-

Posts

2,093 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by IamScotticus

-

The Regular Summary of Classified Ads of Se7ens Found For Sale

IamScotticus replied to Croc's topic in Cars For Sale

I almost thought you had an Excalibur there -

Oxy?

-

No, but I'll look him up. Everybody I've met from Galveston has an interesting story. Yes, Houston unfortunately. It's not very 7able here.

-

I have this mount. If somone will lend me the pump, I will stage these on my car and report. Or, I can install the mount with the standard pump and report. I can do this now while the Cat is laid up. Maybe Dez knows @NSXguy

-

@32eachtime I'm well intended, but very blunt. The screen shot you provided to John cannot possibly answer the question. We are only assuming you have dealt with Caterham Cars. They may be slow to respond, but as for me, they have always gotten me the part. Something may be held up in customs. Who knows. Remember that many UK suppliers won't ship to the USA anymore due to the "I didn't get it" frauds who cancel the payments. Please provide better information on who you dealt with so we can help, or learn something from it.

-

Buy the mount anyway. It's an improvement. I'm surprised to see it still available. Email Burton on the clearance. They sell the pumps and should know

-

Failing an adjustment, Bleed with a pressure bleeder. If you have a external slave, try a pressure test by jamming the pedal down with a stick overnight and observe the position of the slave push rod. I suppose the same test can be done with a concentric slave with the rears off the ground and in gear. Try to turn the wheels in an hour. If the wheels turn freely, you don't have a seal problem. If there is resistance, the clutch has closed due to a pressure loss.

-

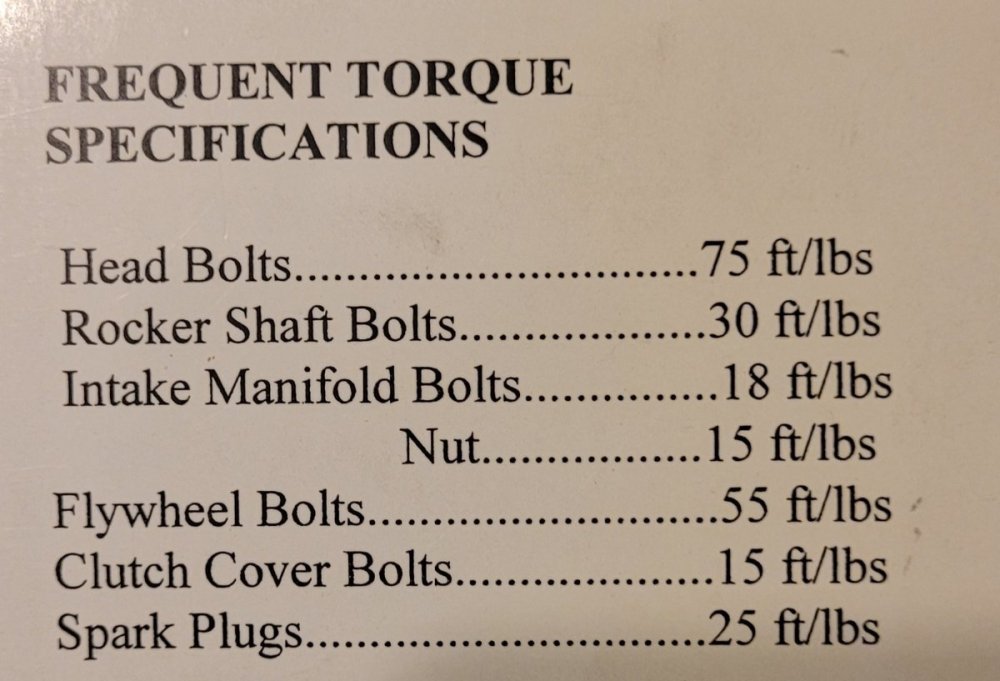

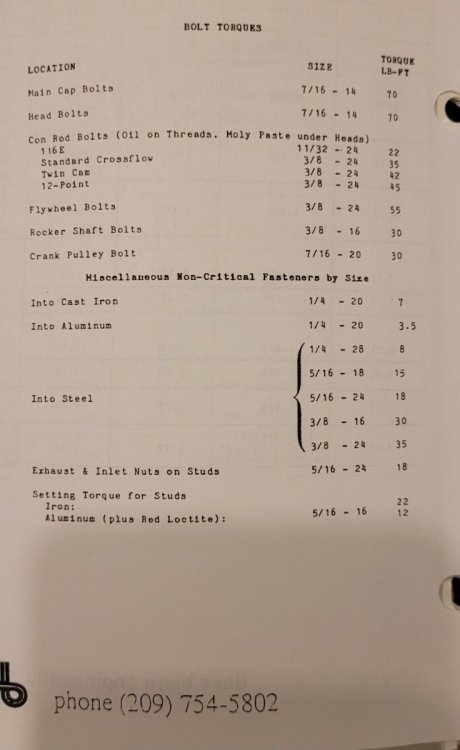

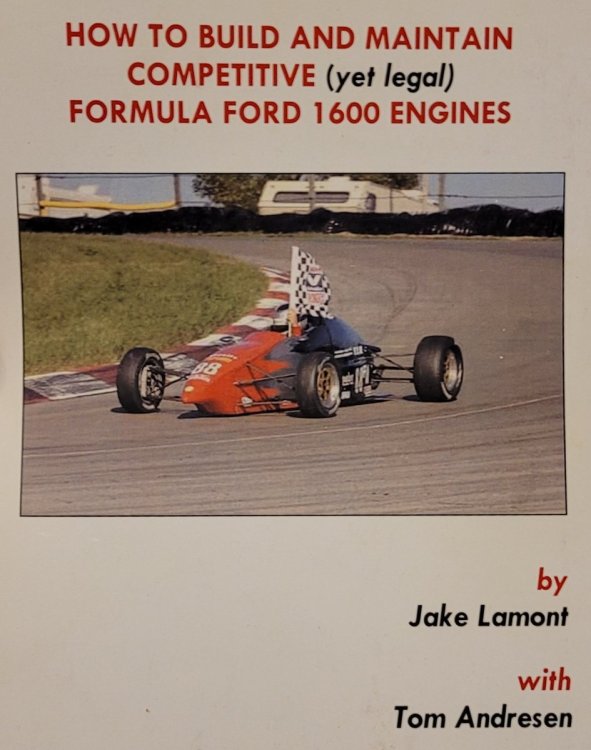

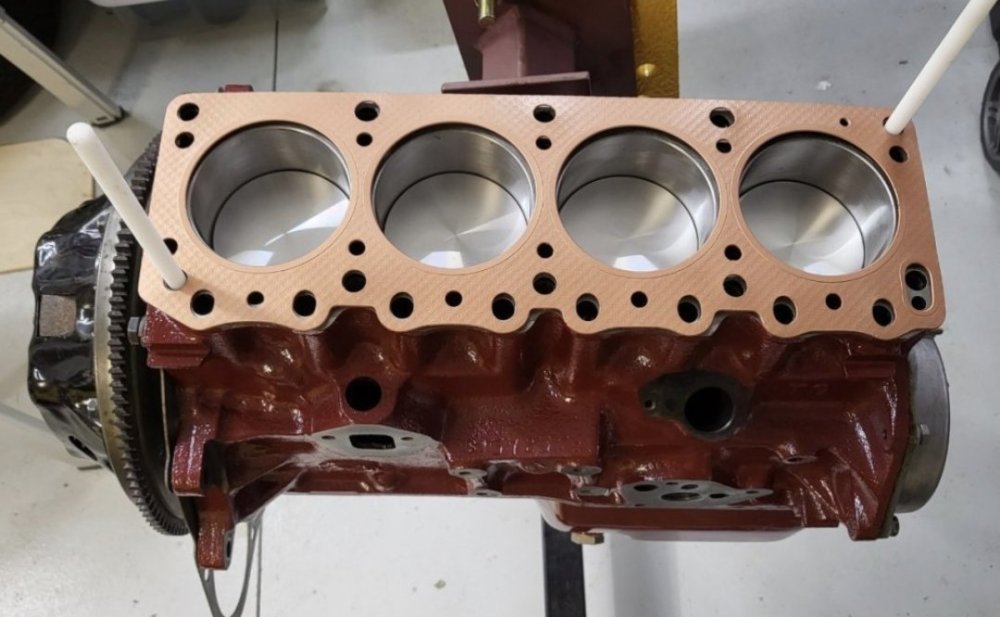

Oil pump bolts torque 12-25 lb/ft. Checked two sources. Jake Lamont likes Loctite 515 Gasket Eliminator under the pump cover, 7 lb/ft. It may not be something you are wanting to deal with, but pump rotor end clearance is an issue with these pumps. The rotor floats in the housing abd is in contact with the inside surface of the end plate. This is the only seal you have between having pressure or not, and it wears. Checking the clearance is standard procedure for these engines. I will PM you the details.

-

Does my 1700 Super Sprint really need an oil cooler?

IamScotticus replied to pethier's topic in General Tech

The "Swinger"? I've been looking for one. -

I think the even distribution of torque is more critical than bolt tension/clamp force. Like drive shaft flange bolts, the torque spec isn't high, It's the grade of the bolt that does the work. I read five of my books on the clutch cover installation and didn't find any recommendation for Loctite on the pressure plate bolts, but at 15 lbs-ft, I doubt it would do any harm if not applied in excess. The most consistent advice is to tighten these down evenly In short steps so as to not warp the cover, AND keep the disc centered. There was one reference to the use of spring washers. These would be preferable to Loctite, I think. I will PM you some book shots, I don't want to poke the copyright bear. There is one very good point to remember on clutch discs.. The disc hub may have a high side at the center. According to Haynes Escort Mexico& RS1600, the high side should face toward the flywheel, assuming there is enough relief in the FW center to allow for disc wear. If it were reversed so the high side is toward the transmission, the spring fingers can foul on the hub? Or is it the other way around, the hub will foul on the flywheel? I suppose some measures are required. I'm not an expert on this, just something to be aware of. I'm surprised Haynes is the only book to mention it. A clutch disc supplier mentions orientation direction on a disc installation instruction website, but they are general and the opposite orientation of the Haynes instruction. None of the 1"x23 discs I got from Burton had instructions with them. Going back and reading your problem, you didn't have a problem before the slave change, but Im thinking the disc may have been incorrect beforehand. It just managed to work with the older slave. New parts tend to wear older parts quicker. Perhaps the disc hub was eventually going to bottom out? The new slave made it happen. The face of the hub definitely shows signs of contact. Nothing should be touching that face. Just guessing. You've checked everything else. PM me for a new 7.5" 1x23 road disc and some shaft lube, if I can find it. It hasn't been used for a long time. And what release bearing face do you have, flat, round? You have flat PP spring fingers. They should have a round, or donut, bearing face contacting them.

-

Does my 1700 Super Sprint really need an oil cooler?

IamScotticus replied to pethier's topic in General Tech

Is there a dry sump here? I've read quite a bit on oil coolers and dry sump for the Kent engine 7s and came to the conclusion that a dry sump is more beneficial than an oil cooler. For one, a dry sump (should) provide a better aerated supply of oil and somewhat cooled from the cycle. The standard Kent oil pump is the Bain of the system and over-driven. Eliminating two sources of frothed up oil gives the oil you need, not cooler oil. Also, I have head from several who, in their particular type of usage, that they couldn't warm up with a cooler. I would say of using a oil cooler, don't go too large. Four row or the water jacket type. -

-

-

You have the front stick location on the timing cover? I'm thinking Anglia and Cortina Mks 1&2

-

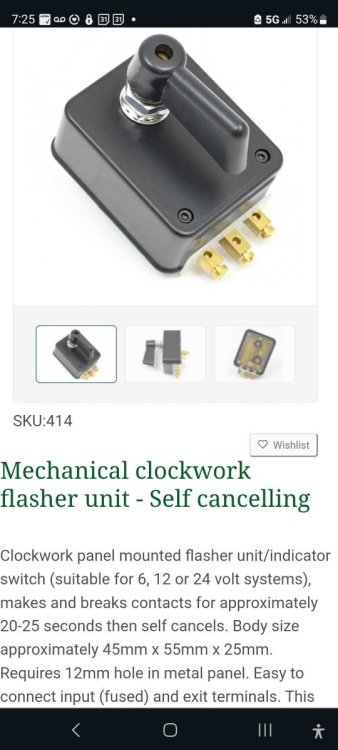

WTB Semaphore/Lucas Turn Signal Timer Switch

IamScotticus replied to IamScotticus's topic in Parts For Sale / Wanted

-

https://www.holden.co.uk/

-

Ok, I know I lack tact and empathy. I'm a jerk on a keyboard. Ignore me. Apologies. But strip away all the hurt feelings (I know there aren't any) and I still make a valid point. So here's something I'll say about the UI (User Interface for the personal check writers). I will admit I am memory loss sufferer. But I am still capable, with difficulty, of navigating multiple open apps and UIs all day at work. I get a mental work out every day. And although I've found the uploaded documents here before, it's still very difficult to locate every time I try. I know probably most Gen Xers are more competent than I, but I can certainly believe the navigation here can be clearer (General Discussion forum?). Others more senior, The "Quiet" generation, I'm sure it's more difficult for them. They're not going to complain about anything. They're much too polite. But they could still run a system well without all this computer and software stuff. They put men on the moon with slide rules. Ok, UI is a low priority. I get it. Too bad. It's still not as bad as FB (Face Book for the personal check writers). The good info is hidden in replies, not discoverable, and gone in days. I just want the good information about these cars to be easily accessible, for me, for everyone. And hopefully here for a long time. Thats all I wish for this forum.

-

Hylomar, anyone?

-

Home>Articles>Useful Resource Links> Ted Bundys bodies aren't buried this deep

-

-

Keeping a spare cable in the boot and the nut wrench in a tool kit is essential

-

Cable adjustment is a constant thing, it's going to stretch out. You will either run out of adjustment or it will snap, whichever happens first, so replacement in-between those two eventualities is ideal. A clutch replacement is an engine and transmission removal job. this means: definitely resurface the flywheel possibly replace the pressure plate (curly finger fingers or platen for flat faced bearing) definitely replace the throw out bearing definitely replace the pilot/spigot bearing definitely replace the clutch disc 190mm/7.5" Dia, 7/8"x 20 spline (4spd), Burton C752AF definitely replace the transmission fluid (Redline MTL is great stuff) definitely replace transmission front and rear oil seals definitely lube the prop shaft definitely replace the shifter saddle, if you have one definitely replace the clutch cable (5 ft)FKC1020 Escort Mk1 1600 burton CCESCYB1 possibly replace the cable speedo with a GPS unit (plug the cable drive opening) possibly replace engine and transmission mounts The good news is after all this you should have a working clutch, if you don't over tighten the bell housing bolts (yes, that is a thing). But before you go to all this trouble, just replace the clutch cable. It can stretch out unexpectedly and yes, snapping off at the top eyelet is a thing, especially with the later cheap reproductions (First Line). good info here: https://usa7s.net/ips/topic/14232-xflow-clutch-replacement/ https://www.caterhamlotus7.club/forums/topic/27661-clutch-release-bearing/#comment-493397 For how-to answers for your clutch job, a good start is Haynes Ford Escort MK1 1100 & 1300 1968- 74. That book should cover your clutch, transmission and most of your engine. Plenty on Ebay. I've bought many books from UK on Ebay. Another must have book is Tony Weale's 7 Restoration and Maintenance

-

I had a Saturn VUE that needed the clutch bled. Instructions were to submerge all 4 ft of hose, master and slave in fluid, and bleed it submerged. I sold off the car. Not because I didn't want to fix the clutch, but for a pesky door latch linkage clip that wouldn't stay connected. My point is, of all the things to do on a car, it's often the bleedings that have the most gremlins. You might have to go to extremes to get it done right.

-

The usual suspects? A re-bleed?

-

and more... https://www.thestar.com/autos/eye-candy-1985-fejer-super-seven-roadster/article_a71d6c8f-01d0-5faa-a01f-ac953bbcb3bd.html