-

Posts

483 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by papak

-

You might want to use a GPS speedometer and cap or plug the drive mechanism. Always accurate, regardless of wheel/tire size or final drive ratio. Always dry too!

-

I know that on my 2015 Birkin XS, the solid rear rotor is from a ‘98 ROW GTI but it has been milled down on the inner side to. 10.5mm, approximately the minimum rotor thickness stamped on the outer edge. Weird but it allows the VW rotor to work with the proprietaryBirkin hub assembly. Wilwoods on the front.

-

I understand that they are from ROW late 80s GTI/Jetta. Check with tbox56.

-

That is John’s personal car. I understand that he has owned it since new. I’ve met him at a couple of C&Cs and seen the car. Very original but in good condition. He is a wonderful fellow to chat with. Very self-effacing.

-

Tom, Best of luck to you and Birkin. Kevin

-

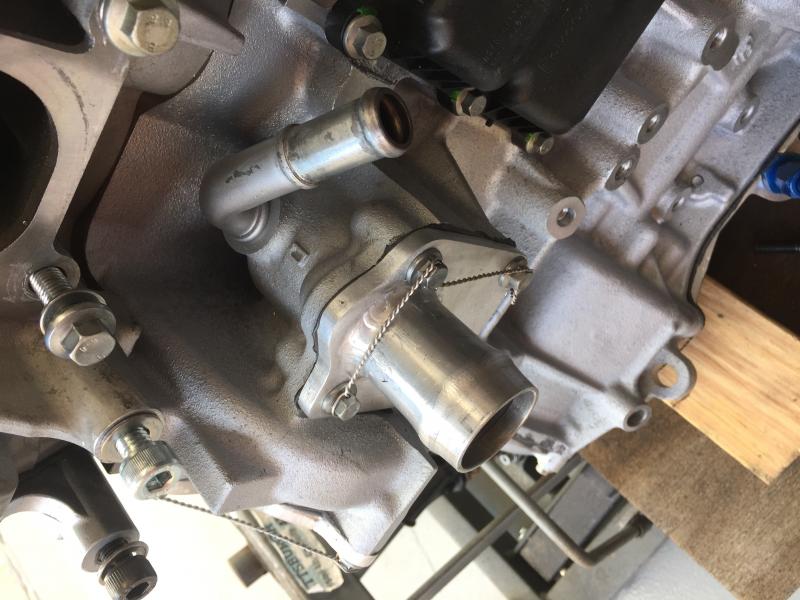

As you can see in the attached photo, I have modified the cooling system by removing the internal water pump and eliminating the thermostat (as per the D-C instructions). By utilizing the D-C EWP controller, the thermostat value is set in the controller and it cycles the electric water pump and cooling fan (according to an internal program) as necessary to maintain the selected temperature. It originally worked quite well but more recently, it has become extremely sensitive to acceleration it seems. Aaaarrgh! I never presumed that I would need an oil cooler but I could certainly add one if necessary.

-

Looking for others familiar with the Davies-Craig EWP controller (the earlier style, Model 8020). Mine has been acting strangely the last few months. It self-tests normally and follows the programmed profile until I accelerate. At that point, all of the indicator lights illuminate and both the water pump and fan activate. This lasts until I drop the revs below 3000, then all is back to normal. The specifications state that the voltage supply range is 11.5 -15vdc. My little alternator (40 amp, internally regulated) produces 14.5v when at speed (>2000 rpm). I have verified this with an external tester. It sure seems like a voltage related problem but it would have to reside in the mother board, I presume. I have traced and tested every wire and connection in the system with no luck so far. The coolant temp probe is a new Ford unit. This leads to the basic problem, an inability to get the engine up to normal operating temp, even after an extended drive. Yesterday it was in the 60s and all I could get was 130 on the oil and 140-150 on the coolant after a 30 minute spirited drive. Any productive suggestions would be greatly appreciated.

-

Love autocorrect. I always wonder what version Trump uses.

-

Apparently, the US Army trained all of the tank drivers out there during WWII before the North Africa operations. You're right though, it's definitely a dry heat.

-

Have they imposed a db limit at Chuckwalla? I ran a test day there in a vintage FV when it first opened. Great "7" course as I recall. It can get quite windy out there. Remember, the nearest hotel is 50 miles away back in Thermal! You need to bring everything with you. it's remote. They do, however, have a short (3500" or so, uncontrolled) runway adjacent to the track. According to the fellow who was running it, the site was chosen due to it's central location between Los Angeles, Phoenix and Las Vegas.

-

I’m still waiting for a reasonably priced electric pickup truck.

-

On the advice of another owner, I welded a threaded bung in the right front corner of the cover to facilitate future servicing of the gearbox. Once you have filled the gearbox, you can mark a dipstick for reference. The right front corner is a location where the dipstick will reach the bottom of the case without screwing anything up. I have suctioned out the gear lube in the past through this port. I eventually got got tired of the oily residue that accumulates on the top of the cover. The box is vented through a small hole in the cover that is baffled by an internal plate attached to the upper selector shaft pivot. I recently welded an AN-4 bung in this location (after drilling it to size). I attached a 12” SS hose using a 90 degree fitting and a straight fitting at the other end. To this I attached a cross drilled cap and secured it to the frame in front of the tunnel opening. Now everything stays clean and dry.

-

Leaky Gearbox - Superformance S1 (Zetec w/ Ford Type 9)

papak replied to Driven's topic in General Tech

I found that the selector shaft was the source of the leak on my T9. Meticulously clean the surfaces and carefully apply either Hylomar or rev. Bone dry ever since. -

Depending on the motor mounts, you could experience a fair amount of vibration in the gauge mounted directly on the rail. It will also pose a clearance issue with the bonnet. I use an inline mount (Earls, Summit) on the supply line as it exits the tunnel and comes up to the rail. Most of the gauges are fluid damped as well.

-

I use a Facet to fill the swirl pot and a Waldron 392 for high pressure. I route the excess from the fuel regulator to the swirl pot as well with a return from the top of the swirl pot to the fuel tank.

-

The Duratec fuel rail has a return fitting on the end. I capped mine and run it as a “dead head” as you describe with no problem. Find a fuel rail that doesn’t have the pulse dampener. It’s a pain to plug and looks ugly in the finished car. I went the swirl pot route but may modify my tank opening to accept an integral pump in the future. The Duratecs require 42-43 psi at the rail. Either use new injectors or have the old ones cleaned and recalibrated. It really makes a difference.

-

The oily film in the top of my T-9 transmission has bugged me since I built the car. While I recently had the drivetrain out of the car, I decided to fix it once and for all. The car is vented through a small hole in the bump on the top cover. This hole is intentionally placed over the the reinforcing bracket that serves as the fulcrum for the upper selector rod. This is due to the swirl pattern of the lubricant when underway. This location allows the pressure to vent but a bit of oily vapor also escapes over time (probably why they built the cover with a lip all around it). I welded on a steel AN-4 bung after drilling the correct diameter in the top over using the original vent hole as a pilot. I fabricated a 12" ss braided hose using a 90 degree fitting on the transmission end and a straight fitting on the other. This I simply bent 90 degrees and secured with a bracket near the rear of the engine (the minimum bend radius for -4 hose is 2"). I covered the end with an end cap that I had cross-drilled. After a couple of 30 minute runs in 80 degree weather yesterday, no residue was observed. Should I start to see evidence of lube at the vent, I can always extend it to a catch can.

-

The viscous LSD was definitely the culprit. After some networking, I purchased a freshly rebuilt R160 with an AP Suretrac LSD from ZF Design (thezfdesign@gmail.com) outside of Denver, CO. They rebuild Subaru drivetrain components for the offload crown over there. Zach Fothergill was quite knowledgable about the compromises between the various LSDs. He can also provide any of the final drive ratios offered by Subaru. At any rate, while the drivetrain was out of the car, I took the opportunity to replace the front cover of the engine (slight crack) and re-index the cams. Crower originally ground them with 4 degrees of advance for emissions compliance. I added adjustable cam sprockets but the indexing was slightly off as this was originally done with the engine installed in the car (either way, it is definitely a two person project). With the cams now indexed to a zero datum, I should theoretically have a bit more torque. As the car hasn't been dynoed, I really don't know. It does seem very slightly smoother under acceleration. Gratifyingly, no leaks after the first weekend of running after everything was back in the car. Great to be back on the road again!

-

I have some Duratec accessories if you end up needing them. New starter, cam covers, stock cams, ITG air filter for the ITBs... Good luck

-

I started racing at the original PBIR in the mid ‘70s. I went through a a couple of Formula Vees there. It was a very competitive group, producing several National Champions (Don Whitney?, George Fissel). There was a drainage canal at the end of the back straight that sucked in a car or two a season. They ended up requiring a diver to be suited up and ready to goin for every SCCA event. I recall a PCA track day there where Gerry Sutterfield looped his 917K on the back straight! Great times! Glad that the track has been updated.

-

John Esposito at Quantum is the only guy I know. He is a bit hard to get hold of. Try him first thing in the morning East Coast Time. I heard that there may be some in Canada but I don't know anyone specific.

-

For those of us that use a Subaru differential, I finally found a reliable and knowledgeable source in the Denver, ZF Industries (303-548-2624). This started out because I fried a viscous LSD in my R160 diff. Zach is shipping me a freshly rebuilt R160 with a Suretrac LSD. All this considered, $900 off the shelf seemed reasonable. He can also set it up with any of the available R&P options as well.

-

I recently found myself in need of an input shaft bearing for my T9 transmission. The search took about 6 hours over two days. Because of timing, I ended up ordering it from Burton in the UK with express shipping but I did end up finding some in the US. Apparently, an outfit in Oregon, Rapido Group (541-544-3322) seems to have acquired much of the NOS stock of Mercury Mercur parts in the US including many T9 parts. BAT Industries also has some parts but they didn't have the bearing I needed. Pretty brusque on the phone as well. The fellows at Burton were great as usual plus the exchange rate is pretty good right now thanks to Boris. Shipped express on Thursday, I should have it Saturday!

-

My Birkin came with 175/F, 200/R for what it is worth (QA-1 shocks set full soft). From what I have heard, this is a fairly standard starting point. The cars are so light that they don't respond well to much heavier spring rates.

-

Try the factory five forum. There is also a woman who works in the Thousand Oaks DMV office who is purportedly very sharp on the SPCNS process. I heard this through a Cobra kit car forum. There are only a few of us active on the California Caterham Forum. Good luck!