sltous

Registered User-

Posts

184 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by sltous

-

This might be a long shot, Rich @ Kampena informs me that the lower differential bolts are M12 threads, 1/2" shank, does anyone in the Bay Area of California have a spare lower differential mounting bolt? I think they are the 85mm long bolts, my good bolt is at the mechanic so I can't easily measure. https://caterhamparts.co.uk/differentials/1559-bolt-m12x85mm-with-1-2-shank.html

-

Thanks MV8. Removal was pretty straightforward, followed the pistonheads process and took my time. Now to get the bolt end out and then 'refitting is the reverse of removal'

-

Hello All, Looking for differential removal tips and tricks. While installing my differential bracing I discovered that one of my lower differential bolts had sheared so I think I need to remove the diff, use a bolt extractor on the half of the bolt still in the diff, and get it all back together. Planning to use: https://web.archive.org/web/20190416085218/http://alcester-racing-sevens.com/prop_-_step_1.htm https://www.pistonheads.com/gassing/topic.asp?h=0&f=101&t=1670013 but any other guidance is appreciated. Supposed to be going to the track on Monday so it'll be a bit of a race against time.

-

For Sale: Caterham P/N 30P316B STRUT - CATERHAM DIFF S3 RH Caterham P/N 30P315B STRUT - CATERHAM DIFF S3 LH I tried to fit differential braces to my S3 which is a 2005 but I purchased braces that are for the newer Caterham / BMW differential and I need the braces for an older Ford differential. I can't help you figure out if they will fit your car. Brand new, only removed from bags to verify that they are too short for my application. Selling for $100 shipped to you.

-

Thanks John. That was clear and made me feel dumb as a box of rocks. Thanks for the photo. Mine now looks the same as this. Thanks all. Thinking it's time to put down the wrenches and call it a day.

-

Hi John and fastg, That's okay, I'm also confused I've taken a quick video of what happens when I remove tension from the throttle pedal. PXL_20220707_221417476.LS.mp4

-

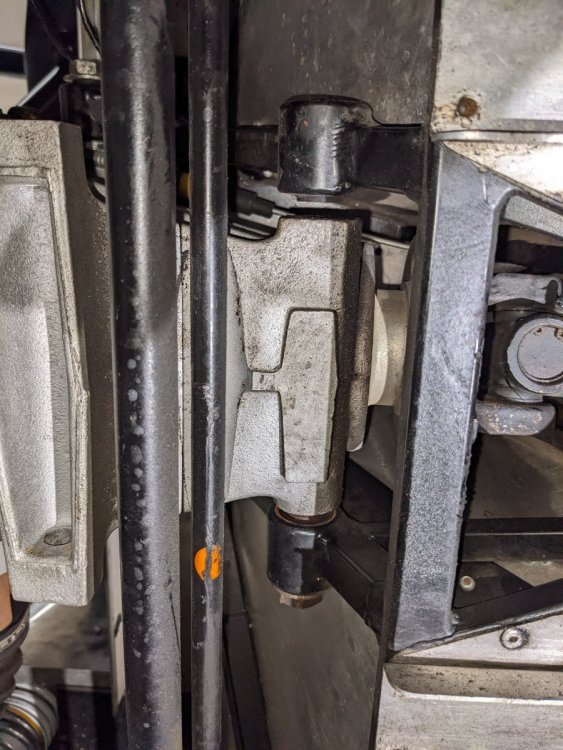

Hello all, I am trying to fit a new throttle cable to my car. The old one was not a standard Caterham part and I am refreshing a few items to go to the track in a week and wanted to clean the throttle cable up. The problem I am running into is that I can not yet figure out how to get the throttle cable at the engine end to follow the diameter of the roller barrels. I am using part number 300E0055D THROTTLE CABLE DURATEC LHD SHORT. Everything else is fitting up acceptably well although the cable assembly is a lot longer than I actually need. Any advice or pictures of how to make this work are appreciated.

-

Help with hesitation at high RPMs - fuel starve?

sltous replied to KnifeySpoony's topic in General Tech

Do you have any kind of data logger? -

Another option is through Beachman Racing http://www.beachmanracing.com/master-cylinder if you select S3/SV and Uprated. I spent a few minutes looking for a direct source but the actual part is an AP Racing part, box picture with P/N attached. I'm sure your favorite Caterham parts supplier can provide it if you ask for the uprated master though. I will note the same thing I note every time pedal feel comes up, I had significantly more improvement by switching to the race master cylinder cap (http://www.beachmanracing.com/brake-master-cylinder-cap-race , AP Racing P/N CP2709-21) than I did by switching to an uprated master cylinder, although both are good.

-

GIRLING 74660152 90s Cat MC replacement ideas

sltous replied to IamScotticus's topic in General Tech

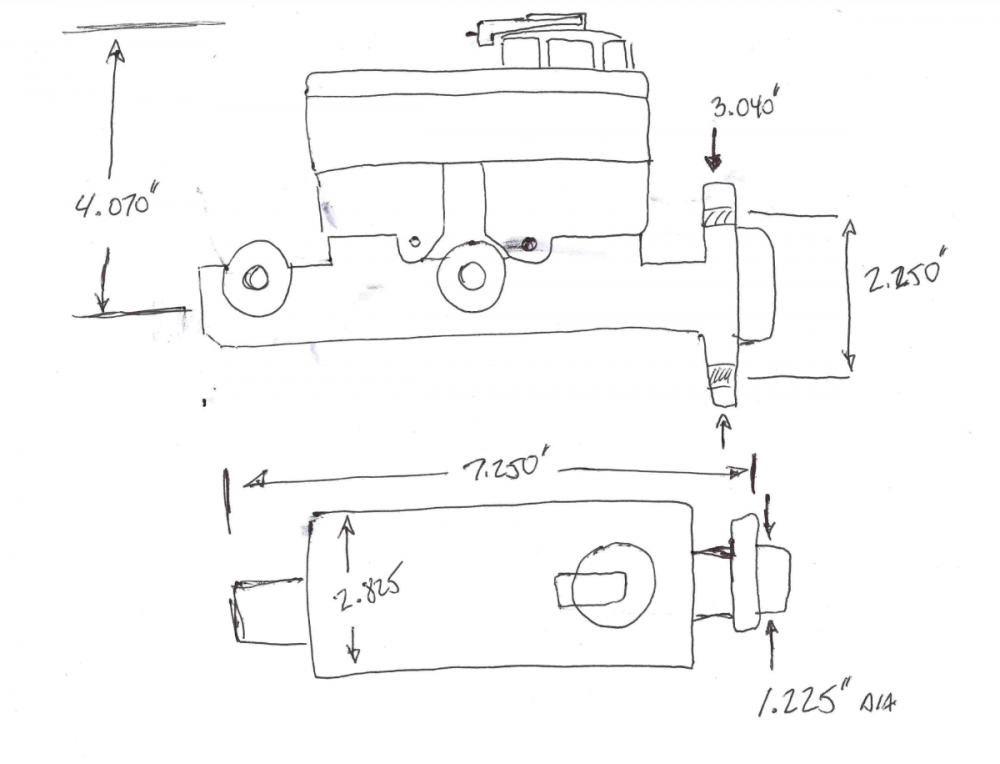

As a follow up note if you are planning to replace rather than rebuild, the 0.7" bore Girling 74660152/TRW cylinders are a drop in replacement for the 0.8" bore AP Racing CP4627-2PRM100 MCYLT-13/16xSTL INTPLA / CC uprated master cylinder. -

GIRLING 74660152 90s Cat MC replacement ideas

sltous replied to IamScotticus's topic in General Tech

Do you have a P/N for it? If it is a Girling 74660152 I was able to get a replacement seal kit for same from Ken @ Dave Bean. P/N SP7657 for the seal kit. Replacement TRW assembly sketch as Ken provided to me of the TRW part is attached. M10x1.00 ports. -

It looks like it's a Smartwool product, most likely their Merino Beanie although I may look into the lighter-weight Sport Beanie for summer. Caveat is that I never go on any roads with speed limits above 45 so my experience may not be appropriate for highway travel or long fast blats.

-

I have had good luck with the Alpine Motorcycle earplugs under a tight fitting beanie. https://www.alpinehearingprotection.com/earplugs/motosafe-race/ . The modern frequency specific filters are kind of amazing, I have heard birds chirping while driving. Aeroscreen only for me.

-

Took the car to work today, at 6kg/s air flow, right around 1100rpm idle it's a surprising sweetheart in light traffic. Not planning to do a lot of stop-and-go but it's easy to drive slow and still has all the get up and go while keeping pretty decent downshift blips I was looking for when I got to open the revs up. @ashyers I may reach out in a bit to try and smooth the idle out a touch more but I'm feeling really good about it right now.

-

Got the car hot with a few miles before I started adjusting for flow. Peppy, clean downshifts, a good starting point. Started at ~6kg/s on all four cylinders, using a 6mm and a 6.1mm drill bit for setting the idle adjustment screw I think my intakes at idle were right around 6.1mm without any further adjustment from the weekend. This might want to be adjusted down just a hair but I'm relatively happy with the car. Adjusted to 5kg/s per the Caterham guidance This was way too low, my idle was unstable dropping down into the 800s. Car drove OK once I got on the beans a little but was not lively pulling away from a stop and overall not the Caterham experience. Maybe if my idle was set a little lower this would be OK. Adjusted to 5.5kg/s This was OK. Intake felt really gulpy and the car was not as lively as at 6kg/s. Idle was good, right around 1k rpm, not particularly stable. Adjusted back to 6kg/s Maybe not 'correct' but I'm generally not going for any max power or fastest lap times, just a nice peppy streetable setup. Idle is back up to ~1100 rpm Next steps probably I should make a real 6mm pin and tweak the idle back down a hair. Using a drill bit I was running into the stamped numbers and getting some drag. I think I'm going to put some more miles on at the 6kg/s flow at 1100 RPM at throttle position 1 and see if I continue to like it.

-

Thanks for confirming. The section of fuel hose I bought seems to be doing fine

-

I found a section of fuel hose at one of the big chain auto parts stores. The newer hose is not cracked and is more flexible so it turned out fine. Would something like the Dorman cooling bypass plugs have been acceptable if I was willing to lose the fuel spill tube? Not sure if the rubber they are made from breaks down in gas vapors

-

I have fitted an aero fuel filler in place of my standard fuel filler but the short section of fuel spill hose has cracked and is very stiff, enough to make it difficult to position the fuel filler. Reviewing the Newton Aero 300 documentation https://www.newton-equipment.com/pdfs/aero-300/ob-za-051-055-048-056-tech-sheet.pdf this looks to be a 16mm diameter pipe, should I pick up some 5/8" ID regular rubber hose or is there something special I need to fit? I am not really worried about structural integrity of the hose as right now the section is about six inches long and about four of those inches have either tank fitting or fuel filler inside of them, probably the more flexible the better from my perspective.

-

Took the long way to work this morning, with the 1000-1100 RPM and throttle position state 1 at idle. Generally went much better, a little gulpy on air but no spitting. I agree with the idea that maybe the air bleeds are opened too far, I'll check this once the flow meter comes in. I'll probably either buy or make a much longer 6mm rod (should be relatively easy to turn down from 1/4" stock, precision requirements can't be anything special) so I'm not worried about losing it down the intake and adjust both the resting position of the intake and the flow rate at idle with the bleed screws to try and drop the RPM a touch further without introducing drivability problems. Overall, thanks for the pointer on adjusting throttle position to 1, that did help a lot.

-

I adjusted to this point, got the throttle cable adjusted to be able to drive and it was absolutely diabolical. This may be how the car is "supposed" to be tuned but in my opinion it was not a street-able car. I think (to be confirmed once my flow meter arrives) that there simply wasn't enough air and by the time I added sufficient throttle for there to be enough air there was a ridiculous excess of fuel. Taking a page from Caterham initial setup guidance I grabbed a ~6mm drill bit and adjusted the idle back up based on that rough guidance (taking super extra special care not to drop it in ) which placed my idle back around 1000 to 1100RPM and my throttle at state 6, I tuned the TPS back down to throttle state 1 (still a change from the initial setup) and got the car back under control. I'll see how things are looking once the flowmeter comes in but my initial testing suggested it's an improvement over where I was when I started.

-

Well, I had the correct idle adjustment screw. Couldn't come up with anything more clever than either replacing the throttle cable or bending the throttle pedal. So I bent the throttle pedal.

-

After adjusting what I thought was the idle screw as far out as possible I was able to get to the idle state 980 rpm, TPS site 1 but now my throttle cable is not under any tension. The cable adjustment is set essentially as long as possible. Looking at the Minister Power site it suggests I might have adjusted the throttle stop and not the idle adjustment http://www.bikerhouse.com/testsite/minister2011/support/roller_barrel_setup_k-seriesr.php, I will need to go review what I did

-

Such a beautiful car!

-

Andy, I have placed an order for the standard flow rate SK flow rate tool. I have done some reading and there is guidance to balance the roller barrels with bleed screws at idle. https://www.caterhamlotus7.club/forum/techtalk/balancing-roller-barrel-throttle-bodies This guidance suggests I am looking for relatively low flow rates of ~5kg/hr so this should be an appropriate tool. Thanks for the advice, I'll have to find a chance to come to visit one of these days, it seems like the place for Bay Area sevens I do note that the Caterham guidance is TPS should be set to ~0.43-0.45V and I am set a good bit lower than this at the moment.

-

Thanks sf4018. I do have the innovate wideband sensor kit available for installation. It is fitted elsewhere now but the car it is fitted to is in semi-storage. Tempted to install but not sure I'll learn anything.