-

Posts

644 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by SENC

-

While you have it off, run a hose into the inlet - would at least give you an idea of what a strong inflow of water should look like from the top. Perhaps it is internally baffled in some way and you wouldn't see obvious flow as in mine.

-

A longshot, but the cap on your swirlpot isn't a high pressure or malfunctioning cap that is blocking the overflow tube, is it? Wondering if there is any possibility that air pressure is building up in the swirlpot and keeping water from flowing up to it. I'm doubting this since you've run it without the cap at least long enough to see/video activity in the swirlpot but just a thought to consider.

-

very strange, I'm at a loss - unless the swirlpot inlet itself is blocked, it seems either a 2nd bad pump (unlikely) or maybe just enough blockage in the engine to prevent high enough flow to get up to the pot, but not enough to prevent water creeping through.

-

Interesting design, though I'd wonder if it would be as effective removing air as the more vertical design. Regardless, that wouldn't be your problem I don't think. Looking at the design, I'd expect to see a gush of water coming from top left of the video on increase of rpms. As you've described, the video shows that isn't happening - it does look to me like the outlet is attempting so suck water out upon decel. That leads me to believe the outlet to radiator to pump section is ok and trying to do it's job, but from pump to swirl pot inlet isn't. I'd rig a hose to the pump inlet and remove the swirlpot to see if some hose pressure gets water up through the head. If not, you could open the drain on the block - if it flows there you may have increased the chances it is a head gasket resteicting flow or clog higher up - if not it would suggest a blockage in the block. In the head gasket idea, I do recall from searching for mine that not all are designed the same - any chance of pictures of that gasket from last rebuild?

-

I just remembered you mentioned the swirlpot is homemade - maybe a picture of that too? Is the design similar to this? Inlet from head to high point on the pot, outlet to radiator at the low point? I'd be tempted to remove the swirlpot and turn the engine over to see if it shoots water up as expected.

-

Odd that you're seeing surge when lifting off the throttle, almost like backwash rather than water coming in from the top inlet pipe. Am I interpreting correctly?

-

1 - I generally wear a pair of Gokey moccasins - just a leather bottom with no outsole. Works well, looks pretty normal otherwise. Soft soles are thick/firm enough for comfortable pedal work - just don't walk a mile on gravel in them. 6 - there are fiberglass sleeves out there that work for this purpose, just Google for them. Not the best looking things in the world but available in different sizes so you can find something that works and slip it on when taking your daughter.

-

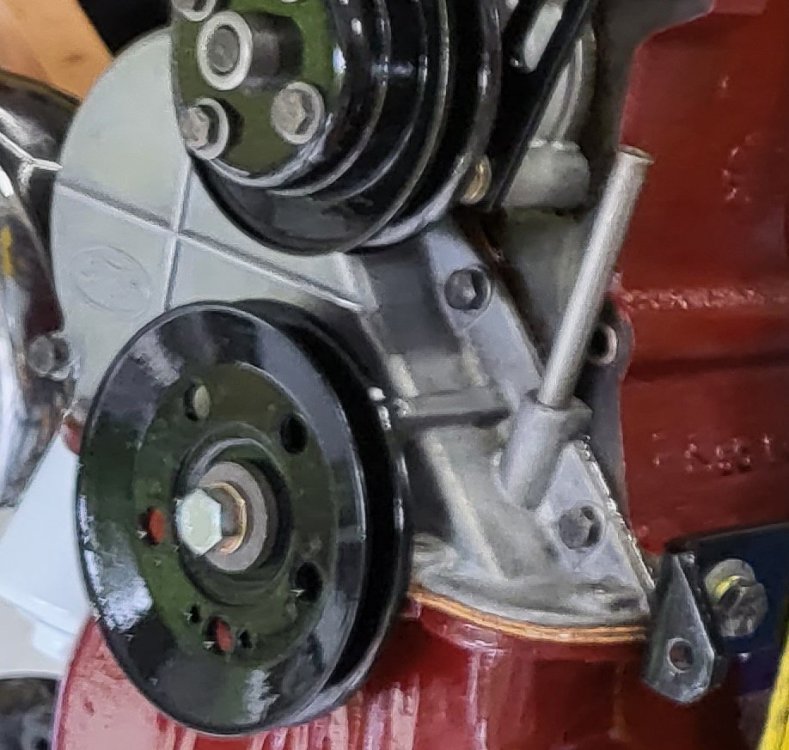

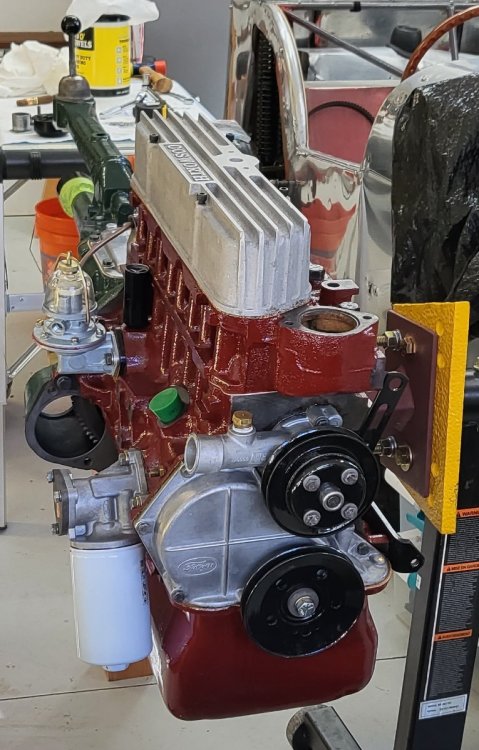

Smaller crankshaft pulleys were used frequently by racers to reduce wear in the water pump - and as they were almost always above 3k rpm it would pump just fine. Here is a closer shot of my crankshaft pulley and timing marks. I'm not with it right now, but it appears they are roughly on the same plane.

-

Agree with MV8 on the relative sizes - I didn't notice your measurements before. Mine is similar to the picture MV8 posted - I can grab some actual measurements if you'd like. I believe the crankshaft pulley is 4" diameter and the water pump pulley slightly smaller. EDIT: my memory was right and wrong! My Elan has a 4" diameter crankshaft pulley, but my Seven is 4.75", as MV8 estimated. My water pump pulley on both is 4.25" If you have the 4" crankshaft pulley you're definitely losing some efficiency at the pump.

-

Yeah I didn't think about that but you're right, I couldn't do what I suggested either. Maybe you can get a hose into the swirl pot and directed towards the outlet. Something to see that you can force water up through the engine and to the swirl pot.

-

The perplexing thing is you were seeing flow into thw swirl pot at higher rpms (though higher than expected), so there must be at keast some flow. You mentioned that on disconnecting everything you discovered the radiator was empty. I'm sure youve double checked the top hose for blockage and thag water flows through the radiator well. The other thing that comes to mind is an airlock within the engine - that expands when it gets hot and fully blocks circulation. In the Elan I learned to be sure to always make sure it is nose up when draining/refilling coolant. Apparently these engines are known for getting air pockets in the back of the block when nose down or even level. Perhaps park it nose up overnight then refill from the swirl pot - or better yet remove the top hose from the swirl pot and add water through the radiator until you see it (hopefully) rise up into the swirl pot.

-

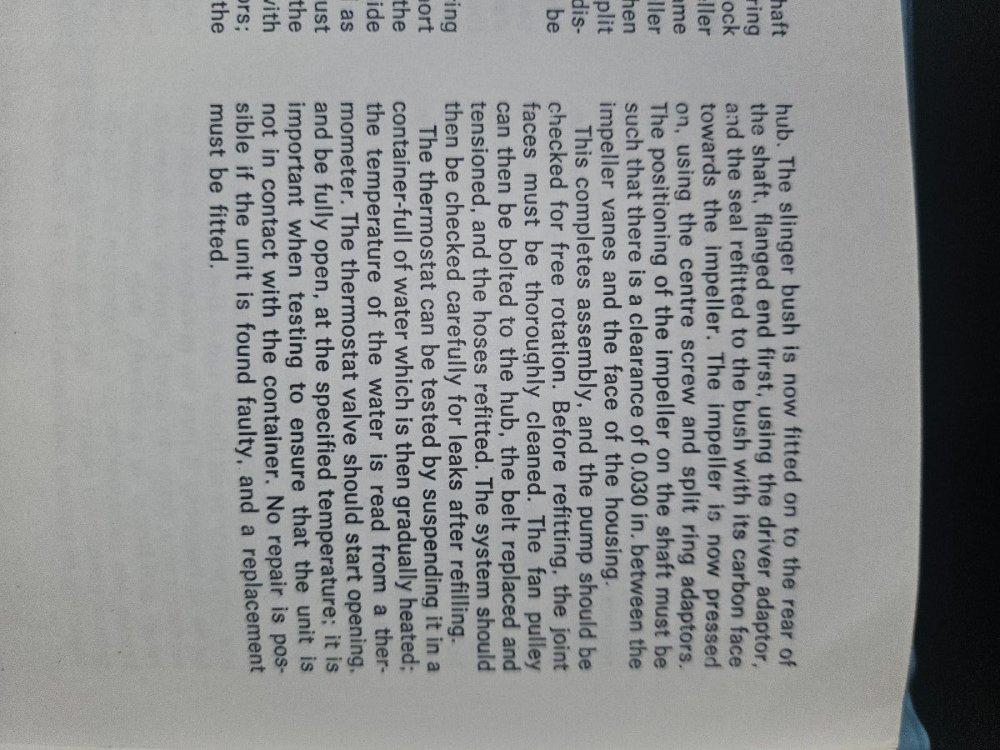

.03", or .77 mm to be exact

-

-

No. I don't have a thermostat in mine, nor are the swirl pots designed for them. The only use for the thermostat is to allow the engine to warm more rapidly by limiting flow through the radiator until it is warm enough to circulate. From all you've described and tested, it seems most likely you're just not getting sufficient circulation through the engine - whether due to restrictions or even blockages or due to an inefficient pump. Have you flushed the engine? Hose to the pump inlet and open the drain on the lower right side of the engine? Good flow? Clear or lots of crap? I replaced my pump when I rebuilt my engine. I'm 95% sure I saved the original - if you can't put your hands on one I'd be happy to send it to you to test if it makes any difference. I didn't replace it due to known issues, but just part of my rebuild.

-

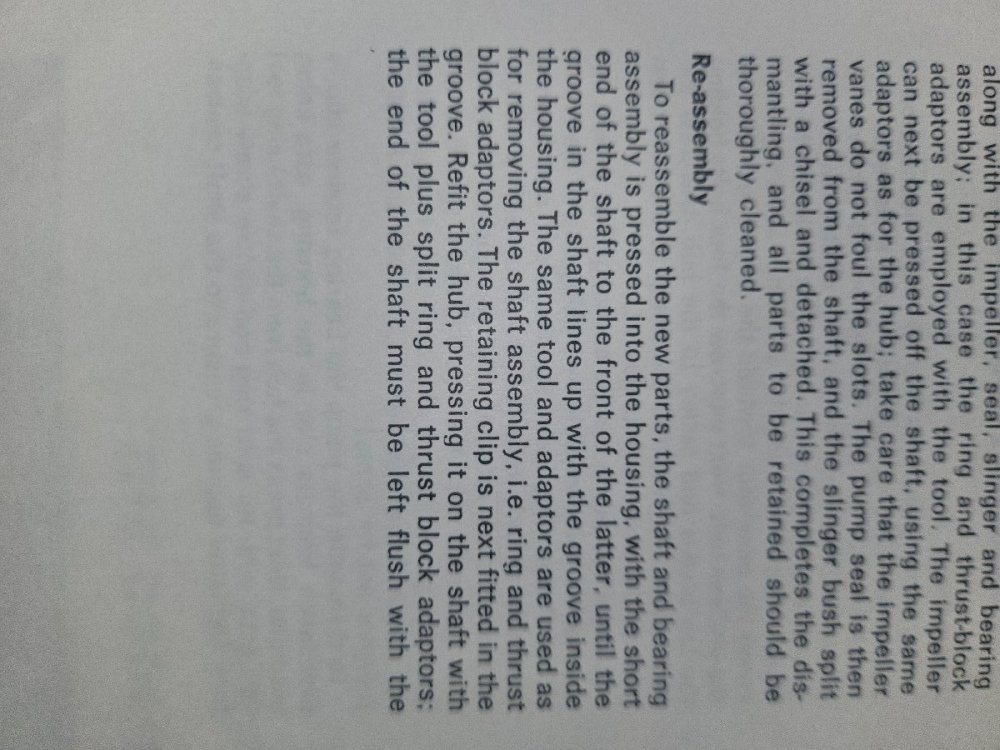

Sharing a couple notes from an old Autopress manual for the Anglia, Corsair and Cortina... could the water pump have been rebuilt without the slinger or with the impeller too big a clearance? Trying to think of why else it may be working inefficiently or even direction water towards the pot rather than through the engine.

-

Timing, if wrong, can also be a big contributor to overheating - worth a double-check of that, too.

-

Unfortunately I fouled up the first video, from dead cold. At cold, water level in the swirl pot is about 1/2" above the bottom. Just jiggling with then engine at idle. When rpms hit 1500-2000 rpms, water begins to gush in from the upper, inlet pipe. This video shows the pot fairly full, but you can see the same effect.

-

Some have installed an electric water pump, others have reported using a smaller pulley to increase pump rpms. This is a topic that has been discussed a fair amount on lotuselan.net and seems common - if you haven't already you might dig around over there. Personally, I have a bigger problem in my Elan than in my Seven - my Elan does NOT like being stuck in traffic and heats quickly - but this is more about airflow as it cools quickly again when on the move. An electric fan and periodic blips to keep coolant flowing generally work to keep it from overheating unless ambient air temp is in/above the 90s. When it is really hot out I just need to get out of traffic. My Seven seems to have fewer issues - but if I'm at a light for any period of time on a hot day a few blips on the throttle yield a noticeable drop on the temp gauge. A few other thoughts/observations, in addition to what others have contributed... 1 - you say it is overheating, but what does that mean? Are you observing a particular temperature on a gauge, IR gun, temp strip, etc., or are you getting coolant overflow? 2 - there are, obviously, 2 main drivers of cooling efficiency - coolant flow and air flow. As it seems you're only stationary, what are you doing to ensure cool air is actually flowing through the radiator? Does increasing/decreasing that airflow have any material impact on the heat measurements you're getting? 3 - are there any signs of even miniscule oil contamination in the coolant, that might suggest leakage at the head gasket. Is coolant blowing out anywhere? If I can get a few minutes to run over to the shop this morning I'll try to grab you a video of my swirlpot when my Seven is idling and when I blips the throttle - that may give you a single point of comparison to what you're seeing - but my recollection is not of gushing flow.

-

I'm not following you on this statement. The pump outputs into the engine cooling cavities and then on up to the swirl pot. Are you giving it any revs, or is this all at idle speed? The pump is notorious for not moving much volume below 2k rpm - so if you're just idling I wouldn't expect to see much swirlpot activity. Otherwise, as MV8 and Croc have pointed out, it does seem like it would be something clogged in the engine cavities restricting flow or an inoperable/reduced efficiency pump. You don't have a heater box on your Seven, do you? That's another place to get clogged up.

-

Similar and generally interchangeable, but some significant differences. The biggest difference is the 105e is a 3 bearing block and the 120e (116e) is a 5 bearing, so preferable. The old Dave Bean catalogue has some great information on engine blocks, if you have one. Some of that may be online now. There are also some good online resources for Kent Ford engines - google that and Cortina and formula Ford as I recall. The following link is to a thread that includes an unpublished book by an enthusiast. A phenomenal resource. https://lotuselan.net/forums/viewtopic.php?f=39&t=52339

-

I was looking around the lotuselan.net site for something else and came across an alternator thread. Some reported the early 70s +2s came with the Lucas 17ACR alternators (type 36A), so maybe that is what you would have had. I can say that many retrofitted with Denso 45 to 55amp alternators.

-

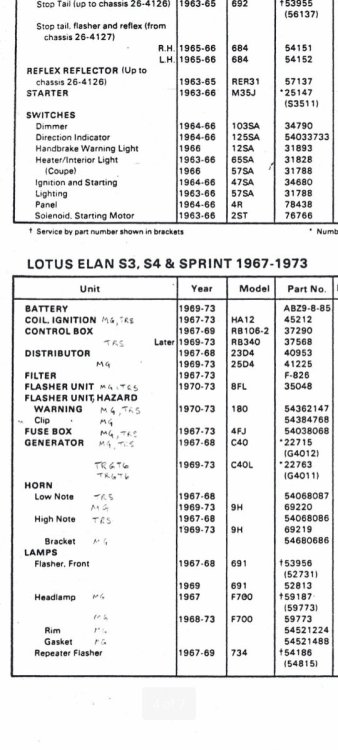

I didn't have anything S3 specific in my files, but the S2 used the C40 generator. So did similar Elams and Cortinas, which then switched to the C40L for late 60s/early 70s runs. Given that, I'd bet on the Lucas C40L generator.

-

Agree. He was extremely helpful to me and did nice work.

-

-

I'll grab some measurements in the next couple of days, but going on recollection I'd guessnthe rope seal side is 1/2-3/4" smaller than the other end.