-

Posts

633 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by SENC

-

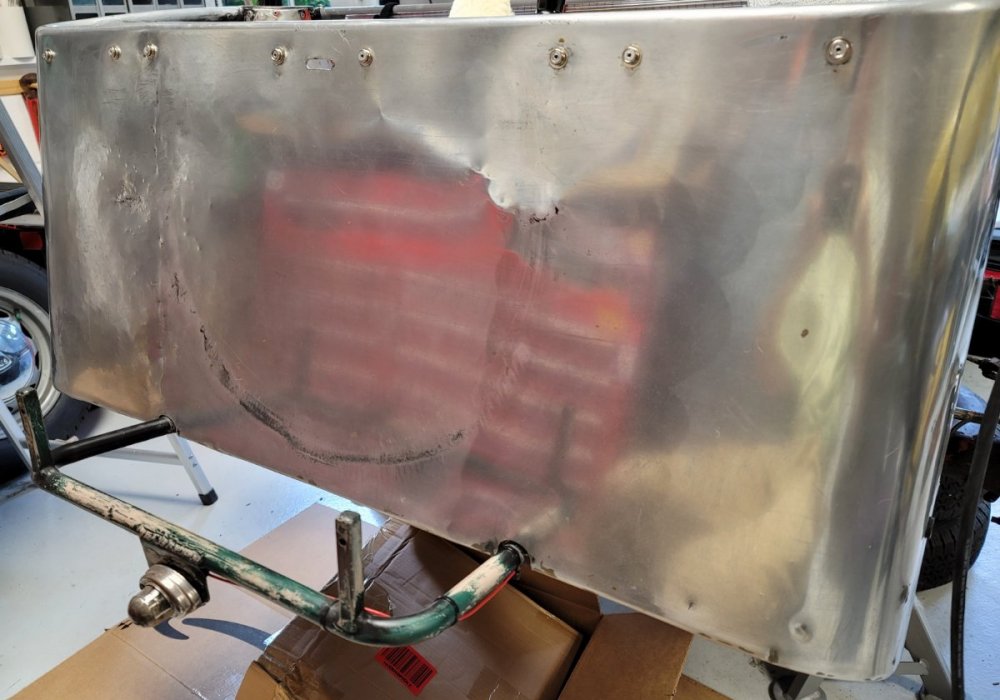

Firsts efforts on the rear of the car - I figured if I didn't like the look it wouldn't be too visible with the spare in place. In sequence are the before, after compounding with a 7.5" wool wheel and Nuvite IIF7, after polishing with the Cyclo and Nuvite IIF7, and after polishing with the Cyclos and Nuvite IIS. As mentioned previously, this car was originally painted all over and scraped by a prior owner around 2008. Deep scratches from the scraping along with other dings and imperfections from 55+ years of life won't be removable without major sanding (even if then), so I knew the result would be far from perfection - and debated a long time whether polishing would be an improvement over oxidized state or just highlight the flaws. In the end, I'm pleased with the result and will continue on - though it is a laborious and dirty job!

-

well done!

-

-

While waiting on the engine boring to be completed, I talked myself into polishing up the aluminum... so prepped today by removing all the fiberglass. Looks nekid!

-

Not the VIN, but a frame number is stamped on the frame, beside the master cylinder bracket (at least on my RHD). And here is a link from the lotus 7 register site, with a little more information... Lotus Seven Register - Miscellany (lotus7register.co.uk)

-

You might reach out to Mick at xtraspecialsevens.co.uk. The PO of my S2 Seven had him replace the loom and he did an exceptional and clean job. He does a lot of Seven work in the UK and may have a diagram. Very nice and responsive. Mike Ostrov, of Elite fame, Tony Ingram (lotus7.com), and John Donohoe (simplesevens and also a contributor here) are probably the most knowledgeable stateside and may also have leads or recommendations if you reach out to them. Keep us posted!

-

Not S1, but there are a couple S2 wiring diagrams in the download section... may be useful if you can't find an S1 manual or diagram.

-

-

Love those pics by the ocean - where is that?

-

Quite jealous! I should have pistons this week, so hopefully will get things back together before it gets too hot and sticky to enjoy - but did get a nice ride in my Elan today, in between painting exhaust manifolds and cleaning intake manifolds. The weather looks nice the next few days, think I'll take it to work in honor of Ross's drive up the East Coast.

-

Agree with this 100%!

-

If the various engine and machine shops I've been chatting with recently are right, anything for updating or modding combustion engines. These particular shops are the old school, mom-n-pop type shops and they have been surprisingly similar in their outlook, based on the fact that it is already getting hard to get many parts they could get easily just a year ago. Don't know whether their suppliers are amping them up, but they blame it entirely on recent and coming EPA changes, exacerbated by the Suez canal and Texas ice storm impacts. According to one of them, as an example, the reprogramming and various system deletes that have been popular among diesel truck owners has been all but prohibited and that they can't get parts or assistance any longer (legally). Guess I missed my chance on my 2010 F250.

-

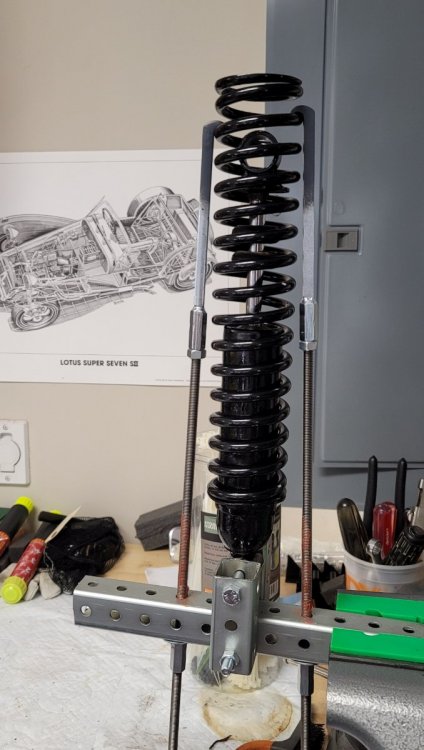

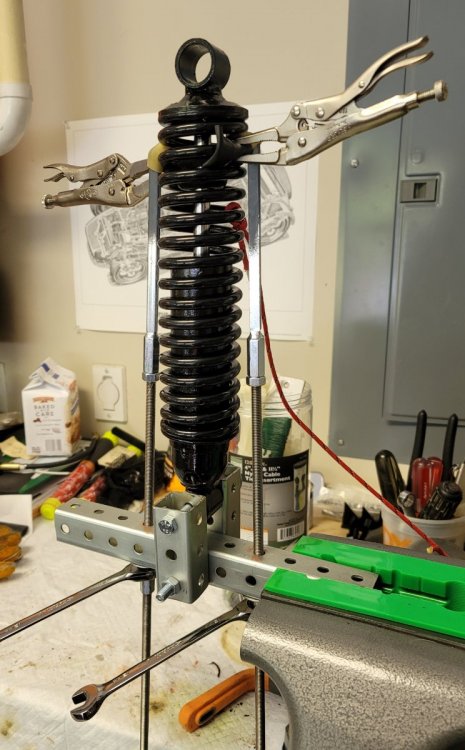

Made a rig to reinstall my coil springs. Little by little getting things ready to get the Seven back together. These are what I believe to be the original 60s Armstrong dampers and springs, which all tested in spec. The vice grips are just to keep the compression hooks from slipping down the coils.

-

That is excellent, thanks!

-

Was just checking out this site and found it quite useful - a number of good articles and lots of good information, particularly for early Seven owners. Well done to Bill! I've encouraged him to join here, too. Henry

-

You make a good point. It really isn't that hard to imagine the Lucas/Lotus gods causing a plague of generator issues with bravado like that!

-

2 rebuilt and running smooth (bench tested as a motor, to bed in the brushes), and plenty of bits left over for the parts bin - though it is hard to imagine enough miles to burn through 2 generators. Next job, while waiting on pistons for engine rebuild, is getting the coil springs back on the dampers.

-

A little puckered after that, I guess?!?

-

No, these constant depression carbs have only 1 circuit (unless you count the cold start device) with metering of fuel delivery accomplished by the needle in relation to the jet. They are ingenious in their simplicity, but as a result adjustability is limited, and all the parts need to work together as designed or they can be very frustrating.

-

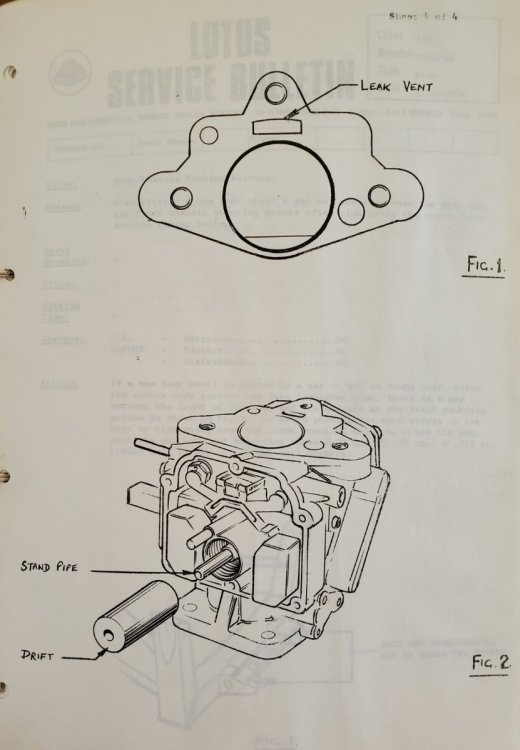

The needles are having the impact you'd expect, given their profile. Move them relative to the jets (by either adjusting the needle height or by adjusting the jet height) and you'll get a change in initial richness. Once those are set, but profile does the rest as the piston rises and falls - and, in theory, the right profile allows more fuel at the same time the opening pistons allow more air, and you have relatively stable AFR across the range (assuming slow, smooth acceleration/cruise type conditions, not WOT). I think I have all that right! The challenge with these adjustable needles is that there is VERY limited adjustment range - just over 3 turns in total as I recall - so the most important bit is getting jet height right. Only then does the needle adjustment allow you to tweak within the right range. Also inspect the jet orifice - it should be round, but if the old jets were retained when the carbs rebuilt it could be that they are worn (a proper setup has the needle "leaning" to one side of the orifice, so over many thousands of rises and falls can wear a groove into the jet orifice). Not knowing the PO's shop, I'd double check to make sure piston springs were actually installed - and maybe inspect them to see if they look old and tired (they're light springs, so not sure anything other than missing, broken, or different one to the other would be visually notable). There are 3 different versions, it may be that you need a stronger spring. A footnote - converting fixed needle 175s to adjustable needle 175s means replacing the pistons. The Burlens/Zenith technical manuals will tell you these are matched components and should never be changed. Plenty of us have done so with positive results, but I guess there is always a chance of something being just out of tolerance enough to cause operating challenges. How is your timing set? You might note in the LSB attached earlier that Lotus suggest a static timing for Stromberg that (as I recall) is lower than standard along with change to adjustable needles.

-

Jet height changes should effect the entire range, I'd think, as relative relation of the needle and jet define initial mix - needle movement with the piston then adjusts with air flow. Lower jets should mean richer conditions throughout the range, higher jets would mean leaner. Though I certainly suspect the relative contribution of jet height is less up the range. The temp compensators and idle mix screws can contribute to lean-ness - I'd make sure the idle mix screws are seated fully, and I'd probably fully seat the temp compensators if I had any doubt about their working condition just to take that variable out of the equation. Do you know whether the fuel needle valves were replaced on rebuild? I can't remember if there was a size change when I rebuilt mine to non-emissions spec. Last, if you haven't seen the LSBs for this modification, I've attached pics - may be helpful.