-

Posts

483 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by papak

-

I changed over from the full windscreen to the Brooklands due to the buffeting, even with the side screens. When on the freeway, I always wear a full face helmet. It seems a bit "dorky" but I regularly end up with a significant bug splat. That's been the worst of it so far but one day, it will assuredly be a stone or such.

-

New LED Headlights on a SuperFormance S-1

papak replied to spitfun's topic in General Sevens Discussion

Where did you get them? -

Any thoughts on the relative merits? My primary’s are getting pretty discolored and I would like to control the heat more. TIA

-

I believe it does.

-

You could mount it on the panel as I did but in order to be fully compliant, you might have to mount the placard on top of the scuttle.

-

I went from a conventional windshield to Brooklands and find much less buffeting. I'll forego the helmet on surface streets but always wear a full face one (currently Racequip) on the freeway. I remove my hearing aids and use foam earplugs, particularly with the helmet.

-

Lightweight (lithium most likely) battery recs?

papak replied to supersportsp's topic in General Tech

It replaced the Braille I was using when it died (9.2lbs). -

Lightweight (lithium most likely) battery recs?

papak replied to supersportsp's topic in General Tech

I am using a Deltran 12v LiFePo (BTL24A480 CW). 8.0 Ah, 480CA. About $250 as I recall. Great battery. Weighs 3 lbs.! -

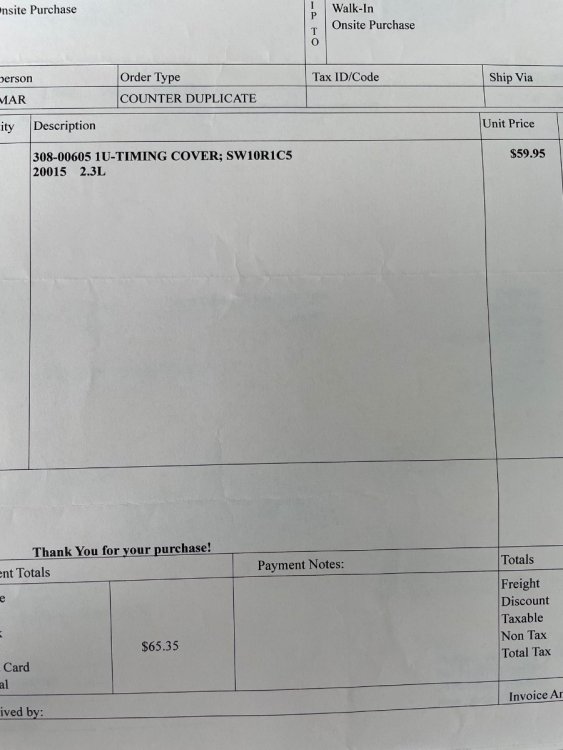

I have one with the port on my 2.3. I bought it from a disassembler online. The invoice shows it to be from a 2015. I had screwed up the threads for the alignment screw below the crankshaft. I'm not sure of the point of it if the cam timing is resolved before then cover is installed.

-

I picked up one and have used it several times now with great success. There is a bit of a learning curve however. I would recommend wearing a leather work glove as the body of the device needs to be held to keep it from rotating along with the internals. It is a bit bulky as well and that restricts where it can be used. On the other hand, I don't have to squeeze the hands together any more. I've gone through at least three rivet guns over the course of my last three builds and this is clearly the best solution except for the space constraint. I even tried a pneumatic riveter (POS!) when I re-skinned a formula car. This is much better.

-

Who did you get the CF ones from? I'm contemplating the same project as mine look like crap after 5500 mi.

-

My first racing experience was in Formula Vee back in the early 70s in South Florida. I started in a Beech and quickly moved on to a couple of Lynx’s. It was a hotbed back then. Our collective group produced a couple of Nation Champions, Don Courtney and George Frizzelle. I always aspired to a D-13.

-

Yes they are and absolutely flawless up close. He had them done by a fellow in OC. Bruce even fabricated aluminum DeDion arms himself. Arch wouldn’t make them for him.

-

That's a great history! I didn't realize that Kaplan had been that deeply involved in the D-13. I restored a 1972 D13 about 10 years ago and raced it a few times with VARA before selling it to a young fellow in San Diego. The paint job was courtesy of the previous owner.

-

The other 7 is a very nice Caterham owned by Bruce Hand. Around 960 lbs. with a 260 hp Cosworth. The man is a true craftsman. The event was very nice but remarkably, not a single XKE!

-

Tom Carlin has done a LOT of research on this and has arranged for a supplier to provide a number of "custom" cv's. They will have the 90mm outer with a 22 spline and the inner "star" with a 32 spline. This will match up to the splines on the standard Birkin half shaft. He should have them in stock soon. The 90mm bodies also have to have the outer body turned down on a lathe in order to fit the inside of the Birkin hub assembly.

-

I have the sleeved ss clamps shown above on my car for 5 years now with absolutely no issues. When I have had occasion to loosen and remove them, there has been no underlying damage. I simply reinstalled them in the same orientation. Pegasus does (or used to) offer molded rubber covers for the exposed end of the slotted band. They definitely help in reducing the injury potential when working in proximity tooth hoses. (best seen at the angled juncture aft of the radiator inlet)

-

I mounted mine on a crossmember in front of the driver's seat. Easy to grab in the heat of battle. Just order two of the brackets. I mounted them to a strip of aluminum that was, in turn, riveted to the crossmember. r.

-

Have any of our Birkin owners ever had to replace the outer CV joints? I'm looking for a part number or vehicle model and year. I think that I have searched every database available to no avail. These are clearly stamped with the VW and AUDI logos inside the outer housing. 22 outer spline/32 inner spline, 139mm overall length with a 90mm diameter. Tom Carlin is looking into it as well. Most likely from a ROW car that was only imported to South Africa. Thanks

-

Retired from 50 years of flying. Bush flying, corporate jets, Viet Nam, three major airlines, more corporate jets. Probably half of the time I was crossing oceans and/or living overseas. An interesting career. I was extremely fortunate in that I knew early how I wanted to live my life. I always seemed to have a restoration or racing project in the garage. As trite as it sounds, do what you love... you will always have some degree of satisfaction at the end of the day.

-

Thanks so much for the model references. This makes a lot of sense as the components of the Birkin are based on ROW models. Let me know when you start looking for rear rotors. That took nearly a month to figure out. Hope you get to dig out soon.

-

None there.

-

I’ll give them a try. Thanks

-

It seems that I have picked up a bit of "play" in my outer CV joints. My Birkin utilizes a mildly modified VW front joint purportedly from an early VW Golf. Tom Carlin gave a part number from one in the shop (Interpart HK VW 1-051 0516). I haven't found a cross reference to this part number in all of my searching so far. After comparing mine to several Lobro joints in local parts stores, the consensus is that this is from a 2.0l car, ruling out the earliest Golfs. As is apparent from the attached photo, the outer mass has been turned down a bit in order to fit in the inboard side of the hub. Nominally 90mm on the inboard side. The axle nut is an M20x1.5. Any help in either referencing the part number or otherwise identifying the part itself would be greatly appreciated. Tom has never had the occasion to replace one of these. The half shafts have always come to him fully assembled. In the course of refining the ECU map, I was encountering a serious surging issue upon accelerating out of a turn with the outboard suspension fully loaded. It seems as though the wear and tear was taken up by the outer CV joint.