EdWills

Registered User-

Posts

237 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by EdWills

-

Hi MV8. I have only once had my James Neill (Sheffield U.K.) 40 - 160 ft/lbs wrench verified for accuracy at a local aero instrument testing centre more for insurance against breaking studs on my family vehicle. It came out as almost 100% accurate on all of the readings that they tested. I realize that for speed, most technicians at auto businesses use the air wrench for doing up wheel nuts, but an experience a few years ago - where my front wheel nearly came off - led me to check the wheel nuts with my torque wrench. The auto business tried to claim that the technician's torque wrench was badly out of adjustment, but I have worked at a couple of auto dealerships, and never seen a torque wrench taken out of its protective case to this date for wheel nut tightness checks. What do aircraft technicians do to ensure that a torque wrench is accurate each time they use one? Do they have a test rig at every repair location to verify the readings before using one, or do they assume the tool is accurate? Scott, does Craftsman still obtain tools under their brand name and manufactured in the U.S., or are they now produced offshore like so many others? I noticed in Kauai a few years ago, that 'K' Mart sold them. There was a company in the U.S. that produced specialized tools for rebuilding many of the North American engines including the Pinto and 1600 Crossflow, but they closed down years ago. A gent in the U.S. was selling off a huge supply of these secondhand special tools that he had bulk purchased. He sold them on the well known web site at a very good price, and I managed to obtain a few tools for the 1600 engine (seal replacement tools mostly). They are excellent quality. I have a Craftsman U.S. manufactured beam type torque wrench, but it is for very low poundage, and hard to read in certain locations on the car. Beam type are not known for their accuracy as much as the other 'click' or digital types apparently. Cheers. W.

-

Is anyone familiar with CDI torque wrenches? I googled all of the options for torque wrenches, and prices and styles are so numerous with various sites recommending one over another. I understand that CDI is a division of Snap-On, so should be good quality I am hoping? I need a wrench for 5 to 70 ish foot pounds, and CDI manufactures one suitable for this range. I also have a U.K. produced wrench for higher torque values that I get checked at a local aero tech centre. Although it has been covered previously (some time ago) about which tools members should consider using for repairing or carrying in their Seven, are there any tools that are still manufactured in the U.S. other than Snap-On? I often see the Mac truck at the various car dealerships in my area, but I really miss the Sears Craftsmen tools that were manufactured in the U.S. and sold in Canada, which were the go-to tools for me at least. I never had one break, and the guarantee was very impressive if you ever did happen to break one. The original tools for my motorcycle in the U.K. came from Europe (Elora, Germany) or France, with a number of Sheffield U.K. manufactured tools to compliment them. The late, great, Carroll Smith was fond of Craftsmen tools although he naturally went more for the professional range for his racing car production. Thanks for any input. W.

-

Hi again Christopher. I have been looking at an older (2020) Burton Power catalogue, and on page 109 it lists some clutches and covers manufactured by a company in the U.K. called Helix. Part number 70-1605 for road or rally is an alternative cover for a SOHC Pinto with 1" x 23 hub (5 speed box types). The 70 Series is described as sprung centre organic drive plate type. Not sure if this is what you are looking for, but the size fits the description and the plate is for a 190 mm clutch cover (which they also sell under the Helix brand). Price for the plate (on the current Burton site) is L163.75 Pounds sterling with the U.K. tax removed (L196.50 U.K. Pounds with tax). I know that U.S. sourced would be best, but perhaps supplies of these items are now much rarer in the U.S. than when the engines, gearboxes etc., were still used in production vehicles? As many owners in the U.K.and Europe are still running cars fitted with all of the smaller Ford engine and gearbox options (including Imperial measurement parts), companies are willing to manufacture new parts for these cars. AP Racing also produces a 1" - 23 spline plate, but it shows that it is for a 216 mm cover (part no. CP5354-38). AP have always been very helpful with any questions I have had, and they don't mind individual inquiries direct to them. (Note: 190 mm = 7.48 inches or 7-31/64", and 216 mm = 8.504 inches in old money). W.

-

Lotus fitted a radio to the one-off 'luxury' Lotus Seven Series 3 'S' model in 1969, and the petrol/fuel gauge and tank sender came with the Series 3 in 1968 (and possibly a bit earlier with the Seven 2-1/2?). Lotus used a mixture of AC (Delco) for gauges and petrol senders, along with Smiths Instruments for other gauges. Rear lights for the Series 2 and 3 were from trailer accessory manufacturers. The one common original accessory to span the production of many Lotus and Caterham Sevens is the handbrake - which, according to published accounts - no one seems to know what original vehicle this came from. Lotus used Lucas electrics (remakes still available), and the Wipac washer system. W

-

Aha. The good old-fashioned Lotus factory method of securing the spare. My Lotus uses a brown leather strap. The hood also has a slot to take the strap. Easy to remove (or steal) the spare! Caterham were still following the Lotus methods up to the early 80s. What brand are those tires please? I see they are 175-70 R13s and maybe Dunlop SP60? W

-

Hi Billy. That fabrication looks like an Arch Motors part. They should be able to manufacture that for you, as they still produce items for original Lotus and some early Caterham Sevens The U.K. Pound to $U.S. exchange rate is not bad at the moment, and Arch will not have to charge you the U.K. Govt. tax, just cost of the part and shipping by good old Royal Mail. Please make sure that they use tracking, but most Royal Mail parcels already include insurance so that if a parcel is lost, the sender is compensated and they can compensate you for the full amount if it goes astray. Good luck. W.

-

Bolts, tubing, oil slinger, models of Lotus cars for sale.

EdWills replied to EdWills's topic in Parts For Sale / Wanted

Hi Pethier.. I'll mark them down as sold to you. W. Please contact me at your leisure. -

Bolts, tubing, oil slinger, models of Lotus cars for sale.

EdWills replied to EdWills's topic in Parts For Sale / Wanted

Hi Scott. It's yours. Cheers, W. -

Hi Christopher. The major source that I know of is Burton Power in the U.K. who are Ford experts, and have tried every known combination of mixing and matching clutch parts. They have a fairly extensive choice of clutch components, and if you get the right person to advise you, they may be able to sort out the problem. I was also going to recommend Repco in Australia, as they used to sell clutch parts for all of the Ford small engine types, but their web site is not cooperating at the moment (they may have been hacked!). Have you also tried contacting Tilton, who really are the experts on clutches in North America? W.

-

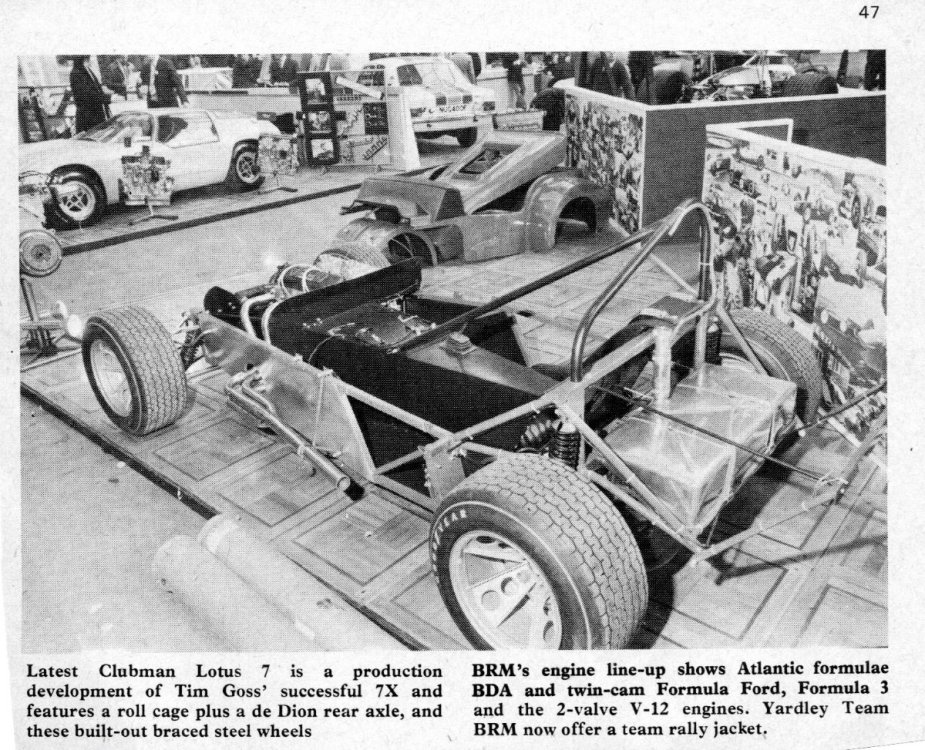

And the one-off Series 4 based Clubman Car at the 1971 London Racing Car Show. The fibreglass bodywork is stacked up nearby.

-

I am clearing out some items that I no longer need, so if anything seems useful, please contact me. 1). Packet of 6 - 7/16" x 1" UNC new/unused threaded set screws (all thread) to attach the 2000E (2821E) gearbox to the Ford bell-housing (4 actually required leaving 2 spare). 2) Packet of 10 - 7/16" x 1" UNF new/unused Hex set screws (all thread) for seat belt attachments. Stainless steel. Westfield Fasteners U.K. Offers plus postage. 3). Packet of 2 - 7/16" x 2" UNF new/unused Hex set screws (all thread) for seat belt attachments. Stainless steel. Westfield Fasteners U.K. Offers plus postage. 4). 2 of - Standard Triumph Spitfire/Herald steering rack tubes - left-hand drive. These have been bead blasted and painted. New rack end bearings. No rack or pinion parts, just for spare in case original rack cover becomes bent or worn. FREE plus postage. 5) 2 of radius arms - oversize tube at one end for a larger metallastic bush (not included), and threaded 1/2" UNF at the other end to take an adjustable (for length) rod end bearing (not included). Professionally Tig welded. Useful if extra adjustment is required to square up the rear axle casing, or if a spherical bearing is also fitted to the diff. Offers plus postage. 6). Shaped 18 gauge mild steel plate to fit between the steering rack mounts on a Seven to strengthen the frame in that location. It has not been cut for any radiator hose or radiator connection. It is longer than needed so that it can be cut to fit accurately. (To be donated if not required) 7). Used Ford Cortina cast iron rear differential crown wheel and pinion housing - no innards, but comes with bearing caps. All parts are still available for this diff. housing (from Burton Power U.K. among others). It is lighter than the Ford Escort case by at least 3 pounds, and has the same bolt pattern as the Escort diff. housing. Offers. All offers will be considered - big or small - with the best offer being chosen. Thank you for your interest. W.

-

Considerations when looking for a slightly older 7

EdWills replied to philso's topic in General Sevens Discussion

Hi Philso. Super 7 Cars (also known as just '7 Cars') on Vancouver Island, is closing down its business after the original owner David Saville Peck passed away a number of years ago. There is a telephone number on their web site for contact purposes, but the site does not open up to see if there are any 7 models remaining in stock. Mr. Saville Peck used motorcycle engines in his Caterhams, and parts supplies for these and the Caterham chassis should not be a problem for quite some time into the future. Maybe storage on the Island could be cheaper than the mainland while you are making your move back to God's country? W -

Hi Scott. No, it's a Lotus casting. Same diff. as fitted to the Lotus Elan with Lotus Formula Ford uprights. W

-

Hi Carz.. Great info. - thank you. I am guessing that Colin Chapman would not appreciate Steele Bro. messing about with a car that Lotus had authorized for construction (the Series 4/IV model only) by this company (although Steelbro did manage to slot in a Lotus 907 engine in some of the cars). The only other Seven/7 to be authorized and constructed away from the Lotus factory was the Argentine Seven (Series 3 model). This used Fiat engine and transmission parts, but not very many constructed. Some time ago, I contacted the New Zealand Lotus Seven Club, and they may still hold the molds and jigs for the Steelbro 7 Series IV. When Caterham bought the rights to the Seven from Lotus, Caterham commenced construction of the Series 4 until some of the specialized parts started to run out with outside contracted manufacturers deciding that small build numbers were unprofitable for them. That is when Messrs. Nearn and Wakefield decided to resurrect the Series 3. Last incarnation of the 7X. It is featured in the magazine shown in the photo. The Series 3 rear end had been removed from the car and a later rear wing added. There are more photos of the original 7X on the Lotus Seven Register by John Watson and also at anglocanadianlotus7.ca The 7X was based on the Series 4 chassis with ally panels and some fibreglass as per the Series 3. W.

-

Just a P.S. Forgot to add, that in my opinion only, this is what Lotus should have done with the Series 4. Not so much fibreglass, and aluminium and frame from the Series 3 with the Series 3 SS additional tubing for strength. This would then follow on from the 7X in appearance (although the 7X was heavily modified over the few years that it raced due to less than optimal frame design strength). The one-off Series 4 Clubman used the Series 4 frame and some of the bodywork, but retained aluminium for the side panels the same as the car shown above. Would also note that the aluminium body work on this car - around the dash - looks very well done. If I was in the market for another Seven, this would be right up there on my wish list. Cheers W.

-

Admin note: this thread was split from the following for sale thread. https://usa7s.net/ips/topic/15452-1979-lotus-super-seven-mk4-twincam-steelbro-nz/ Although interesting information, it is more appropriate for a dedicated thread in the General section than it is within someone's for sale advertisement. A Series 3 and Series 4 Hybrid? Back end looks Series 3, front end Series 4. This is similar to the combination of chassis parts used on the Lotus 7X Clubman race car. Never seen one advertised like this before, and no pictures of Steele Brothers producing a car like this using alumimium for the body panels. Would be curious to see the chassis frame work. Interesting! W

-

Hi Dreamer. Very good news about the repairs. Earl really sounds as if he has a handle on your Caterham repair. Sorry, but I haven't seen the article on your car. I tend to lean more towards Lotus Seven information in order to learn more about the owners and repairs/parts to these cars. There is another Lotus Seven forum that I belong to, but you cannot post photos or diagrams on the site unfortunately. Also Simple Sevens has been a great resource for me, along with all of the information provided by John Watson in the U.K. on the Seven. The Caterham cars have seen so many changes to their frame construction plus engine/transmission/suspension arrangements, that it makes a Lotus designed Seven (any of the Series), seem so much simpler and much more basic, which of course, it is. Parts for the Lotus Sevens are also becoming harder to find these days. Cheers for the updates. W.

-

Hi Dreamer. If you can, try scraping the paint away from a couple of the welds to see if it is an Arch gas flux bronze welded chassis, or perhaps a mig welded chassis from Caterham (Cages or Caterham factory?). If it is gas flux braze welded, no tig or mig should be allowed near the bronze welded joints if possible. Heat can be applied carefully with an oxy/acetylene torch to straighten tubes as necessary, but the body shop tech should be advised regarding the chassis tube joining method. I have seen a couple of good body shop videos (one from a Nissan tech in Japan) who did wonders with a damaged Nissan car. It is amazing how body shops can restore bent metal back to shape and make it as good or stronger than the car came from the factory. If the car needs to be stripped, can you store the engine, transmission, fuel tank etc. at your place to save on any storage charges and prevent possible theft? Good luck. W

-

Error

-

I'm probably preaching to the converted, but don't sign anything until you've thoroughly checked everything on the car, and you are satisfied that everything possible has been calculated regarding parts and labour to fully repair the car back to normal. Not sure if Ontario has a no fault insurance arrangement, but where I live, this is happening. You could replace the damaged panel with a new one that is re-riveted up to the first rear upright beside the cockpit rather than replacing the entire side panel (which would of course require a major strip-down). As you know, the panels are not structural on the front of the car, and the old rivets can be removed with the car raised up so that you can drill them out easier. The replacement panel can be Tig welded on to the original panel towards the rear. Not sure if your car has a rear front wing stay, but if so, this would hide the join. Or get the replacement panel sprayed the same colour to match the original paint on the car, attach it to the frame and use a sealant to join the new panel onto the original. Again, the seam will not be too noticeable under the front wing even without the rear wing stay. Check the rack inner ball joint on that side to see if it took a hit as often 'curbing' or a hit such as you have experienced, can easily bend the inner ball joint where it joins the rack (the 'neck' on the inner joint can be quite narrow on some racks and bends easily). Caterham should be able to provide all the parts, or perhaps Arch if the car chassis was assembled by them? Courier costs/duty/taxes should also be calculated of course (from the U.K.). If this is all too obvious, my apologies, but after the stress of the incident has passed, figuring out what to do afterwards can be more stressful (I know as I went through it years ago). Do you take a payout or get the car fixed (if insurance is willing to allow this)? If the insurance company writes it off, do you buy it back and then try to fix it, or just take the money and buy a new one at a much higher cost? If you have replacement cost insurance, so much the better, but some insurance companies may not offer this. Good luck, and really glad to hear that you and your wife were not injured. Best, W.

-

I never realized that Caterham went to the extra length of rolling the ends of the water pipes, but it does provide a better method of sealing of course. Lotus merely used pipe without any rolled ends (cheaper to produce) and relied on the wire clips to hold the rubber hose on to the pipe. I still have the original 1968 metal piping, some rust build-up evident inside, but heavy gauge mild steel and no leaks or weak spots. I think that Mick Jagger has rolled, raised lips, but not sure if they are at both ends? W

-

A beautiful rebuild of your Seven. Genuine Unirad chassis with correct graphite paint colour (or powder coat?). It looks fantastic. W

-

Hey Scott. I think it just harks back to the Seven being driven in the U.K. where it seems to rain all the time, and the dampness just soaks into your bones! The old Smiths' heater probably just warmed the feet and knees of the driver and passenger. Lotus included a template in the Series 2 manual to show where the necessary holes needed to be cut to fit the heater, possibly indicating that it was not always included in a kit or factory assembled car? Many of the Series 3 Lotus Sevens imported into Canada (that I have viewed), didn't come with a heater, as driving a Seven in the middle of winter here wasn't the brightest of ideas. We don't get a lot (or any?) sports car owners driving their cars in winter here because of: a) bad road conditions (ice, pot holes), plus other drivers new to our province not bothering to fit snow tires and not used to snowy conditions. b) rock chips from passing cars, as our city loves to dump as much gravel on the roads as possible (thankfully spring clean-up starting now). The worst heater I had was fitted in my 1963 VW Beetle. The glow plug would forever foul up, and the only heat for the windshield was from the engine heat being vented through the car. A scraper was a necessity to scrape the ice from the inside of the windshield. I agree with 11Budlite that a motorcycle jacket is a good idea. In the U.K. the Belstaff m/c jackets and pants were oiled cotton, and pretty much waterproof. I used my set year round as they also kept the cold wind out. Cheers. W.

-

Hi Scott and MV8. According to the Jake Lamont/Tom Andresen book on how to build and maintain a competitive (yet legal) Formula Ford engine, (page 75 in your song sheet Scott), the FF rules in the U.S. allowed the Holley 5200 to be used in place of the 32/36 DGV. The Holley 5200 was 'basically a licensed copy of the Weber unit'. As you probably know, the Weber carbs are mostly manufactured in Spain these days. Not sure if Ferrari owners still insist on the originals from Italy though? W.

-

Hi Scott. You may have checked already, but on Amazon there is 'Weber Redline' (U.S.), listing a new 32/36 DFEV carb, or try Pierce Manifolds U.S. for the same type. The DFEV is the opposite throttle orientation to the DGV series of downdraught carbs, but is in the same orientation as the 32DFM that Ford and Lotus used on the 1600 Crossflow engine. The 'E' is of course electric choke, but a couple of sites on the web offer a fairly cheap conversion for manual choke operation. Lotus and Ford used a manual choke to operate the 32DFM (which was cast for manual operation). I purchased a kit on th' e bay' (Chinese manufacture, free postage, came out of Eastern Canada - go figure - must have a rep there!), and I can advise which is the correct kit to order (actually for a 38/38 Fiat Weber carb if memory serves as it is the same orientation as the DFV, but I will check). Do not go for the DGV manual choke kit (as I originally did - as one site noted it was o.k. for a DFEV - not), as it works the wrong way for the DFV choke cable set-up to operate the choke correctly. I beefed up the Chinese choke control (try saying that fast a few times), with a brass bush which I can send you gratis as I have a few. It makes the choke operate more smoothly and takes out the minor slack in the mechanism. You can carefully take the electric mechanism off (Peter Wallage shows how in his 'Ford's Kent Crossflow Engine' book, or I can photocopy and send the pics to you (with Credit to Peter and Valerie Wallage and Haynes Publications). I did purchase a couple of spare lock tabs for the carb from Pegasus, as the flimsy one on the carb may break when removing it. The Weber throttle lever may have to be removed as Lotus used a lever from their Type 51 Formula Ford car for the throttle (along with a pre-formed Lotus 51 alloy bracket). Ivey Engines (or Pegasus, or any FF tuner) can tune these carbs to your choice of tune. Note: I wish we had an Ivey type of machine shop in my location, but they have all retired - which is good for them, not so good for me! W