-

Posts

483 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by papak

-

Sorry folks, sold it this afternoon.

-

All I have are the Brooklands windscreens. The components to revert to a conventional windscreen and top are available from Tom Carlin (Birkin USA).

-

I’m in town on the 14th. Give a call when you get in and I can pick you up. I’m only 10 min from LAX. The engine had 78,000 on it when purchased from the yard. I rebuilt it according to the Ford manual with all new bearings seal, etc. I recently rebuilt the head with new valves, seat, guides. When I installed the new cams, I used the upgraded springs and retainers from Crower.

-

It is similar in size to an SV. The VIN was assigned by the California Highway Patrol during the course of registering the car and is riveted to the chassis. I have a standard, clear California title for the car.

-

I’m finally putting the Birkin up for sale as it’s about time for me to move to the next project. I had long wanted a Seven so after some research, I purchased the kit for this car from Tom Carlin in 2015. I had the opportunity to test drive several alteratives (Caterham, early narrow-bodied Birkin, original Lotus). I found that the footwell and pedal cluster were too narrow for me, thus the wide-body version (the SS3XS is 100mm wider and 75mm longer in the cockpit). I took my time assembling it, doing some minor re-engineering, engine and transmission rebuild along the way. I finally completed the SB100 registration process in 2017 (registered as a 1962 Lotus). The car now has a little over 7600 miles. Many many thanks to Tom for his help along the way. The basics: 2.3l Ford Duratec (no balance shaft), Raceline wet sump 4x48mm Jenvey ITBs Crower Stage 2 ¾ race cams New valves, seats, guides New upgraded springs and Ti retainers Lightened steel flywheel (12.7 lbs) water pump delete, replaced with Davies-Craig pump and controller Ford T-9 with heavy duty bearings, new synchros and seals Subaru R160 diff with AP Suretrac LSD New Haltech ECU Recent dyno session showed 186 hp/176 ft/lbs at the rear wheels Repainted two years ago in Porsche Mint Green Kirkey seat, fresh belts AntiGravity lithium battery, 40a Nippondenso alternator Includes numerous spares, unique shop tools, full documentation and well annotated build book. The car is in excellent condition, a gas to drive, currently located in West LA $30,000

-

The brake components on the Birkin are mostly late '80s VW/Audi from GTI ROW inventory. My 2015 came with Wilwood front calipers while the rotors are from a 2005 GTI. My rear calipers are 2005 ROW GTI. The rear rotors are the interesting part. In order to mate correctly with the Birkin hubs, the VW rotors have the back of the disk cut back, a challenging machining process while keeping the outer and inner surfaces parallel. Not sure of the thickness dimension (around 10.5mm) but the rotors end up at approximately the VW minimum dimension. These components accommodate the handbrake setup while providing sufficient brake capability. As a front engined car, the rears normally wear much less than the fronts. This era Birkin also comes with an adjustable bias setup to balance the separate brake master cylinders. Tom Carlin can usually provide the parts.

-

There're wider clamps available online (Summit or Jegs) and even "stepped" ones to help deal with a diameter change. I also use Wurth exhaust sealer. It's a white paste that helps the pipes slip together easier and helps seal the joint. It firms up with the increase in exhaust temperature.

-

These CV joints are early ROW Golf CV joints that have had the back side machined down to conform to the Birkin hub assembly. Tom should have a few on the shelf if needed.

-

I did the same thing in 2015. I arranged to pick up an enclosed U-Haul trailer close to Vail on the way over (from LA). I think U-Haul offered "contents" insurance by the day. That along with "creative" parking at night got me home without any trouble. Try posting your route home on this forum and maybe you can get some secure parking for the couple of nights needed. As I recall, I parked the first night across from the police station in Glenwood Springs. The next night I was able to back the rig in under the ramp in the parking garage of the Marriott we stayed in in Las Vegas (I was a frequent visitor for work for a number of years and knew the bellman). Next night home. I would be more worried about the trailer being stolen as the contents will be a chassis sitting on the floor filled with boxes of parts, none of which are readily marketable. All U-Haul trailers have a tracker built in now. Good luck. Tom's a great guy.

-

Of course he is working toward a Ph.D in philosophy. Maybe he knows more than I do about happiness.

-

They are good lads. One of them, at age 24, still has no interest in getting a license!

-

Having restored and raced a wide range of cars over the years, the purchase of the Birkin in 2015 satisfied a long time itch. I had always wanted a 7 but the more I looked into an original 7, the more monumental the project realities grew. Caterhams seemed relatively pricey as well. I was fortunate to run in to some generous folks in SoCal who let me drive and experience firsthand the differences of the various 7 alternatives. The Birkin was the right choice for me. For all of the skills I had acquired over the years of restorations, this project provided new challenges as I had recently retired and had much more time at my discretion. I'm coming up on 77 now but I still put a grin on the neighbor's faces when I have the car out. It will probably end up on BAT eventually as my four grandsons, as accomplished as they are, have not one collective wit about mechanics. Cars are appliances to them. Where did I go wrong?

-

Does anyone have any expertise on one of these units? I would dearly love to locate a dyno shop in SoCal that would take on the tuning job. TIA

-

While I have a 2.3l Duratec, I was similarly concerned about ground clearance . I run a Raceline aluminum wet sump currently. The Raceline dry sump extends nearly the same distance under the block so no clearance benefit there. I use an aluminum skid panel instead. It clears the sump by 1/2" and matches the bottom of the T-9. It is fabricated from ⅛" aluminum and mounts directly to the chassis. It's strange enough to absorb the hits and durable enough to be pounded back out after the major ones (and that's after being laser focused on the road surface while driving!). ong

-

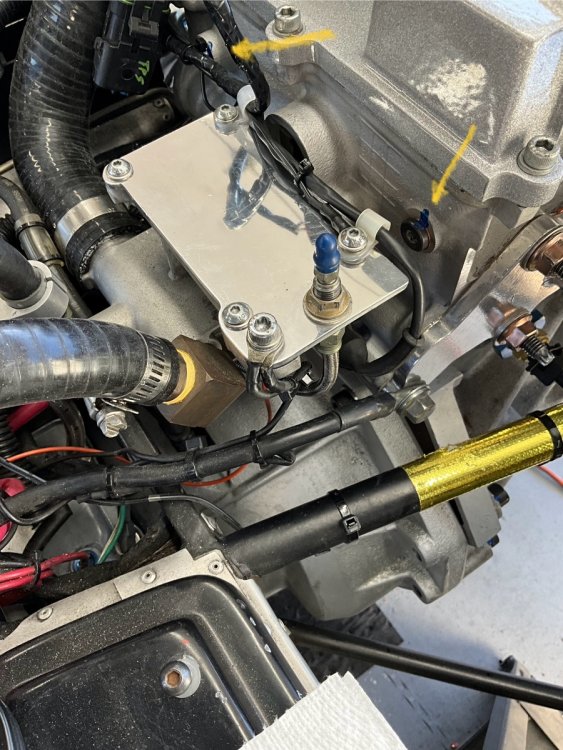

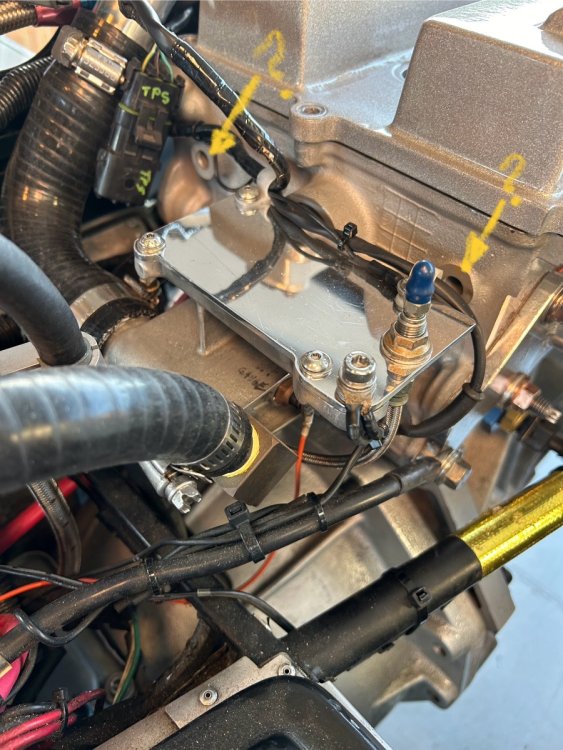

I ended up tapping each galley for an M10x1.0 threaded plug. After tapping each hole, I fabricated a high velocity nozzle for the shop vac and kept at it until I was sucking clean oil. I verified the cleanliness of the galleys with a boroscope. As may be evident, the threaded plugs come with copper crush washers. Taking the "belt AND suspenders" approach, there is also a careful application of silicon sealant on the threads as well. Whew!

-

So I finally get the head back on the motor, motor and transmission back in the car, all ancillaries installed, oil filled and coolant filled and bled. I disable the fuel pump and ECU and spin the motor to generate some oil pressure. The needle OP needle quivers a bit but no real pressure. I only turned it for a few seconds so no presumed damage. It turns out that the machine shop removed the plugs at the back of the cylinder head at the rear of each cam oil journal and didn't replace them. AAARRRGGGHHH!!! My fault for not checking but it shouldn't have left the shop that way. The task was clearly noted on the work order and checked off. I wouldn't mind if it was simply a matter of pulling the head but due to the close quarters in the engine compartment, I really need to drop the engine again in order to remove the crank pulley, front cover, cam chain, etc. Does anyone know the size of the plugs for the indicated holes? The holes measure about 9mm ID. Is there an obscure Ford part number?

-

wallisek, Thanks for the heads up. For some reason, I had lost the bookmark for Burton. They are the only place that had this gasket in stock. Yes, it will cost $70 to get it here but I will have it next week as opposed to next month through Summit Racing. Kevin A40D1195-F27C-47F3-AA2F-749F0D7B53B1.heicA344BDE3-4511-4742-BA30-3BECE740D6B2.heic

-

I'm looking for an exhaust manifold gasket without the tail end for the EGR cutout. When the head was recently at the machine shop for new valves, I had them weld in the outer edge of the #4 port in an effort to balance the exhaust flow a bit more (reducing the dead volume of the #4 exhaust passage). Nothing like striving for that last micoblivet of horsepower! Cometic makes one (C48411-064) and while I have ordered it (end of December, maybe early January), I am still hoping to find one in stock somewhere. The alternative is even more improbable. SCE made one as well (SCE 223084). Unfortunately, they went into bankruptcy during the pandemic and got purchased by another European firm. They no longer offer them. Can anyone think of another option? Thanks

-

Try John Esposito, Quantum Mechanics (203-463-8299, john@quantumechanics.com). He is located in Oxford, CT. He is a good resource stateside. You can also try Chris Clainger at BGH Greartech in Kent, UK (011 44 1580 714114, bghgeartech@btconnect.co.uk). Chris is VERY knowledgeable and stocks a deep inventory of T-9 parts. I have used both of these gentlemen over the years. They are the real deal.

-

I did the same as FE07. I made a buck out of 1" particle board ( had a remnant) by tracing the outer dimension of the inside of the nosecone. This allows the formed screening to wrap forward around the inlet. I fasted it with 4 small SS buttonhead screws with large washers on the back of the screening. Where I to do it again, I would fabricate a bracket in front of the radiator and just rivet the screening to that. I would advise to leave it unpainted. The small pebbles and such that hit it will just chip the paint.

-

Turns out it is a leaking head gasket between 3 and 4. Since there is no evidence of fluid transfer between oil and coolant, it hasn't been a huge issue. I'm in the process of removing the drivetrain over the next few days. Parts are on the way. I'm taking opportunity to be upgrade the cams to Crower Stage 2, ¾ race along with the valve springs. Crower said 2-3 weeks for the cams to arrive. I'm having hand surgery at the end of August so I'll be hustling to get the car back together before then. In the interim, it will be all out disassembley, cleaning and prepping.

-

Once it's warmed up, it pulls just fine. I replied the coils with a spare set. I'll be running compression check today as well as checking the injectors. When the newly coated exhaust was reinstalled, I checked the temps and they reflected the past experience where the center cylinders ran about 20F lower than 1 & 4. COP with stock pistons (9.5).

-

I was running the engine the other day (2.3l Duratec) in preparation for an oil change and decided to check the header temps with a laser pyrometer. To my surprise, the temps at the top of the header pipes , 1-4 were 390, 370, 170, 162. I was so surprised that I replaced the battery in the pyrometer. No change. I checked the plugs and they showed a predictable pattern, #1 whitish grey, #2 tan/grey, #3 sooty black, #4 wet and black. I replaced the plugs as well as the coils. Still a relatively smooth idle with the same temps. I’ll pull the cam cover tomorrow to check the valve springs and I have a query in to Specialist Components to determine how the coil signals are paired in the ecu (Typhoon 2). The engine has 7500 miles on a full rebuild. The injectors were cleaned and rebuilt at the time of the rebuild as well as new rings, valve guides and seals. The induction is 48 mm Jenvey ITBs. Any other suggestion as to what to look in to would be appreciated. This temp discrepancy was not evident a few months ago when the headers were ceramic coated and reinstalled. We’re it not for the pyrometer readings, I wouldn’t know anything was amiss.

-

Glad you worked it out.