-

Posts

2,297 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by MV8

-

computer for 2002 thru 2004 Ford 4cy fuel injected SVT

MV8 replied to HUTCH's topic in General Sevens Discussion

Consulting only gets you part way. How did you determine that the ecu does not have pats? -

computer for 2002 thru 2004 Ford 4cy fuel injected SVT

MV8 replied to HUTCH's topic in General Sevens Discussion

Hutch, I am a Master ASE and your responses don't make sense. More ideas are not the answer. I'm sure you are very good at whatever you do or did when working. There is no shame in not understanding newer drive trains designed to make you dependent on the industry. Please take it to a professional, pay the price, and be back on the road. The longer it sits and the more you tinker with it, the more it will cost to repair. -

I see no flaws in that. I'd probably use a main relay to feed pin 30 and let the headlight switch toggle 87/a between DRL and low beam, using a separate relay for high beam.

-

What do you want to know? If you have the full harness, it should be straight forward. The DRL controls the high beam bypassing the headlight relay (red/wht).

-

The can location can be high or low if it won't be configured to auto drain back to the engine. The can should have a clear path to drain with a pan close to the port or hose so as not to make a splash, spraying oil drops everywhere. There should be a block vent on the exhaust side as well as the valve cover vent. Hoses should be compatible with hot oil, like automatic transmission hose. They will still have a shorter life than typical hoses and will need replacement when they get stiff/hard. A leak under the nose sounds like something else. A cleaning followed by a shorter drive should help locate the source of the leak. I'd probably fit a basic, quart can with a small filter on top, quick release drain valve just above the bottom chassis rail in the corner opposite the exhaust (curb side) and connected to the valve cover with metal line down the block or firewall and compatible rubber hose as needed. I'd drain it when checking the oil. If there is seepage around the filter on top (maybe from cornering splash and too full), it needs draining.

-

If you want to keep worm drive clamps, they are available fully banded so as not to damage soft silicone hose. If a hose clamp is too big/too long a tail when tight, the excess can be trimmed. I use spring T-bolts for boosted applications so the clamps don't loosen from the heat and pipe expansion cycling. Be sure to order the max size based on the loose hose od versus the pipe od.

-

The VDO "Classic" temp gauge is very close to the AC unit in every way. Just needs a custom face marked 40-110 instead of 40-120c.

-

computer for 2002 thru 2004 Ford 4cy fuel injected SVT

MV8 replied to HUTCH's topic in General Sevens Discussion

A repair shop may be a better choice. I thought it was at the upstate Ny Cat dealer? Is the fuel pump running? Crank sensor pulsing? Temp sensor in tolerance? "Yuns waaan I should top up the humanera halogen fluid?" -

computer for 2002 thru 2004 Ford 4cy fuel injected SVT

MV8 replied to HUTCH's topic in General Sevens Discussion

Depends on many things. I'd be surprised if they could not but these are over 20 years old now. Dealers often are not willing to work on old cars. -

computer for 2002 thru 2004 Ford 4cy fuel injected SVT

MV8 replied to HUTCH's topic in General Sevens Discussion

Again, I suggest you take it to someone qualified like any other profession (i.e. doctors, lawyers, pilots, etc). -

I don't know how much electrical work you want to do. I see the fitment issues as a result of the fuse/relay block length. However, those are four, separate fuse blocks that slide together to form a single. You could slide them apart for two, shorter blocks. They also don't need to be rigidly mounted. I'd avoid a hinged/swinging block assy as the wiring needs to lay a certain way to prevent damage from repeated swinging (bundled together to run the length of the hinge with rub protection and secured at the ends so the twist is spread over as much length of wire as practical). For the panel to face the seat by rotating the mounting face 90 deg, a strip of .050" or thicker 3003 half-hard could be formed into an L shape over two 2x4s C-clamped together and "slapped" (across the grain) with a third 2x4 about a foot long or you could use a 2x2x1/8 aluminum extrusion (home depot) across the footwell and bolted to the firewall. A window in the firewall (drilled corners, offset tin snips, and flat file/debur tool) would work well with a strip of angle to rotate the block, riv nuts, and an cover overlapping about 3/4 inch on each side but I don't think you will be able to get to it once everything else is added under the bonnet.

-

If you can't buy, I'd expect 1x0.250 steel strip frames based on what I can see. With Senc's dims and a good upholsterer you should be golden.

-

computer for 2002 thru 2004 Ford 4cy fuel injected SVT

MV8 replied to HUTCH's topic in General Sevens Discussion

Sure it does. Also, PATs involves more than key recognition but I understand if you want to go with what sounds likely based on your experience. -

computer for 2002 thru 2004 Ford 4cy fuel injected SVT

MV8 replied to HUTCH's topic in General Sevens Discussion

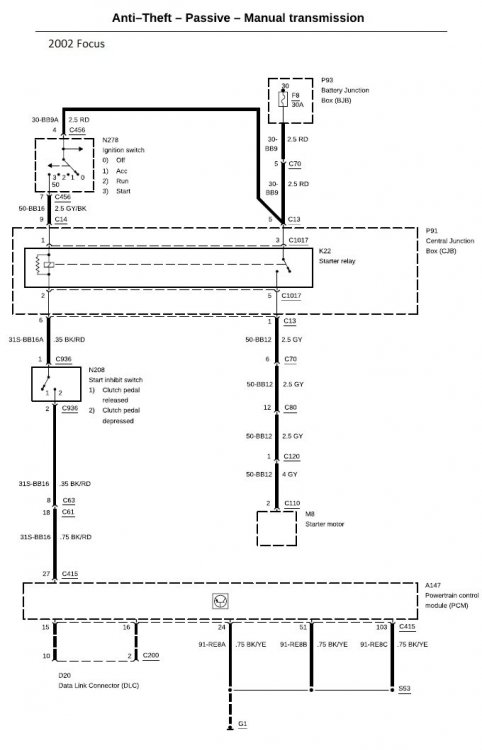

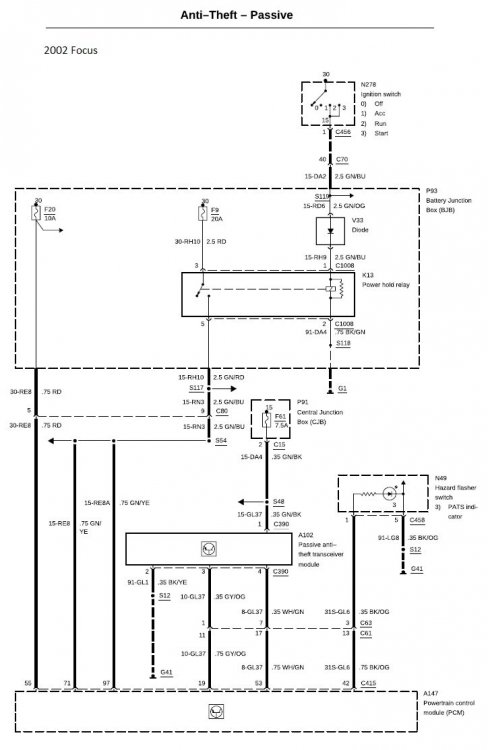

Depth of experience (different problems of course): -

-

computer for 2002 thru 2004 Ford 4cy fuel injected SVT

MV8 replied to HUTCH's topic in General Sevens Discussion

What year and model caterham do you have? If they can't get actual efi schematics from cat, you'd be better off with a shop that works on older efi systems regularly and have the diagnostic equipment. However, I'm sure they are great at caterham specific chassis work. It sounds like they have done their best. Cut your losses, politely collect your car, and take it to a shop with ASE techs and older ford EFI experience. I suggest a shop like Eric O.'s (South Main Auto, NY): https://www.youtube.com/c/SouthMainAutoRepairAvoca It's hard to find qualified people with time to figure it out. -

-

A new, similar plug with sae thread can be found from an industrial hydraulics supply. If it were metric thread, a similar plug is available as a replacement oil drain.

-

Rear brake caliper rubbing on radius arm/forward watts linkage

MV8 replied to KnifeySpoony's topic in General Tech

Push-pull the dedion tube from side to side while observing the A frame bushes and joints at the attachments to see if the lateral movement is excessive versus the tube rocking normally on the center joint. An inch longer top arm on the bellcrank of the watts would probably be enough, have no significant effect on the watts system, and could quickly be returned to original if you don't mod your original bellcrank. Fabbing a new upper link is another alternative but it would need to be heavier. A jig for the existing arm length would be drilled, then an essentially identical arm made but either: A) about six inches of solid rod would be bent to clear the spring and caliper and inserted into the tube ends or B) simply bent to clear (slightly longer tube so slightly heavier). I wonder if the upper link clears without the watts system. I'm guessing the standard upper link is the same length as the watts kit upper link. -

Rear brake caliper rubbing on radius arm/forward watts linkage

MV8 replied to KnifeySpoony's topic in General Tech

I've seen the watts side linkage two different ways. I've not considered which way is correct or better. Does the forward link connect to the top or the bottom of the swivel? -

A dremel with a 1/8 shank carbide double cut ball would be quick and easy. A small area can be touched up easy with auto touch paint with a brush cap.

-

If that is a pic of your rad, why does the plug need replacement? A pic of the removed plug or the opening would be easier to figure out. Looks like a flanged, straight thread plug similar to an oil drain plug but it could be npt. I'm guessing 3/8 but a few measurements could narrow it down. A thread pitch gauge may be necessary or if it is for an optional fan temp sensor or switch, check the thread specs.

-

Rear brake caliper rubbing on radius arm/forward watts linkage

MV8 replied to KnifeySpoony's topic in General Tech

I didn't assume what the scratches were from. As the outboard pad wears down, the contact will be worse with the floating caliper. I suggest going back to the old ears, keeping fresh pads on, or fixed calipers. -

Rear brake caliper rubbing on radius arm/forward watts linkage

MV8 replied to KnifeySpoony's topic in General Tech

If it doesn't rub (i.e. doesn't roll far enough or have enough suspension travel), you don't need to do anything. -

computer for 2002 thru 2004 Ford 4cy fuel injected SVT

MV8 replied to HUTCH's topic in General Sevens Discussion

"Stock" means original equipment from the manufacturer (OEM). The computer is not standalone. That is a stock computer that requires a PATS module and a chip usually located in the ignition key. The chip is matched to the computer. You must have the correct chip/key and module to operate the computer. There is no practical way around that to use the stock computer. Bypass kits typically just relocate the module with a box to put the correct key in proximity. I expect the chip/key is buried with the module in the cowl somewhere and is always together so you can use a standard chipless ignition key for controlling the ignition. It is probably something very minor that may cost nothing to actually "repair". The cost will be to find the problem. Whomever is working on it should know these things.