-

Posts

2,297 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by MV8

-

John's verbal judo is strong. He had me at "updraft". Actually I do have an updraft on my antique iron tiller. Works great, but this is not a race. Carbs are great, but not for everybody most people.

-

Rope is another option. I'd rather not hang anything off a rare, aluminum head. I like hanging from above the bell so the cg is below the attachment and bolted-on tabs can't slip out of place during the process. The chain should only touch the tabs and the sling beam.

-

Which loctite retaining compound did they recommend?

-

I expect the WOT pedal stop, once adjusted, can be trimmed to protrude from the nut to no more than a half inch. When trimming, mark threads with a permanent marker, remove from the car, reinstall the nut all the way down, clamp the end to be cut off in a bench vice, then use a hacksaw to make the cut. Dress the cut end at a 45 deg angle to a bench grinder or flat file, then remove the nut which acts as a die to chase the threads. Run the nut back and forth, off and on by hand until it is easy to turn and then paint the cut end. Don't cross thread. There should be a little slack adjusted with the cable end with the pedal against the UP stop; more if you want to set the height lower to match the other pedals with the ball of your foot. Too tight and it won't return to idle well. The WOT stop saves the cable from breaking after so many cycles. At pedal WOT, there should be minimal tension against the engine WOT throttle stop. As the cable wears in the sheath and stretches, the stop would be adjusted to protrude further from the firewall and/or the cable adjusted at the threaded ferrule on the engine. For adjusting the WOT rod, I suggest holding the engine throttle fully open with a helper, then lightly taking up pedal slack and adjusting the rod to touch, then jamb.

-

Three 1/8x2x4 strips with one end drilled to 3/8, some chain big enough for a 3/8 bolt to fit through at the end link, an adjustable balance point beam the length of the head. Two for the upper bellhousing bolts and one for the crank bolt, bent 45-90 degrees in a vice with a hammer (must be far enough away from the crank bolt washer for the bend to start). Most of the weight would be on the bell bolts which would be fine if the bolts are normal tight. The front would just be for balance and everything should be easy to remove after it's back in. Can use rags or bits of plywood to prevent potential gouges/scratches. Possible to do without the strips and use the pump flange but why risk it?

-

Paul Brodie, craftsman and brazing guru. Two good videos to watch (includes gas fluxer design and use). https://www.youtube.com/watch?v=OjRMbBl_Tbs https://www.youtube.com/watch?v=Y2CnJ9lmlQo&t=135s

-

For steel on steel with some lap, any bronze should be fine bare (heated a little and dipped in powdered brazing (not soldering) flux) or flux coated. You can find some at the hardware and home improvement stores but I prefer to go to a welding supply store. There are a number of specialty rods that are very expensive, but you essentially have to call them to get a recommendation. You can read the MSDS to get an idea on the make up for comparison. Avoid cadmium and low fume zinc is preferred; both for health reasons. Working temp around 1500f. Another consideration is that some alloys become very watery at the melting point which is good for wicking into pipes but bad for filling a lap that isn't very close fitting. I think the ones used for "braze welding" are less fluid. You can weld around brazing if not using a torch that dumps a lot of heat into the area compared to mig. The higher than brazing temp heat from welding is what ruins an existing braze. You can also use wet rags or heat sink putty around the brazed areas to keep them cooler and weld an inch, let it cool, weld an inch, etc like when welding sheet metal.

-

I would try loosening the two bolts in the right side of the tail housing so the plate is free to move around, work the shifter back forth to try to find some shifting improvement, then retighten. See video around 49 min.

-

That's easy. Take a Navy day, add some PT, then take away a few privileges.

-

What a guy! You'd do that for me? I'm speechless. I was thinking of a trade. How do you feel about Bud Light? Only joking!

-

Well...you seem really confident. Let me know when you are ready for me to come drag it away and end your suffering. No charge!

-

How about a link to the video?

-

If it happens to be brazed, a fluxer can is not required but they are available. It goes between the acetylene tank and the torch, picking up liquid flux on the way.

-

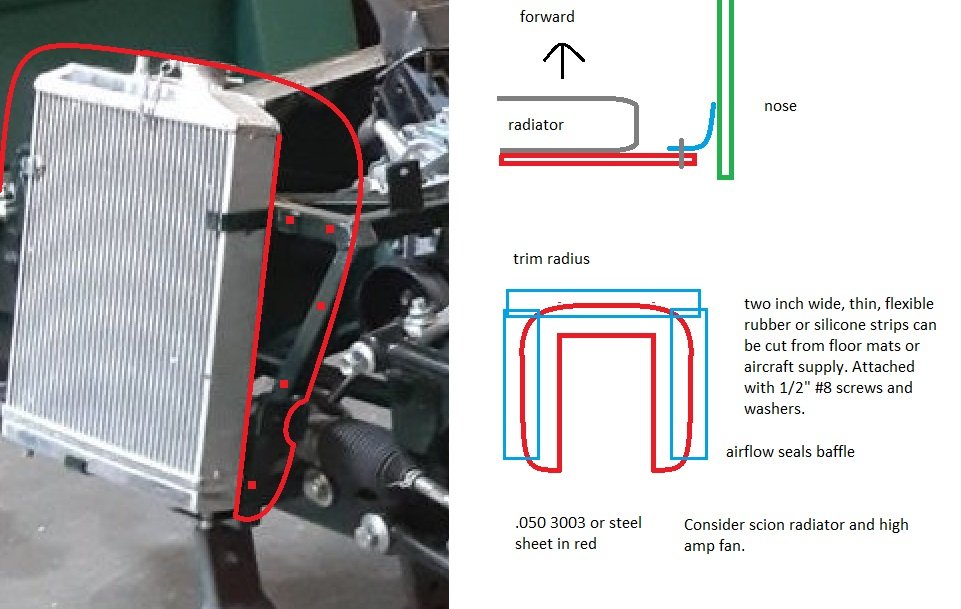

The 00-06 scion racing rads are no longer available. The traditional/book sized seven nose is just a little too small in width for most radiators. Forklift radiators almost fit. How thick is the core on your radiator? Should be a full two inches if it is the best honda radiator. What is the model number on the 12 inch fan? If you want to test before committing, put cardboard around the radiator in the nose. I wonder if your grill insert is restricting as well. I assume the heater fittings are capped so no coolant is bypassing the radiator. Does it run cooler with the hood/bonnet off?

-

Cork gasket? Do you have an inch-pound torque wrench? Most people do not and a foot-pound wrench that clicks or deflecting beam is not very accurate at 5-6 ft/lbs or 60-72 in/lbs. Use a screw driver with a 1/4 drive end and a socket. Better too loose and leaks than too tight and cracks the aluminum cover, leaks, and splits the gasket. "snug and even" is the goal. Some newer rubber gaskets have a positive stop for a set preload but you are just trying to squeeze the gasket a little, evenly, all the way around.

-

Minimal, even torque you can apply with a screw driver. Use rtv on the head side or the valve cover side but not both. If the gasket is extruding, it is too tight. All fasteners are brought up to torque evenly by going back a forth like when replacing a head gasket.

-

No oil, just a good synthetic wheel bearing grease. The boots are for keeping dirt out of the rack.

-

Looks like you have the honda two row which should be adequate if optimized. Baffles will help it cool at all speeds. The flexible blue strip baffles (can be made from a cheap floor mat) help but are not necessary if the red baffle is close to touching the inside of the nose. Make a card board pattern. The red baffle can be made from three strips 3-4 inches wide and screwed/rivetted together with a little overlap. A high amp fan (that will fit over the honda core) will help below 45 mph. Good universal fans are not cheap but you could run two cheap fans with one in front and back. Not best practice though but whatever works. If you want a better radiator, consider the scion racing radiator with no filler and a much larger surface area or a three or four row honda type. The honda upper tank and filler wastes space that could be filled with more core.

-

The one I'd most like to drive is the stock or stage one for most area under the curve with no spikes or holes. I spent some time as a motorcycle mech and had to drive everything I worked on. I much preferred the standard class bikes to the racers. They tend to surge with light to medium throttle and were more difficult to drive normally.

-

I put one about that size on a miata I turbocharged (no water jacket) to help extend the oil life to normal change intervals. I don't see the need for a cooler on an NA application. There is also the extra plumbing taking up space, oil pressure drop through the cooler and lines, plus oil drain and fill complications. If you need extra cooling, consider an aluminum radiator. More efficient than the cooper/brass.

-

It should be free to rotate the shaft in the gate. If it is stuck like you say, then it should be pulled. It may or may not be doing damage each time you drive it.

-

A few examples in there of the danger of running open wheel to open wheel/no bumpers. A little fiberglass over a rear wheel doesn't seem to do much to prevent launching the over-taker, tire to tire.

-

I'd pull the shifter and inspect the pocket. The saddle bushings don't last and are cheap to replace. Should help align your shifter and bring some precision back. I'd be surprised if Burton Power did not offer these. Ford D9BZ7K453B These fit many ford transmissions https://www.ebay.com/itm/Shifter-saddle-seat-bushing-damper-1-5-for-Ford-SROD-Mustang-F100-F150-T170-RUG-/361424507749?_trksid=p2349526.m4383.l4275.c1#viTabs_0 Some excellent info on these bushings with more sources, designs, and materials: https://vb.foureyedpride.com/showthread.php?170953-Shifter-bushing

-

I assume you have a steering wheel that comes off with three screws under the center cap, leaving a hub with three threaded holes and a big nut in the center. Harmonic balancer pullers also double as steering wheel pullers. https://www.amazon.com/ATP-Harmonic-Balancer-Steering-Puller/dp/B0721H8S84/ref=asc_df_B0721H8S84?tag=bngsmtphsnus-20&linkCode=df0&hvadid=80882941400106&hvnetw=s&hvqmt=e&hvbmt=be&hvdev=c&hvlocint=&hvlocphy=&hvtargid=pla-4584482468443972&psc=1

-

I don't see a fuel issue. I don't have experience with every injector out there but generally, injectors are powered open, not closed. Never short an injector across a car battery for more than a split second if it is high resistance/impedance; not at all if testing a high performance, low resistance/impedance injector. Use a 9 volt to pulse injectors open for testing or cleaning to limit current. A typical wiring arrangement is full battery voltage to one injector terminal with grounding controlled by transistors in the computer. High and low impedance injectors are not interchangeable on the same computer due to the low impedance injector acting as a short through the computer transistors. It is true that a test light can be used on the injector connector to see if the computer is pulse grounding, but the tester needs to be an led type, not an incandescent bulb to prevent damaging the computer from too much current.