-

Posts

3,266 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by JohnCh

-

So, tell us a little about yourselves

JohnCh replied to slngsht's topic in General Sevens Discussion

Congratulations @TobyinNJ, that's a very nice spec! -

I have split this thread and moved the lengthy PCV conversation to a dedicated thread below and in the correct sub forum. Please remember to start a new thread when dramatically changing a topic to ensure it is easier for people to find when performing a search in the future, and to ensure people see your question rather than ignoring it given the significantly different thread title.

-

So, tell us a little about yourselves

JohnCh replied to slngsht's topic in General Sevens Discussion

Yes, there are several threads I don't split simply because I don't have the time or patience, or I didn't notice the conversation was part of a completely different thread. The Spotted thread is a great example of one that has gotten completely sideways. Splitting out the registration component is too messy because of how that portion has gone, but there is a cleanish split for the PCV conversation. I'll do that now. -

So, tell us a little about yourselves

JohnCh replied to slngsht's topic in General Sevens Discussion

I've moved the battery thread here: Just a reminder to everyone to please keep threads on topic. Switching it up to ask completely different questions and start a new sub-topic makes it harder for people to perform searches in the future and also means many people may miss the question because they are not watching the original thread. Thanks, John -

27-1570SS with the 613/7SS retaining pin. The latch has a safety catch, so with the pin, it's a belt and suspenders approach.

-

It might be worthwhile to post a picture of a latch so other S3 owners could chime in regarding originality. I'd also start with MV8's suggestion about tightening things up with a new or thicker gasket. Maybe try some foam rubber shims under each latch point to see what works best? In terms of other options, Caterham uses terry springs on the front and conventional over center latches in the rear. For my Westfield, I went with overcenter catches with a locking pin from https://protex.com/. With those pins in place, there is no possibility for the latch to open.

-

If it's to supplement the Caterham, is an open top a requirement or even desirable? For me, it wasn't and why I bought a FHC Elan. When I want the open top experience, it's the Westfield or Caterham. If the weather is a little iffy, I grab the Elan. If it's really iffy, then the Miata with bolted on hardtop and no soft top, or the 993 get the nod. They each serve a different purpose and accommodate a different mood. Figure out what purpose and mood you want to accommodate with the new car. If you want raw, I suspect you are looking for a modified car. Factory setups have to appeal to the masses -- even if those masses are a relatively small group -- and as a result, rawness is diluted. But how raw do you wish to go? Do you want a modern car, with all the goodies like ABS, traction control, air bags, great HVAC, etc. or do you want something that has reasonable safety, but forces compromise in exchange for the driving experience? With that information, I am happy to help spend your money

-

Is this to replace or supplement the Caterham?

-

Annual Gathering of Sevens; And, a Request!

JohnCh replied to rider's topic in General Sevens Discussion

If you are willing to travel to NJ: -

The Regular Summary of Classified Ads of Se7ens Found For Sale

JohnCh replied to Croc's topic in Cars For Sale

Caterham 310R: https://bringatrailer.com/listing/2020-caterham-310r-s3/ -

No, the blue car pictured was fitted with a 2.4L RST V8. As mentioned earlier, it uses Yamaha 5-valve heads vs. the Hartley's Hayabusa heads. Similar in concept, just as nuts, and sounds just as fantastic, but not the same.

-

As I recall these were custom blocks with 5 valve Yamaha motorcycle heads. The engine was used in special versions of the Levante, Ariel Atom, and the Radical and available as a crate engine in the day. There was a 2.0L, 2.4L, and a supercharged variants and it was stupidly light. 200lb? Hartley did (does?) something similar, although I believe he built them around Hayabusa heads.

-

Someone on the USA2005 tour had Caterham fitted with this engine. 2.4L, 400hp, 10k rpm. It sounded like a Cosworth DFV whenever he took off. -John

-

Congratulations! Glad to hear it was something simple.

-

So, tell us a little about yourselves

JohnCh replied to slngsht's topic in General Sevens Discussion

-

The Regular Summary of Classified Ads of Se7ens Found For Sale

JohnCh replied to Croc's topic in Cars For Sale

I suspect that's a typo. It reads the seller has added 200 miles since acquiring the car in 2011. Mileage claimed is ~43,800 with an odometer photo showing 43,758. Yet the invoice from Kampena in 2018 lists mileage as 42,992. -

I received permission from Drive Auto Sports to post the video they took of a power sweep. Gotta love the exhaust flames at the end. -John

-

My Driving Impressions, Thoughts and Questions

JohnCh replied to rider's topic in General Sevens Discussion

As per @Vovchandr there is a noticeable difference in size between the SV and S3. You should find an S3 with standard floors and see how that fits. I suspect it will be much better. Below is an overhead shot that illustrates the size difference between the two. Pay particular attention to the interior comparison. It's not subtle. The shifter height in relationship to the dash bottom doesn't bother me at all. I quickly adjusted to moving my hand forward to rest on the gear knob rather than drop it on from overhead. My gripe with location is it's a little further forward than ideal for me given the steering wheel location. But again, it's something you quickly get used to after driving for a bit. -John -

Agree. I'd prefer something like these 917 inspired key blanks:

-

Just order a new car and they'll give you two for free!

-

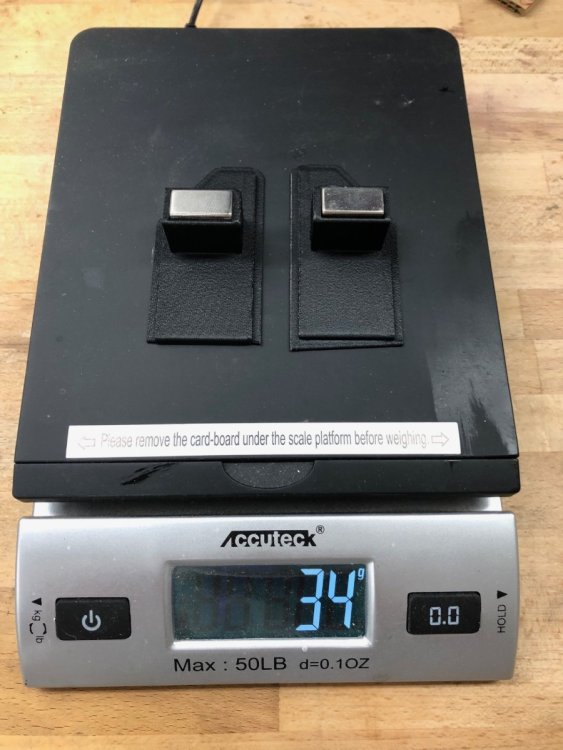

To put the weight in perspective: And yes, I was surprised the weight was identical. I even put them on the scale together to make sure the scale wasn't broken. -John

-

I have heated seats. If you don't make fun of me for that, I'll ignore your carpeting. Deal?

-

A simpler way to do it is cut out a piece of aluminum, spray paint it black to match the panel, and if you don't want fasteners, adhere it in place with silicone. It's a lot more trouble to remove, but that should be a rarity. If you want to get fancy, make a buck out of an old 2x4 that's a bit smaller than the cover, then gently hammer over the edges a bit (20-30 deg angle). That gives the cover a more finished look and provides some space for the silicone.

-

The R-pack cars don't come with carpeting on the rear bulkhead, which unfortunately exposes the cutouts to access the upper damper bolts. It looks a bit unfinished to my eyes, but I didn't want to drill more holes to affix aluminum cover plates. So once again, I pulled out the 3D printer. A Neodymium magnet is glued to the print and affixes it tightly to the chassis. For some reason though, printing it flat was resulting in some discoloration I haven't seen before with this build plate and filament combination. Not sure what's going on, but to keep the surface color uniform, I had to print it on its side which resulted in a little elephant's foot, but you have to look closely to see it. The cover is easy to remove, stays in place, and requires no holes. Not as inconspicuous as a piece of black painted aluminum, but I'll take that tradeoff. I also discovered these really are hand-built cars. The cover for the passenger side had to be shaped slightly differently to avoid a gap on the lower left corner. Mirror imaged they ain't. -John

-

Not at the price I would need to charge