-

Posts

3,087 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by JohnCh

-

No progress to report thanks to spending most of the day SUV shopping (yawn). When we returned, I took the Elan out for a much needed, head-clearing blat, but came upon this group just as the corners began 1.5 miles from home. They did not want to move and were in no way intimidated by either the sheer size of the Elan or the angry scream of the revving twincam. I was tempted to try the horn, but it's a Lotus and with my luck it would have released all the Lucas smoke contained in the wiring harness. I'm beginning to wonder if I really screwed up in a past life... -John

-

The ARP values above are from their website for these specific bolts (see link below), so I'm not sure they would provide a different answer. My guess is that from an engineering perspective, 95 ft-lb creates sufficient clamping force, but to Croc's point, SBD has a lot of practical experience in this area with high revving, big power Duratecs. Their approach and slightly higher values are probably what they find best in their builds without failures. 251-2802.pdf

-

Car looks great! Good to see Caterham emblazoned the dash with the model name in large letters so the passenger is clear on exactly what just scared the living hell out of them :jester: Looking forward to seeing this beast in the flesh. -John

-

When i upgraded the cams in 2007, I also purchased ARP rod bolts and ARP flywheel bolts for the increased redline. The flywheel bolts were purchased form Cosworth and arrived in their packaging, but the bolt heads are stamped ARP. After removing the engine back in 2007, I discovered ARP flywheel bolts were already in place. These were the bolts Raceline supplied as part the Duratc kit I purchased in 2003/4, but at the time I didn't notice they were ARP. Since there was no point in replacing the bolts at that time just for the sake of replacing them, I left them alone and kept the sealed Cosworth bolts in a box until I needed them. Like now. I'd be surprised if Cosworth, SBD, and ARP each have bespoke versions of those bolts. Having ARP do something different isn't cheap, and that would mean that SBD or Cosworth thought there was something wrong with the original spec. It seems a stretch. I think I'll go with the SBD torque value, but include an initial lower torque third step to more closely align with the Cosworth approach. It's interesting that both Cosworth and SBD specify multi stages, yet SBD's initial stage is higher than Cosworths final stage. I also find it interesting that the procedure with the lowest final torque value uses no thread locker and the one with the highest value uses the strongest. As for the Loctite 242 vs. 243 conundrum, Amazon made that decision. 243 wouldn't arrive until Thursday, but the 242 will arrive tomorrow. I'm tired of waiting... Thanks, John

-

160F seems awfully low. If working correctly, that would keep the temps in the 150s or possibly lower. The 180F (82C) seems like a much better choice. If you are still having issues after that, Anker has good advice. All fans aren't created equal (current draw is a decent proxy for effectiveness) and keeping minimal clearance between fan and rad core (+ shroud) increases efficiency. Are your temp issues just in traffic, or are you also having high temps at speed? If the latter, make sure you have shrouding that ensures the air entering the nosecone is actually funneled through the radiator rather than around it. -John

-

Thanks guys. I'm sure Croc will be along soon to weigh in on my lack of sanity. I decided to install the flywheel after lunch and researched the correct torque and if Loctite is required. I last did this when the engine was built in 2004, so have no recollection of the process. When I had the engine out in 2007 for the first cam upgrade and to install ARP rod bolts, I also bought a set of Cosworth flywheel bolts (stamped ARP but in a nice blister pack that has Cosworth printed all over it) as an additional upgrade. However, when checking the flywheel, I discovered it already had ARP bolts installed. These must have been what Raceline supplied as part of my original engine kit. Consequently I left them in place and stored the new ones away for future use. This is where things get interesting. The CSR build manual includes torque specs and process for their flywheel bolts, which are presumably ARP like what I purchased years before. SBD also sells ARP flywheel bolts and have a download on their site for their installation. Lastly I checked the ARP site and downloaded their instructions for these bolts on a Duratec. None of them align. Cosworth Torque in 3 stages: 37 ft lb, 59 ft lb, then 82 ft lb There is no mention of thread locker SBD Torque in 2 stages: 85 ft lbs., then 105 ft lbs. Use Loctite 243 ARP: Torque to 95 ft lb. Use Loctite 242 So very different final torque values and although Loctite 242 and 243 are both medium strength, the 243 handles slightly higher temps (360F vs. 300F) and has significantly higher breaking torque (230 in. lb. vs. 110 in. lb.) Torqueing in 3 stages makes sense, but at what value do I stop? I'm leaning towards the stronger 243 and torqueing to 100 ft lb, but anyone have an experience or counter advice? Thanks, John

-

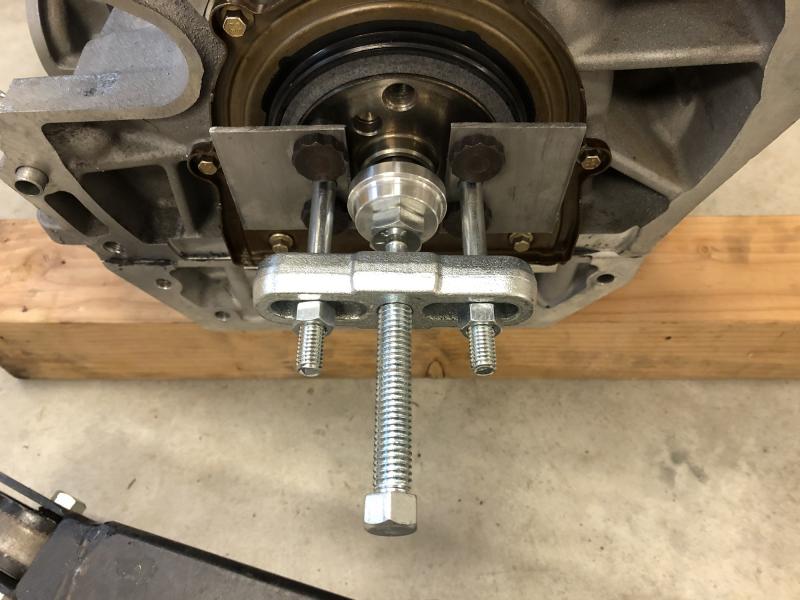

I just read this again before hitting submit and realized it's a lot of long-winded drivel that many of you would prefer to skip. So for those who would rather me just get to the point so you understand the context of the photos and move on, here is the executive summary: This morning I made a tool to install the pilot bearing. Worked great. Took a lot longer than anticipated. The end. And now for the rest of you... Any masochists out there who have actually waded through my website will know that I have a theory called the Rule of Three. No matter how pessimistic I am when estimating how long a job will take, I'm always off by a factor of three. Even knowing that when going into the planning process and multiplying the initial estimate by three to short circuit the process doesn't satiate the gods who control this aspect of my life. It still takes three times longer -- or, in that case, nine times longer than what my original estimate would have been. Consequently I no longer apply that fudge factor to my estimates. Life is too short. Anyway, this morning I had planned a small list of items to complete by ~10:30am: Install the pilot bearing, flywheel, clutch, test fit the engine without the transmission to remind myself where all the wires and fuel hoses need to go and ensure the engine mounts are lined up correctly, and finish installing the AEM WBO2 setup. Easy list, right? Arriving in the garage with a hot cup of coffee, I looked around and realized this place was a nightmare. I needed to clean it up before progressing. Once that was done, and with cup #2 in hand, I began the process of getting the engine off the engine stand to gain access to the back for the pilot bearing installation. More futzing around was done as I looked for the correct bolts to attach the cherry picker to the engine. With that completed and the engine on 4x4s on the floor, the engine holder was removed to expose the back of the block. Looking at the crank and thinking about that little pilot bearing that was finishing up a 24 hour soak in the freezer, I began to have a little trepidation about this step. A little more research was conducted to ensure I knew how deeply to seat the bearing and which end faced the transmission. This brought up lots of mentions of damaged thrust washers from beating the bearing in place. The Cosworth CSR260 engine assembly guide does mention to install it before installing the crank in the block for just this reason. Unfortunately I read that bit after I received the short block back from the machine shop. Given I still don't know if the shop did the assembly correctly, and I could still discover issues once it's back in the car and running, doing something they could then claim was the root cause seemed like a bad idea. I finally came across a guy who used a steering wheel puller to press his bearing into the crank. Hmm. Instead of threading the bolts into the steering wheel, you thread them into the flywheel bolt receivers on the crank. Made sense and I have an old steering wheel puller I could modify. First step was figuring out the size of the new bolts required. Grabbing a flywheel bolt, I had an uh oh moment. They have very fine threads. M12 x 1.0 to be exact, and I needed two bolts at least 60mm long to make this work. Once at the hardware store I confirmed that this is a really oddball bolt size. M12 very fine spec is 1.25 and I needed 1.0. Super fine? Driving home and not wanting to wait a week for McMaster Carr to save the day, I started thinking about other options and decided that there was a way to fabricate a a different attachment method from the leftover 1/8" steel stock I used to make the dial indicator stand, and that would allow me to incorporate the stock flywheel bolts. Out came the hacksaw, calipers, stepped drill bits and drill press. A little while later I had this: The good news is it worked great. The bad news is that I had now nearly doubled the amount of time I had budgeted for the various jobs today, and I had only done one . Oh well, it's still a win. Just a slow one. -John

-

Papak, I jut remembered I posted a photo of the dipstick tube with dipstick sitting out of the bottom here on post #5. It will give you a better idea of the design. -John

-

Thanks, that confirms leaving it alone is the right decision. For the controller's other wires (switched 12v+, ground, sensor signal, sensor signal ground) the Emerald supplied engine loom uses a Superseal connector to make the attachment. Much cleaner and simpler than my old Innovate which had the signal wires directly connected to the ECU plug and the 12v+/- to the chassis loom. The dipstick is the Ford factory blade-style -- same one Raceline supplies (or at least used to supply) with their wet sump. It would work better if the tip was spherical, as this would allow it to more seamlessly make the transition from hose to connector, but I cant' find a good alternative that has a flexible enough tip to also make it around the 45 deg bend of the bottom fitting. Unfortunately the blade tip will hang up when it hits that hose-to-connector transition unless they are in a straight line. Hence the reason for the hose's curved route vs. a straight shot down to the sump. -John

-

My original intent for the oil dipstick's upper mount was to use aluminum sheet and perform a little origami magic to add strength. Unfortunately I didn't have any on hand and was too lazy to make the trek to Home Depot or Lowes, so repurposed an old bracket made years ago from a piece of 1/8" aluminum stock. It's a little dinged up, but after some sanding it's acceptable for a part not easily visible from above. The mount attaches to the engine via one of the thermostat housing bolts. Given that's a low torque fastener, a lock washer was added to (hopefully) counteract any potential loosening stemming from repeated oil level checks. Amazing how much time and effort has been invested to correct an issue resulting from a simple oversight when the engine mounts were fabricated years ago. Fingers crossed this version actually works and is drip free. I finally settled on how to route the wires for the AEM X-series WBO2 sensor. As mentioned previously, they assume it's going into a car significantly larger than a se7en and install a very long wiring harness on the O2 sensor end. I'm reluctant to introduce a failure point by splicing those wires, so have opted to keep them in tact and route them around the front of the engine bay. They can always be shortened later should I determine that's a better approach. -John

-

The article doesn't give any detail on how the 2g was measured. Was it an average around the skid pad, or a mid corner transient on a specific corner on a specific track? Big difference... Remember, a good marketer can tell a lie with the truth. -John

-

I've been having trouble getting in touch with the welder I've previously used, so revisited dipstick placement last night. With a little grinding of material from the alternator mount and re-clocking the fitting at the base of the dipstick where it screws into the sump, I have "just" enough clearance to make this work as-is. With everything torqued, the very top of the fitting and the bottom of the engine mount touch (barely), but there isn't any pressure exerted onto the fitting. I think I'll stick with this for now and see how it works in practice. Next step is to fabricate the mount that holds the top of the dipstick tube in place. I haven't done that kind of work in a while and am looking forward to it. If it turns out ok, I'll post a photo. If not, I'll simply mention it in passing The gasket for the oil filter adapter arrived yesterday, so that's now fitted, and the O-rings for the DTHTBs also arrived and will be test fit tonight. -John

-

I love touring in the Westfield and have done well over 10k miles that way. I'm definitely up for adding to the total. As for parts potentially missing...that never happens. Never! :jester: -John

-

I avoid driving my Westfield in the rain (not fun for me), but even in the winter, it's rare that the car doesn't make it out at least a few times per month. Overcast and cold isn't a problem. Are they doing the engine and transmission installation before shipping it out, or is some assembly required? Thanks, John

-

Fantastic car! Great to see another se7en in the area. That makes 3 Caterhams + me within about 15 mile radius of Bruce's shop. We'll need to do some drives before the summer is out. -John

-

Here are some photos of the engine mount and the area I'm thinking of cutting away (noted by the black sharpie), then having a local fabricator patch up with steel stock of the same thickness. Any feedback on this approach? It seems to me that the strength wouldn't be unduly compromised, but that area is on the bottom, and my structural expertise is limited to what I've seen on Motor Trend TV. Is there any risk that the heat from the process could slightly warp the mount? Again, it doesn't seem to me like it would based on size and location, but anything that leads to misalignment with existing mounting points would be bad. Thanks, John

-

Peter just answered my email. The O-ring size is 47.6mm x 2.4mm. Assuming the first number is ID vs. OD, the O-rings you posted above will fit. Ordering them now. Edited: when placing the order, I noticed they have a metric section. Turns out they have the exact size Peter specified, so went with those in a couple of different compounds. Thanks, John

-

We don't have any rules about not making offers in a sales thread, but it might be best to do that via PM. Otherwise these threads might turn into auctions, and although that could prove entertaining, the business part of my brain might be compelled to propose to Mazda we start taking a cut of the sales ala Bring a Trailer A little more seriously, rule #5 does state "5- For sale section - Let's keep each post about the specific item for sale. If you don't like the price being asked, or see something wrong with the listing, take it to PM." I think publicly offering $9k below the asking price falls into that territory. Now back to the sales thread. -John

-

Thanks Andy, that helps. I tried Jenvey this morning but after some hemming and hawing was told I need to go to Raceline for that information. It almost sounded as if they weren't certain they didn't do something specific for Raceline's version back then. Next I tried Peter at Raceline but kept getting voicemail so sent an email. I'll check out that part number, take some measurements from my current ones and go from there. -John

-

Henry, it's frustrating, but it should be an easy bolt to source at the local hardware store. Thanks Greg, but I'm hoping it's the full throttle experience that will be the conversation piece The gasket for the oil filter adapter is handled. It's a standard Ford part and should arrive in a few days. Of course, that is offset by the realization that I never obtained the O-ring size for the Jenveys (they seal the DTHTBs to the head). Although the current ones appear fine, they are older and could be on the way out. It seems prudent to pop in new ones, which is easier to do now then after the engine is installed. I'll call Jenvey in the morning to see if they'll provide me with the size, then I'll source them here. I spent more time looking at the dipstick this afternoon. I'm beginning to think it might be worthwhile to have that engine mount modified to provide more room for the fitting and avoid headaches down the road. On the surface it seems as simple as cutting out a small section that's interfering and having some material welded back in to seal it off, but I want to ensure that I'm not compromising strength. I'll take some pictures later and ask for feedback. -John

-

panamerico, I am happy about that and am saving my worrying for something that needs it. I'm sure that something will be along soon Today I installed the front cover, crank sensor (the alignment tool is still in place in the photo below), water pump pulley, idler pulley, valve cover, torqued the crank pulley bolt, and temporarily installed the alternator, driver's side engine mount, DTHTBs, dipstick, and still-to-be-gapped sparkplugs. With tape on the injector & exhaust ports, and the oil filter take off, the engine is sealed from debris, and no longer requires a cover. And most importantly, it looks like an engine again! One reason for temporarily installing the above parts was to figure out which items I forgot to order and what fixes I missed. First, I can't find the gasket for the Raceline oil filter adapter. I saw a note to ask Peter about it before placing my original order, but didn't write down his response. It's not on the manifest from them, and oddly I can't find the old one (I intentionally didn't throw things away). Hopefully it's a Ford gasket, or I can find the old one. I have a feeling he may have said to reuse it or use sealant which is why it wasn't ordered. I am also missing one of the bolts for an engine mount. Not a big deal, but kind of strange -- it's not in the bag marked "engine mount bolts" or on the tray with the mounts themselves. When previously test fitting the custom dipstick, clearance to the engine mount was feeler gauge tight. What I didn't realize until the alternator mount was in place today is that it is also slightly touching that part. Again, not a big deal and something a die grinder will correct. I also need to fabricate the upper mount for the dipstick now that the DTHTBs are in place. At this point I'm planning a staycation the week prior to the 4th of July, and targeting that week for the first drive. Fingers, and other body parts, crossed. -John

-

After posting the above, I contacted Amazon, explained the switch was stuck and would not turn with hand pressure and asked for my options given my desire to have a replacement quickly. I had suggested cross shipping and offered to pay for the new one now and they could wait to credit my account until they received the return, but was told it wasn't an option because the item was unreturnable. However, I then learned that Amazon's definition of unreturnable in this situation is different than mine. They mean they will send me a refund via gift of Visa card, but they don't want the item back. This seemed a little too good to be true, and somewhat illogical for an $80 part that was likely repairable. But no, the agent was very clear and even sent an email stating the item was mine to do with as I pleased. Apparently the cost to ship, receive, and deal with any kind of warranty or restocking kills the margins more than simply giving it to me gratis and taking the write-off. The replacement was immediately ordered and the gift card arrived about an hour later. Given I now own the Noga, I decided to force the issue with a set of large Channel Locks and a sacrificial bit of rubber to protect the switch from cosmetic damage. If it broke, it broke. Cranking really hard, and just reaching the stage where I was thinking of giving up, there was a loud "crack!" and the switch broke free. It now rotates as expected, but is occasionally sticky at the end of its travel, so not perfect. But certainly good enough. Setting the timing still took a while, but the process was significantly easier with the new equipment and very repeatable. If anyone goes through this process, I can recommend this set up: Mitutoyo"2416S" Dial Indicator Noga DG61003 Regular Duty Dial Gage Holder Anytime Tools Dial Indicator Extension Stem Rod Set Once TDC and cam timing were confirmed, reconfirmed, and reconfirmed again, cam bolts were torqued, which was followed by a final round of confirmation just to be safe. Next, the front main seal was replaced, and final prep and test fit was completed for the front cover. Only potential snag is that the top of the front cover is no longer flush with the top of the head due to the clean up of the head and block. It's only a 10/1000" difference which I'm hoping the valve cover seal can accommodate. If not, I'll probably just need to apply a little sealant at the step between the two surfaces. -John

-

The Noga articulated holder for the dial indicator arrived today It's beautifully made and incredibly easy to adjust: turn one knob and all the joints loosen allowing for very easy setup. Just one problem: the magnetic base is broken. The knob won't turn. I've verified there are no special tricks like pushing in or pulling out the switch and even found an online video review that showed the switch flips very easily, but I can't get it to budge by hand. Using a wrench for leverage might be enough to break it free...or just break it. Looks like this is going back for replacement -John

-

As usual, Croc is correct. Apparently 3 were made. The Ghia emblem on this car doesn't have the script underneath it like the car in the original photo. Looks like wheels are also different. Very cool. -John