-

Posts

644 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by SENC

-

And this is only happening when the engine is running? Easy gear movements when not running, colf or hot? I suspect you're getting closer to few options but to pull the engine and gearbox for a look. Have you changed the gearbox oil? How'd the old oil look? If you haven't, I'd drain it and put in some Redline MTL - that definitely made a notable difference for mine.

-

Agree that ensuring it was fully seated should yield the same end result if you have enough adjustment room on the rod. Regarding setting the rod/dome nut versus the clutch lever - as I recall that process includes manually holding the lever rearward (away from the slave) and setting the gap (without the spring in place). Is that what you did?

-

I'll have to measure the mount on the bellhousings of my Seven and Elan - thinking it is also possible the mounts on earlier bellhousings were shorter in length.

-

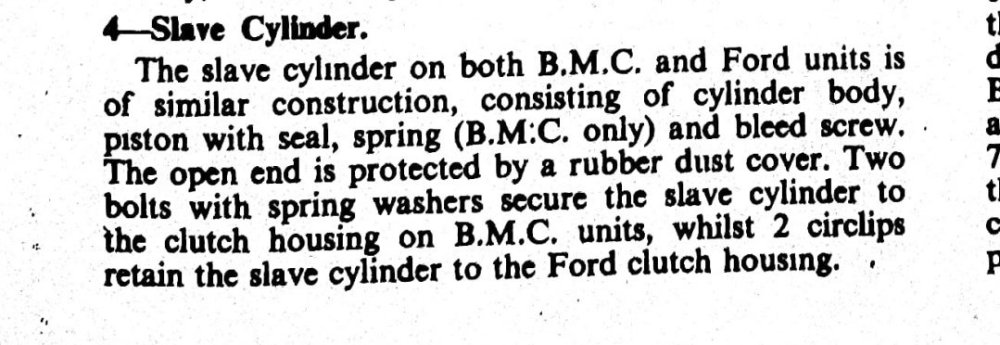

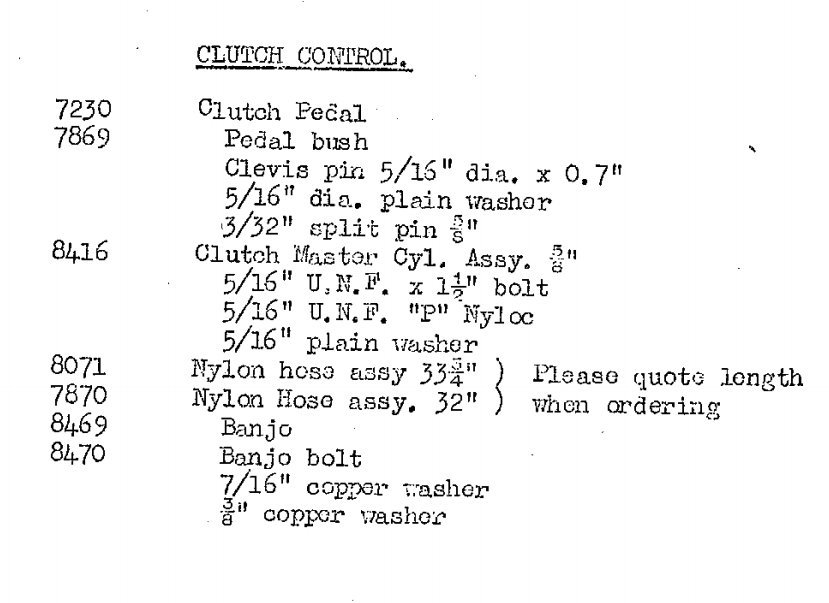

A quick search in my files didn't yield anything about the washer but the Seven owners manual does indicate there should be 2 circlips. On a previous note while checking the Lotus Seven Parts manual, I notice it refers to the clutch master being 5/8" - contradicting the 3/4 listed in the Girling catalog and other places.

-

I first reinstalled without it (unintentionally), and noticed the pressure on the rod forced the circlip up snug against the mount on the bellhousing, leaving a gap on the front side. The space took up that slack, effectively locking the slave cylinder in a rearward position. I'd have to measure it to see how thick it is and how much it actually impacts it, but estimate about 1/16. I feel like I've seen a reference to it, but will have to look around to see if I can find it. I don't remember it, either, on my Elan, but may have had a thicker circlip.

-

Do you have the spacer/washer in behind the circlip on the slave, to ensure it is positioned (and remains positioned under pressure) correctly? If not, you're losing about a 16th of an inch. Enough?

-

Put a flashlight in the rams then open/close the throttle and you'll be able to see them.

-

Yep, one of the frustrating things about old Lotus - always lots of conflicting evidence - and evidence that they really did frequently stick whatever they had on these cars! Bottom line, I think either work for both brake and clutch, just require different pressure and different pedal strokes. Don't feel to bad, I had exactly the same thing happen, though I was on the road taking an initial test drive after getting everything back together. Mine was due to slightly missing on the setup of the dome nut, which allowed the piston too far forward when I fully depressed the clutch. I was only about a mile from home and had my son pick me up to get some tools and a spare slave cylinder I had. It was a royal PIA to get the stuck slave out (I had to cut the rod, too) and a new one in and adjusted on the side of the road. But I was thankful it wasn't my Elan.

-

Since you have 2s as well, the tuning thread for mine on Keith Frank's site may be somewhat useful, then. As I recall there are a number of pictures there of progression holes and where the butterflies sit that you may be able to use as comparisons. I did fully disassemble and rebuild mine, and took lots of pictures along the way should you go down the same path and want to see anything. Among other learnings that had an impact on how my engine runs, a significant one was the realization that the mixture adjustment screws come in 2 varieties (should be short taper on ours, but most critical is not mixing and matching), that if screwed in too far they can damage the ports, and that they can/do leak air. Per Keith's recommendation, I used EZTurn fuel lube in the threads to solve that particular air leak. If your carbs haven't been touched in a long while, it is likely that the leather seals for the spindle will also leak. EZTurn or vaseline from outside may provide a temporary solution until you rebuild and replace those seals.

-

The following is a note from John Watson in a thread on the now essentially defunct se7ens.net mailing list: According to the Girling catalogue:- LOTUS SEVEN SERIES TWO - June 1960 to October 1961 and LOTUS SUPER SEVEN October 1961 on BRAKE MASTER CYLINDER = 5/8" CLUTCH MASTER CYLINDER = 3/4" CLUTCH SLAVE CYLINDER = 3/4" Cheers, John. I also had this in my files, from page 3 of a Girling catalog. I'll also attach the pdf of the catalog if the forum allows me to do so. Girling Dunlop Parts Catalogue G262.pdf

-

Tony Ingram (lotus7.com) or Mike Ostrov would be the folks I'd contact - if anyone has done it I suspect they'd be aware.

-

What type 40DCOEs? Mine are type DCOE-2. The type and individual carb numbers may give some clues as to whether they may be original to the car (the numbers may not be sequential, but should be in a similar range). Lotus sometimes recorded carb numbers, but even if they did not record them for yours you may be able to piece information together from others that helps you determine if yours are in the right ballpark for your year and chassis number. Lotus recorded the cab numbers for mine as 222xx and 221xx

-

Confirmed my brake master is 5/8 and clutch master is 3/4, for what that is worth. I have no reason to believe that is not the original orientation, but who knows for sure what a PO has done. I've found Lotus literature that says the clutch should be 3/4, but have also seen contradictory evidence. Regardless, I dont thing either size would contribute to your problem. It is definitely a "strong" clutch pedal with a 3/4 master. I tried to look back on some old threads and notes, and it looks like the incorrect push rod length may have been a master cylinder rod length issue rather than a slave cylinder rod length issue. You mentioned a new clutch master, so it may be worth checking it's rod length and comparing that to the old one. Non clutch related, you might check your gearstick turret. If that turret had unwound itself at all, it may not be putting the lever in exactly the right places. I had this issue after my rebuild - I'd neglected to add a little threadlock after adjusting gasket thickness to get it situated correctly and engine vibrations had unwound it just enough to keep me from selecting gears.

-

I think you're OK with 5/8 master - lots of debate on whether 5/8 or 3/4 in various places. Slave should be 3/4. It may be worth checking the length of your slave cylinder rod. These apparently came in different lengths. I dont remember the correct length offhand, but lots of discussion on lotuselan.net about this topic.

-

-

You may or may not find you need a bigger fan - I have an original small fan on mine and it seems to do the trick when idling in traffic as long as I keep water flowing periodically. That said I don't have the oil cooler you have restricting airflow when driving so yours may have different needs. Re clutch bleeding, like our Elans the rotational angle of the slave cylinder and location of the bleed screw can cause issues with air in the slave itself. On my Elan I added a length of brake hose and fitting and effectively raised the bleed screw to near the master - which made for much easier bleeding and ensured air from the slave reached a higher point. The Seven is open enough I haven't felt the need to do that. I also found that the pumping action when bleeding agitates the fluid and introduces air throughout, that then finds its high point and stays there. My solution to that has been to use a board to hold the clutch (or brake) pedal fully down overnight after changing fluids. This seems to give the air a path out to the master cylinder. A top off in the morning and I've yet to have a problem. If your problem is air in the system, perhaps this will help.

-

That is the way I read it. For mine, the 116e/120e variant it calls for a 1/8" advance, so I settled on the outside edge of the right side of the markings on the case (rather than between them). That said, a contemporary HLR newsletter on the cosworth engines I indicates a 1/8" retard - and, of course, cams could have been changed - so I'd use the manual as a general guide to get started and running then tweak from there as gap/dwell and carbs are adjusted.

-

Sorry, I didn't mean to imply dwell was in there - I meant to point to the timing advance. Yes, I think you are correct on dwell. https://vintagetechnologygarage.groups.io/g/sidedraft/topics and, specifically, the thread of back and forth on mine a couple years ago... https://vintagetechnologygarage.groups.io/g/sidedraft/topic/tuning_advice_65_seven/74580852?dir=asc

-

Be sure to check the dwell, then readjust timing as per the manual. I found that much more accurate than setting gaps via feeler gauges. I really struggled with carb tuning until I got some help from Keith Frank on his iogroup page. Perhaps due to wear, my butterflies were closing a bit too far and covering the first progression hole (this was resolved by swapping butterflies for a set with a different angle edge bevel). Not at all suggesting you'll need to do this, just that Keith is extremely helpful diagnosing problems.

-

-

When the timing mark is at the pointer, you should be 10°BTDC. The mark on the smaller wheel my be for TDC? Pretty sure that's the case on the Elan.

-

So your rise is about 1.5", roughly double mine. The pictures may be deceiving, but the top of your radiator looks to be higher than the top of your cam cover. The top of my cam cover is a bit (maybe 1/2-1") higher than my radiator. Is your radiator sitting down in the chassis mounting holes (with top hat style bushings)?

-

The top hose? I can't remember off the top of my head - seems like I searched for a bit for what it came off and found another British car of that era and then found a NOS hose. If that's the one you're talking about I'll see if I can get lucky and find an invoice for it. This might be it... https://bpnorthwest.com/triumph/radiator-hose-upper-spitfire-62-to-78-gt6/?gad_source=1&gclid=Cj0KCQjwsPCyBhD4ARIsAPaaRf1OLe4nEubif6utMAYrZo2ME68CRHeaZytA6J2t7LO76VPTHoiuCZkaAlTIEALw_wcB Or this... https://www.ebay.com/itm/190848712318?chn=ps&norover=1&mkevt=1&mkrid=711-117182-37290-0&mkcid=2&mkscid=101&itemid=190848712318&targetid=&device=m&mktype=pla&googleloc=9010076&poi=&campaignid=20394324446&mkgroupid=&rlsatarget=&abcId=9317262&merchantid=6365194&gad_source=1&gclid=Cj0KCQjwsPCyBhD4ARIsAPaaRf1qfqrAFgZSJzYmNR7t0s9bnBvLJ_864xc6cmZ23RW0cWvJruxYgL0aAk_6EALw_wcB

-

Was at my shop some today so took the opportunity to take some measurements - maybe something here will help you in evaluating your system. The bottom of my swirl pot is roughly 1" below the bottom of the radiator inlet pipe. My swirlpot outlet is about 1/4-1/2" above the bottom of the pot - so overall rise from the bottom of the outlet inside the swirlpot to the bottom of the radiator inlet pipe is roughly 3/4-1". As the cold level of water in the swirlpot is about 1/2", it requires a rise of roughly 3/4-1" before unpressured water would flow to the radiator. My swirl pot is about 4" diameter, so if my math is correct it only needs about 7 ounces or less of water to get enough rise to start unpressured flow. Our cooling system holds about 12 pints, just under 200 ounces - so thermal expansion takes care of most/all of that rise at 200F (93C). Ie., it wouldn't take a lot of pressure on the downstream side of the pump or suction on the upstream side of the pump to get and keep circulation flowing. I'm still confused why you don't get visible inflow into the swirlpot at higher than idle rpms. Perhaps measure the level when cold and observe the flow immediately upon start-up. Is the pump pushing up water to the pot (with rpms) when cold but not getting high enough in the pot to flow to the radiator. Is the pump eventually sucking air from the radiator and "running out" of water to push? Other measurements - my swirlpot inlet is about 2" higher than the swirlpot outlet. That puts it an inch above the radiator inlet. The top of my swirlpot is about 1/2" above the top of the cam cover. The design of my swirlpot would naturally flow water from the inlet pipe around the opposite side of the pot, and directly towards the outlet pipe, so even before a rise in water level would send a good bit of water to the radiator. If your rise from swirlpot outlet to radiator inlet is larger than mine and you determine the swirlpot needs to be elevated, it shouldn't be difficult to machine an aluminum or brass spacer/riser to fit between the head and the swirlpot inlet flange.

-

I want to say that there is a very slight incline from my swirlpot outlet to radiator inlet, but it isn't much. Without looking at it in person, I'd guess the incline is less than the ID of the outlet - and that any rise in water to/above the outlet inside the pot results in flow to the radiator. I'll post a couple of pictures for comparison. I've been trying to think through whether/how that is contributing to your circulation problem. Presumably it worked at some point so I'd think it would be ok - but perhaps minor efficiency losses due to restricted water paths, pump wear, etc. are combining with a marginal design to result in your outcome? Considering the water level in the swirlpot during your video - can you estimate where that is in relation to the high point in the connection between the swirlpot outlet and radiator inlet? Ie., is that high point above the water level in the pot? If so, I could see that being an issue. The water pump pushes what it can through the engine and to the pot until it reaches that level, but if (at that level) gravity doesn't force water back to the radiator the pump would quickly run out of water to push. Perhaps the post-rev gurgle you're seeing is the result of a little vacuum created upstream of the pump through the radiator trying to suck some water through? Or opposite, a release of some air from the radiator due to back pressure? I'll be interested to hear today whether your radiator appears to have very little water in it today as it did yesterday.