-

Posts

644 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by SENC

-

Effective wind deflector/buffeting reduction?

SENC replied to Cueball1's topic in General Sevens Discussion

Agree completely. -

Effective wind deflector/buffeting reduction?

SENC replied to Cueball1's topic in General Sevens Discussion

They all, essentially, grab air from the top of the windscreen and drop it down and a bit outward behind the windscreen, filling a bit of the negative pressure "void" to reduce air being pulled in from the sides. I'd think the square design of our screen surrounds would make a fairly easy and solid place for attachment and allow quick/easy install/deinstall. -

Effective wind deflector/buffeting reduction?

SENC replied to Cueball1's topic in General Sevens Discussion

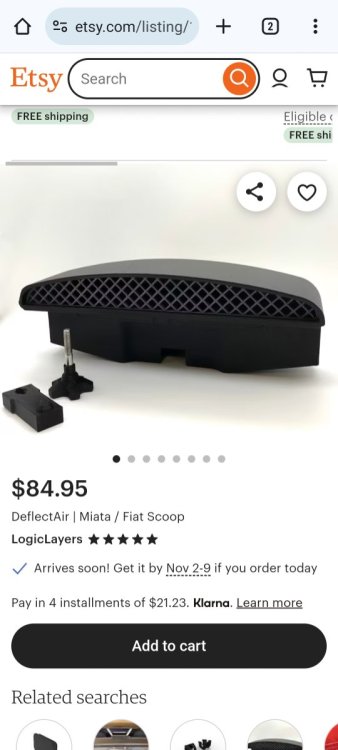

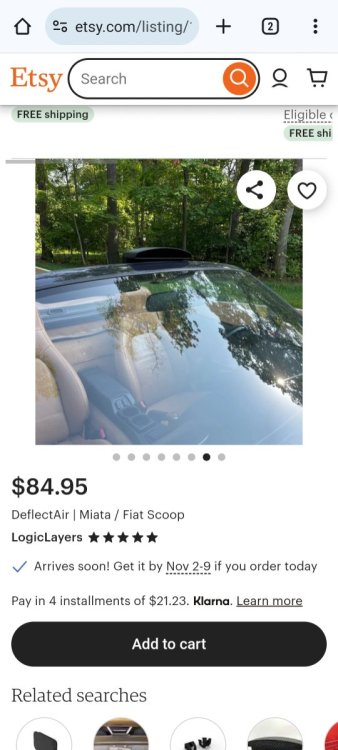

Here are a couple pics from ebay/etsy... and a link to a product offered by JASS... https://www.jassperformance.com/shop/fresh_air_scoop_mx5?srsltid=AfmBOoqWHbY8qzJmeq53wQ0G07Vl2_YFtCGNpB6FWRnUcR1N_5bva6jSirk -

Effective wind deflector/buffeting reduction?

SENC replied to Cueball1's topic in General Sevens Discussion

Has anyone tried to create a windshield mounted scoop/diverter like some have for their miata? I'd think this would be quite effective in changing the air pressure behind the screen, thereby reducing the buffetting. I need to find someone with a 3d printer to help test the idea. -

Looks great Al!

-

Weale indicates that Ford hubs have larger diameter wheel studs than Triumph hubs, so that may be what you have. Weale isn't specific about the hubs on the S2s, just that they are Triumph. The rear axle hubs, brakes are all from the Standard 10 and Herald. The early S2 wheels were from the Triumph/Standard Herald (3-1/2"), replaced by the 4-1/2" Lotus Elan wheels. I don't know whether the Spitfires used the same as the 10/Herald.

-

Nothing in particular, mine is in good shape. Just saw the post and thought, if close enough it might be worth it for the future.

-

Where are you located @fotsyr?

-

As I recall they are from the Herald. If you have a copy of Tony Weale's book it may say - if you don't have it I'll check mine later when I get back.

-

Normal behavior on mine (pos earth and generator): at idle and/or with significant load it will read negative - as rpms rise it will read positive, even with some load. Obviously, dead zero when ignition is in off position.

-

Remember that the axle is unloaded in the picture, so that bit of angle should be expected. Once the car is sitting on its wheels and carrying weight it should be approximately horozontal, allowing some movement in the vertical plane in either direction.

-

Check with Tony Ingram at lotus7.com and with Chris Mintoft at Redline in the UK.

-

I can't positively identify yours, but here are a couple pictures of the S10 axle from my 65 when I had it out for cleanup. You should be able to zoom in for markings, but I don't see any similar to yours. The 2nd pic is of the handbrake tree arrangement.

-

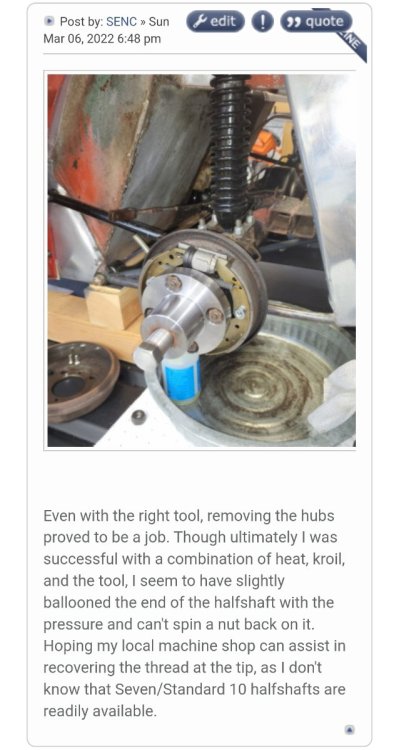

Here is a picture of the churchill-style hub puller from a post I made on another site. As I suspect is obvious, it bolts to the hub and supports it at the entire circumference, reducing the risk of bending the hub with other types of pullers. The central bolt is tightened against the half shaft. Generally, a couple cycles of penetrant and heat before mounting the a good crack in the tightened bolt with a small sledge will break the taper seal and allow the bolt to be turned further extracting the hub. As noted in my post, I really had to wail on one side and ended up slightly distorting the thread end - but that was fairly simply machined. Once the hub is out, the half shaft should come out without much effort - but (on the opposite side of the difficult hub), the half shaft was quite stubborn and I had to rig up a set of spacers and use the wheel nut to pull it. Once you confirm you have a S10 axle, the following semi-active forum may be useful to you in any rebuild.

-

I didn't look closely enough at your photo to notice the flat cake pan on its rear. As MV8 said, could have been a mod for oil, or perhaps a way of strengthening. There should be some markings on the nose/front side - maybe grab pictures of those and any other distinguishing features and someone may help definitively identify. The Standard 10 axle has a breather hole on top of the right side casing arm. I'll find and post a picture of the hub pulling tool.

-

There is a manual for the Standard 10 rear axle in the "downloads" section of the site. Pulling the hubs/driveshafts is easier while the entire axle assembly is installed, but you definitely need a special puller tool as the hubs are easily bent (and not easily found). It took several rounds of penetrant and heat and lots of patience with mine - one side in particular fought me for a couple days. If you aren't familiar with the puller tool I'll find some pictures and where I got mine. Also a good time to order and replace bearings and seals. If you determine you need to fully open the box, I agree with MV8 that it can be done from below (with room), but I think I'd do it on the bench. Removing/replacing the assembly isn't difficult and gives you the opportunity for a full cleanup and a coat of protective paint. Mind the breather hole!

-

I was told by several UK Seven owners that he is not currently trading. No insight into whether this is a permanent closure or a temporary closure.

-

Nice, wrll done!

-

BLO has some thinner already (metal thinners to aid drying that are added when the oil is heated), but to your point probably needs further thinning to be sprayable. Turpentine is the traditional thinner for BLO (in woodworking), but white spirits or mineral spirits would work as well. Linseed oil and tung oil are among the very few "drying oils", meaning they actually do cure to a dry film. Other oils, whether vegetable-based like canola, or mineral-based, don't fully dry and remain in a fluid state (to some degree). The downside to LO (and tung oil) is a very long drying/curing time, so adding the drier additives and heating reduces cure time for linseed from 30+ days to just a few.

-

Excellent!

-

I don't recall, but if not you can get them from Chris Mintoft at Redline. He had a tonneau made for me that I'm very happy with.

-

I can attest to the seats from XtraSpecialSevens. The PO had Mick make entirely new seats for my Seven, they are superb.

-

111 max Db, 138 lbs. Not sure the power to weight ratio meets Lotus standards. Needs to add some lightness. Perhaps they should have done bookshelf speakers rather than floor speakers.