to check tire temps outside, middle and inside. This tells us where the impact is from that track. For street use, using a pyrometer would be of little use. Good luck.

-

They may have not understood that their product would be immersed in gasoline all the time, and then again, with the use of ethanol now, the problem is no longer just plain gasoline. Alcohol has effects on plastic products that may not have been foreseen. You are correct, get out the welder and do it correctly. I think you have a good idea in building a fuel sump system to prevent fuel starvation.

-

First of all, I don't know squat about mapping out ECU's. However, doesn't it look like there is an anomoly in the 2500 rpm section of the map you show ? Why would the ignition timing drop to 2 degrees at 2500 rpm at 0.1 TPS or is this showing that there is a problem ? The other map from the DIYAutoTune is more progressive or linear. Perhaps I'm not understanding this.

-

How much difference is there between an imperial chassis and a metric chassis ? My R300 was built in 2004 and I assume to be an imperial chassis. Fasteners are US/imperial threads. Maybe there is no difference in the chassis, maybe only the dimension references changed from inch to mm..............don't really know.

-

That's funny and it seems to show a commonality of opinion of GT2/GT3 owners. A couple of years ago, my buddy and I were at Roebling Road with our 2007 Z06's for a track day. The Porsche club from Nashville, TN rolls in with some awesome trucks, trailers and of course, cars. I was amazed at the quality of their gear (read that jealous). We went out for the first 30 minute session. We were lined 2 x 2 on the false grid so I was beside one of the GT2 cars. I motioned a thumbs up to the driver on his car only to be looked at as if I was trailer trash. Ok, whatever. Well gloves were off after that, and my buddy and I lapped the GT2's and GT3's easily, several we lapped twice, and one I lapped three times in 25 minutes of running. Second session we were even more brutal. Then we broke for lunch. Ron and I went over to see their rigs and they refused to talk to us, pretended like we didn't exist. A bunch of rich guys with beautiful capable cars who can't drive worth a crap. You can't buy class.

-

This is the reply I received from John Bauer yesterday; Hi Mike, We do accept FIA certified roll cages. For cages meeting the GCR cage rules, the side protection rules are not optional. The car will have to comply with them. -John From what he says, I would deduce he means the FIA cage is fine but you have to add the side bars. I would also say any cage built by any shop here in the US that meets the GCR metal and fabrication requirements are SCCA compliant. It would have to pass tech and be issued a log book, and it would have to have the two side rails as described. The second rail on the side can only be above the "door line" since there's no room beneath it.

-

This is an interesting thread. I race a spec Miata and I'm going to run my Caterham R300 in the SEDIV SCCA timed trials events this year. I do spend a lot of time on the tracks, more than roads. Yes, the R300 is an ideal car that is well balanced and can carve like a scalpel. However, when I hit the straights at Sebring or Roebling, I wouldn't mind an additional 80 or 100 hp to keep ahead of every car I just passed on the twisties. And I know there is argument both ways, but I don't think there is a substitute for pure sheer speed, it gives me an adrenaline rush. So, I'd like a little button on the steering wheel that I can turn on at will for the extra power. Yeah, I hate seeing that GT3 coming back at me on the straight only to repeat the whole ordeal on the turns. However, I'd hate to ruin the balance of this fine auto. Can I have it both ways ? With my Z06 I'd hit 175 on the straight at Daytona before jamming on the brakes...talk about a thrill.

-

I just checked with Jon @ Catherham USA about roll cages. He said he had several available to order from, and if someone can wait until he gets his container shipment, the shipping charge isn't such a killer. Actually, I thought his price of $2100 fob Colorado was reasonable. They're available in the S3 and SV variants but Jon cautioned on saying they meet the SCCA GCR since this seems to vary from region to region and inspector to inspector. If someone is far away from Colorado like I am, the additional shipping charges for a bulky item like the cage can add another $200 or so. However, it will fit the car since its built for the car and to Caterham's specs. I also sent an email to John Bauer at the SCCA tech office in Topeka to see what his take is on the variance allowed for the 7's. John has been extremely helpful in the past and does take a very common sense approach to the implementation of the GCR, within limits of course.

-

I've been reading the GCR regarding the roll cages for GT and Production cars, section 9.4, and I don't see where they mandate that only a cage manufactured by the original car manufacturer and meets FIA is acceptable. In fact, they go to great lengths to describe how to build the cage in accordance to their minimum specifications and where variations apply, as in the case of Honda and Miata specifically. On GCR page 112 of the latest GCR, section 8 states that cages made by the manufacturer which are FIA homologated cages are acceptable. They don't say that ONLY THEIRS are, but more including them as well (9.4.G.8). I'm going to contact John Bauer at SCCA Tech department in Topeka and ask him specifically about the local manufacturing of roll cages for the Caterham to see what the HQ's view is on this. Wow, you figure around $500 for shipping. Too bad they can't just ship the tubes unwelded, shipping cost would be considerably less I would think. QC may be an issue and it would certainly not be FIA certified but maybe that doesn't matter.

-

I'd be interested to see what the freight bill is on the cage from England. I'd guess around $350. If my math is right, about $1600 (900 GBP) for the cage, so likely around $2000 plus duty fees. Then you have to either install it yourself or pay someone. Its only money !!

-

Do you guys ever work your way south or do you just do track events in the NE ?

-

I think the confusion starts with which car are we talking about ....the orginal Lotus 7 or the Caterhams, never mind the stalkers with their supercharged V6 or LSX V8 engines. Another guy driving in the SEDIV TT has a 1971 Lotus and is running in the SPU class, but he has a full roll cage. I'm not sure if its the original Lotus roll cage, in which case he may be grandfathered and only have to add the NASCAR bars (don't know how). Also, each division in the SCCA may have different sets of "local" rules. I talked to John Bauer at SCCA headquarters in Topeka, KS for guidance. He readily admitted that the Lotus/Caterham variations pose a problem because of the variety of power train combinations and the very limited size of the vehicle to make adhere to the standard safety rules. He told me there are some cases where individual appeals from racers were taken into consideration and a variance was granted, but it was a difficult process and not one he recommended.

-

One question.............how in the world do you get into the car with this cage ? I don't know about you but I'm no leprechan, 5-10 and 215 lbs. My 12 year old granddaughter might be able to crawl through those bars. For the record, the original Lotus with the 1.4 or 1.6 L engines may well qualify for E Modified class but the Caterhams won't with the 2.0 L or 2.3L engines. That is why they're being thrown into the SPU, which is Super Production and I think the U means unlimited but not absolutely sure on that. However, if you're in the SPU class, you need a full FIA/SCCA approved roll cage. That being said, unless you're a very small person and have a 28" waist, how much fun would it be to spend 30 minutes trying to crawl into the collosal mess of tubes, then have to call the fire department to cut you out of it. Not for me.

-

European racing doesn't follow SCCA rules but seem more into the FIA scheme of things. The SCCA seems to follow FIA procedures for safety, like seat belts, race suits, helmets, etc.

-

My GCR book doesn't show that regarding the 1.1lbs/cc but my book is 2010, and when I talked to John Bauer at SCCA, he never mentioned it either. He is very familiar with the Caterham R300 so its not like he doesn't know what I have. The ASP designation is not in the GCR, its in the Solo rule book. You know what this is all about, TOO MANY FRIGGIN RULES. If there is anything I really hate about the SCCA, its their rules. They have become like the government, bogged down with rules. We just want to have fun.