-

Posts

2,297 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by MV8

-

You might consider welding a flat strip of low carbon/common 1/8 steel across the bottom of the lowest point as a wear strip/reinforcement.

-

It is a crankcase port like a valve cover. Could go to an inline pcv or a can/breather filter.

-

There are inertia safety switches that were used by ford in the 90s, normally found in the trunk, that shut off the electric fuel pump if the car is hit. It is a ball in a magnetic cup that can roll out, breaking the contact bridge through the ball. A button resets the cup into the ball. Used are well protected and work fine, especially if using to control a pump relay. You can see a master cut off switch installed on GregM's DSK. The lever is hidden under the dash. His is installed on the ground side of the battery. There are different schools of thought on that. I'm not sure what the rules say exactly for what you want to do as to positive or negative, location, etc. Not all master cuts are the same. Same have multiple contacts that make or break. Many different sources.

-

Looks like a KNN e-3341 filter from a 56-1350 assembly, fitting Weber DCOEs. Overall assembly dims 4.5 x 7 or 5.5 x 9?

-

Good to know. Sounds like it runs well. Does the exhaust loop up over the axle or run straight back under the car? I've seen donkervoorts loop over. Some handy info on premix/oil injection: https://rotaryperformance.com/blogs/news/84479876-to-premix-or-not-to-premix It sounds like a pre-88 refurbished mechanical system would be the most practical.

-

Nice score with some minor/fun fixes but clean otherwise. I don't see an oil injection tank so you will probably need to mix it yourself or retrofit an injection system but I've no experience with that. I think oem apex seals when treated well can last about 80k without excessive smoking. Something to look for is the internal chrome plating can be damaged and require replating. These are known to be very loud so for road use, you might consider shelving the race exhaust and make/have made a quiet system in stainless or have it ceramic powder coated using an oem application 6-7 inch round muffler and a transverse oval or resonator/glass pack under the trunk/spare. I can post a pic of a list I recently put together of oem replacement walker mufflers and resonators that could be suitable if you are interested in the option later.

-

Funny, though it would work like a baffle. I'm thinking daisy chain. Yes, I kid, I kid, is joke.

-

Dry sump is a big step for a little clearance. Your wet sump pan can be altered. I expect it is steel versus aluminum. The drain does not have to be on the bottom and the pan depth can be reduced without loss of capacity by widening or use of a higher capacity filter. An increase in ride height may be worth the effort. A local shop could mod the pan or you could mail it to a company that specializes in oil pans and pickups. Moving a drain should not cost much or require pickup mods.

-

13/16-16, 3.25 pad fits chevys, ferraris, vipers (smaller base), etc. https://www.cantonracingproducts.com/content/Instructions/Engine Filter Thread Size.pdf

-

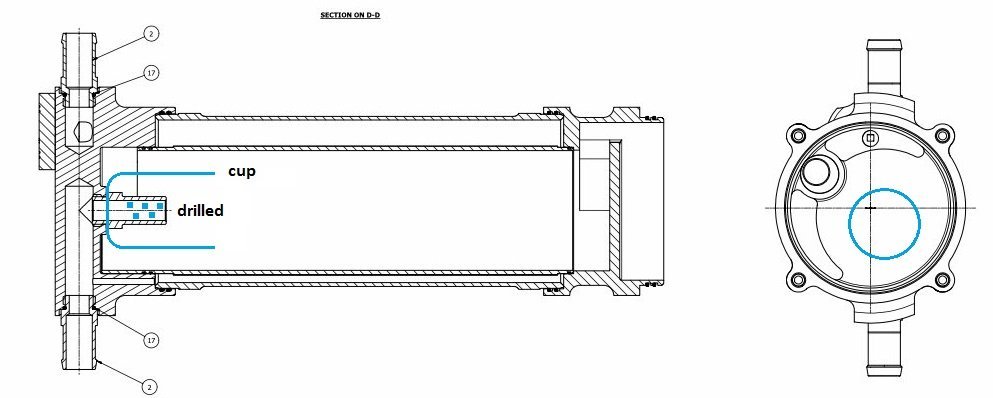

I think a deep cup held by the inside vent fitting and drilling holes in the fitting tube would help to vent air versus oil. A screw on oil filter adapter to a remote filter base that accepts a common GM v8 filter could be used to add one or two quarts depending on the filter.

-

So I tried researching this (selfishly for my own benefit/knowledge) and what I found was piece-meal at best and most of it from Croc. I still don't know what the low bell housing ports on each side go to or the design of the tower internals. It seems to me the system check of spitting to the catch can is only for max oil volume and if that is needed, then the bell housing/tower tank is too small. If that is the case, a cooler, remote oversize oil filter or aux reservoir spliced in somewhere could add some capacity and allow a lower system level. FWIW, I'll share what I know. I am a master ASE and aircraft mech among other things if it matters. A catch can can be service free with an open port to drain to the tank, a fitting, or any line with a normally open solenoid rated for gas/oil and a 12vdc coil. When running, the valve is powered closed and drains when shut off. If you don't want to do all that, here is a tank with a sight glass with more capacity and ports for running the vent and drain valve. Mount with well nuts and run. This one has push-on hose barbs but they also have An10x2 and x4 if interested. https://www.ebay.com/itm/393643262812?hash=item5ba6f7835c:g:0RMAAOSwKDZhcoMJ The orientation of the catch filter is not important as long as the port is on top. If oil reaches the top, it will leak out of the filter anyway, so it might as well route down and away from anything you care about. It also does not have to be a racy filter. It could be a tube or hose with a screen over end or for less restriction, a couple inches of perforated tube on the end of a 3/8 tube that end near the lower frame rail with a remote drain routed next to it if not an automatic drain. No need for AN fittings or orings. The pressure is very low. Since we are talking about blow by, provent makes a great oil separator for turbo diesels and they are cheap. You can plumb the upper fitting into the tower catch port, the lower off the pressure valve into a filter, and the oil return into the dip stick hole (assume there is one that is plugged). Basically a very short dip stick tube with a hose slipped over. https://www.mannfiltersrus.com/media/catalogues-pdf/MANN_HUMMEL_Crankcase_Ventilation_EN.pdf https://www.ebay.com/itm/264532161728?_trkparms=amclksrc%3DITM%26aid%3D1110006%26algo%3DHOMESPLICE.SIM%26ao%3D1%26asc%3D238213%26meid%3D20401273eafb42a281f4187e4a6cf255%26pid%3D101195%26rk%3D3%26rkt%3D12%26sd%3D184954557133%26itm%3D264532161728%26pmt%3D1%26noa%3D0%26pg%3D2047675%26algv%3DSimplAMLv9PairwiseWebMskuAspectsV202110NoVariantSeedKnnRecallV1&_trksid=p2047675.c101195.m1851&amdata=cksum%3A26453216172820401273eafb42a281f4187e4a6cf255%7Cenc%3AAQAGAAABIF5w9SIYA7LCsjjN3P6Yl26VztH0VKUH9PSWDJnasZbD1yCZJUhd3q2YXl6I7nNELecZEIiewtb0d1ttsdLu1kMb6p%252BjWblBYHLAkZ5L6FWUhAI8Ck%252Bk%252FuDUkY8z3MEFZuYbOa5QdSk3GYrDpPR%252F3mHaoueQrBjAZJlEwVTeJ%252F12BTpjnndVhnxDsA%252B0N2Q2MfSyc668ECfrzpmRTFSfEwgt29XY6AV2NO0eUTh9%252FHqwW8YZ4UTsi8tj9G8VfCv3QnmBrMeWbnAjy4hsS%252F%252Bl8uBIm8Szp1d7LELCo9r7bvGv8Qv5geG%252BMyPrej12FBLWk8I0xpW%252BMQhvmz6lQotlIHqa8GP6Ue9k71odPAM%252BmW5QT3CjuemqprPxA6tbL3YG6w%253D%253D%7Campid%3APL_CLK%7Cclp%3A2047675&epid=8033953319

-

I don't think it will be overbuilt using unistrut. The allstar stand weighs over 50 lbs. It looks like .125" wall 1.75" tube with 1/2" pins for a 2000 lb capacity. Unistrut is 0.780" wall and smaller in cross section with 3/8" holes. Definitely need thicker wall tube than unistrut for the lower tube if building the same way as allstar. Also, welding galvanized metal produces toxic zinc oxide fumes that if inhaled, can make the welder very sick. The casters should be capable of handling 250 lbs each. It adds up quick given today's inflation. I'd use black pipe for most of it with 1/2 rod pins with hairpins and drill adjustment holes as needed.

-

Maybe the level fluctuation is due in part to no air-oil separator that could briefly affect the level shown. My understanding is the spitting into the catch is from reaching a level in the tank (running and hot), notwithstanding any pockets of oil determined by the system's condition and efficiency. I found a 2021 owners manual for dip stick equipped that says to check the level within a window of between 30 seconds and one minute after hot shut off. A recheck of the level after adding any would be outside the window and require a restart and run for a minute. The 30 seconds could be for the foam to settle. Interesting anyway. Think I will stick with wet sumps....

-

It sounds like the bellcrank bushing is binding or the spacers are worn or were not thick enough to begin with. If the bolt is not as tight as it should be, wear can occur between the spacers and the inner sleeve of the bellcrank. This wear could reduce the thickness of the spacers, reducing the clearance to the bellcrank body or bushing, causing it to bind before the bolt can be fully tightened. The spacers should not contact the bellcrank body. It could be the clearance was never enough and the bolt was not fully tightened. Clear pics of the spacers and bellcrank sides could help. The fix could be adding appropriate sized washers to the ones you have to provide enough clearance when the bolt is fully tightened. You can use a six inch dial caliper to measure what if anything is needed (ID, OD, and thickness) for adequate clearance or take the parts to a machinist to measure. Fairly cheap at harbor freight or ebay and accurate (tested side by side with a $600 dial caliper). Also make sure the inner sleeve rotates freely in the bell crank bushing.

-

Wow that is tedious. I used to check turbine oil levels (also a dry sump) between flights for the airlines and it wasn't that much trouble. I would use your current method of hot and just starting to spit to the catch tank to know the system is at the correct level, then immediately shut it off. Pick up a full length pencil or 1/2 dowel. Insert the dowel to reach the oil level with your thumb sitting on the tank neck. Remove the dowel and mark where the end of your thumb is and where the hot oil level is. The next day, start the engine and run for a minute, shut off, pull the cap and watch the level for a minute at most. Repeat to find the cold level. There are several ways to make the dipstick. One is to use 1/4-20x12 inch threaded rod, two nuts and lock washers or nyloc nuts, and a fender washer larger than the tank neck opening. Using a common bench grinder, grind away the threads on one side about 2 inches to provide a reference of the level lower than full cold. Assemble and adjust so the distance from the washer to the ground area is the same as the marks on the dowel for hot. With a hack saw, saw a small groove in the ground area for the cold distance. You can cut off the excess rod above the washer to screw on a knob or just enough to grab. Red loctite the nuts. A smooth dip stick would be easier to clean but require welding. The level can be checked with the dip stick any time within a minute of shut off but subsequent checks after adding some oil will likely require a restart to repeat the procedure. A dipsticks value will always be time sensitive relative to shutoff. You could also make a T shaped stick without the washer or bent wire that will lay flat in a glove box in a zip lock bag. A sight glass would be great then you could add marks to the tube. The heating is gradual compared to my bodum french press. Some ideas for adding a sight glass: https://www.mcmaster.com/sight-glass/

-

What are the specs and thickness on the gasket material? I'm not familiar with your intake. Is the purpose of the coolant jacket to guard against throttle icing? Is it necessary for your usage? If not you could fit a metal gasket that stays on the head and blocks the passage, like a full soft aluminum or annealed copper, or fit the paper gasket on top of the metal one. No more coolant and sealer to deal with as long as the system is not pressurized when you remove the intake.

-

I've seen much better component placement on other models. I agree; a terrible place for a battery. Oems have used insulating walls around batteries subjected to less heat than this. Easier than moving it to sit between the heater plenum and the oil tank, remote in the boot, or fabricating a heat shield. Why not just start the engine cold and let it idle for a minute, shut off, and fill to the cold mark? If you need to check after the oil has reached normal temp, shut off, fill to cold. Obviously a little low is better than too much which can cause the catch tank problems among other things.

-

Other options are grommets with short spacers on the fastener that prevent over tightening, vibration damping mounts, sleeve/step washers, or a rubber washer under the head as well as underneath. Not as flush/pretty though.

-

Any marking on the uk hose to indicate ethanol compatibility? It appears to be standard replacement zetec type fittings for 5/16 nylon and M14 but with an unmarked rubber and crimp sleeves. Does the hose need to have the flexibility of rubber or can you go to an oem type nylon? You'd need two splices to make it longer. Not a good idea imho.

-

Third vote for a standard barb push on for rubber.

-

Nut keeps coming loose - any long term solutions?

MV8 replied to KnifeySpoony's topic in General Tech

I looked at a 420r watts kit and see they use long shanks with minimal threading which is good. However, it could be the bolt shank is not threaded far enough to clamp the inner sleeve. It may be from tight build tolerances and/or a hardware mismatch. Washers generally are not made to a precise thickness. If you had a dial caliper you could measure the grip length and the sleeve length and compare. The bolt is just a clamp for the inner sleeve. If you don't have that then just add another washer with an id smaller than the step in the shank the washer causes the nut to stack tight further out and see how it goes. You should still have a few threads protruding above the nut. -

Nut keeps coming loose - any long term solutions?

MV8 replied to KnifeySpoony's topic in General Tech

Hello, I have no first hand experience with your model but I have a lot of experience and I also stayed at a Holiday Inn Express recently. There should be a steel sleeve within the bushing to act as a positive stop for the bolt and nut to clamp against. If the sleeve is there but too short, the added washers can help loosen the nut. Sometimes instead of a sleeve, a positive stop is provided by a shoulder on the bolt near where the threads end and the unthreaded shank begins. Either way, the sleeve or shank (step/shoulder to head) should be as long as the width of the bushes. With a step shank versus a sleeve, washers reduce the effective length of the shank. After that, jamb nuts, a new nyloc or other prevailing torque fastener such as a nord loc should work great! A pic of the hardware or exploded view of the assembly may shed more light.