EdWills

Registered User-

Posts

237 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by EdWills

-

Where can I get a nose cone for a Series 2, Lotus 7?

EdWills replied to Bill's topic in General Sevens Discussion

Hey Scott and Bill. Just found this post, and checked my files for other measurements on my Seven. For a replacement Lotus nose cone from Redline, Chris advised in 2020 that the replacement colours available are yellow, green and red. He also provided information that the inside measurement dimension - where it is held by the Dzus fasteners on the top of the chassis - is 25-1/2 inches with easy flex of 1/4 inch larger or smaller. I have checked a nose cone that I purchased from Mick at Xtra Special Sevens, and his is slightly narrower than this to fit nicely on the chassis. Arch (Bruce Robinson) advised me some time ago that their "current Lotus S2/3 bonnet is 37 1/2 inches (measured along the centre line). This would have been an average length of what had been previously produced". It came without any cut-outs for the 1/2 ice cream scoop or the cut-out for the downdraught Weber carb. He later advised that Arch were no longer selling the Lotus bonnet, but I'm not sure if this was temporary or permanent? My notes from my original car show that the the Lotus Seven nose cone from the very front to the Dzus fastener centre is 23-1/2 inches and the scuttle is 8-3/4 inches from top to bottom measured in the middle. The centre of the Dzus bracket on top of the chassis, to the front of the chassis is 12-1/2 inches for a Lotus Seven S2/3, and this is confirmed with other Seven chassis drawings on the web. I don't know if they are still posted, but Pat Prince who is/was a Seven chassis builder in the U.S., posted a series of drawings for a S2/3 taken from a Lotus Seven chassis. Likewise another gent posted measurements from his Series 2. Just a note: There were two chassis builders of the Series 3 - Unirad and later Arch. Each built their own jig with measurements supplied by Lotus. My replacement Arch chassis does not exactly correspond with measurements that I took from my original Unirad chassis. There is not very much in it, and possibly of no consequence, but adjustments may be required if fitting panels, for example, from one to the other. If anyone requires other measurements, I can check the drawings I have from the various sources, to hopefully come up with a satisfactory answer. W. -

Ford Anglia 100E produced 1953 to 1959 (photo on wikipedia)

-

-

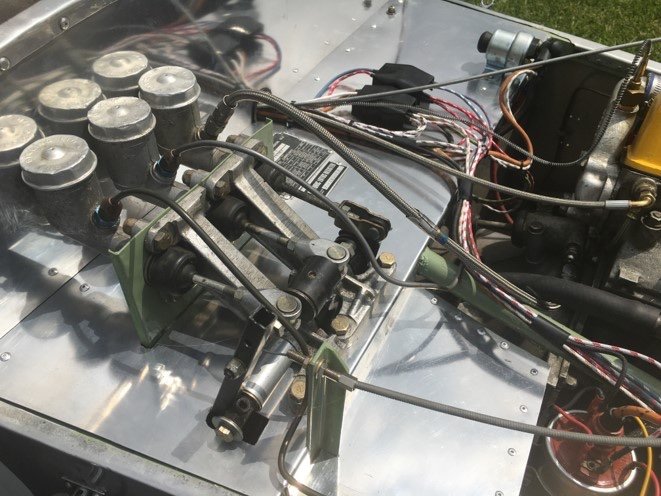

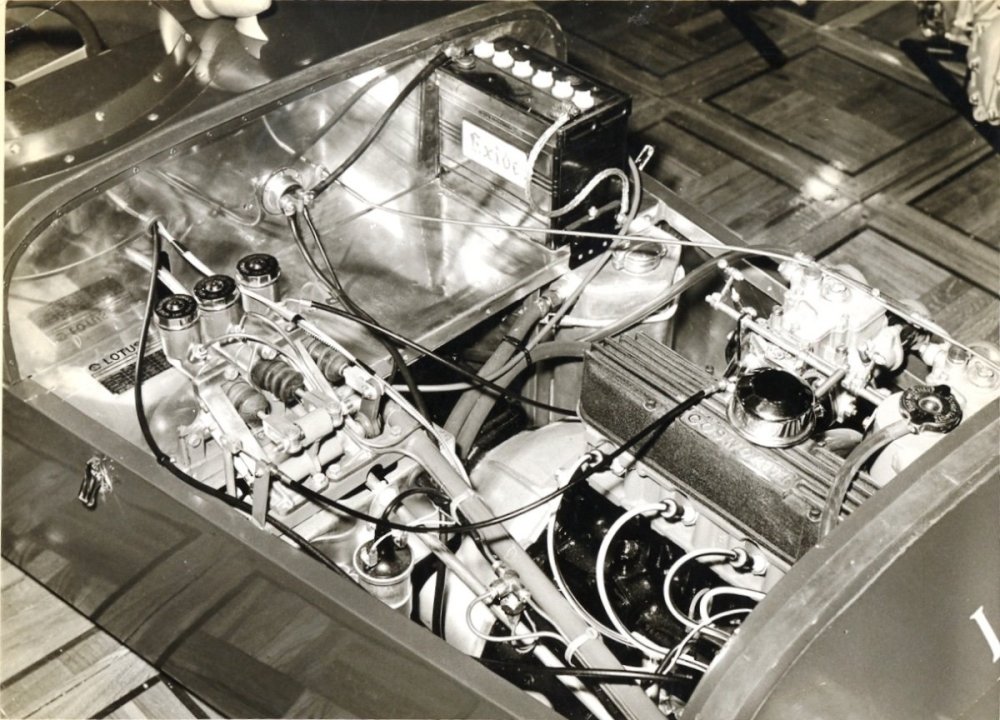

Joe, absolutely nothing wrong with your set-up. As long as any conversion is sturdy and safe, go for it. I have attached a couple of photos of a Series 1 owner's car with a brake bias bar set up (courtesy of Simple Sevens). Similar to Joe's system, a metal plate has been used to strengthen the two 100E brackets with the second one being mounted beside the original. Tilton Engineering manufactures an adjustable brake balance bar that is very suitable for a Seven (part number 72-250 for 2-1/2 inch centre M/Cs.), and fits perfectly between the brackets, allowing full adjustment, and permitting the brackets to then fit comfortably on the front angled bracket (just one extra hole required in the angled frame piece). A small extra frame bracket (from Arch) is required to be welded on to the square section frame tube (located behind the angled frame piece) to secure the bracket lug/ear of the second 100E bracket. Arch/Caterham manufacture/sell a replacement Lotus Seven clutch pedal suitable for bias bar modification (I purchased an original Seven clutch pedal secondhand) which allows for correct spacing of the 3 pedals. If you try to use the original brake pedal without modification, there is insufficient spacing available as it moves it too close to the accelerator pedal. With the Tilton bias bar pivot sleeve attached to the top of a clutch pedal, using 2 clutch pedals gives correct spacing, should provide good heel and toe control, and doesn't require unnecessary bending of the original brake pedal. If you want to return to just the one brake master cylinder, the brake pedal is easily replaced to return the car to as originally produced. I used an appropriate metal cutting hole saw to obtain the correct 'half moon' cut out for the pivot sleeve, and made up a jig which allowed my local Tig welder pal to correctly locate the bias bar pivot sleeve onto the top of the pedal for welding. It permitted him to centre the pedal as necessary (using spacers/washers) and get it all square. The pivot sleeve may then require reaming, as the welding process may cause it to shrink very slightly and not allow free movement of the bias bar bearing. Note: My second-hand original Lotus Seven clutch pedal had the pedal pivot bearing tube welded off-centre by the manufacturer (Universal Radiator?), so washers aided in centering it. I no longer require this jig (along with a suitable hole saw) if anyone wants to try this modification to the pedal. GMT/Lee Chapman Racing sells a clevis that is an exact match for the type used by Lotus and fits the M/Cs and the Tilton bias bar arrangement. As a thought, Tilton is in a perfect position - if they ever consider it - to manufacture new 100E brackets. Their engineering and manufacturing know-how is first class, along with their quality. Probably a minimum production run would require thousands of dollars to set it up, but not being anywhere near a business minded person, I do not know for sure. Cheers, W.

-

Here is a photo of the original 1965 Lotus 37 on its introduction at the Racing Car Show. Lotus used two of the 100E brackets, sawing off lugs on the second bracket to clear the frame and added an extra frame bracket to secure the second (right hand) bracket. They placed a balance bar in between the brackets and used one long pedal pivot pin instead of the originals presumably for safety, as trying to use 2 pedal pivot pins doesn't really work. Photo courtesy of John Watson - Lotus Seven Register. W.

-

Hi MV8. The solid steel pedal pivot pin is a tight push fit into the bracket. The hole in the bracket to accept the pivot shaft pin is slightly tapered, and the pin will only come out (or go in) - without damaging the bracket - one way (I recall that it inserts from left to right when looking towards the front of the car, but I will have to check). It can be safely removed by placing the assembly in a large vice (I used a 5 inch vice with protected vice jaws), then using a suitable sized socket (or some tubing) press the pivot pin out. The pivot pin is knurled in the middle to ensure a tight fit. With the brake and clutch pedal mounted on the shaft, 2 'omega' shaped square section spring clips hold the pedals on. The phosphor bronze bushes inside the pedals are a push fit, and I used suitable sized sockets to push the old ones out, and the new ones in. I sourced mine from the original Redline Company, but the new one may also be able to source these. I did a recheck, and there was also a Ford Anglia 100E produced and built in the U.K. and Australia. It was not the same shape as the later produced Ford Anglia that had the raked rear window area and which was featured in the Harry Potter series. If you check Wikipedia for Ford 100E, it shows the variations of the car all looking much the same. The 100E series was a smaller version of the Ford Consul range. There was even a Ford Escort 100E version long before the later, very successful Ford Escort that spawned the highly successful Mexico car. Scott. Caterham also produced versions of the bracket for their various cars and would cut a lug off for cable clutch versions. Hope that the GMT bracket suits the purpose. W.

-

Hey Scott. As noted by Croc and yourself, Ford Pop 100E, Prefect 100E, plus Ford Squire, Ford Thames van (also known as the Thames Trader 300E) all probably used this bracket. I read that the bracket shown in your photo was fitted upside down in the Ford application. Lotus of course placed it the other way up. I purchased one of those brackets from GMT (originally Lee Chapman Racing), the casting was fine, but whoever machined it after it was cast didn't do a great job and it turned out very crooked. At $198.00 U.S., obviously not cheap. I sent it back for a full refund, and later found that Mike Brotherwood in the U.K. had one for sale at a reasonable price. Check out his website for Seven parts. A company now long gone called Neal Products, San Diego, California (spare parts may be available second-hand?) manufactured a slightly similar looking bracket for their brake master cylinder set-ups. They produced brake bias bars and other brake components - all of very good quality. A shame that they went out of business. W.

-

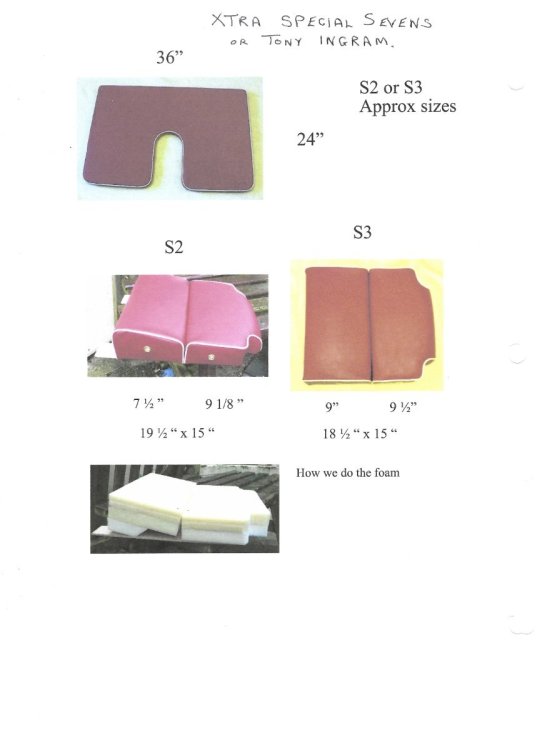

Just a P.S. Not sure why Mick drew the Series 3 seats without the front wooden seat 'tabs' (and produced them 1 inch shorter) as my Series 3 certainly had the wooden plywood extensions on the front and exposed to the elements. I have seen an alternative type of seat squab on later produced Series 3 cars, so obviously the seat manufacturers at the time made slight design changes. EW

-

Hi MV8. A very good idea if the seat cover manufacturer has not included mesh vent ports in the sides of the seat squabs. A few years ago, a very helpful Seven owner in the U.K. (via the lotus@se7ens forum) introduced me to a U.K. seat manufacturer called Aldridge, who also produced manufactured seat covers for Europas and Elans. After producing the seat covers for the U.K. Seven owner, and myself, the company advised that due to the time it took to produce them, and the labour involved, they politely advised that they would not be doing it again. But - perhaps they may be persuaded to reconsider? They sourced the identical vented basket weave vinyl as used by Lotus, and hot melted the exact same seams into the material. Round brass vents were added to the squab sides. Failing Aldridge, the Caterham U.K. seat manufacturer - Oxted Trimming - may be a good choice. EW

-

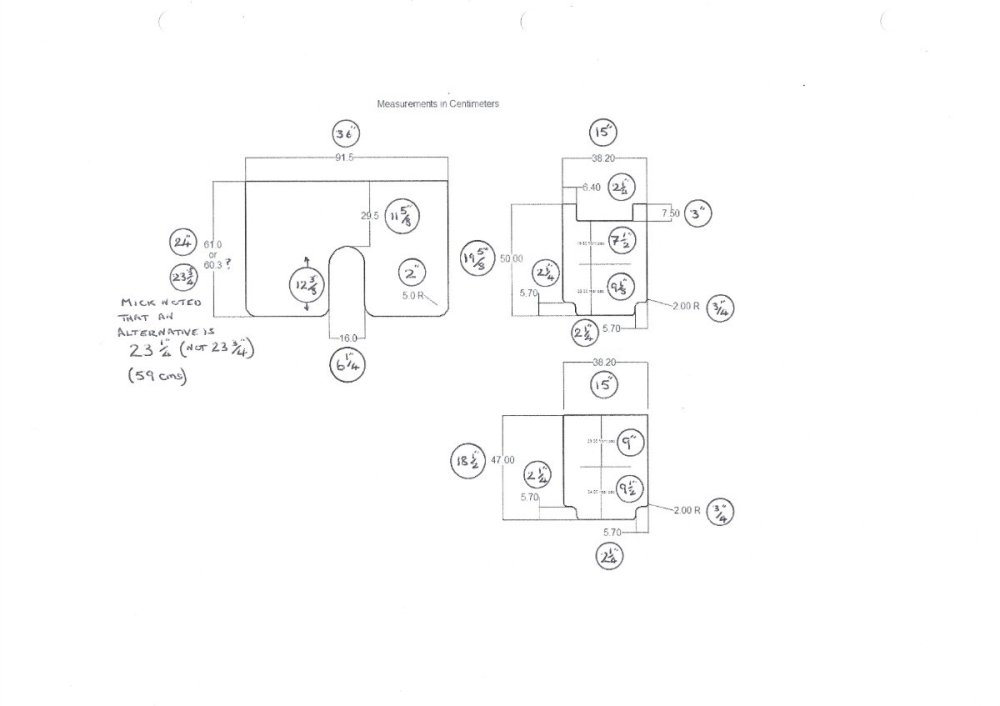

Your choice of course, but 3/8 inch thick ply may be a tad too thick, and can still warp. To avoid the possibility of warpage (wood has a mind of its own as we have all experienced probably?), you can use varnish or paint to seal the ply, on each side and the edges. No guarantees it won't warp, but worth doing. Water based varnish or paint will raise the surface structure of the wood, so sanding may be required after treatment. Lotus used a black painted thin ply sheet for the boot top also. On my old seats, 1/4 inch ply was used by the Lotus seat manufacturer. The previous owner discarded the wood boot top, and used sheet aluminum instead. I used a hand stapler to reattach my seat covers as the original wooden base was starting to rot and develop mold (mould?). I used 3/8 inch staples through the seat covers into the varnished ply. Scott, on your chassis, and on my new one, Arch welded in a 1 inch square tube at the bottom of where the seat back rests, but Lotus never included this in the Series 2 or 3, so if this extra tube it fitted, it may force the bottom of the seat back forward a little bit. If refitting used seats to a chassis that has this tube added, it will mean that the length of the seat squabs may require adjustment (slight shortening) either at the front 'tabs' or in the total length starting at the back. For all of the suggested 5.7 cm inside radii, a 2 inch hole saw does the trick. EW

-

Hi. I think you'll find that those measurements came from Mick Beveridge at Xtra Special Sevens (now sadly out of business). Tony Ingram was importing the seat covers in the U.S. sewn up by Mick's wife, but Tony notes on his website that he is out of the covers. Tony would be able to confirm measurements for you though, as he has rebuilt his own Series 2. Cardboard cut-outs are a very good idea, as in some cases Caterham specified slightly different prop shaft tunnel widths from Arch depending on the chassis. In one case the prop shaft tunnel was 6 inches wide (seats were 15-1/2 inches wide + 6 inch tunnel width, and 1 inch x 2 lower side tubes to produce 39 inches wide total chassis width (Imperial Lotus measurement chassis built on original Lotus Seven jig). Arch (Bruce Robinson) advised me that the tunnel could be 5 inches wide (old Lotus chassis measurement) and therefore the seats could be 16 inches wide. Bruce provided another possible measurement that 5-1/2 inch tunnel width had been used, so there seems to have been enough variations for the need to make up a good template for your particular chassis. Don't forget to allow for the thickness of the seat material all around (to fit inside the chassis snuggly) when cutting out the plywood. 5/16 inch thick ply seems to be good, but perhaps 1/4 inch would be o.k.? In Canada we can get nice Baltic ply and also waterproof ply (not just for boat use) but expensive these days. I've asked on another Lotus Seven forum what comes first (not the chicken or the egg!), but does the seat back fit over the seat squab, or does the seat squab go in last to secure the bottom of the seat back in place? If the seat back fits over the seat squab, it might sit too high for seat belt mounts behind the seat back. (61 centimetres in the drawing equal to 24 inches - 60.3 centimetres drops 1/4 inch off this measurement). Mick's 91.5 centimetres seat back width equals 36 inches, so with the chassis rails of 1 inch each side for a total of 39 inches (this measurement was confirmed on my 1969 Lotus Seven chassis as well on various Seven diagrams on the web), there is a slight gap of 1/2 inch each side of the seat back which is o.k. with the seat cover material taking up the gap. Mick used double stacked foam to produce the raised front section of the seat squabs. Lotus had their seat manufacturer produce a one piece wedge for the front, but unless you happen to have a hot wire cutter (or can make one?), stacking 2 foam pieces may be easier. Good luck with your upholstery project. Check Tony Ingram's site as it shows the seat covers that Mick produced for the Series 2. Cheers EW

-

Hi Steve. According to the Tony Weale book, the 1700 Supersprint (my apologies, I thought that you had the 'Sprint' model with the A2) was fitted with the 'Caterham BCD' camshaft. Years ago I inquired with Caterham and the parts manger advised that the BCD cam was actually a 234 camshaft (Kent Cams product possibly?) with 1300 c.c. pistons fitted to the engine for higher compression ratio and Weale puts this at 9.75:1. The 234 cam is 280 degree inlet and exhaust with valve clearances cold at inlet: 0.022 inches, exhaust: 0.024 inches. The engine capacity is listed as 1690 c.c., and the bhp rpm is as you note, 135 @ 6000 rpm.. Kent describe the 234 as a 'superb sports road cam, flexible enough for use in a lightweight se7en, good for track day use'. Timing 37/63 73/27. Plug type NGK B8ECS. Just an fyi, James Whiting in the U.K. is a great source for NGK plugs for the Seven range. I tried my local auto parts shop, and they couldn't find some of the plugs listed for the original Lotus Seven or the Caterham variants in their NGK booklets. Maybe NAPA or similar can order them? Hope that this helps? Ed.

-

Hey Steve. According to Tony Weale in his book "Lotus Seven - Restoration - Preparation - Maintenance" the 1600 Caterham Sprint version was fitted with the A2 camshaft with clearances of 0.020/0.022 inches as standard. The h.p. rating for that car was only given as 110 @6000 rpm with 2 Weber 40 DCOE carbs. Weale included a note that the 1600 Sprint engine up to chassis CS3 4099 had clearances of 0.012/0.014 inches.

-

P.S. An aircraft welder friend recommended LPS3 to spray inside the frame tubes. His aircraft repair company uses this product, and it comes with a long and small diameter nozzle that can easily be inserted in a 1/8" or possibly a 3/32" hole. I purchased mine from a local Grainger store (no connection, just a satisfied customer) W.

-

Excellent advice from all, and Pegasus is very proactive in their search for handy tools. One way to hold the rivet while drilling is to use a small centre punch (or a sharp pointed nail possibly?), lightly tapped into one side on top of the rivet and angled away from the drill bit, then drill away. The punch should stop the rivet from spinning. Either that, or wedge a flat tipped screwdriver that has been ground down to a sharp edge, as per MV8's suggestion. Don't be too concerned if the hole you are left with is a tad on the large size, as Carroll Smith in his excellent series of books, suggests that a No. 30 drill for 1/8" rivets, or No.20 drill for 5/32" rivets allows for correct expansion and clearance when inserting a 1/8" or 5/32" rivet respectively. A comparison chart that I have from Snap-On shows that 5/32" is 0.1562" and a No.20 drill is 0.1610". If you do happen to drill too much oversize, go to the next size of rivet for replacement, in the case of 5/32" go to 3/16". If, when doing a complete ally body removal and chassis clean-up, you really feel the need to remove those drilled out rivet pieces (tails?) from the chassis inside tubes, a hole can be drilled in the very front square blanking plates top and bottom (I used 1/2", but smaller may be o.k.?), and with the chassis held/propped up at the rear at a good angle, the rivet pieces will roll down the round and square tubes and can be vacuumed up at the very front of the chassis. I did this with my old Lotus Unirad chassis (O.K., anal rules?), and removed most of the rivet pieces as the top and bottom tubes from front to back are mostly open even when 3/4" tube is connected to 1" square tube. The holes in the front can then be welded or brazed shut as they pose no problem to chassis integrity of course. Only the cross and down tubes will retain the rivet 'tails', but there are far fewer than in the main chassis rails. Cheers, Will

-

Hi Andy. I just checked my parts boxes, and found some original chassis bushes that were intended for repairs on my old Lotus Seven chassis. These bushes are 0.691 inches o.d. (my equivalency chart says 11/16 inches is 0.6875 inches), and the i.d is 1/2 inch (in your original post you mentioned 5/8 inches i.d.?) and a half-inch bolt fits snuggly inside the bush. These bushes are over 1-1/2 inches long so they can be reduced in length for a good fit. They are free if you don't mind paying the postage, but, (here's the big 'but') Canada Post is on strike, and if you are in a rush for them to complete a project, I don't know when they can be posted to you. As the outside diameter is slightly larger than you require, (and also the length of course), a competent machinist can reduce these to your specification. A local high school with students learning the trades may be a possibility if permitted (without incurring legal liability problems?). To do some welding jobs for me, I approached a local high school in my city, and the shop teacher advised that for a box of doughnuts for his students, he would do some work for me for free. Not too bad a deal! Let me know if these would be suitable. Will

-

Just a note on the bolt type for the water pump pulley (and fan blade attachment fitted by Ford on some of their older Kent engined vehicles). The pulley hub may be threaded for metric bolts not Imperial. A Quinton Hazell manufactured water pump on my 711M engine has a metric thread. It requires metric bolts M8-16. Mine are 8.8 grade nickel/zinc coated, 1/2 inches long (slightly longer if a fan blade is attached). Burton carry a new QH water pump on their site and similarly advise that the required bolts are M8. Will.

-

-

Hi. Is there anyone in the general vicinity of Calgary, Alberta, Canada who is building or repairing a Seven or Locost lookalike who requires some 18 gauge 3/4 inch, 5/8 inch and 1/2 inch round and 3/4 inch square mild steel tubing pieces for extra triangulation on their chassis? Some pieces are already mitred for triangulation and were made to fit an original Lotus chassis (dimensions same as those shown in various web diagrams of the Seven chassis). I also have 2 steering rack strengthening plates used to bridge the original Lotus Seven rack brackets, one with a cutout for the bottom radiator tube (originally from Arch, U.K.) I have already donated some longer mild steel tubing to a local high school welding shop as these are hard (expensive) to ship anywhere. (In exchange, the shop teacher will complete some Tig welding for me - win, win!). I have some small spacer tubes that Lotus/Arch/Caterham weld in the square tubes of the chassis for engine support brackets, wishbone attachment, and various other suspension locations (originally from Arch or Xtra Special Sevens). A piece of 16 gauge 1-1/2 inches by 3/4 inches by 3 feet long will make a good rear chassis seat belt anchor (welded between the upper rear damper towers behind the seat back), or as Arch did on a racing chassis - for the bottom dashboard support tube across the chassis. These are free for anyone who is able to collect them. She who must be obeyed - and especially me - are clearing out aIl of the bits and pieces I/we no longer need, so hard-to-find parts will be sold, others will go into recycling, or to the scrap yard. I note that the Locost USA site seems to have disappeared from the web maybe permanently, so anyone who was on this forum in my area may have transferred to USA7s hopefully? Cheers W.

-

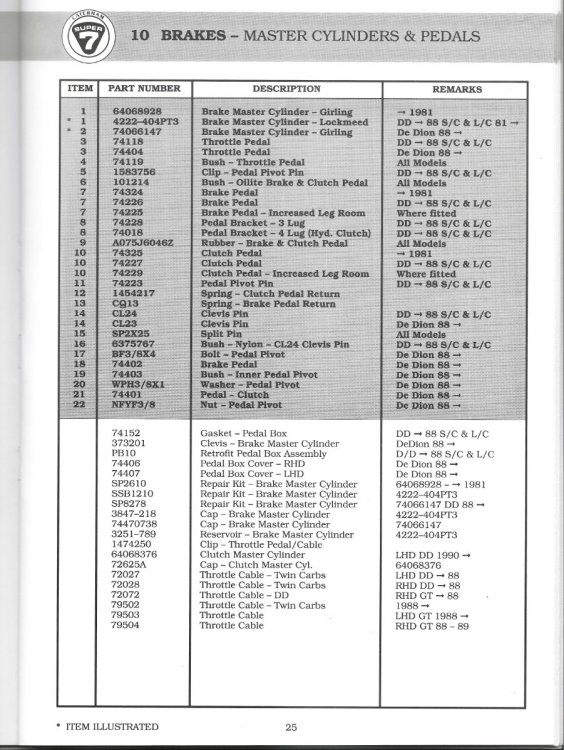

Hi Pethier. I went across the pond to visit family in the mid 1990s and my brother-in-law and I took a trip from S.W. England to Caterham in Crayford, close to Dartford. I needed some parts, and my brother-in-law had business in the area. Graham Nearn gave us a great tour of the factory (which was so very different from the cramped quarters in Caterham, Surrey), and the staff were very friendly and helpful locating the parts I needed. The parts manager gave me the parts book and some other brochures detailing the new cars. My family and I used to live in Bexleyheath, about a 20 minute drive away from Caterham’s new digs, but it took me a few minutes to get my bearings and it was hard to recognize the Crayford area from when I lived nearby in the 1960s. The parts book does not have a publication date inside, but there is mention of the upcoming 1992 racing season for the 2 racing categories for Caterham cars. The parts book is in good nick and hardly used as many of the parts pictured inside do not apply to my Lotus Seven unfortunately. Just an fyi. When the original Redline took over the parts distribution for the Lotus Seven and early versions of the Caterham models, Mick at Redline did not use the original part numbers to identify the various parts. He just needed a good explanation and possibly a photo to identify what you required. Previously, Alex Davids at Caterham knew all the parts and part numbers off by heart. John Donohoe of Simple Sevens sold me a front licence plate bracket originally from Caterham, that was painted in the graphite colour and still had the paper tag with the Lotus part number on it. This parts book uses Caterham’s part numbers for the newer cars, and some of the original Lotus parts identification numbers along with line drawings. Cheers. Will

-

Curious Oil Gauge Reading & Valve Stem Oil seal question

EdWills replied to Tony's topic in General Tech

Should read: This type may not provide a sufficient amount of oil for bronze valve guides. EW -

For sale: A good condition complete Ford rocker assembly for engines from Ford Anglia up to pre-uprated Crossflow 2737E. There is no discernible wear on the rocker arms on the shaft providing a snug fit on the shaft. The contact pads on the rocker arms show minimal wear and although I no longer have the original speedo from my car to prove it, The engine died at 12,370 miles, and the engine was taken apart with parts sold on. I recently found this assembly in the bottom of one of my spare parts boxes. It has the adjusters with the locking nut on the adjuster as used on the early Kent series of engines. The slotted heads on the adjusting screws are in very good condition and the heads are not damaged as sometimes found when the wrong screwdriver has been used on them. Asking $140.00 Canadian (exchange rate says approximately 1/3rd less in U.S. Dollars) plus postage. Due to a clear-out at my local Ford dealer a couple of years ago, a pal who worked there found some original new boxed spare parts for the Kent Series of engines which I purchased. These are camshaft sprocket lock tabs, and camshaft thrust plate lock tabs. Engine tuners suggest that these should be replaced every time the engine has to have the old ones removed. Pegasus shows these out of stock, but lists them at $12.99 U.S. and $8.49 U.S. Asking $13.50 Canadian for the sprocket lock tab and $9.50 Canadian for the camshaft thrust plate lock tab or $20.00 Canadian for one of each type. Postage extra. A pair of adjustable rear radius arms with threaded end to take a ball joint, and a larger sleeve to take a bigger 'Metalastic' bush. These were manufactured by a local Calgary company that was trying to break in to the Seven lookalike market, but eventually closed up shop. They are manufactured from 4130 steel, tig welded and painted with primer. A pair of Metalastic bushes will be supplied to fit, but rod ends are not supplied. $100.00 Canadian the pair plus postage. A Spitfire/Herald rack tube and geared rack for a left hand drive Lotus Seven or Seven lookalike. The bearing at the end of the rack tube is brand new, and the geared rack is straight with no damage. $40.00 Canadian plus postage.

-

Curious Oil Gauge Reading & Valve Stem Oil seal question

EdWills replied to Tony's topic in General Tech

Just a P.S. You may not have to remove the head to install seals if you have access to a compressor and an adapter to fit the spark plug hole. Using air pressure to hold the valves in place in each cylinder, after removing the valve cover and unbolting the rocker arm assembly, a special valve compressor tool can be used to remove the collets, remove the springs and cap, and install stem seals of whichever type you choose. Then reverse the procedure. Some tuning shops will have the necessary equipment to do this, and it does save the time and energy (and maybe cost?) required to remove the cylinder head from the engine. Note: Mark the spark plug wires so that they go back in the correct order (if not already identified). EW