fastg

Registered User-

Posts

609 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by fastg

-

WTB/RENT OR BORROW Portable English Wheel

fastg replied to ChuckM's topic in Parts For Sale / Wanted

The tools are simple, the necessary skill is not. Basically a ripple is caused when metal stretches, so it gets longer, but the surrounding metal constrains it. This new longer piece of metal has to go somewhere so it curves in or out. To fix it you need to get behind the ripple using a block or dolly, then hammer the top of the ripple to shrink the metal back down, a slapper is often used. But it takes skill and a good eye. See is you can find a skilled "painless dent removal" specialist, and see if he can help or point you in a good direction. Graham -

WTB/RENT OR BORROW Portable English Wheel

fastg replied to ChuckM's topic in Parts For Sale / Wanted

I cannot see the roller shape in you picture, but English Wheels stretches metal, if you have ripples you generally want to shrink metal, so you might be barking up the wrong tool. Graham -

Save The Date - Annual USA7s HPDE at NJMP - September 18-19, 2022

fastg replied to Croc's topic in General Sevens Discussion

Gingerman is a great track, fun, changing, safe. and 7 friendly. I have done trackdays there on not bikes and cars. Graham -

It could be a lot of things, you need an AF sensor, you will learn more in 5 minutes that you will after hours of faffing around. Using a vacuum guage, go old school, try a piece of hose, stuff one end in your ear, he other and in the throttle body, with a little practice it amazing how good you will get. That assumes you have something like regular hearing. Graham

-

Save The Date - Annual USA7s HPDE at NJMP - September 18-19, 2022

fastg replied to Croc's topic in General Sevens Discussion

I will be there this year, how do we book? Graham -

Well Santa came a little early, but it looks like my winter project is already decided. The hold grail cylinder head for a K24 block is the large port K20A2 head off a Civic Type R or an Integra type S. I thought lets look in Craigslist, a trip to Reston VA and $200 secured a nice specimen. So I guess we are now on the hunt for 275bhp:) Graham

-

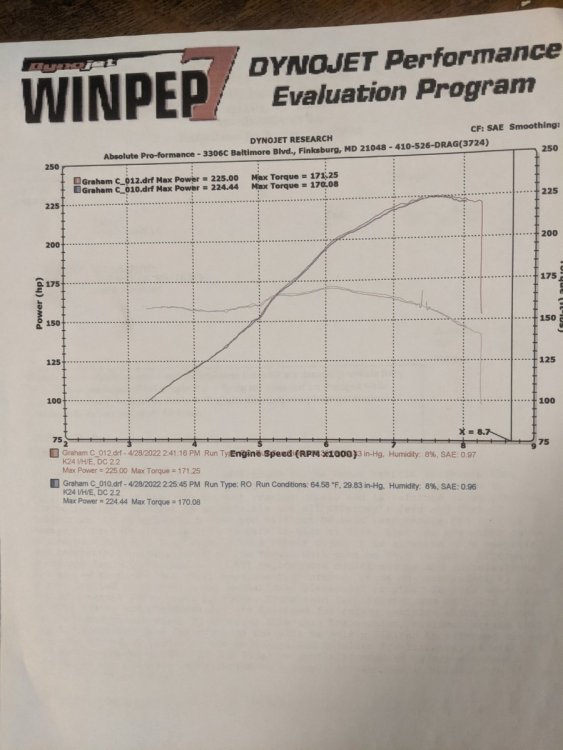

It's a ripper, much better midrange and it sings right up to the red line. I could tell on the later dyno runs, the front wheels were lifting while he was running thru the gears. The new find power and the new 6 speed trans and going to make major improvements on corner exit. Graham

-

Selling tools, that is just not right. You know Murphy is an evil bastard and you will need them the week after you sell them. Never going to happen here. Graham

-

I have not had the chance to drive it yet other than on and off the trailer. I will take it out over the weekend. It's going to Pittrace in about 3 weeks so that will be the first real test. Graham

-

I guess there not big number, With a CNC ported head, Skunk2 inlet manifold, 90 mm throttle body, and Drag Cartel 4.4 cams 250-260 is the norm. I have the small port TSX head, the holy grail is the K20A2 large port head, with the same set 275 is the norm, all on a stock bottom end. You can guess what I am searching for:) Graham

-

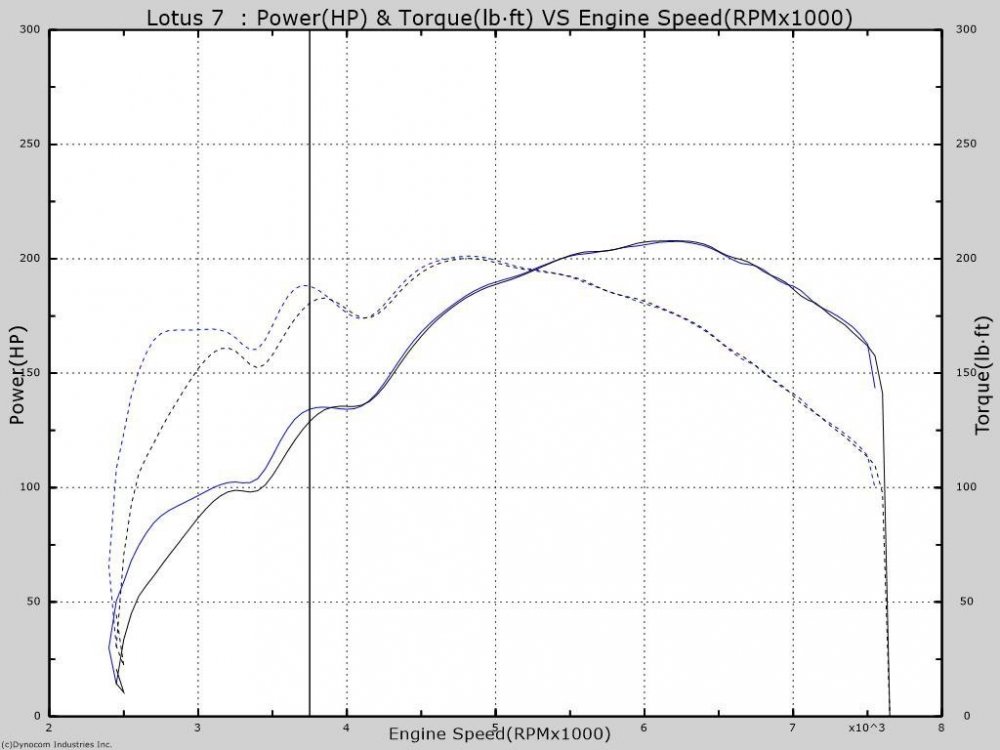

When to Absolute Pro-formance yesterday, John the owner is a Honda guy, vast experience, many trophy's on the wall from drag racing. He spent 4 hours adjusting the car. 17 runs in all I think. He started by giving the car a detailed inspection, most of the specials/engine swaps he sees a total train wrecks, but mine got a passing grade:) A little background, the K24 setup is complicated. There is a fuel and ignition map for each 10 degree of cam angle, 0-50 degrees. There there is a complete set for Vtec high lift and low lift, a lot of maps. He spent 1/2 hour just smoothing out the maps because they were all over the place. Many runs, has to increase the fuel pressure as he were getting a little high on the injector duty cycle. We ended up a 225bhp, we did see a partial run at 227, the car was getting very heat soaked by the end, he is confident it would be 227-229 maybe touch 230 on a fresh run. But as you can see from my prior runs, more power everywhere, much smoother. Great torque curve, just starting to flatten off at the very top end.

-

Lotus 7 series 2 rear axle housing-free

fastg replied to Christopher smith's topic in Parts For Sale / Wanted

Brazing is high temp soldering. The parts have to be clean and a good fit, but if the surface area is good the joint will be very strong. The two surfaces have to touch, then as the braze flows it creates an alloy between the 2 surfaces. When you solder something it not the solder that creates the joint. Solder is a soft as butter but can make some amazingly strong joints. If the joint fits well and the right temperature is used an allow is created that bridges the 2 metals creating the joint. Graham -

Lotus 7 series 2 rear axle housing-free

fastg replied to Christopher smith's topic in Parts For Sale / Wanted

If a crack has been brazed it will be very difficult to weld. If it was brazed well it will have spread deep into the crack making it very difficult to clean the area before welding. Welding rod a brazing rod do not mix. Talk to your favorite welder for his opinion. Graham -

The Innovate setups are almost the industry standard. Huge range available, you need one with a dial so checkout. They can feed an ECU but you don't have to, they can be stand alone setups. https://www.summitracing.com/parts/inn-39180?seid=srese1&gclid=CjwKCAjwsJ6TBhAIEiwAfl4TWAP-tnl3VRixMKsEhyQIEQUhj35daI8qpe4r6_9LJzJr3Iydken5FBoCUpMQAvD_BwE Graham

-

We took out first test drive Saturday. Everything went perfectly apart from the speed display on the dash. The car is louder and definitely has an angrier disposition. The new 6 speed shifts very smoothly, but has a slightly longer throw than the 5 speed. The speed display issue proves Murphy is a evil bastard. I had removed the scuttle and disconnected all the wiring. The scuttle is one piece on a Locost so looking at the wiring is a neck twisting endeavor. But I could find nothing. So I changed my approach and started at the sensor end, Grrrrr, just were the cable goes around the upper control arm. All soldered back together and working perfectly now, but I will have to re-program the dash for a 6 speed trans. Well be booking a dyno session next week. Graham

-

Has anyone any information on ERT, they list a light duty 5/6 speed sequential transmission. There web site is no help, but they have an active Facebook account https://www.facebook.com/eliteracingtran. https://www.facebook.com/eliteracingtran/photos/pcb.5281324811912773/5281319305246657/ Graham

-

One issue with Rotary engines is VERY high exhaust temps, so it will take carful design, and maybe why the current setup looks a little overbuilt. Graham

-

It looks very well put together, all neat and tidy, just needs a good clean. It that twin alternator belts, if so a little strange. Getting a airbox with cold air would help a lot, just sucking air from under the bonnet is never good. Supertrap exhausts suck, they may reduce sound but the kill performance. I had a Supertrap on the first Honda setup to reduce the ear splitting sounds levels. The dyno operator said that has to go, we removed it for the final dyno runs and picked up 25BHP. Graham

-

The Regular Summary of Classified Ads of Se7ens Found For Sale

fastg replied to Croc's topic in Cars For Sale

Nothing is more visceral than the hit of a big 2-stroke. It blubbers, turns into a gurgle, then a wail, the horizon jumps up, grab the next gear and it does it again. Graham -

The Regular Summary of Classified Ads of Se7ens Found For Sale

fastg replied to Croc's topic in Cars For Sale

I am not sure why this is a surprise to people it's been common practice in the Rotary works for many years. All the later RX7/8 have oil injection anyway, your just augmenting that. The guys I know add about 4oz of oil per 10 gallons of gas. That amount is not going to change your octane by a measurable amount. There are some people that dump the oil injection system totally and run only pre-mix. The following web site has a nice review. https://rotaryperformance.com/blogs/news/84479876-to-premix-or-not-to-premix Adding oil in the fuel might not have the effect you might think. When we were racing 2-strokes the privateer teams would buy the latest and greatest oil that claimed the highest mix ratio 80:1 or higher, thinking they were getting more gas so more octane and more power. They just destroyed there engines. We would run as much oil as the plugs would fire 25:1 or lower. The latent heat of oil is much higher that gas. So just valorizing the oil require heat. The engine runs cooler, the combustion temps are lower, you could run more ignition advance. Our motors would run better longer, especially late in the race, and as a bonus they would last longer. Graham -

The Regular Summary of Classified Ads of Se7ens Found For Sale

fastg replied to Croc's topic in Cars For Sale

They are both piston ported engines, they have great similarities. Rotary's are very dirty, when they tried to clean up the RX8 the outcome was a disaster. Most rotary owners run pre-mix oil to protect the apex seals. Direct inject a 2-stroke and it's a very clean engine, I think there is a new 2-stroke motor that has just passes the new European very strict pollution requirements. Graham -

The Regular Summary of Classified Ads of Se7ens Found For Sale

fastg replied to Croc's topic in Cars For Sale

Being a huge 2-stroke fan I have always lusted after a rotary, but the stars have never aligned. They are misunderstood rather than unreliable, run rep-mix and you should be good. It's a great package for a 7 fits very easily. Dan have a purple turbo rotary Rotus is his shop the last time I was there. Graham -

Proposal for a new 2021 Sevens HPDE in SC - Gauging interest

fastg replied to Croc's topic in National Events

I would be interesting on attending, it's a track I have never been to. It's about a 500 mile trip from Baltimore. Graham