-

Posts

3,087 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by JohnCh

-

Given the difference in offset, any concern about changes to the scrub radius negatively impacting handling? It's not a huge amount, so probably not a big deal, but given the Caterham's best feature is arguably the front end, might be worth considering. -John

-

Between the Westfield and the Elan, it's hard for my wife to take my car-related safety talk seriously. Yesterday afternoon I wrapped a piece of 600 grit sandpaper around a large shoulder bolt, slipped it through the hole in the cam gear and rolled it around the bench for a while. Worked great and that gear is now a slip fit on the cam. I'll remove the other gear and tackle it today or tomorrow. -John

-

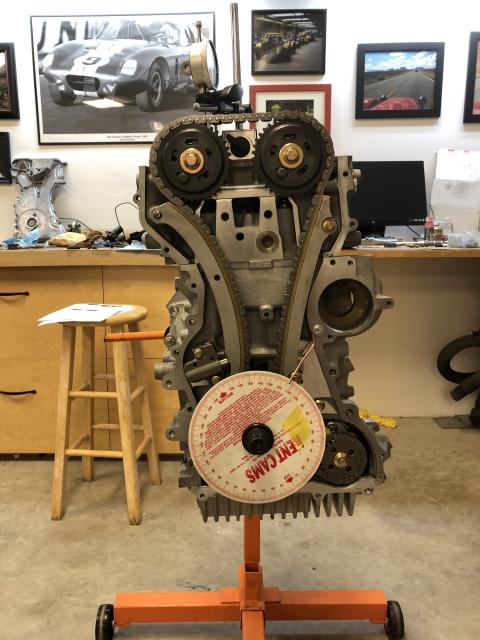

Good to know you haven't had an issue. SBD Raceline, and Raceco (back when Ammo was still around building Duratecs) all recommend the manual tensioner for engines that spin at high rpms. Outright failures aren't common, but they have seen them, and finding broken teeth in the sump from the plastic ratcheting mechanism is reasonably common. Apparently letting off of the throttle at 7500rpm plus can result in enough chain stretch that the tensioner over tensions the chain resulting in broken teeth or accelerated chain guide wear. It seems like a prudent upgrade. The Kent gears are adjustable in the same sense as the factory units. Unlike the Massive items, they are not marked by degree, which isn't optimal for dyno adjustments. However, I'm fine losing that feature to have that specific cam grind. These things are always a compromise. I agree about tuning on the dyno, but unfortunately I don't have one in my garage. When I asked my wife about buying one, she said something about already having too many tools and that a dyno won't make the kitchen function any better. Hard to argue with that logic. The degree wheel is to ensure that the cams are at a known and safe starting point until I am able to get the car to a dyno facility. Given the current situation out here, I doubt that will happen for quite a while. Thanks, John

-

Just got off the phone with Kent. Surprise, surprise, they haven't seen this before. He said the gears are heat treated and sometimes can expand a bit during that process, but not to this degree. He suggested attacking it with sandpaper. I'll give that a try this week and see what happens. -John

-

Way too close to the finish line to throw in the towel. I'm not sure I would characterize the build as rough -- a vortex of WTF moments is more appropriate -- although it still has the potential to turn out that way. If that happens, this thread may become the manual for performing an exorcism. The good news is that I went through the timing exercise before calling a halt due to the cam gear issue, and it was looking good. With cams at the baseline setting, the crank rotated without contacting any valves, dial indicator readings were repeatable, and it appears the machine shop located the keyway in the correct position for the crank position sensor. I even found the alignment tool for the latter, which I was sure I had thrown out. -John

-

Thanks Shane. I've updated my post with the new emoticon. -John

-

After unsuccessfully trying to reach Kent's technical department for the past hour (I'm sorry, no one is currently available to take your call), I had an epiphany and did a search. Yep, today is also a holiday in the UK. Do we have a Bollocks emoticon? Edited to add the new Bollocks emoticon -John

-

Thanks Shane. I must admit I never intended for the thread to become this interesting, or to last this long. :banghead: -John

-

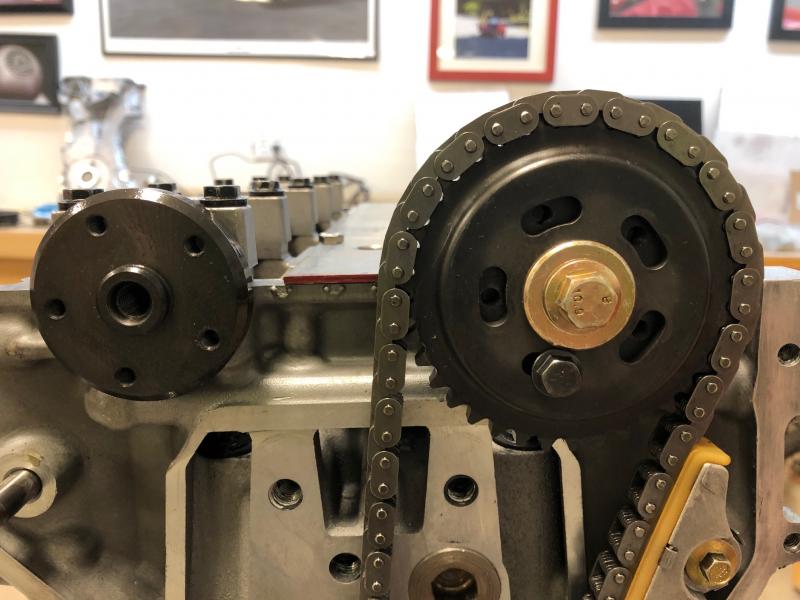

I removed the timing chain and exhaust side gear from the engine, and put the gear on a DTEC10 cam to make sure my memory of fit was correct. Surprisingly it was. Although tight, the gear was easy to rotate on the cam end by hand. In contrast, the gears are a tight enough fit on the new DTEC20 cams that a gear puller is required to remove them. The calipers showed the problem. The nose of the cam end that forms the stop for the bolt and sticks through the face of the gear (see left side of photo) is .006" wider than the nose on the old cams. Just enough to cause a problem. I think I'll hold off any attempts to enlarge the hole in each gear until I can speak with Kent Cams tomorrow. -John

-

Head is torqued, cams are installed, and the chain drive assembly with new mechanical chain tensioner is in place. The factory Duratec uses a hydraulic tensioner, which works fine, but can have issues in high rpm engines that result in over tensioning or broken teeth on the plastic ratcheting mechanism. The fix is a simple modification that replaces the plastic ratchet with a threaded metal stop. I ran into a slight issue when attempting to time the cams. Kent uses their own adjustable cam gears that aren't interchangeable with the factory set. For some reason the tolerances between my old gears and new DTEC20 cams are much tighter than with the old DTEC10 cams. They're more of a press fit than a slip fit which means they aren't really adjustable, but I tried anyway until running out of both patience and time. I'll remove the timing chain and cam gears tomorrow, take some measurements, and figure out if lightly sanding the coating might free up enough room. If not, I'll call Kent on Monday. -John

-

Mike, thanks for posting those. Great reads and photos. I even recognize a couple of the cars from USA2005. Ah, to be on a tour right now, driving like a hooligan on epic roads in the middle of nowhere... -John

-

FedEx has updated the tracking. It still shows it arrived in Troutdale yesterday around noon, and was in transit to Westminster shortly after, but they have now added that it left Troutdale last night (timestamped more than 8 hours after the In transit to Westminster timestamp) and arrived at my local hub early this morning. If that's true, I should have the head torqued this afternoon. -John

-

The Regular Summary of Classified Ads of Se7ens Found For Sale

JohnCh replied to Croc's topic in Cars For Sale

Nice looking pre-lit Westfield just landed on BaT: https://bringatrailer.com/listing/1984-westfield-seven-2/ -John -

Thanks, but I've become an expert at pressing the big red Croc...er, Ban button. -John

-

Good point. Let me get on that. -John

-

It looks like the torque wrench is delayed. It left Fresno, CA on Monday and was supposed to arrive here today. Checking tracking, it was in Sacramento on Tuesday (good), hung around Sacramento until yesterday (less good), arrived in Troutdale, OR today at lunchtime (good-ish) and is now in transit to Westminster, CO (what???) I'm not great with geography, but even I know that's not on the way to Seattle. Tracking now says it will arrive tomorrow, but the CO mention doesn't inspire confidence. Time for a Martini. -John

-

Check out Schroth Harnesses with their Flexi technology. They allow you to switch the lap belts between pull up and pull down configuration, and as part of that, you can position the adjuster closer to the buckle. Frees up room and they are very comfortable and well made. -John

-

Welcome James! The only folks we don't welcome are the se7enless spammers who keep trying to bust their way in here (hence the reason you were initially moderated). I'd love to hear more about the CSR260 project. What are your plans? Any pictures? Cheers, John

-

Given the rarity of red Westfields in the US and the small size of Menlo Park, you can file this under weird coincidences: My car's original owner had it when he lived in Menlo Park. -John

-

Wait, that color scheme was intentional?? I thought you were just trying out different paint samples to decide if you wanted to paint it white, or green, or, black, or blue, or... -John

-

Thanks Andy. I think the issue is isolated to those threads, but I am being careful with every fastener I tighten. Made more progress today. And experienced more frustration. The sump is now on and no threads were stripped in the process. Next up was the oil pump chain drive system. I didn't have a tool to hold the oil pump gear in place while torqueing the bolt and didn't have any metal stock on hand, so I fabricated something out of an old, unused metal wall track for an adjustable shelf system. Looked odd, worked great. Had a bit of a WTF moment when installing the ARP head studs. Ford uses torx head bolts, but ARP uses studs with washers and 12-point flared nuts. Step 1 in the instructions is to install the 10 studs finger tight. When installed this way, nine of the studs were 3" above the deck and one was nearly 1/2" higher. My initial assumption was that port needed another pass with the thread chaser I fabricated from a used head bolt, but that was not the case. Long story short, after trying the chase in that port, then in others, and swapping studs between ports, no combination resulted in a stud in that port aligning with the others. Then came an ah-hah moment. Per my calipers, the diameter of the threads is about 4 thousands wider on the ARP studs then the Ford bolts. Apparently there was a tiny amount of gunk deep in the recesses of those threads that the chase couldn't quite reach and that was creating additional friction for the ARP studs. It only took a little more than finger tight torque to screw in that stud further, so I opted to do that until the height above the deck matched the others. Next, the threads, washers, and nuts were lubed and the head was dropped in place. It was then I realized these were 12mm 12-point nuts, and my 12-point sockets start at 13mm. Sigh... Deciding to step out of my isolation bubble, I donned my hazmat suit, and braved the social distancing dance at my local Ace Hardware. Deep well 12-pt socket in hand, it was finally time to attach the head. Ford calls for tightening the head bolts in 5 steps: 5 lb-ft, 11 lb-ft, 33 lb-ft rotate 90 deg, and finally rotate another 90 deg. ARP, however, states to torque to 60 lb-ft in three equal steps. I decided to err on the side of caution and do a blend: 5 > 11 > 20 > 40 > 60. The first two passes were done with my small torque wrench which tops out at 18 lb-ft, then the medium torque wrench was pulled out for pass three. While tightening the first nut it was quickly clear that I had gone a bit past 20 lb-ft without a click, so I rotated that nut back to a little under 11 lb-ft and retorqued it to that level. Testing the medium torque wrench on a nut and bolt in the vise, it took a lot of torque to reach the 20 lb-ft reading. Going to 30 lb-ft seemed closer to double that figure, and when attempting 40 lb-ft, the bolt snapped. Okay, that's not going to work. A new medium range torque wrench is on order. The delays continue... -John

-

I don't think that's it. The hole was not drilled, and the outside of that thread bundle is smooth, whereas the Heli-Coil has threads on both sides. I'd expect some of the ridges to remain. Also, the resistance when hand tightening that bolt was the same as the one next to it. If a Heli-Coil was put into an unthreaded hole, even if it was drilled to the correct size, it would squeeze down and create a smaller threaded opening for the bolt. The other possibility is something happened to the engine before I bought it. It was purchased as a factory line take-off. Ford would remove engines for QA and then sell them to a handful of companies who would resell to customers. When the engine arrived it was clear that it had never been fired, but a corner of the coil pack mount at the back of the head was broken, so not pristine. Perhaps they over torqued the bolt in that hole on the assembly line and pulled it off, or perhaps did that during QA? -John

-

Internet crapped out at my house this morning which made work difficult given the lack of cell service on the property. While waiting for the muppets at the Internet provider to get me back online, I decided to head into the garage and affix the sump to the block. It's an easy job. What could go wrong? Yes, there I go again with the foreshadowing... Raceline calls for torqueing the 11 fasteners to 15 ft-lb, whereas the Cosworth CSR 260 manual calls for 25 Nm (18.4 ft-lb). I compromised and set the torque wrench to 16 ft-lb, then laid out all the clean fasteners, did a quick practice run with the sealant to make sure I could put down a proper bead, wiped the mating surfaces with mineral spirits, and temporarily attached the front cover to ensure the sump would be properly aligned while torqueing it down. Then it was time. Other than the sealant can puking out a big slug of sealant after hitting an air pocket, things were going fine. Sump was placed on the block, and all the fasteners were snugged a little over finger tight. Then it was time for the torque wrench. Starting in the middle and working my way outward in a circle, I had one bolt left before the job was done. It's one of the two long bolts at the back of the block. Starting to apply torque, it snugged a slight amount -- perhaps reaching 5 lb-ft -- but kept turning without tightening further. Uh oh. Fearing the worst, I backed out the bolt and removed this from the threads. The bolt was barely more than finger tight, yet the threads from the block stripped right out. No idea what happened. Metal fatigue from prior installations? Damage from the machine shop (did they use that port to bolt down the block during any of the machining work)? Or just bad juju? Regardless, it happened. Fortunately I have the correct size Heli-Coil kit on hand and after thoroughly taping up the block, the hole was drilled, tapped, and the Heli-Coil installed. That was enough fun for today, so perhaps I'll try installing the sump again tomorrow. -John

-

The Regular Summary of Classified Ads of Se7ens Found For Sale

JohnCh replied to Croc's topic in Cars For Sale

Given it's a dealer, I'm surprised they didn't spend time polishing off the labeling someone did to the dash. Sure, that person's penmanship is leagues better than mine, but it only adds to the amateurish vibe. Interesting claimed history though. If true, that will offset the mismatched gel coat for some bidders. The fact it has a Weber head Big Valve engine will also drive some interest. -John -

I'm curious, what is the max advance you can get without clocking the distributor? -John