-

Posts

3,087 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by JohnCh

-

It was a little more than that. One of the wires in the injector harness connector wasn't fully seated. You could see the rubber seal sticking out the back. With the plastic cover inside the connector removed, and that pin fully seated, we noticed it was still a couple of mm shorter than the five other pins. Now whether that's an issue with the connector itself, or that pin is physically shorter, is an open question. Regardless, it now makes the connection and consistently fires the injector on #1. If there isn't an occasional electrical issue, it can't be British :jester: -John

-

I keep my tools in a tool roll attached via velcro straps to the top of the passenger footbox in front of the scuttle. The exposure to heat and dirt under the bonnet is irrelevant -- they're tools -- and they don't take up valuable boot space when touring. The shape of available real estate in that area is a little different in a Caterham, but it's workable. -John

-

Um, that day/night mirror is in a Westfield. And we can get very soft. I even have a locking boot with a separate key to keep things safe from valets! -John

-

Not a GoPro. My video consultant (i.e. Croc) put me into a DJI Osmo Action Camera, and Audio Technique microphone. -John

-

The situation today is one reason I love se7ens so much; the community. Mike's on East Coast, probably having a mid-afternoon bourbon, Bruce is on the West Coast finishing another coffee (mandatory here in the PNW), but between the 4 of us, we got the car running and were able to salvage the drive. Greg's car is beautifully finished and painted in the fastest color Short, but fun drive today! -John

-

Proof Pokey's car can move under its own power! -John

-

Met up with Pokey today for a short blat. The rolling pylons were particularly bad, although strangely only of the motorized variety. Typically this route is full of bio-powered pylons whose idea of sharing the road is to ride 3-abreast in the lane and force you to either risk a fairly blind pass, or settle in for a 25mph drive. As we approached the base of a particularly fun uphill section before the turnaround point, the Blat gods smiled upon us and the traffic finally parted. Woo hoo! With over 400 miles on the engine, I'm starting to use a little more throttle and revs. -John

-

Usually it's jets and air correctors that change for altitude, not the chokes. But the chokes are frequently changed when going to more aggressive cams. -John

-

Swindon is still around. A bit of a longshot, but they might have some information on the various tunes they can share. Another option is to see if anyone on the c20xe Facebook page you mentioned on BaT know carb settings for stock cams and the various Swindon stages. I bet the chokes go up in size with each HP increase and that's an easy thing to check. e.g. if a stock vx engine uses 34mm chokes and yours are 38mm, then you know your engine is flowing a lot more air....or someone really screwed up the carbs -John

-

I connected with AP Racing to help me identify clutch condition. Below are the specifics they provided (note: this is for a Duratec). Looking this information over again, I notice they state the clutch is rated for 7000 rpm. I previously used 7500 rpm redline with no issues, and plan to increase that 500+ rpm with the new engine. Guess I'll see if that creates a problem: From the numbers provided I can tell you that the driven plate is an AP Racing component CP5352-5 Ø215mm, spring centre, organic friction linings, Ø1.02x23T spline. Rimmed retainer plate for increased strength to spring windows Increase damper springs strength to accept 250lbft torque High Mu friction linings (0.3mu) to increase torque. Rated to 7,000 rpm New clamp thickness = 7.11mm Minimum worn thickness = 5.6mm Pressure plate # LC03JR 003B is just the cover pressing # used in a number of clutch assembly builds including standard service units produced by Raicam here in the UK. We both use this same Ford pattern pressing, but APR produce the uprated / high clamp / high torque units. APR Part # CP5905-500 (RED paint code on spring fingers) Rated to 220lbft -John

-

Well, that would explain things. Yikes! I'm using an AP Racing clutch and pressure plate, and a Raceline steel flywheel. I believe Caterham and SBD also use AP Racing clutch components, but I'm sure someone here can refute if that's incorrect. My clutch was out as part of the rebuild, and after 32k street miles, there was plenty of meat left on the disc, and both the pressure plate and flywheel mating surfaces were in great shape with no obvious burn marks or wear. -John

-

This is what I've used: Neoprene Weather Stripping -John

-

Vintage green is definitely a little lighter than BRG, but the photos in that BaT listing were either processed or lit to make the color pop as much as possible. These pictures on Caterham's site are more representative of the shade. Still a little lighter than BRG, but not as big a delta. https://www.caterhamcars.com/en/in-stock/model?id=7487 -John

-

-

Have you checked with Beachman Racing or Rocky Mountain Caterham? They both have parts inventory and it's possible one/both of them have the 13" wheels in stock. -John

-

-

When it comes to aesthetics, the only opinion that matters is yours. There will be some people here who think it adds a lot of interest and is gorgeous, and others will think it's too busy and strongly dislike it. But our opinions shouldn't matter. My advice is to leave it in place for a couple of days and see how you feel about it every time you walk into the garage. If it makes you happy, keep it. If it doesn't, pull it. If you know you want stripes, then maybe overlay the black stripes in a couple of days and repeat that experiment. -John

-

Vimeo is less stringent than YouTube... I suppose a live pay-per-view screening could help recoup some of my costs. Thanks for the idea! -John

-

Enjoyed, as in past tense? Don't go anywhere yet Shane, it ain't over Provided there are no surprises, I still need to report on perceived power and shape of the torque curve compared to the old engine, then add the dyno results. Logged another 100 miles today so now halfway to the target of 500 miles before getting on the dyno. -John

-

Did a 30 mile run over lunch and no leaks, so it looks like the T fitting was the issue. -John

-

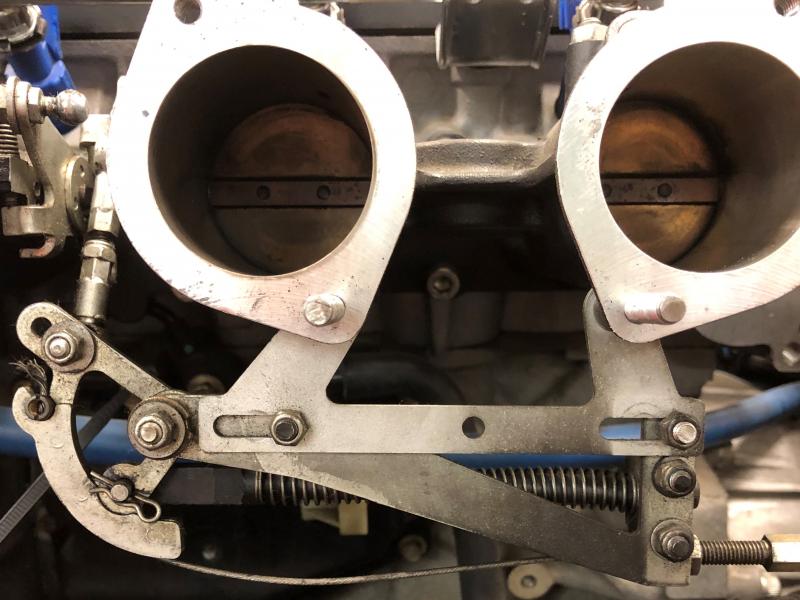

The engine has covered 100 miles so far, a number I hope to triple over the next couple of days. Much to my relief -- and surprise -- the oil leaks from the sump and blue sump plug have not returned. However, the one from the oil pressure assembly remained and was (no surprise) unaffected by the addition of thread sealant. As an experiment, I removed the T fitting for the low pressure sender, and attached the 3AN fitting off the line feeding the gauge directly to the M12 to 3AN adapter in the side of the block. I wasn't able to drive it afterward, but did let the engine idle for over 5 minutes and blipped the throttle several times. No drips. Hopefully it stays that way. After the drive to seat the rings, I noticed the revs weren't dropping between shifts as quickly as expected. Closer examination showed the throttle linkage return spring assembly seen in the old photo below, jumped ship. Fortunately the springs on the Jenveys are strong enough to make this just an inconvenience, but Raceline is working to secure replacements. Other than that, things have been thus far been uneventful. The ECU is now operating in closed loop adaptive mode, where it logs fueling changes based on a target AFR table. It was running fine before that was enabled, but even better now. Once I hit 500 miles, I'll do another oil change, switch from the the break in oil to a synthetic, and schedule dyno time. -John

-

The Regular Summary of Classified Ads of Se7ens Found For Sale

JohnCh replied to Croc's topic in Cars For Sale

With the original car, I'll never forget the first time I attempted a U-turn on a residential street. The question WTF went through my mind several times. The wide track fixed that, and the LSD made even that change superfluous. Just crank the wheel over hard and hammer it -John -

The Regular Summary of Classified Ads of Se7ens Found For Sale

JohnCh replied to Croc's topic in Cars For Sale

I'm curious, does the Caterham wide track allow for a tighter turning radius? On Westfields (or at least the older ones) with the standard track, the rack is fitted lock stops to prevent the cycle wings hitting the body on full lock. This results in a rather large, SUV-like turning radius. With the wide track option, no lock stops are necessary, thus the turning radius is more in line with the car's size. -John -

My high school physics teacher had a favorite acronym: TANSTAFL which stood for there ain't no such thing as a free lunch. People tend to conveniently forget that adage when evaluating various alternative energy sources. That doesn't mean they aren't better, but they ain't perfect. -John

-

My condolences Let us know what you learn when you pull out the old one. BTW I have both versions in boxes, so if there is any confusion or hard to read part numbers on yours, I can provide measurements. Thanks, John