-

Posts

189 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by inchoate

-

Interesting... my speedo drive is on the right side.

-

Good call. The car is on blocks at the moment and it will get it's nose raised when I fill the coolant system. No big deal to bring the back end up for a little bit as well.

-

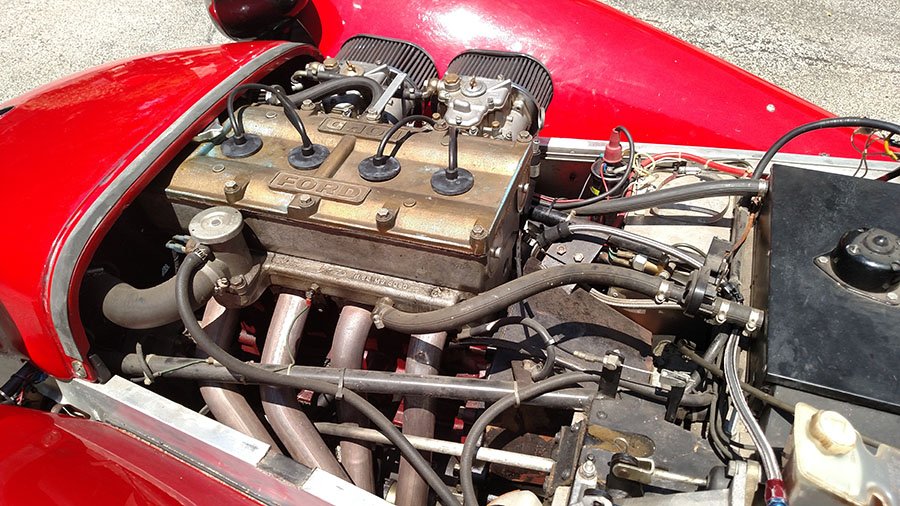

It's been a while but I thought I'd update things and maybe save someone some trouble in the future. I managed to solve all of my packaging issues and get an oil tank from Patterson that would fit. I put the Titan pan on for a final test and that's where the fun began. Turns out that my motor has a built bottom end and has ARP rod bolts. The dry sump pan is designed to work with the stock rod bolts and the longer ARP items foul the windage tray. The solution is, apparently, to machine down the heads of the ARP bolts until they clear. Not a big job but I noticed that there's a significant weight difference between the bolts before and after machining. I'm not sure that a the amount of weight would cause an issue but given the hassle involved in getting that motor rebuilt if something goes wrong I chickened out. The motor has always run really well so I'll assume whoever built it knew what they were doing. I paid someone an obscene amount of money to fix my wet sump pan and I'm putting everything back together. My plan is to drive the wheels off it and when it blows up and I have to get the motor rebuilt I'll do the whole dry sump thing when I can get the rotating assembly balanced. TLDR: Titan Kent block dry sump oil pan is incompatible with ARP rod bolts, check before you proceed.

-

I use VR1 mostly because that's what every BD specialist has told me to use. I also run it in some of my old bikes so double win. In the end use whatever you want, just change it when it needs to be changed and keep it topped up.

-

FWIW I have a standard roll bar and it's 12" high and more or less perpendicular to the chassis, it might lean back 1 or 2 degrees. maybe someone with a competition bar could chime in.

-

Wow, turns out I don't spell very well when I'm multitasking. Sorry about that. The transmission dumped most of it's oil out of the tailshaft when I pulled the motor and I sucked out everything I could get while it was on the bench. I guess once it's back together I'll drive around a little bit and see if it will take a little more, not a big deal to top it off.

-

I'm busy getting my engine back in my car and I went to refill my T9. Everything I've seen says it should take 1.9L of oil but I started to get oil out of the side plug hole after about 1.25L. Should I worry, or just get on with it?

-

interesting. my t9 was converted to hydraulic but every now and then i think about going back to the cable.

-

FWIW with a "standard" BDR mounting the oil fill cap lands right at the nosecone/hood interface. I don't have confirmation but I believe that the cam cover was factory (and I use the term loosely) modified to lower the filler cap to allow it to clear. Any reason you can't just use the stock cam cover?

-

I've got a long cockpit chassis so there's less room than usual. The tank was a bit of a battle but I'm pretty sure what I have will work. Won't know for sure until the engine is back in the car.

-

So, I'm pretty sure I'm the king of the morons. I spent all day screwing around with templates and such and didn't make much headway. After a lot of head scratching it turns out that all I needed to do is cut two 1/2" square notches in the original plate and it fits just fine. I'm not sure what I was seeing the other day but it was clearly wrong. I'm starting to think I need to take a week off from this car and get my head back in the game. Anyway, one problem solved but now I'm deeply worried about my oil tank clearing the air filters. Can't really figure that out until the engine is back in the car though.

-

yeah, the starter mounts to the bellhousing and retains the plate. The plate is only there to keep the larger rocks out of the bellhousing. making something out of CF would be very trick but I've got a piece of steel lying around and it'll be way cheaper and easier just to make something up and then beat on it until it fits. The car's been on blocks since early june and I'm getting itchy to get it back on the road.

-

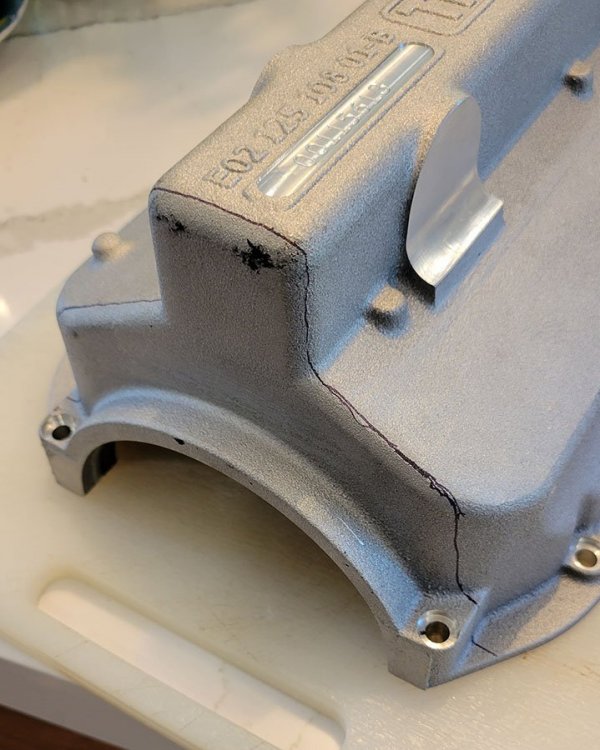

The black line is where the front of the bellhousing lands. Because the pan is cast it sits about 3/16" further back than the pan that came with the car. I've looked around but I can't find anything. It's sort of interesting because a BD motor with a T9 gearbox and a Titan dry sump can't be all that uncommon. As much as I'd prefer an off the shelf solution I'm pretty resigned to making one. In theory I could modify what I have but in this situation it's easier to start from scratch. I've got a friend who's a pretty good metal shaper so I might enlist his help and make something actually nice. No end of fun working on 7s.

-

My dry sump conversion is moving along "nicely", which is to say that I have all the pieces but fitting everything together in the space provided is an ongoing challenge. The big obstacle at the moment is that the Titan dry sump oil pan is fouling the original lower bellhousing cover. The current plan is to fab up a new one but before I get started I just thought I'd ask if a lower bellhousing cover that will clear a Titan pan is available somewhere.

-

good call on Sevens & Elans. Chris was able to hook me up with motor mounts and he also was able to get another thing I've been having trouble finding.

-

I'll watch this thread with interest. I've had a heck of a time finding BD folks in the states. My motor is good for now but I always worry about what I would do if it became a problem

-

Sevens & Elans?

-

I might be in the market for a pair of engine mounting rubbers for an S3 Caterham. Does anyone in the states stock these or do I need to go across the pond?

-

McMaster-Carr. I bought a bunch of them in different lengths years ago and I replace them when they start to look sketchy. There are probably cheaper options but McMaster is easy and I have confidence that they aren't going to sell me something defective.

-

-

That makes sense. I think the exploded diagram I have for the T9 is incomplete and so it wasn't entirely clear what was supposed to be going on. I'm tiptoeing on this one because I'd really rather not break anything.

-

I started preliminary removal and I have a stupid question. Should the output shaft of the transmission stay with the transmission or the u joint? mine looks like it's pulling out of the back of the transmission. My T9 service manual isn't much help as it covers service, not removal.

-

I've got a load leveler for my hoist and the car is on blocks about 18" off the ground. It never occurred to me to drop the engine out the bottom but that's a really good idea. I don't have a lift though, so maybe next time. I wasn't aware of the issues with the gearbox loosing it's oil through the tailshaft, so I'll prep for that.

-

I'm pulling the engine out of my Caterham later this week to do some work on it and the engine bay. Not my first time pulling an engine but it is my first time with a Caterham. Any general advice? I don't seem to have a lot of clearance in the front so I was going to pull the engine and transmission together unless I hear otherwise. The car is on stands so I have some space below for tilting etc.

-

Proper jets for Weber 45s on a Cosworth 2.0l YB Red top

inchoate replied to Jacques's topic in General Tech

It's probably worth giving the carbs a good cleaning before you start messing with jets etc. I don't know what gas is like where you are but ethanol is very hard on carbs.