-

Posts

148 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by dallasdude

-

If you want to go with supercharging or turbocharging, Tom (1turbofocus) logged on this board from time to time. I have his email and phone # in case you need it. I think the has more experience with turbo Zetecs than anyone, but I believe the installs were in a Ford Focus. He would know if there is a good supercharging setup but I believe packaging would be a problem in a 7 with a turbo or supercharger. He can also help you with a NA build, with a cylinder head or a complete engine. Quicksilver or Raceline can also help you with a complete engine or performance cylinder head. I believe someone here had Raceline build a complete engine a year or two ago. Seems it was expensive, but I'm sure it was a good product. Burton Power in the UK also sells performance cylinder heads and complete engines, but they are more of a wholesaler without the value add of the other people I mentioned. There is a little bit of power to be gained on the dyno with the stock cams by retarding the intake and exhaust cams, according to Quicksilver if you want to continue tuning what you have. The stock cams and ITB setup is similar to their FF2000 spec engine. Building these engines is not rocket science. The are close relatives to the Mazda engines of that era. In fact Mazda used a Zetec in the early Tributes. The only thing that is a little difficult is the valve adjustment, required when you change cams or do a valve job. Getting the clearances right where you want them requires a selection of cam followers or a little machine work. This is the same as some other solid lifter OHC engines, including the 99 and up 1.8 Miata. I spoke with Tom a week or so ago and he has a Ford Racing cylinder head......brand new. I have one also that I am going to use in my Elan when I get around to it. It is a very nice piece with oversize valves and moderate porting, all already done. It with a set of cams from the UK would certainly pep up and Zetec. Tom's advice would help you come up with a combination that would work well with your bottom end, and he could pre install and clearcence the cams.

-

This doesn't exactly match my experience, but you may be talking about the early (pre 98) Mystique/Contour engine. The 98, 99, 2000 version had mechanical lifers. The adjustment was by a little puck or disc that sat on top of the cam follower. I used that series head at one time, but we used the later cam followers (Focus) which weighed 3 or 4 grams each less, and which didn't use the puck. I believe the head flowed the same. The engine did use an extra idler pulley for the Timing belt which was omitted on the Focus engines. I believe the problem with using Focus cams on the 98,99,2000 engines, is the front exhaust cam journal is much larger because VVT mechanism. It feeds oil pressure to the mechanism that adjusts the cam. Most the cams are coming from UK and EU now, and of course their emission standards are different, so I think they never used VVT on the exhaust (Mistique Contour) or intake (Focus SVT). The home trigger on the back of the intake cam is different also, but with the Pectel ECU, it doesn't matter. There was never much made in the way of performance parts for the early cars here because there was a V6 option for the Mystique/Contour. Your point on keeping cam timing moderate on low compression engines is well taken. I have dealt with 10-1 compression spec engines for years, back to 1.6 Miatas. You want to be sure the cam does't have too much duration, but setting the cam timing on a dyno is very very important. You can get the intake valve closed and start building cylinder pressure. In our case from straight up to the manufactures specs to where we run, about 15HP. If the quench is correct, I believe you can run 10.5 to one on pump gas...maybe even more.

-

Couple more things to add..... If you are gong to add much power you also need bigger (and better) injectors. The ITBs on my Elan are only 18 pounds or which is good for less that 150 HP. Bigger injectors or more fuel pressure is recommended. The ones on my Elan have a terrible spray pattern also. An EV-1 style injector that flows 30 pounds or more is recommended, along with some more pressure. We use the stock SVT injectors at 50 PSI. You can buy them off E-bay, but always have the cleaned and tested if your are buying used. Maybe new for that matter. We also use stock SVT spark plugs, copper core no reason to use anything crazy. They are 2 or 3 bucks apiece from auto-parts stores or Summit. If the engine is going to spend much time above 7000 rpms or so...you need to change the oil pump. It is part of the design, which a lot of the engines of that era use, including 1.6 and 1.8 Miata engines. The oil pump sits around the nose of the crank so the secondary vibrations inherit in a 4 cylinder engine get transferred to the inner workings of the pump, potential causing a catastrophic failure. At one time we used billet gears in the stock pump, but now Boundary makes a complete updated pump for Zetecs (Miata engines too). The alternative is a dry sump, which relocates the pressure and scavenge pumps to an eternal belt driven pump. Duartecs solve this problem with an internal chain driven pump. Massive keeps the Zetec pumps in stock. If you are doing a moderate performance engine, you can use the stock pump, but with the range the ITBs are optimized for, safety requires something else. I can't remember what the stock SVT redline is, but I wouldn't go past that. Which I think is 7200 RPMs. I spoke with Erik at Quicksilver and they are willing to do Zetecs to any spec. For several years, they were out of the billet gears and the Massive pumps weren't being made yet, but now with them readily available, it means they can build a complete high performance engine without having to go to a dry sump. They have a tremendous amount of experience with dry sumps, that's what the FF2000's use and others they build, but of course they add expense and packaging problems with a 7. The also know the Pectel T2 ECU very well, although they have and adapter to go from he T2 harness to the Performance Electronics ECU, as well as base maps. I am doing a conversion for some PE ECUs to Zetecs which replace the full harness and I might be willing to build some extras. The PE ECUs are a good modern update, made in the US (Ohio I think). SCCA uses them in the Sigma engines in the Spec Racer Fords, and that's hundreds of ECUs on small Ford engines right there. I think they are about 1200 bucks without a harness.

-

Burton Power keeps some of the parts. Getting stuff from them in the UK is not a big deal. https://www.burtonpower.com/parts-by-fitment-type/parts-by-axle-all/sierra-axle.html Raceline is a source of parts in the UK also. https://www.raceline.co.uk/products/index.asp?categoryID=6 The units I believe were used in the Mercury Merkur here, but I think not maybe people keep those spares. To some extent, bearings are bearings and seals are seals. You might be be able to match locally. The are several differentt types of LSD units. On clutch type units the pats maybe to come from the LSD manufacturer. I believe the most problematic are the Titans that were sourced with the CF clutches. Scott Young here in Texas has one of mine now rebuilding it. They have done lots of T-9s and variants. Not sure if they have done any Sierra diff's before, but they should be far enough into mine to know if they want to do anymore. https://www.sy-gearboxes.com/

-

Getting back to the orginal question, underpreforming Zetecs....... If you look at it, these engines were rated from the factory at about 130 Hp and 130 foot pounds. In a lot of cases the only modification is to bolt on a set of ITBs. No other mods except ECU. With the stock cams and head flow, they simply don't work at the RPM's the ITB's are designed to work at. It is a function of intake runner length. The stock Ford intake is about 17 inches, much longer the SVT (although it is variable), and way, way longer than the ITB. At low to moderate RPMs, you get a significant ram effect from the long stock runners....with a sizable plenum. If you run simulations on a computer, the stock throttle body is more than big enough. After all is said and done, those sexy ITBs are a setback to the stock power with no other mods. So no wants to go back to the stock intake (although you can make lots of torque) So you want to move the power curve up to where the ITB lack of ram is not a problem. The long runner turns into a liability the other way....past 6500 rpms or so. Even without the variable part, the SVT intake is the best of both with a runner length between the two. Probably the simplest real thing is go get a set of moderate cams a put them in a Focus head. Do a good valve job with Supertech valves, (stock or oversized), and with a thinner head gasket and or a cut to the head increase compression a little. You do want variable cam gears, as we find big gains on the dyno with adjustment of the cams. I would think with this you could pick up maybe 20 hp or so at the rear wheels with this, with some increase in torque. You could dyno tune it with just adjustable gears and gain a little (you are moving the cam lobe centers to raise the optimum RPM range up to closer match your intake). There may be a few HP to be gained there without opening everything up. An increase in compression by cutting the head would help too....increased compression helps everywhere. Low RPMs, high everwhere. To run very high compression on pump gas, the quench has to be optimized but that's another story.

-

I take it this is a Mistique/ Coutour engine with VCT on the exhaust side. This was for emissions only and could only be controlled by the original Ford ECU. Someone probably deleted it when they installed the Pectel. There are three different head configurations, mostly interchangeable. The Mystique/Contour as mentioned with the exhaust cam only variable. The problem is no one makes aftermarket cams for these. You could have some ground, but that's the only choice as far as I know. Getting cam grinders to grind custom cams is a PITA. They are really special people. Really. The 2001-2003 Focus head with no variable cams. Camshafts are harder now to find in the US but Piper in theUK and Cat Cams in Belgium are good choices. Crower and Comp cams in the US had off the shelf grinds but I think they are all about gone. As far as I know, the Focus and Mystique/Contour heads flow the same. Focus SVT head with variable intake cam. No aftermarket cams are available as far as I know, but the stock intake is a monster anyway. Massive has the kit to bypass the variable intake. This head flows a lot, and can be used on other engines, but it has combustion chambers with much smaller volumes, so a big compression jump without the dished SVT pistons. The intake ports sit higher in the head so they don't line up with other intake manifolds. but that doesn't seem to matter.

-

Nothing wrong with Esslinger at all. I think at one time USAC midgets were headed toward Zetecs. Ford actually had Robert Yates build some engines (yes Nascar Robert Yates). My guess is the Midget and sand rail engine business Esslinger does went a different way, so they moved on. If they are willing to do an engine, then I am sure they would do a very good job. We have a pretty good formula for a dependable engine. With the single early Focus throttle body and manifold, about 180 Hp at the rear wheels and 155 foot pounds of torque. (Dynojet). With ITB's a little more Hp and a little less torque. You can add about 15% for at the flywheel in either case. We run race fuel, but with just a little additive for safety that engine can run on pump gas. Getting the proper quench allows for more compression with lower octane. Quicksilver does a lot of our basic machine work, they have done hundred of Zetecs. They got away from doing custom performance Zetec engines, but things have changed a little and their spec FF2000 engine bottom end, makes a very good starting point for most any Zetec performance engine up to maybe 11-1 compression. The availably of the Boundary oil pump now , makes doing a wet sump Zetec hot rod build a lot more practical also. They just did a short block for me that will wind up on one of our race cars or my Elan. I don't want to get into the engine building business, but I am willing to help anyone.

-

It is stepped stud..... two diameters if no one mentioned. We are racing this weekend but I think I have some in my shop. I'll check. Quicksilver probably has a bin of them they removed somewhere. @11Budlite is correct. All others things being equal, my understanding is a Duratec is 35 pounds lighter and makes 35HP more, but Zetecs are pretty tough, and overall cheaper to build. Between the Caterhams and an Elan S2 conversion, I'm pretty well married to them. The SVTs use a different cam follower and they are even harder to find, but most other stuff you can get in the US or UK, but yes it's not as easy. SVT heads flow more for sure. I have a NOS for racing head the Lotus is going to get.

-

The Gates catalogue is a good idea. If you don't find it there, here's the NAPA one. Coolant hoses start on page 181. Sometimes it takes a combo or two hoses or parts thereof with a piece of tubing in the middle. Cut the hoses with snips or better yet a chopsaw..... I also use this catalog for 6 grove belts, they have a huge selection. BTW MoBoost, how's the Emira? Dealers are getting a pretty good selection and I am considering one of the AMG powered ones. Sorry for the hijack...... NAPA an hose corssover.pdf

-

I have a Raceline sump with the cutout for the leftside low strater mount. Its on one of our cars now but the engine will be coming out for a refresh, and we have some other unmodified Raceline sumps. As far as the alignment for the current bellhousing, be sure you install a spacer between the bolts that attach the bellhousing to the sump. If its not there, the bolts will pinch the bellhousing out of alignment, causing a bind between the transmission input shaft and the clutch splines. Don't know that is your problem but something to be careful of. You can shim it with washers, I but make a spacer out of a piece of the blocksaver sheet metal so it matches the top exactly I believe the original bellhousing was made by a Denver company named Quad for Rods. They make a bellhousing for Olds Quad 4 engines to T-9s and some others, including Zetecs. I may be wrong about the origins, but its all I could find. The company is long since gone I believe.

-

I gave my last ones to Quicksilver. T2's is still the spec computer for FF2000 engines. Might want to check with them. We converted everything over to Haltech a long time ago.

-

Good list of suppliers but you could add Esslinger Engineering. They do Pintos mostly for midgets and sand rails, but with their cylinder heads and parts.....the lowly Pinto can make big power. Since its the engine used in Sport 2000s, Quicksilver does rebuilds also.

-

I had a side to side with another car in a race in Atlanta. The Minator on the front didn't break even though it had huge rubber marks all over it, the Panasport racing wheel on the back did. Not very scientific, as they were probably subjected to quite different loads, but I'd lay money on the same thing again. I think the racing only wheels are lighter and a little more fragile and don't have to comply with JWL (or TUV for that matter) standards. Yes, the Racing Only label relieves the manufacturer of some liability, but not having to comply with road standards reduces costs also.

-

The Mystique/Contour Zetecs have a lash cap that fits on a cam follower, much like a Duratec, but I suspect you are talking about a shim on top of the valve stem. You usually use than when you have camshafts that have been ground to a smaller than standard base circle. The little cap makes up the difference. These are fairly standard, (6mm in this case) the last time I got some was from Supertech. Not sure how these could seize, but they can crack.

-

As a point of reference, we weights are with a full cage, a 190 pound driver and and 30 pound of ballas on the passenger side. Wet sump Zetec and a cast case T9.

-

This is correct. Try to get the cross weight close to 50%, but try not to have the LF and RF over 40 pounds difference. On a LH drive Caterham, the left rear is gonna always be heavy, so the RF is gonna be light. Bottom line is, try to get to 50% cross, but compromise before you get the RF too light. Or LF in the UK.

-

General Zetec powered Caterhams/7's discussion

dallasdude replied to Vovchandr's topic in General Tech

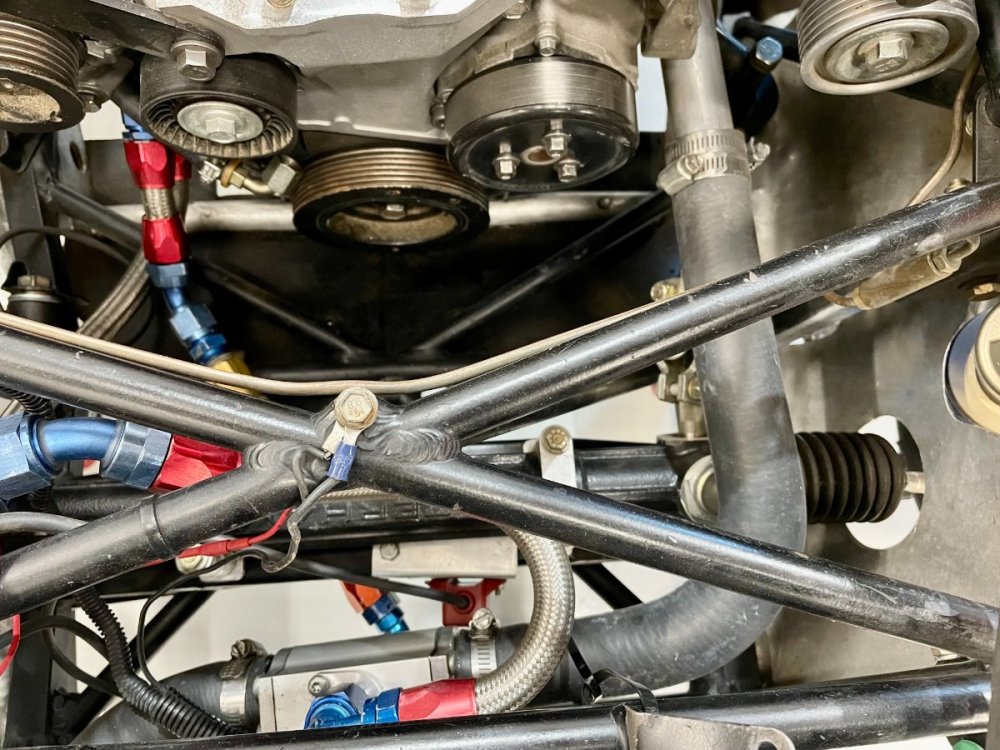

The water pump interference problem is common, made even a little worse if you use bump stop shims under the steering rack. The simpler thing to is cut the nipple back on the stock WP housing. I also normally cut the little nubs off, and use two hose clamps, one outside in the normal clamping place, and one behind the rings to make sure it is retained and doesn't slip off. I also did some right angle housings which is the better solution if you can make it work with the rest of your plumbing. Quicksilver has assembled an engine with one of these pump housings on it. Eric can probably help you. I attached some pictures. We regularly make about 170 hp, 150 foot pounds at the rear wheels on a Dynojet or Mustang dyno With a HP peak 6800. . That is with a stock early Focus intake, stock pistons and rods, 10-1 compression and Comp cams camshafts (pretty mild). There is a lot of attention to detail, valve job, cylinder sealing, windage etc. Qucksilver did a lot of the work. Giving the engine the cam timing it wants is critical.....the difference between straight up at the timing marks and optimized is close to 20 hp. The main reason for not running in the RPM range that ITBs begin to make a difference is not the crankshaft itself but the way the oil pump mounts around the nose. Creates a vibration that cause it to be ineffective or the gears shatter. A dry sump of course solves this. The is an aftermarket wet sump pump that is probably good for 7500. At one time Quicksilver made billet gears for the wet sump pump. The Duratec has a chain drive pump. On thing that has become a problem for building Zetecs is the cam followers are on longer available new. You wind up limited to the thickness followers you have, and to get the right valve clearances you have tip the valves....remove them and take a little off the stem. Labor intensive. -

Source for S3 rear brake caliper kits or replacements?

dallasdude replied to truckin-on's topic in General Sevens Discussion

Moss Motors or Pegasus Racing can fix you up on the front kits. Much easier to deal wit than the rears. There is one trick on the rear calipers.....you have to screw the pistons back in after they adjust out. I use the same tool I use to change out disks on my 5 inch angle grinder. -

Arm restraints are required in SCCA racing (or a window net) but I don't see it in the requirements tor track night. Probably not a bad idea to use them and they are cheap. They do mention some tracks have more stringent requirements however. https://www.tracknightinamerica.com/pages/rules-and-regulations

-

SCCA/Tirerack Tracknight in America series is a completely different thing from SCCA road racing and the General Competition Rules. Tracknight was set up to be very inclusive. I doubt you would find an SCCA chief of Tech there. It has been a very popular program in most parts of the country and is a good value for tack time.

-

Honestly, we never had a problem with bedding. Usually take it easy for a lap or two and then go on. Part of the bedding process is the transfer of pad material to make up an invisible material layer on the disks themselves. You should always replace (they're cheap) the rotors or rough up the surface with sandpaper when changing compounds.... the deposits on the rotors need to match the pads. Otherwise bedding can take much longer.

-

I have used Carbotech pads for years. They normally have no problem supplying the rear (Ford Sierra) or the front Spitfire pads for Caterhams within a few days. The most they might ask for is cores for the rear. For track use, you have 3 reasonable choices, depending on the braking torque. XP 8, 10 and 12. We always used XP10s front and 8's rear. We do use a bias valve on the rear. Recently we changed one car to the Caterham uprated /Jack Webb/Canley front calipers with vented rotors. Huge pads compared to the Spitfire pads. We went to XP8's all around. Certainly easier to warm up on the pace lap. The other car we converted to the Ultralight setup. The pad is a little smaller (I think Elise front) but we went to XP8s on it also and still maintained good balance. This setup is really light, couple pounds less unsprung weight than stock and several pounds less than the uprated setup.

-

Jeff is a great guy and about as straight as they come. One problem an independent machine shop will have with your Zetec is getting the valve lash correct. This is normally done with different thickness cam followers, although the valve stems can be cut. Its pretty tedious to get it just right. I have a pretty good selection of followers. Older engines use shims that sit on top of a follower, but if your engine came that way it was probably converted...the shims add about 3 grams to the weight of the valvetrain. I will be glad to help with followers. I have at least 50 . Otherwise you could do worse than sending the head to Eric at Quicksilver. They can cut all three valve angles at the same time. Anything to do with the dry sump setup they are experts on also. They have built hundreds of these with dry sump for FF2000.

-

Two ways to run a Caterham in SCCA without backdating to 60's specs. As a S3 narrow chassis Zetec with a full width cage. You can build your own approved cage but it must have a full width of the cockpit front and back. A fuel cell is required. Most one the cars with the spec were brought over a part of a spec series here about 20 years ago. You can bring over an Academy car (Sigma engine) from the UK (or replicate it here). The SCCA allows more modifications than the series does there, but someone brought one back after racing it there, put on better tires than allowed in the UK and was competitive. The FIA cage used in the Academy series is approved. The SCCA requires fuel cells in cars where the tank is not protected by the main vehicle structure. Your 310R probably could be modified to this spec and would probably be cheaper over seasons to maintain with a Sigma rather than a Duratec. Both these cars run in E Production. A class with a lot of history, but not one of the classes on the way up as far as participation. A car with a Duratec (MZR) would race against Miatas with the same engine...that would have to weight hundreds of pounds more. I see you are from Georgia. Last year a Caterham set a new record (or close to it) at Road Atlanta. To give you an idea of what Zetec in SCCA trim can do, I think it was about a 1:36. The back straight is a limitation for a Caterham at that track, I could never do over 130. I almost ran a NASA race a couple times but their fuel cell rules are more strict. Their classes were (and I believe still are) based on power to weight based on a required dyno test. There are modifiers that move that up and down, but from what I could see you would be in a group with some very large powerful cars. Difficult to compete with and not as safe.

-

I do have a used radiator set up for Zetec. I'm close to DFW airport.