-

Posts

989 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by powderbrake

-

Thans for the pics. I will have to put the museum on my bucket list.

-

A couple S4's and an S1 or S2 ( forgive me for not beingable to identify the earliest s models) at the USA7s meet , 7/7/07 at the Tail of the Dragon. The S4's are merely "different"

-

WCM Diff/ driveshaft vibration thunking noise

powderbrake replied to wcmgoldie's topic in General Tech

I had some wierd clunking noises when I first assembled my kit. After pulling the diff, and lots of looking, I finally took out the driveshaft, and the front u-joint cage was broken, and balls were loose in there. I called Brian Anderson and he immediately sent me a new driveshaft, and all is well. -

Interesting and a solid approach to getting good data. I am not surprised that there is a 10% difference in the two sensors. I doubt that oil temp is that consistent between engines/ drivers/ sensors. You approach to calibrate them will give you an accurate reading.

-

A "Stack-O-Ultralites" :cheers:

-

I have an Ulralite, and replaced the hydraulic switch twice. Hydraulic brake switches are notoriously unreliable, particularly on a car that does't need much brake pressure to stop. I replaced mine with a mechanical switch actuated by the brake pedal.

-

I guess someone needed the S2K motor for an Ultralite, and he had to replace it with something.

-

It proves once again, the key to a job is more education. Somebody has to be the guy who invents, buys, or directs these machines...... be that guy.

-

At 170 mph in a Seven.... who has the time or the guts to look at a speedometer?

-

If you get near the Dragon, by all means run it. It may not be as fast as you might expect, but the severity and frequency of the curves makes it great. Here's a pic of my car at the Dragon, the weekend we spnt there with the USA7s group in 2007. Photo purchased from Killboy.

-

-

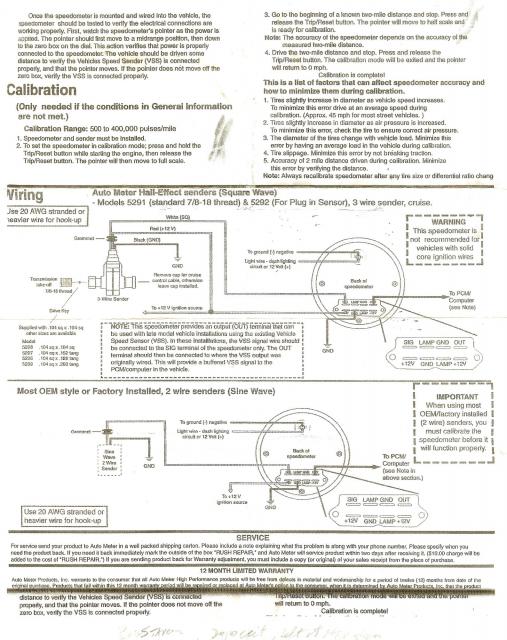

I am posting this here to answer a question on the Ultralite Yahoo groups, as I can't easily post pictures there. I am using a Subaru wheel speed sensor as the pickup, and to do so, you must epoxy a small 1/4 to 3/8 diameter magnet to the CV joint housing to activate a signal with each revolution of the axle. I used one of those neodymium magnets which are commonly available on ebay. Only one magnet is needed, as I have checked my speedo against a GPS, and the odoeter against the mile markers on the Interstate, and it is accurate. After installation, the Autometer Speedo must be calibrated.I have included a pic of the calibration sheet, and a PDF if it is difficult to read in the pic. Use the TWO WIRE hookup at the bottom of the page, don't worry about which one is signal and ground, it should work either way. Speedometer Calibration20001.pdf

-

Rubber is typically ground to size, not turned.

-

WCM adjustable pedal carriage mounting rails

powderbrake replied to Blindcars's topic in General Tech

I am one of those who clamped my adjustable pedals in a fixed position. Yes there was a "spongy" feel to the brakes when there was loading on the slides, so that was why I clamped them. I am sure that your high tech solution will work, but I suggest it may be overkill. Once you find the spot that works for you, lock it in place. Others may drive my car, but it's only a short test drive/ thrill ride, and they can put up with the inconvenience of a non-optimal pedal position. Fitting up the fuel and brake lines with custom sweglock tubing/fittings will make a very nice package. Don't be afraid of the fittings from variuous manufacturers, thay will work OK. I bought all my fittins for my brakes from a local Hot Rod shop which had a large variety, and a good stock of parts and tubes, and I have never had any leaks. The fuel line was a nightmare of changes in size of tubing, SAE and Metric fittings, but once completed, no leaks. -

Of course everone is deeply saddened by such an event, but Sprint car racing is probably the most violent, quick, dangerous, adrenalin filled and contact ridden of all the racing types. Walking on the track during a race is sheer madness.

-

I had a 59 Berkeley. I hade top bows for it, as they were missing when I got it, and bought a top and side curtains from Warshawsky. It was small, I drove it into the corner of my 1 car garage, got out, lifted the rear end over to the wall, then drove in my 60 Corvair coupe. I also had my motorcycle and my lawnmower in that garage. Great fun car, 3 cyl 500 cc 2 cycle Excelsior motorcycle engine, I ran Castrol so it smalled like a racer, Start engine in reverse to back up Yes, it make my seven look huge....... I wish I still had it.

-

New differential mount bushings

powderbrake replied to Blindcars's topic in General Sevens Discussion

:iagree: -

this particular topic

powderbrake replied to john hennessy's topic in Politics, Religion and Controversy

I agree, IMO is your qualifier. -

Blindcars: I know exactly what you mean. It is a mind blowing experience. I let a friend and his wife take my Ultralite for a drive. Look at their smiles.... they lasted for hours.

-

this particular topic

powderbrake replied to john hennessy's topic in Politics, Religion and Controversy

It is difficult to resist flaming the drivel that I have seen in this topic, and I do not agree that corporations work to keep the workers down. I have been a principal or owner of 4 businesses. A service business, a real estate business, a sporting goods busines, and a manufacturing company. I have been president of two manufacturing companies. I have endured having 3 companies I worked for or was president of, be purchased by 2 different manufacturing companies and one venture capitalist. I purchased a manufacturing company and rolled it into the one I was running. So, I've been around the block a few times, and I have had 55 years of manufacturing experience. I have NEVER heard or experienced any owner, principal, stockholder, venture capatalist or executive express any comments related to screwing the worker, or keeping him down. In fact, there is always great concern that in times of change, the workers, both plant and office, be carefully treated to insure their staying with the company, and that their insurance, benefits and fringes be maintained. If you have at least a partial fragment of a brain, you know that the people are the assets that are important, and you cannot succeed without them. I am no different than most executives, owners or presidents of companies. They know what it takes to make a buck ( which is the basic purpose of business) and who helps them do that. Those evil "people" and "corporations" are the minority, not the representative group. So to those who claim the companies are ruining everything, I say, get off your butt and start a company and see what it takes. Yes you have the right to complain and bitch and snipe from the sidelines, this is America. We have a constitution and hundreds of years of soldiers fighting and dying to protect your right to bitch. I also have a right to ignore your silly ass bitching, and so I choose to ignore it. -

Maybe you need some strings to measure the wheels being parallel, and equidstant from the sides of the frame. I tied a long 1" square aluminum tube ( Home Depot) to the wheel/tire which established a line at the outside of the wheel. Then measure from the tube to the sides of the frame. This may allow you to adjust the linkages to prevent the rubbing. You can also see any toein/toeout of the rear wheels. To my knowledge , all the ultralites have the shock mounts in the same location, and the springs won't rub when all is aligned..

-

WCM S2K bent rear hub rod/tube question

powderbrake replied to GunshipDriver's topic in General Tech

I used a heavier wall steel tube to replace the aluminum part I received from WCM. -

My Ultralite is 1400 pounds with aboout a half tank of gas, NO driver.

-

Good to hear that he is awake, and will be rehabbing. I have to admire his family for their stalwart refusal to participate in any media circus, as it is a very private matter.

-

And they do this without the benefit of drugs or alcohol (supposedly) Can't you just imagine one of them saying " Hold my goat's milk and WATCH THIS"