-

Posts

3,087 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by JohnCh

-

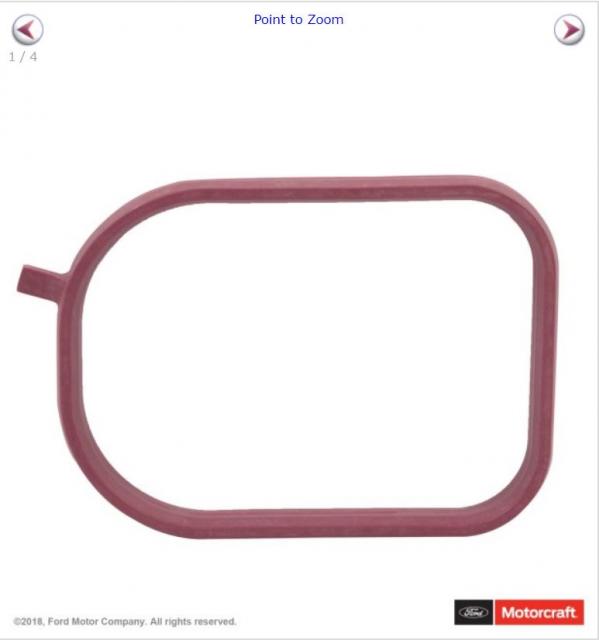

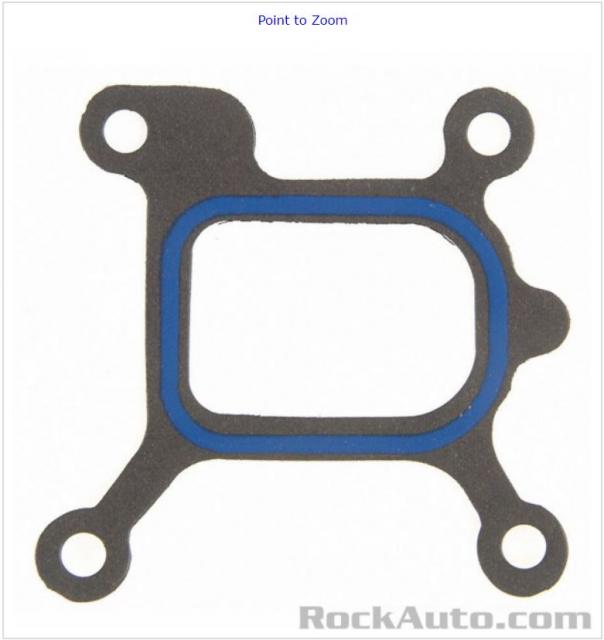

The rebuild has been on hold while I awaited delivery of the missing gaskets for the oil pump and for the water outlet at the rear of the head. The later wasn't actually causing delays since attaching the water rail is one of the last things to do prior to installation, but it is needed. The online Ford dealer I use for Duratc parts normally ships quickly, but with Covid-19, it took much longer than normal, and then USPS seemed to misplace the package for a few days. Thankfully it's here now and the plan for this weekend was to finally begin reassembly. First step was to install the oil pump which arrived with my first shipment of rebuild parts back in October. At the time, I took a quick look to confirm it was correct, and although there were some slight differences to the casting from my circa 2002 pump, the key aspects were the same. However, this morning I discovered something overlooked during my initial examination: one of the two locating dowel pins was missing. The pump body is machined to accept it, but it was neither installed nor in the box. Then I took a look at the oil pump gasket to make sure it was correct. It is. However, the water outlet gasket wasn't even close to the correct shape. Rather than a flat plastic gasket with 4 bolt holes splayed out, this was a rectangular extrusion that was meant to fit in a groove. The part number matched the order and a visit to their site showed the drawing of the correct part. However, entering that same part number on a different site revealed a drawing of the part I received. Hmm... A visit to RockAuto's site was next to view photos of both parts from various manufacturers. The water outlet gasket is a little odd. They show both styles and the descriptions match, but one shows a hybrid with the extrusion fused to the flat gasket. My best guess is that the Ford setup uses both, but the water rail just requires the flat gasket. Photos below of the flat, extruded, and hybrid versions. The oil pump photos created more confusion. Two of the pump brands include photos of the back side where the dowel pins are located. However, both show only the single dowel pin like I received from the Ford dealer. Given the pump body is machined for the second dowel pin, this seems odd. Does anyone have any experience with this? If not, I'll give Peter at Raceline a call on Monday. Thanks, John

-

Evo just published a short review here. -John

-

I like the concept and the fact they even went to the effort of fitting the Jenvey Heritage Throttle Bodies to maintain the old school vibe under bonnet. I wonder how long it will be before someone attempts to 3D print a BDA-style valve cover to complete the look? -John

-

I went through that hassle too. It was easier to find and order the Duratec tappets from a Mazda dealer. Ford dealers didn't even seem to know what they are Croc, didn't the K series have headgasket issues? Could the use of pantry items be related? :jester: -John

-

Earlier I mentioned the dowel pins that locate head to block were removed when the deck was blocked. I have the originals, but they were damaged during removal. Finding replacements proved a challenge. They don't show in any of the online Ford or Mazda parts diagrams, and calling the parts places that are still open resulted in Catch-22 conversations. Apparently a parts expert is highly capable of ordering parts, but incapable of finding them without a number. I suppose the only reason they state on their websites to call if you can't find the part in their online catalog is so a live person can tell you they can't help without a part number. Who says e-commerce killed the personal touch? One online parts search under cylinder head did return something that looked right but showed as a starter bushing when drilling down. Further searches on the part number at other sites confirmed that description and additional searches for starter bushing turned up a second part number. Hmm... Both were ordered and arrived yesterday. According to my calipers the first one is correct. If anyone is in this position again, the correct Ford part number is W701183-S300. -John

-

Sadly there are some things in life you just can't unsee... -John

-

The pictures certainly help, although I am surprised that Dave Andrews isn't mentioned in the attribution. He wrote that many, many years ago, well before the 2011 publish date. Regardless, it's a good basic primer. -John

-

Below is s good, basic resource for DCOEs and includes a simple but effective guide to setting idle and low rpm running. It's probably safe to assume the various jets and emulsion tubes are correct, but it's probably worthwhile taking them out to see what is installed and make sure they are the same in each carb. It's an old car and sometimes people do stupid things along the way. I'd also make sure the float levels are correct in both carbs. Apologies if you already mentioned this earlier, but a synchrometer or unisyn is a worthwhile investment to properly sync the carbs. http://www.s262612653.websitehome.co.uk/DVAndrews/webers -John

-

Good idea, but I'm afraid Jack Daniels wont' do it. Too wimpy. You need at least 60% alcohol to kill the virus. Something like this 127 proof Bruichladdich should do the job. -John

-

Mike, it should work now. If not, let me know and I can connect you two. -John

-

After my last post I looked at the specs for the two versions of Loctite. The 680 sounds like it's designed for exactly this purpose, so I ordered a bottle. You can never have too much Loctite or too much duct tape on hand I forgot to also provide an update on the O-ring and thimble described in the wet sump instructions. According to Peter the design changed quite a while ago to provide more latitude when aligning that port with the oil pump which can be cocked slightly when installing. Not an issue, but it does mean I need to take a little extra care when bolting everything together to ensure the port is fully aligned. -John

-

Thanks for the tips on the elbow fitting. I just spoke with Peter at Raceline and he said that he uses Loctite 270 when reinstalling. I have some of that on hand, but let me do a little digging on the difference between that and the 680. Vov, the actual range of the throw seems about the same in both slaves. With the I4 version I can push the throwout bearing well past that inner silver tube, but when released it will only extend a little above it. The V6 version when pushed down only goes to about the top of the tube and as you can see from the pictures, is quite a bit above it when extended. This should mean that with the I4 version, the pressure plate will not move as far when the clutch pedal is pushed. My assumption is that you would not get full disengagement, but without having all the parts in place, it's just speculation. As long as I was on the phone with Peter, I asked him about this and he confirmed that the V6 version is also correct for the Zetec installations. He also indicated that the I4 version can over extend and start to come apart spilling fluid inside the bellhousing. Have you noticed a drop in fluid level in your clutch MC? -John

-

Thanks Papak. I plan to do some more digging into the right approach with the elbow. I don't see signs of an adhesive, but it doesn't make sense that it's simply a press fit. Vovchandr, the 10mm extension means pushing the the fingers of the pressure plate closer to the back of the block. Here are two photos borrowed from RockAuto that highlight the difference. The first is the the 4 cylinder version (Sachs Part # 94ZT7A564AA) and the second is for the 6 cylinder (94ZT7A564BA). The end of the inner sleeve (see silver tube in the middle of the opening) is the same distance from the back of the slave cylinder in both versions. However, if you look closely, you can see how the V6 version places the throw out bearing much further forward. -John

-

Time for more pictures...and problems, albeit nothing significant. This morning I moved the bagged short block from the safety of the dogs' car into the shop. The goal for today was to get it on the stand, look it over for problems, reassemble the Raceline wet sump which the machine shop disassembled to thoroughly clean, and if I was in the mood, install the new oil pump and the associated chain drive components. Issue 1: The shop removed the locating pins and the 90degree elbow from the top of the water pump housing so they could deck the block. I completely forgot about the locating pins and need to find replacements. I also am not clear how to properly reinstall the elbow. It appears to have been a dry press fit, but trying to seat it just now feels like I can do so with hand pressure alone. I would expect a tight seal like that to require a little more force. Anyone have any experience with this? In the picture below, the port is in the upper right of the block immediately below the letters AN. Issue 2: I forgot to order a new oil pump gasket for the new oil pump. The Ford gasket is plastic, and although the old one looks great, that's not a short cut I'd like to take after this much effort. At this point I also realized that I need a new plastic gasket that fits between the back of the head and the water rail. I had ordered one from Raceline and although it is on the invoice, they sent me a paper gasket for something entirely different. Issue 3: The machine shop disassembled and cleaned the Raceline sump. In anticipation, I had Raceline include 2 sets of replacement O-rings with my piston order (they're cheap, and I like spares since I'm a bit of a klutz.) My sump uses 2 O-rings on a small wedge-shaped block that mates the oil pump to the sump pick up port, and 2 slightly larger O-rings that fit around the end of the pickup tube that feeds into a small chamber beneath that port. However, my order included 3 different sizes of O-rings. Hmm moment #1... Fortunately they also included the sump assembly instructions. Something they didn't have available when I purchased my sump in 2003. Looking through the instructions revealed the 2 thickest O-rings go on a small alloy thimble (their words. it's just short, thin walled tube) which is then inserted into the port in the sump that feeds the pump. My sump never came with that thimble. Hmm moment #2... Doing a little measuring shows the ID of the O-rings is 17mm, meaning the OD of the thimble is a tiny bit bigger and the ID is probably ~15mm. The port on my sump is only 16mm. I suspect that they now drill that port bigger for some reason and the O-ring/thimble assembly is to restrict the size. I'll attempt to confirm with Raceline this week. Issue 4: Another bonehead move by me. I ordered the wrong clutch slave cylinder. It turns out I needed one for the V6 Ford Contour and I ordered one for the 4 cylinder version. The two parts look the same and the part number differs only in the penultimate digit, but the throw is about 10mm different. A replacement is on order. I'm still not sure what happened with the keyed crank. It measures at 3.06mm and the pre-slotted crank pulley measures 3.00mm and fits fine. There is no slop with the key in the crank, which is good, but you can see a very fine scratch on the nose, which I assume is from whatever tool they used to enlarge the slot cut by the subcontractor. My best guess is that the subcontractor screwed up and I paid an extra $145 for the primary shop to fix it. ARP rod bolts and main studs -John

-

Greg, based on that BlatChat post, it sounds like like Caterham previously used slotted trans mount. Would that solution give you enough room, or would there still be an issue based on the location of the engine mounts? -John

-

Given I live in one of the Covid-19 hot zones, I'm anticipating a shelter-in-place mandate is imminent which will likely close the machine shop. Fortunately I was able to carve out 90 minutes around lunch today and just picked it up. No pictures for now as it's in a bag in the back of the dogs' car, but I hope to pull it out over the next few days and will take some shots then. I did learn more about the overage for the keyed crank. As we had previously agreed, they subcontracted out that work to a different shop which had the specific tool required. However, they provided them with the instructions I supplied from SBD which state to machine for a 3mm key. It turns out the key is actually a little bigger than that. This meant the slot in the crank was too small and had to be painstakingly widened. Also, because I purchased pre-keyed chain gear and crank pulleys from SBD, the simple solution of narrowing the key to fit the slot wasn't an option. My bad for not measuring the key myself when it arrived (something I'll do later today), although I am disappointed the machine shop didn't do the same, or at least supply the key with the crank to the subcontractor. Oh well, if that's the biggest problem with their work, I'll be happy. -John

-

Thanks Mike. My surprise wasn't that the Atom was faster -- honestly, I couldn't care less about that sort of thing, as it's the driving experience that matters most to me -- it was simply the apparent instability of the 620R in that video. I can't recall seeing any other S3 Caterhams behave that way on track and was curious if that was exacerbated for entertainment value or if at 310hp, the S3 has reached a stage where it's finally more engine than chassis. Although I see where you had a moment, it certainly doesn't appear you were fighting the car like Chandhok. I suppose that could be down to show, track temp, or you were showing far more respect to the throttle. Now since you responded nicely and scored extra points for posting a video, I'll leave it to Shane to comment on your driving ability :jester: Thanks, John

-

I watched a rerun of Fifth Gear that pitted the Zenos, Radical, Atom, and 620R against each other in a series of knock out tests. The tests and order were chosen in such a way that the Atom and 620R would be pitted against each other in a short race at the end. Although it's not surprising that the mid engined Atom would have a lot more traction out of corners, I was a bit surprised how unstable the 620R looked. Croc, as I recall you've driven one on track. Does this mirror your experience? Fast forward 52 seconds for the track action. -John

-

The machine shop called Friday to say the short block work is finally done and ready for pickup. It came in about 15% over budget which is a function of the bearing issues and previously undisclosed issues with keying the crank. Unfortunately I'm not yet clear on the specifics of that latter overage. The conversation with the owner was brief and he seemed to be getting a little defensive as I asked a few probing questions to understand what happened, so I'll wait to get the complete rundown when I pick up everything (hopefully) next Friday. -John

-

I tried something different yesterday given that everyone is working remotely. My team and I did a virtual happy hour. We set up an online meeting, everyone used video, had a beverage in hand, and agreed absolutely no work talk. We ended up shooting the sh*t and playing online trivia for an hour, which proved a nice escape from the pressures and anxiety of the current situation. As one person put it "this was the first time in 2 weeks I've gone more than 30 minutes without thinking about Covid-19." Recommended for those of you working remotely and missing the non-work interaction with colleagues. -John

-

Looking forward to reading Croc's color commentary on this late breaking story: (CNN)An Australian newspaper has printed an extra eight pages to be used as toilet paper after coronavirus fears prompted customers to bulk buy supplies, leaving some supermarket shelves bare. Full article here: https://www.cnn.com/2020/03/05/world/coronavirus-australia-toilet-paper-scli-intl/index.html -John

-

I am selling all my stock and liquidating my 401k in the morning so I can go all in on toilet paper Futures. I'm going to be rich, I tell you. Rich! Another potential money making opportunity is the Covid Cone. -John

-

My starter is out of the car, however, the label with the part number is worn and difficult to read. Combining the upper and lower numbers on the left of the label gives (I think) 3S4T-11000-AB which is the part number for the starter on the Duratec-powered Ford Focus. I don't see any starter numbers that include the numbers on the lower right of the label (3K17BY) and I'm not sure if they have any meaning for this discussion. Anyone have insight or can confirm that the Focus is the right application? One caveat on my starter. The install was done in 2003/4 when the Duratec was only available here in the Ranger and that starter would not work with the Raceline bits. The correct application at the time was the Duratec-powered European market Mondeo. My guess is that's the same as used in the Focus, but it would be good to have confirmation. -John

-

I spoke to the machine shop today. The second set of rod bearings arrived safely, but they had to mix the sets to achieve optimal clearance for each cylinder. This is not uncommon with Duratecs. Consequently it's not a big surprise, but still a little annoying as I now have an extra mixed set that doesn't serve a purpose except perhaps as the basis for a new art project. Maybe I'll have one too many martinis this weekend and come up with a design I can sell on Etsy to finance part of the rebuild. Anyone looking for a unique ring, bracelet, or necklace for their wife or girlfriend? The shop hopes to have the rotating assembly balanced and the short block assembled by the end of next week. Of course the machine shop is in Kirkland, WA the hot zone for the Covid-19 outbreak in the US, so retrieval runs a risk to more than just my checkbook. Oh well, I've never liked doing things the easy way... -John

-

One more thing regarding the question of soul. I've never found a difference in that respect when driving, but it definitely exists in the ownership/maintenance/tuning aspect. Using a laptop to make changes, or using data logs or a multimeter to track down a problem is far less soulful than changing gaskets to stop raw gas from seeping out, tweaking float heights, or playing with a various combinations of jets, emulsion tubes, and air correctors. -John

.jpg.d6a2573e2b6b3b2b7de4c47bab2e8c18.jpg)