-

Posts

644 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by SENC

-

You can look at it without disassembly. Check to make sure it isn't obviously cracked, missing a chunk, or distorted/out of shape/oblong (sometimes when sitting for a long time the yoke can get stuck to it). You should be able to push on it to see that the rubber inner ring still has some pliability. Also inspect the yoke for signs of pitting/damage or even wear from the seal. Put some assembly lube or similar on the yoke and insert it into the tailshaft extension and onto the shaft and inspect for any obvious poor fit. Since you haven't reported leaking from the gearbox before removing it, the seal is likely OK. Leaking now from that area is a non-issue - there is nothing to prevent it. The seal seals against the yoke. You might also make sure the plug in the base of the yoke is well-seated and holds oil. It is possible, if not being careful, for the tailshaft to hit the plug from the inside of the yoke and to unseat that plug - which would then leak.

-

Also be sure to inspect the seal in the tailshaft extension (where the yoke/propshaft enters). If you need to replace it, it is much easier to do so with the extension removed from the gearbox - and off you can also inspect the bushing for unusual wear. This link may be helpful, as well... https://lotuselan.net/wiki/Gearbox_(Transmission)_-_Fault_Finding

-

Manually turn the drive shaft and use the selectors to get 1st, 2nd, 3rd, and 4th gears. Smooth? Any obvious hitches or problems? Spin the drive shaft slowly and look at all the brass and steel dogs/teeth any obvious damage? Are the baulk rings butt up against the gear dogs, or is there a gap (I haven't found my note on the expected gap, but if no gap that would be a sign of heavy wear). Use a light and see if you can get any angle to look at the ends of the selector forks - you may be able to tell if there is any excessive wear. Any obvious specks of brass when you drained the gb oil, or in the bottom of the gb? Check the end float on the main shaft - does it move forward/backward to any significant degree? I think either the Seven or Elan manual indicates proper end float - but it shouldn't feel excessive. I agree with wdb that you can't do a lot of definitive assessment without opening it all up - but with the above you may be able to make a preliminary assessment of whether there is reason to go further.

-

As I recall I searched for a while for a NOS clutch disk and PP, and eventually found both (separately). Keep your eyes open for AP (owned B&B rights in UK) and parts seemed to have been marketed/sold as AP, B&B, and AP B&B. #50803 is the part number on mine, there should be cross references out there. I'm assuming yours is also 7.5"? Anglia/Mk 1 Cortina should be the same. You might also check with Moss Motors - I think they sell a range from AP Raicam, who now have the rights to mfr AP B&B UK parts. As I recall some of the MGs (Midgets or Sprites maybe?) also used a UK Ford gearbox and so may have used the same clutch and pp.

-

Arm looks fine to me - here is the arm from mine for comparison. I assume this is the same as your gb mount? Check with DBE to see if they have one. I seem to recall getting mine from an Anglia parts vendor, ir maybe even the 105e anglia club.

-

-

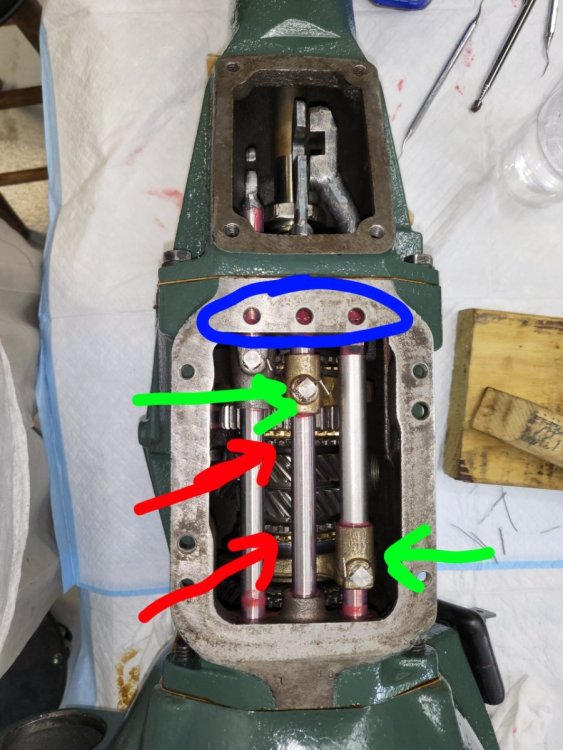

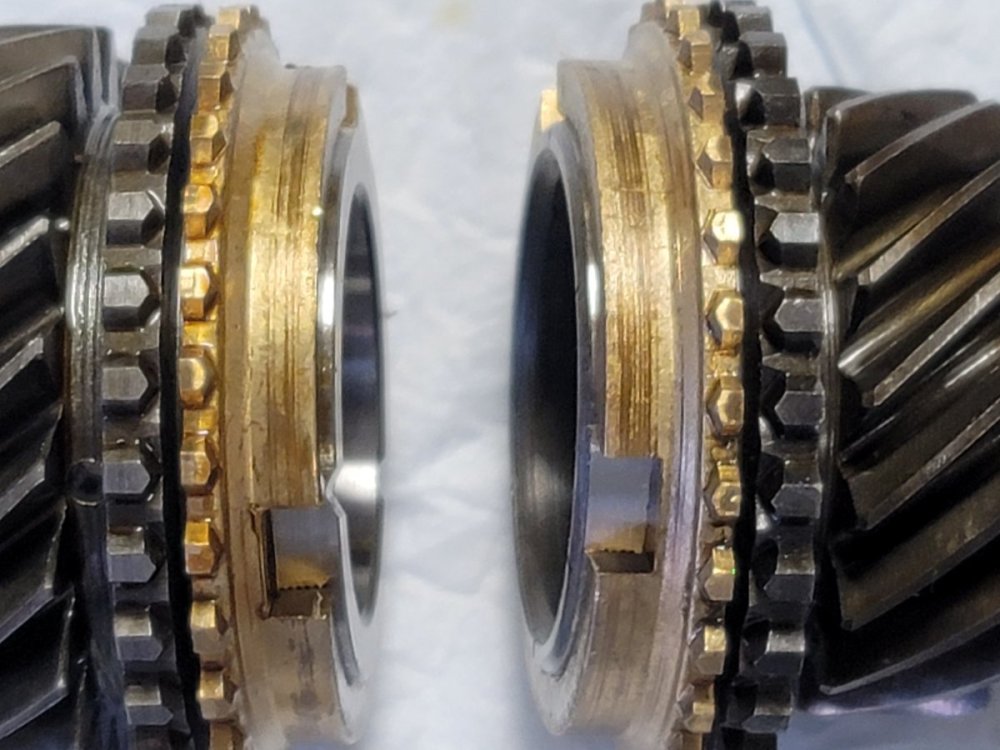

A few pictures from my project... My ring gear, notched after cutting it for removal. It doesn't look all that different from yours until you look at the areas of most wear. If you have portions that are this worn, you might go ahead and change it out. Picture of an open gearbox. Blue circles the location of the springs and detent balls. Red arrows to the baulk rings. Green arrows to the gear selectors. The brass baulk rings ride on a tapered cone and have internal ridges that wear. You obviously can't see those ridges without pulling everything apart, but manually shifting the gear levers you can observe them and how they move - if they but up right next to the gears with little/no gap, they are very well worn. Also look at the teeth of both the baulk rings and gears for signs of damage/gear crashing. Here is a closeup of 2 sets put of the gb during my rebuild. Also try to look down at the gear selector forks to see if you can identify excessive wear. I don't have a side view of a fork showing high wear, but here is a picture of the areas you're looking to observe.

-

You cut the ring gear off, but it doesn't look that awful to me. You can get a new one on by popping the flywheel in the freezer overnight and heating a new ring gear in an oven. It took me a fair amount of effort with a mallet to get mine in place. The pinion gearing does look pretty chewed up - you can still find these NOS, just match the number of teeth. I have a tool to aid in removing the pinion - happy to loan it to you - I'll see if I have any pictures when I was rebuilding mine, might give you an idea of alternate solutions you have on hand. As long as that starter is off, might as well look in on the brushes to make sure they have life left. Check before you change starter types - that ring gear looks to want engagement from only one side, and gear reduction starters (I think) engage from the other side. Your theory doesn't sound crazy to me, but I still wonder about something in the gearbox. I can change gears in mine even without the clutch with a light touch and if I time it right. If I'm understanding your problem correctly, you can't select a gear at all in certain circumstances - whereas I'd think a stuck plate would result in grinding gears. I'll find pictures of an open gearbox. One note as you open the top - there are 3 springs under the tailshaft end of the cap (putting pressure down on detent balls that keep the gear lever bars from popping out of gear) - be aware of them so you don't drop them down into the gearbox.

-

Looks identical to the one I pulled out of mine. And same release bearing type as well. I can't see the ring gear clearly enough to tell whether there is any wear or damage. Have you opened the gearbox to see how it looks?

-

Will - Brian Buckland's book on the Elan has a good bit size list, some of which may be useful given the same block. If you don't have a copy to check I can see about grabbing that section for you.

-

Came across this thread while searching for something on lotuselan.net. https://lotuselan.net/forums/viewtopic.php?f=37&t=51905

-

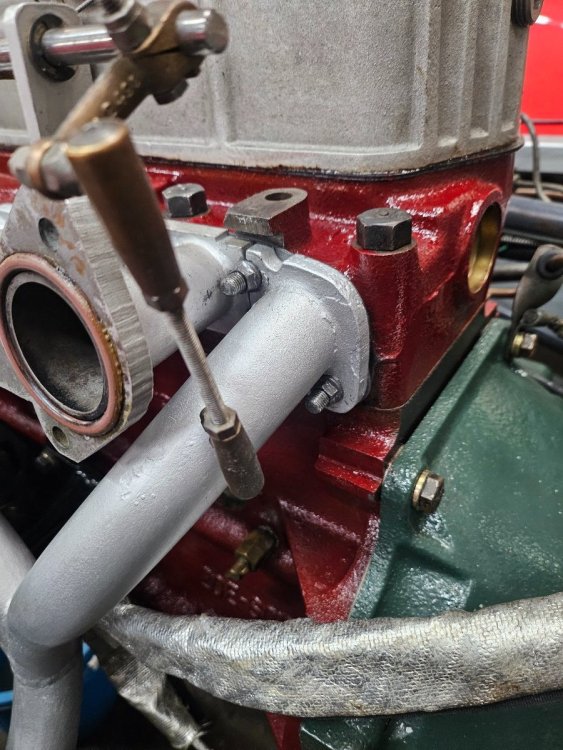

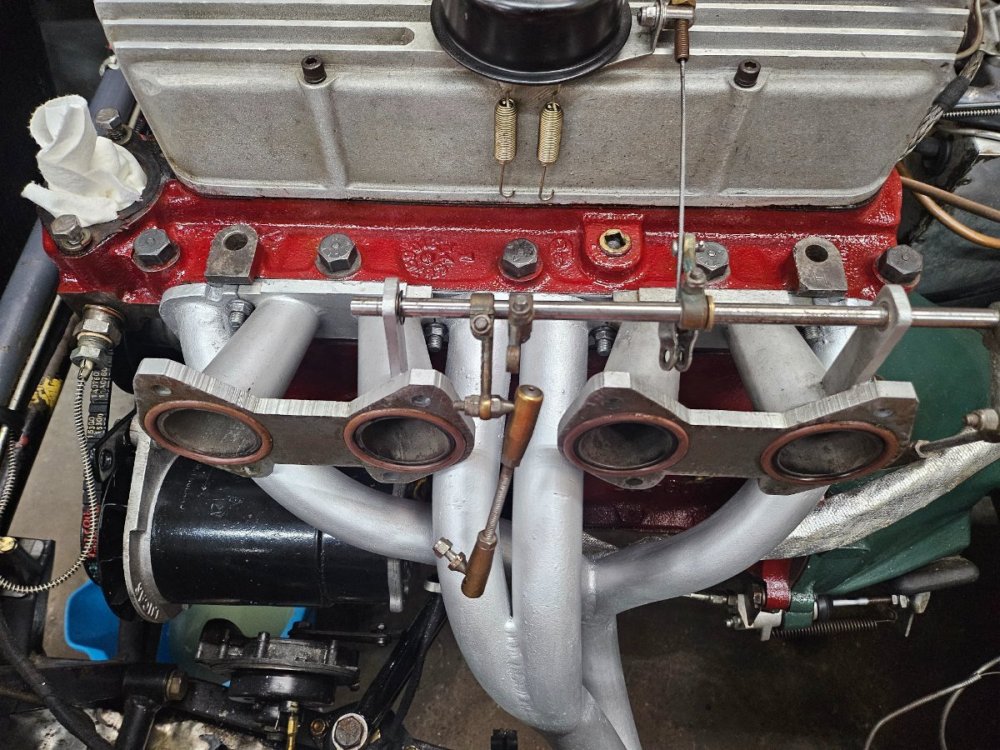

Studs and AN jet nuts made the job a good deal easier. The only tough ones were the outer ones between the intake manifolds and the outer exhaust manifolds - can't get a socket in there. I ground the lobes off an extra 3/8" wrench and that worked perfectly - though those locations are the easiest for the allen key to reach so the ideal solution might be to retain those bolts and just use studs/nuts elsewhere. Got the carbs reinstalled today - hopefully will get it running later in the week to check for leaks.

-

From memory, the radiator needs to come out. The engine will just barely clear the crossbar behind it (cut and slit a piece of hose to cover and protect it and electrical wires running along it). I don't remember if the others are necessary or if they were just as easy to remove first.

-

Not exact, but as I recall the fork/arm fulcrum is near the center of the fork so probably not far from 1:1. I'll have to see if I have a cross-section diagram somewhere. What's driving my suspicion is that he's getting clutch disengagement (at least when cold) so he's got enough travel occurring unless something is shifting. I'm just not sure lack of an adaptor or incorrect bearing is going to be variable or cause shifting. I could certainly be wrong, and it could be that he's right at the limit of tolerances - but after going back through pictures during my disassembly and rebuild I'm confident I don't have an adaptor though the DBE catalogue suggests I should, and I'm not having any issue with clutch disengagement. Fractured or weak fork/arm could be possible, though I'd think that would get progressively worse and not recover when cold. Weak pressure plate springs I guess could get worse with heat- perhaps? Or possibly a point of wear at the fingers/platen/bearing that finds it's place when running? I'd also wonder about the spigot bearing and the possibility it has fully or partially frozen or become damaged and transmitting rotation from engine to input shaft. Not sure why that would only reveal when leaning on the shifter though - unless internal wear/end float is allowing forward pressure, too. Will be interesting to see what you find when you pull it. Yes, you need to remove the remote. I'll attach a removal sequence I made when I removed mine for the first time. Definitely check the spigot bearing as well as the tailshaft extension bearing and seal - these are common wear/failure items. I'd also at least open up the top of the gearbox for inspection of gear selectors and bulk rings (I think you can estimate baulk ring wear based on where they sit relative to synchronizers or gears, but I'll have to go back through my notes on that).SevenEngineOut.docx

-

Though I follow your logic, I think this is may not be the issue. There is enough "swing room" for the clutch fork that it could easily take up that difference, and once the slave rod is adjusted to the fork it should have essentially the same lift at the release bearing. I suspect the adaptor and matching the release bearing to clutch type has as much to do with preventing premature failure of the bearing and/or damage to the bearing or fingers. As he's not hearing bearing or other noise in the bellhousing, I suspect that isn't the issue. The more I think about the primary symptoms of difficulty getting gears, the more I wonder about baulk ring wear and/or weak blocker springs - which combine to "brake" the shaft speed to match engine speed for smooth gear changes - or gear selector wear. Both brass items designed to wear before damaging gears. I think it was worth trying to eliminate clutch hydraulics to try to resolve before pulling the engine and gearbox - but the symptoms described seem to me to more likely point to gearbox rather than clutch. TEM - the good news is that pulling these from the Seven is a good deal easier than doing so from the Elan - but as with the Elan be sure to empty the gearbox of oil or you'll have a heckuva mess!

-

There's only 1 reason I park on the grass.

-

Yep that's the main point. There was a time when you needed special chargers for each battery type, but these days they're almost all "smart" and capable of charging flooded, agm, and gel alike (theyre all lead acid) - and a growing number also handle lithium. It's easy to get a lot invested in ancillary stuff like this that adds little value. Inexpensive maintainers are readily available (deltran, noko, ctek, etc) and perfect for keeping multiple battery types of multiple low use cars in good shape. IMO, unnecessary for cars that are actually used every few weeks (unless that usage is limited to short, in-town type trips) - but cheap insurance if a vehicle goes unused for a long period or is only used for short drives. Keep them topped up and healthy and you prolong their life and never really need a jump/booster or a true charger.

-

You're overthinking it, Randy (imo) - treat it like your Miatas. It really isn't any different. I think the only thing to watch out for is the old battery chargers - most of the ones available now handle agm and traditional batteries just fine. Though I have a high end charger/maintainer - for the purpose you're describing I have an inexpensive battery tender maintainer. I rotate it between my Seven, Elan, and 560SL, switching every couple weeks if I for some reason I'm not driving one or the other.

-

Dry fit today and pretty confident it will work, as long as the studs used are less than 1.5" long. AN jet nuts only require a 3/8 socket or wrench and it appears I can just fit those in. I'm waiting on gaskets - will likely be late next week before I get back to it and can officially confirm, but feeling good about it after testing.

-

You'll need an adaptor like this. https://www.ebay.com/itm/276306378622?chn=ps&norover=1&mkevt=1&mkrid=711-117182-37290-0&mkcid=2&mkscid=101&itemid=276306378622&targetid=1645685074288&device=m&mktype=pla&googleloc=9010076&poi=&campaignid=20133407470&mkgroupid=147476396765&rlsatarget=pla-1645685074288&abcId=9312979&merchantid=6481494&gad_source=1&gclid=CjwKCAjwjqWzBhAqEiwAQmtgT14ddC4Lq5zxKU9JJdwuQqcw_Yk-0PmZ8cwOyi3l2BpIdXOi5jyaBxoCOdEQAvD_BwE I agree with JBCollier's recommendation.

-

I just took mine back off to deal with an exhaust leak at the head. I use a long allen key with the short side cut down to about a 1/2". Carbs off first. Loosen the 2 middle bolts, then 2 on the outside of the intake manifolds. You may have to work back and forth. You'll get to the point that you can angle each intake manifold out (way from each other). This will be the reverse of the way you'll put them back. I'm planning to try going back with studs and jet nuts- will let you know if successful.

-

If not, let me know. I seem to recall having a second copy at some point and happy to look around to see if I can find it. It is a great resource.

-

-

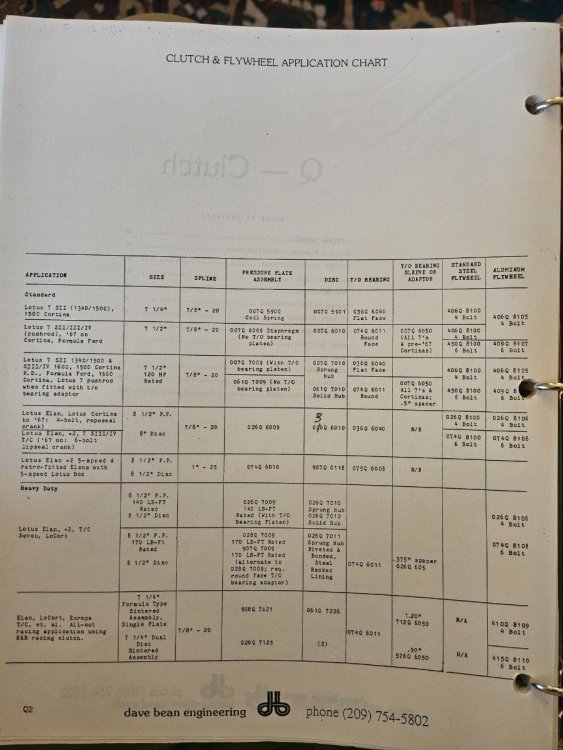

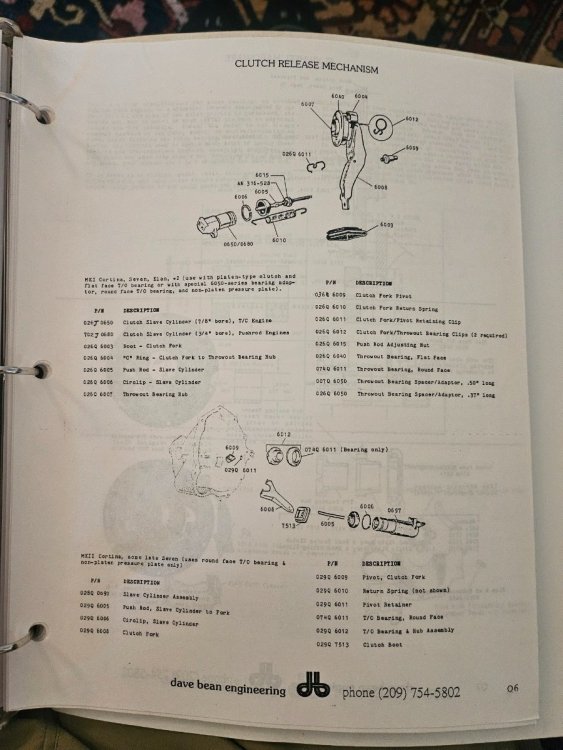

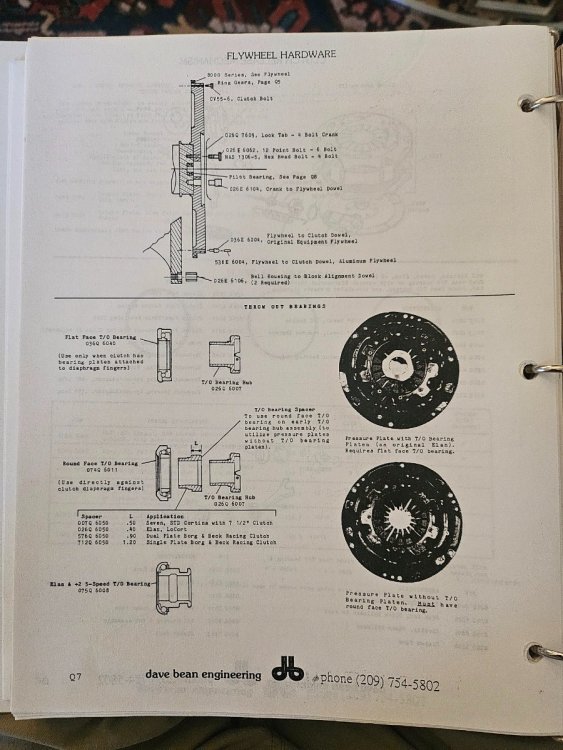

Was looking through an old DBE catalogue for something and took a peek at the clutch section while there. Adding pictures of a couple pages. Of note, indication that pushrod engines used a 3/4" MC (matching the Girling information but contradicting the Lotus parts manual) and a description of the different bearing carriers/hubs - and the spacer MV8 refers to. There is a specific note indicating there are actually several different sizes. I don't remember seeing this anywhere else, and have to admit I don't recall which carrier I used rebuilding mine - time to go look through rebuild pictures for a clue!

-

There isn't a spacer for the release bearing beyond the carrier - but your line of thinking does bring a couple possibilities to mind... As this car was used for racing, could it have been fitted with a larger 8.25" clutch? These were standard, I think, on Elan plus 2s so should have been a fairly straightforward way to get a larger clutch in place. The biggest difference (other than diameter) is that these didn't have a thrust plate on the fingers and required a different, rounded/domed release bearing. Perhaps the wrong release bearing was used? You may be able to identify the clutch bearing type and whether a thrust plate is on thw clutch fingers via boroscope. Additionally, there was a different sized bearing carrier that was used in some plus 2s (5-speed, I think), so perhaps something got mixed up in a prior rebuild? Another possibility is that the fork itself is getting weak and flexing.