-

Posts

2,303 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by MV8

-

Crossflow Cooling System -Overflow Tank or Expansion Tank

MV8 replied to KS7's topic in General Tech

The '88 S3 you bought has a closed cooling system already (swap filler caps if it does not have the sealing ring in the cap). It is hidden inside the nose. The existing upper hose neck has an integral filler that the new one you ordered does not have. If you want easier access by adding an expansion tank tee'd into the heater circuit, then you can swap out the necks but there is no need. What you need is access to the expansion tank for keeping halfway full. That can be moved out of the nose with a longer hose. https://bringatrailer.com/listing/caterham-seven-2/ -

What makes you think it has a VIN? The plaque is just a convenient, accessible location to show a chassis number. If it were assigned a VIN for public road use, it would not be on the plaque. What is the history of this car?

-

I cannot. Those are links to pics on the web. My dog does not bite, but it is not my dog.

-

Maybe admin can slide the post over from here?:

-

I expect the rpm would drop about 300 or you'll be going 6 mph faster at 4100.

-

As for a 190mm / 7.5" x 23T x 1" clutch, I'd change flywheels or redrill the old one to accept a thin, 8.5" diaphragm pressure plate (for bell inside clearance if needed) and common replacement clutch discs.

-

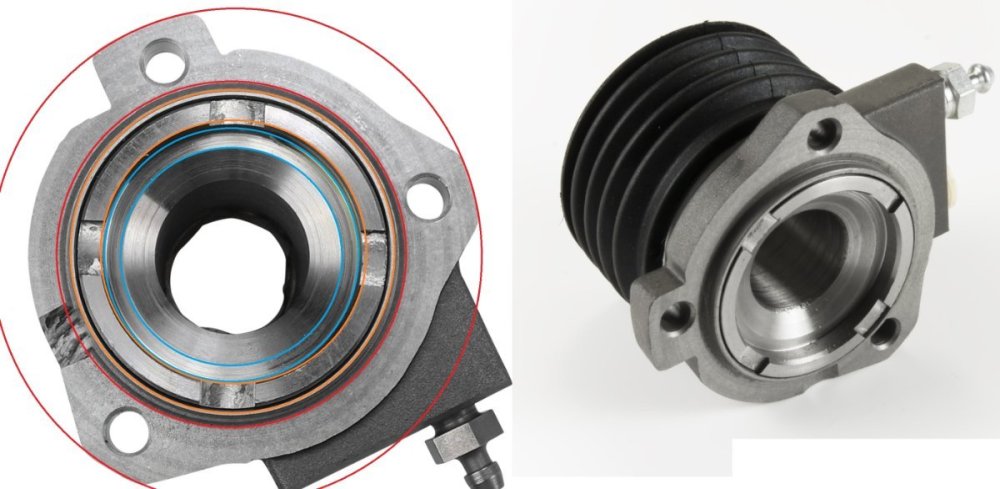

It sounds like the slave is being slightly over extended. Looking back at your clutch mystery topic, I see you are missing the rubber dust boot that keeps the area of the slave clean where the release bearing boss slides back and forth on the slave main body that bolts to the transmission and the release bearing. Not critical but worth having and typically included in a replacement slave. Maybe it could not be used due to this being an adaptation? Also, the slave has limited travel so where it starts from matters. If the slave is shimmed away from the trans, the release bearing will not be as extended on the slave with the pedal to the floor. The slave should not be shimmed tight to the clutch to where the release bearing cannot be pulled away from the clutch at all. This gap is what allows the slave to self adjust to clutch wear. Compare your old/spare slaves off the car (pushing and pulling to find range of travel fully extended to fully compressed. Try to see how that compares to peering through the bell. If it is a half inch or more from fully compressed when the release bearing is touching the clutch, I would definitely shim the slave away from the trans by an 1/8 to a 1/4 inch or so with either washers or fabbed shims. Looking at a Saab 900 slave, I see it is not flat. The contact point between the slave and trans is what needs to be shimmed. That could be any of these colored shims. It could be you've eliminated lost motion that was present in the system before you first took the car apart, combined with it being a new clutch system that slightly changed the location of the pressure plate levers relative to the slave.

-

The voltage applied to the gauge is part of what determines the indication. I would not be concerned about the non-running indication. A traditional temp gauge is normally independent of cooling fan control. A gauge uses a variable resistance where a fan or fan relay uses a thermo-switch that is open or closed. There are computer controlled systems that use one variable resistance temp sensor to control the gauge and the cooling fan among other things.

-

I think it will be ok. Looks like a normal rotation alt fan to me. A ccw fan for a pre-90s application is very rare.

-

The engine must come out. The trans comes with it. If it were an S4, there would be enough room to separate the two in the car, leaving the trans in-place. Many steps to doing this well. I suggest an adjustable balance lift attachment for the steep angle and possible axial rotation needed. Completely drain fluids. Tunnel cover and shifter out, protect front upper chassis cross member from engine contact/scratching.

-

SPCNS (Caterham) registration in the SF Bay Area

MV8 replied to Maggie S.'s topic in General Sevens Discussion

I'm not sure that it will matter much either way to the tax man with an SB100 process, but "Turnkey minus" is a kit manufactured by Lister. https://www.lbspecialistcars.com/faq/ -

SPCNS (Caterham) registration in the SF Bay Area

MV8 replied to Maggie S.'s topic in General Sevens Discussion

The kit is "turn key-minus". You'd be the primary assembler of the kit unless you had someone else do it. A kit must become a kit before it can be assembled primarily by anyone. Lister is not primarily assembling kits; they are using a basic kit to manufacture the "turn-key minus" kit. if you were to buy the basic kit, then have some one build that up to a point where you installed the drive train, it would still be splitting hairs as to who is the primary. I suggest a locally sourced drivetrain from an auctioned Alfa. I think I'd like the conservative STR; no wings, spoilers, and same size wheels all around. -

The motorola ID is just the regulator; not the alternator assembly. Typically a foil label on the external regulator that shows the settings. Domestic applications include the late 70s Mercury Capri (prior to 1979 when the capri and mustang started sharing the same platform/chassis) and 78-80 Ford Fiesta. Look for the three spade terminals in a row plus the battery stud. Replacements have subtle differences in case shape and connection placement. Potting compound tends to leak and run with age and heat. An excellent price no-tariff replacement: https://www.ebay.com/itm/375528898791?_skw=alternator+13107&itmmeta=01KB532ARSSEMPNYEAWNFDD0TE&hash=item576f4440e7:g:pn0AAOSwi2tmjYKA&itmprp=enc%3AAQAKAAAA8FkggFvd1GGDu0w3yXCmi1d2y9hu20McFWhwFk5DzPxfMn38dIcOheMzMjzvzqvsVmWolrHV52jv%2B1sqJH5Z9MKDhxB5FmJGfBf18MyAd9CfRz08Uy%2B9sdG1J7ME7OjLOjQ%2FGuq%2BwOxY2%2BhjyHHKBek%2FOIz7%2FqFDbsATtPVc9VCydxjNz70WCA708X8u%2BkbxTKhDfCXKSU%2FhCfEs6klY8ntlBhRCwMpAB%2FXhLER8IDn2fX4CB8lz5RMGAUZssuGFXQKZTT3HhkTNOoWms0TkZ5bD6TwrW5UzUhWv51nNutoYi1fevsZeeNeE5xHE7G%2FMtA%3D%3D|tkp%3ABk9SR8qsiaPZZg

-

I don't think so. Two times the tensile area, which is the circular area calculated from the thread root diameter. My point of providing the link was that a "rule of thumb" cannot determine a minimum or maximum. Actual Triumph studs are roughly 9.5mm. Also consider changes to offsets and weight if making these greater. The original wheels for this are already much greater than they would be on a triumph. The already narrowed safety margins are what make these cars so much fun imho. What you do is up to you as it should be. I'm just typing with zero skin in this game.....

-

https://www.engineersedge.com/thread_strength/thread_minimum_length_engagement.htm

-

I don't think they make a wink style narrower than 2-1/4 or a 3-1/2 panel. You might consider "Blind Spot" mirrors. They are under 2 inches wide and come in 3-4 inch lengths, swivel, and attach with double-sided tape to glass. Unlike winks, they are individually adjustable and require no attachment mods to the seven windscreen frame. They are easily removable with a razor blade. Maybe 2-3 inch round ones in the corners and couple 1x4s to the passenger side.

-

The spindles are a Triumph design that has vented rotors added and the clearance shown is reduced from a solid rotor spitfire application. I don't know what topic/post/forum you are referring to as far as a washer somewhere. There are a number of ways to provide more clearance. Washers in general don't make it unsafe but details are important. It would take specially made washers to move the arm away from the rotor and may require a longer bolt as well and it won't be going far. 0.100-0.125" would be reasonable and nothing would be modified, but you should discuss with CAT before getting creative. There are tolerances with any part.

-

Fuel gauge: check GRN/BLK continuity to ground at the gauge or the terminal on the tank with a DVM. What is the value in ohms? Check for voltage (can use a test light clipped to ground) at the gauge connector with the key on or skip if there is a face indication that power is reaching the gauge. The last check would be to pull the tank pump assy to ensure the float is attached and the arm swings freely. Throttle Volt spike: Good to see you have baro and may have MAP which would make this speed density instead of AlphaN (a good thing). The TPS should not spike as it is slowly rotated by hand. I suggest requesting a replacement TPS and treating it like fine china. Basic Setup/Tuneup Specs: Ask what the TPS and RPM should be at idle as this is the setting. I would expect (a GUESStimate) to see the TPS rotated to show around 0.32-0.35v when the idle speed screw has been adjusted to the specified idle rpm. If Cat support can't tell you these basic set up specs to check then you may need to go to SBD's MBE Tech Support. Brake Bleeding: There are topics here about brake bleeding issues. Throttle response: No kit to reduce off-idle response. The TB quadrant could be machined for a ramp groove transition instead of a steady ratio cable groove. There are ratio adapters for motorbike engines in car conversions but they just reduce the ratio.

-

"Cold weather" gear in South FL? Socks? I'd take a screw driver to try to clean the rust scale/deposits while they are out and flush with a water hose and the lower hose off. They tend to collect in the corners furthest from the water pump and can break free to clog radiator tubes.

-

I've had to replace several decades old steel plugs that had eventually failed/leaked due to corrosion from rust through (not the edge). I use a finger wipe of rtv on the edge before installation. The plug metal is very thin sheet metal and the first thing to go from rust. If you don't have good access with a hammer, pick up a 1-1/2 rubber plug at your local store. Here is a link to 1-5/8 but it may need to be slightly smaller to clear the recessed lip. https://shop.advanceautoparts.com/p/dorman-help-rubber-expansion-plug-1-5-8-in.-size-range-1-5-8-in.-1-3-4-in.-10232/22140133-p?product_channel=local&store=3841&adtype=pla&product_channel=Local&store_code=3841&&&&&msclkid=cfb785ea93e114756d3ceccab7900024&utm_source=bing&utm_medium=cpc&utm_campaign=b_shopping_all_dorman_gen_gen_gen_evergreen_eng_aap_us_all&utm_term=4580221855580131&utm_content=Bing_All_Dorman - Innovation_Body&gclid=cfb785ea93e114756d3ceccab7900024&gclsrc=3p.ds

-

Many names for them (freeze, expansion, or core). Here is how to install them properly: https://www.mgaguru.com/mgtech/cooling/cool_105.htm The second engine appears to have rubber "expansion" plugs that serve the same purpose and don't use any sealer.

-

M10-1.25, Emgo part number 20-46210 https://www.ebay.com/itm/205715575233

-

Croc, are you referring to the dedion standard radius arm versus the dedion watts radius arms? Check the adapter lug thread if you plan to use different lug nuts. I've had adapters that look like that and claimed to be a specific stud thread size but were not. They only accepted the included plain nuts. The studs were not to a standard either.

-

The slave mounting support should be attached to the engine (versus the chassis) so it can move with the bell housing as the engine rocks under load. The rocking movement is much greater when driving than what can be seen blipping the throttle out of gear. The purpose of the support plate is to keep the slave body from moving away from the bell when the pedal is not being applied. For someone adapting this without replacing an existing pull slave, the slave body could be mounted a 1/2 inch further forward to get it off the bell opening (rod would just pass through so no need for a flange bushing in the bell) and a stiff support bracket made using the full length stud provided but removed for this installation/repair.