-

Posts

3,266 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by JohnCh

-

I've searched for a Bosch cross-reference using some of the more common manufacturer's specific part numbers, but no luck that way. I'll see if have better luck searching for Bosch replacements using some of the car models that use the sensor. BTW this is one of the lists I've found: https://www.autodoc.co.uk/car-parts/oem/md091056 Switching sensors may be the final solution, but I first want to exhaust other possibilities. That sensor came with the car and consequently is plug and play from a wiring perspective; a simple one wire connection with the ground through the body. I like that simplicity. I also didn't realize getting the sensor data would be so hard. I hadn't considered building the map via the gauge. Great idea. I have that sitting on a shelf. I'll look into that option as well. Thanks, John

-

I know this is a longshot, does anyone know the calibration data for the temperature sensor Caterham uses for the coolant gauge and oil temperature? (parts store link here) I need this data to configure the AiM dash to accurately display oil temperature. Apparently, it's a very common sensor used by a number of different car manufacturers and made by several sensor companies under the generic part number MD091056, but no one seems to publish any of the data. I've already checked with both US and UK AiM support, a few Caterham specialists who install AiM dashes, and sensor manufacturers without success. When testing the resistance output at a few temperatures between freezing and boiling, it became clear this is not a linear output, which means mapping it myself with any accuracy isn't really an option. Thanks, John

-

. I am all too familiar with this The 9A9 is a lot more sophisticated than the 9A4. My challenge with Easimap is I'm used to the Emerald software which complicates my learning curve. It's not just learning how to use it but unlearning how I expect things to work given that prior experience. Please let me know how the mapping session goes with Steve.

-

I was very surprised at how easily it started and how well it ran. Hopefully that means the rest is reasonably close. I supplied them with the ignition map for my current engine which has the same compression ratio and a little less cam overlap and does well on local fuel, but they did the fuel based on their engines. @Bartman, are you having SBD do any remote tuning? I'm curious how well the logging and self-mapping work compared to the Emerald which makes that process pretty easy. The tach issue is resolved. There is AiM documentation from 2018 that discusses wiring CAN for the Caterham 420R. It indicates to select "Caterham 420R" from the ECU drop down list. It turns out that the MBE must have had some minor tweaks since then, and for current cars, MBE 9A4 should be selected instead. BTW had a bit of a scare when I tested this. The engine wouldn't start. A quick glance at the fuel pressure gauge showed zero pressure. It looks like the vibration from the air saw when cutting the opening for the fuse box had tripped the fuel cutoff switch. Another simple fix. -John

-

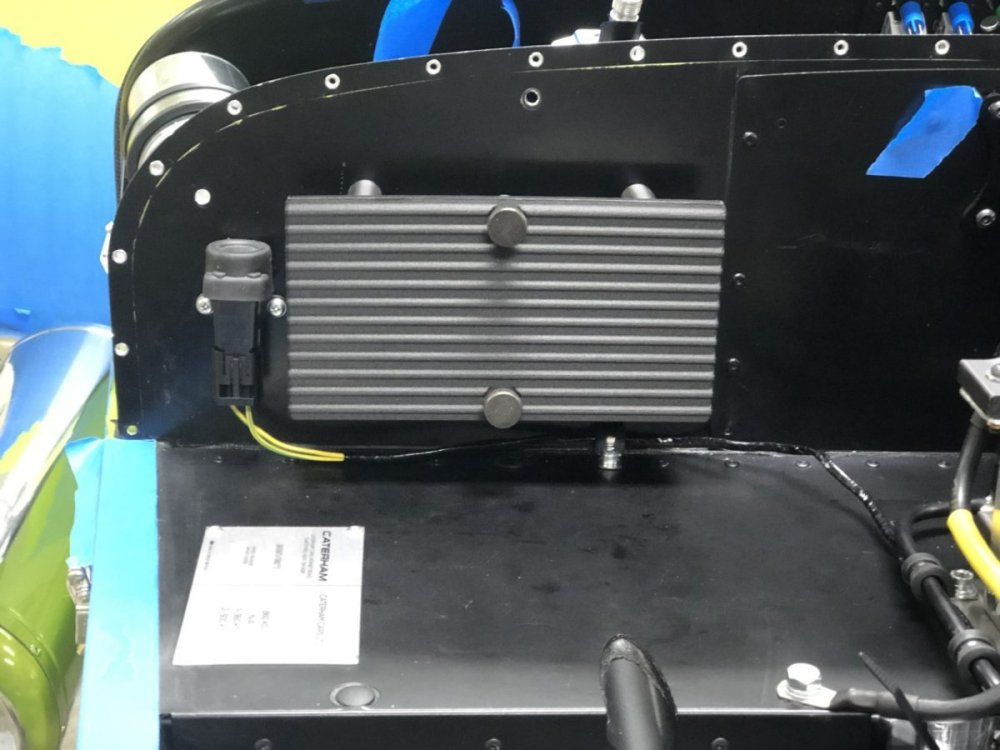

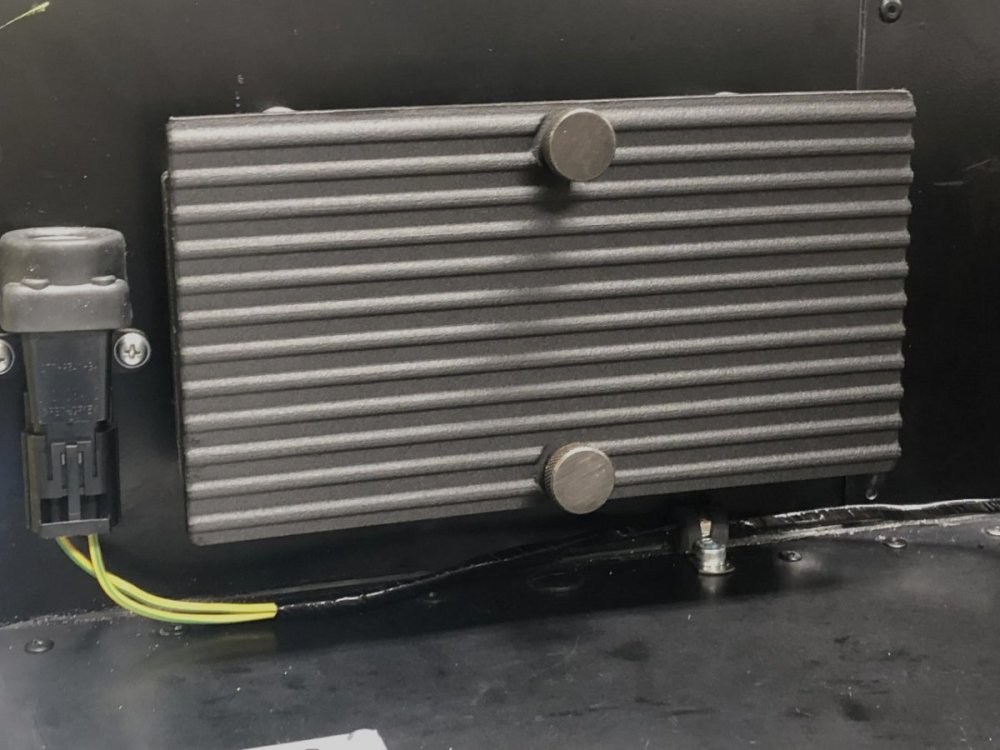

Thanks Bruce, I'm pleased with how it came out. I agree about the harness. It's a mess. To be fair to Caterham, it appears they have a single loom made for all cars and all markets. I'm sure that helps with the cost, reduces risk for a specific loom being out of stock, and eliminates another opportunity for them to install the wrong part in the wrong car Of course it also means there are a lot of unused wires and connectors for a given car. At some point in the very distant future, my plan is to rip out the harness and replace with a PDM. -John

-

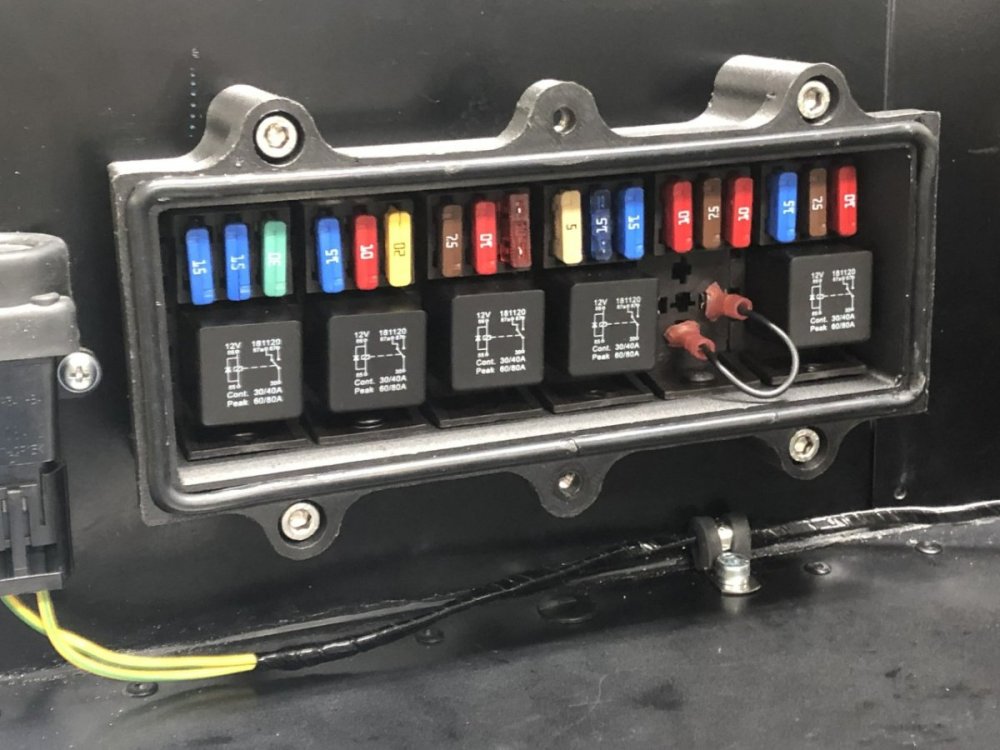

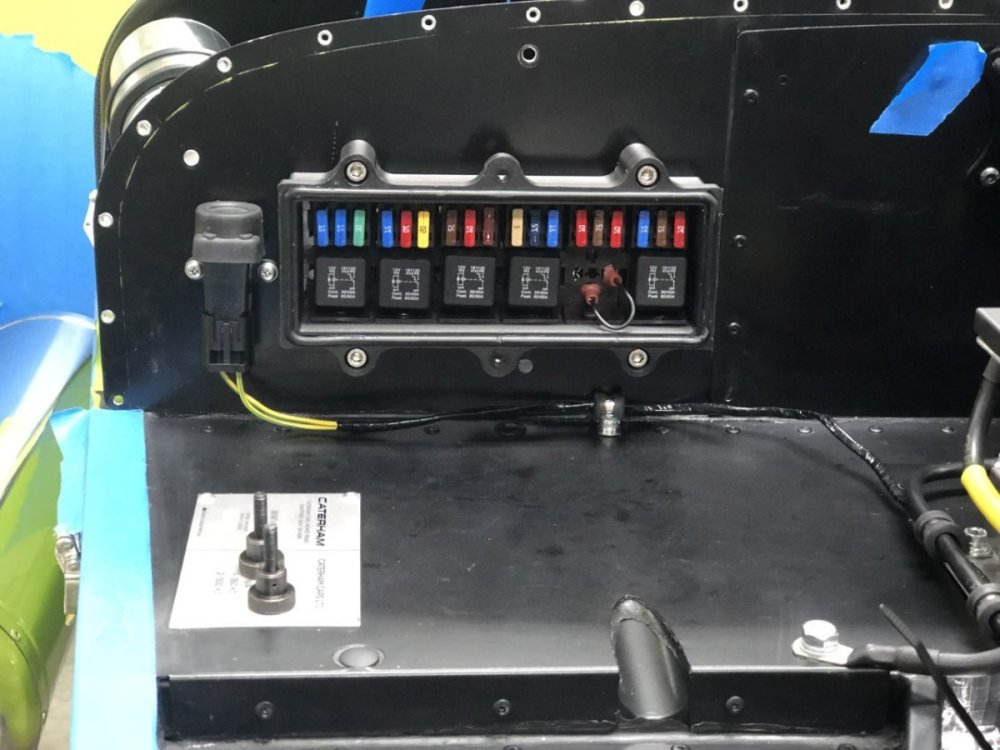

I realized when I started the engine this afternoon, I still had the fuel pump relay bypassed that is normally controlled by the ECU. Therefore, not a good test of the system and another attempt was warranted. This time, I also hooked up the laptop to check out what the ECU was seeing while the engine idled. The car still fired up perfectly with the relay in place, and while the AiM still showed the tach pegged at 10k rpm, Easimap showed it was 850 rpm, and apparently reading correctly. Easimap also showed the reason for the CEL: Rad Fan 1 Relay Fault. Not sure if there is actually an issue or the ECU is looking for something that isn't there, but it is a question for SBD. Next, I plugged the AiM into the laptop to check a few things. I didn't see anything configured differently than the instructions and the live screen showed that other data from the ECU sent over the CAN Bus was reading correctly. That's good news. I have a feeling I either missed something obvious, or the MBE had a change that moved the RPM output to a different channel than indicated in the instructions. I've sent a mail to AiM support to see what they suggest. With that out of the way, I decided to finish the fuse box install. That required cutting a hole in the firewall. It's the kind of job I always approach with trepidation because it's an opportunity to showcase my spastic tendencies. Fortunately, it come out great. Very pleased with this and it will make changing fuses and relays a lot easier. -John

-

I had a few minutes after eating lunch so decided to see what happens when I pressed the starter toggle. I turned it off quickly to avoid running the engine at low rpm before the cam break-in procedure. Before doing so, however, I glanced at the AiM and noticed the tach was way off and the check engine light was on, but the beast started immediately and had a nice idle, so I'll call that a win for now. Next step is buying some support time from SBD to go over some open questions and also get some guidance on identifying what triggered the CEL. -John

-

I'm sure @Crocwill be along soon to correct that misperception -John

-

My point was the design brief is tightly coupled with acceptable complexity. If the design brief contains a principle that supportability must continue for X years, then that would factor into the decision. Bottom line: know what you are trying to accomplish, know the constraints, and know how you value different things that are part of the process and outcome. That helps optimize the solution for you. -John

-

I'm a big believer in the simplest solution that meets the design brief, but that latter point is important. An old updraft carburetor is a lot simpler than a sophisticated electronic fuel injection system, but there is no question that if the design brief is to maximize power, fuel consumption, and drivability, the more complex EFI solution wins. If the design brief, however, is to allow the engine to run and make problems easier to diagnose, then stick with the updraft carb. -John

-

Loctite 648. I have 680, which is also used for tight fitting slip joints, but after looking into the specs, the 648 has much higher breakaway strength and that strength is not diminished to the same degree with heat (100C). Given these plugs are in the head which can get hot, and coming loose can lead to bonnet damage, it seemed a prudent delay. -John

-

I think it's a little late to tell me that -John

-

2023 USA7s HPDE at NJMP Lightning - CHANGED TO October 14 and 15

JohnCh replied to Croc's topic in National Events

The CSR (silver car) and Race nose cones also have the vent. A 620 nosecone adds a scoop for the intercooler. -John -

I did a number of things over the past week in anticipation of starting the engine this weekend. Unfortunately, that attempt will need to wait a few days. It turns out I forgot to order the special Loctite recommended to seal the aluminum plugs that block the unused injector ports in the head. On the positive front, I was able to speak to Variohm this week to get the calibration specs for the factory oil pressure sensor. They were very nice, very helpful people. With that information programmed into the AiM, it displayed the expected 0 psi with the engine off and reached about 46 psi while cranking. Having oil pressure at this stage was a relief. Next was prepping the fuel system. Which didn’t work. At all. After checking fuses and confirming there was no continuity between the pump and fuse box -- huh?? -- it dawned on me the fuel cutoff switch must have tripped. With that reset, the newly arrived capacitance fuel sensor worked, and the fuel pump kicked in. Aside from a slight leak at the pressure gauge, things were tight, and pressure was set to spec. Spark plugs -- which are something else I forgot to order earlier -- were gapped and installed, coolant was added and bled, throttle butterflies were set to 0.05mm and the TPS adjusted to 0.37v…and then I discovered the Loctite issue. Oh well. With time on my hands, I cleaned up some of the wiring under the dash (not that you can tell), added a Deutsch connector for power and ground for the AiM, and also did final prints for the new fuse box, oil filler cap, and air horn extensions. I'll save photos of the fuse box for when I do that install next weekend. -John

-

There are a lot of unused connections on current harnesses so that part is not a surprise. Reading the thread linked from your other thread about the unused connector, it appears Caterham only uses the MAP sensor for barometric pressure in the Sigma (not air temp like in the Duratec), so its absence should not be an issue at your elevation. -John

-

Thanks for clarifying. I cringed when I read that as full throttle and high revs with the engine still cold I just took a look at the factory map for the Duratec and there is very little coolant temp correction, but there is fairly significant air temp fueling correction. Based on your other thread, and assuming the Sigma map is similar, and like the Duratec, the Sigma also uses the MAP sensor as an air temperature sensor, I wonder if that is the issue? Check to see if the MAP sensor (should be in the back of the intake?) is plugged in. If it is, unplug it and make sure all the pins on the connector are fully seated. I've seen a bad connection on a new Caterham before caused by a poorly installed pin at the factory. -John

-

Is the above accurate or was the car already at operating temperature when you tried full throttle? If you had only driven it 2 miles at night, it's unlikely the engine was up to temperature. It could be that at full throttle, the coolant enrichment map was making a big fueling correction contributing to or causing the issue. Have you tried full throttle when the car is up to temperature? -John

-

After some correspondence with Caterham and a conversation with Variohm in the UK, I have my answer and posting it here in case anyone tries this in the future. The sensor is part of Variohm Eurosensor's EPT2100 series but is it a special configuration for Caterham. It outputs a linear signal of 0.1-5v and reads 0-7 bar, meaning it's 0.1v at 0 bar, 2.45v at 3.5 bar and 5v at 7 bar. -John

-

I'm approaching the home stretch and preparing for the first attempt at starting the engine. That means sorting out the upper radiator hose, hooking up the AiM, and finishing a number of other minor jobs. First, the upper radiator hose. The factory supplies a complex, molded hose that snakes under the intake and around the belt tensioner. Unfortunately, it won't work with my car due to changes required by the Jenveys; underslung throttle linkage and different belt tensioner. My initial hope was that cutting off the 90 deg elbow section at the back and replacing it with a longer elbow would create clearance for the throttle linkage, but that moved other bends forward, creating new interference problems. To resolve these, I opted for a Gates Vulco-Flex which is a convoluted hose that can make the gentle transitions around everything until it reaches an elbow at the back. The only issue was proximity to the tensioner pulley. There was only 1/4" clearance which would likely quickly go to 0" when the car was underway. A simple double bracket eliminates that risk. The lower portion clamps to a chassis diagonal and the upper part wraps around the hose to prevent it from moving closer to the tensioner. Next was finishing the wiring harness for the AiM, programming it, then setting up the MBE for CAN. Unfortunately, not everything is working correctly at this stage, but that was expected. I don't (yet) have the calibration data for the oil temp and oil pressure sensors, the tach is reading very high (7000rpm when cranking), and I noticed today the odometer shows I've already driven the car 3 miles despite the fact it doesn't run. On the positive front, the warning lights for turn signals/hazards and high beams work correctly as does the battery voltage readout. The AiM has a lot of sensors in its calibration library, including a Variohm oil pressure sensor. Because the current Caterhams use a Variohm sensor, I selected that absent of the actual sensor data. It's clearly not correct, showing -33psi when engine is off and reaching over 50psi when cranking. The positive is that the engine turns over and it appears to have oil pressure. I've been waiting to install the silencer until the passenger seat is in, but the seat runners have been delayed for a while. First, because they were out of stock, and now because customs has been sitting on them in Memphis for over 2 weeks. I was initially told not to worry about clearance issues between the primaries and side skin -- plenty of room to compensate for the 13mm taller engine -- and that seemed correct. Until today. With the springs in place to connect the collector and primaries, the clearance decreased to the point that it makes me a bit nervous: 2.5mm-3.7mm over the top two primaries. The Westfield has the same engine mounts as the Caterham. Starting it from cold to see how much the engine and the primaries moved during the lumpy idle phase and when the throttle was blipped showed virtually no movement. I'm hoping this means it will be okay. Unfortunately creating more clearance at this stage is potentially a lot of work as the dry sump tank is in the way of removing #1 (the one with the least clearance) and that is now full of break-in oil. I'll give this one additional thought. -John

-

-

Back in the game! And a (probably stupid) question.

JohnCh replied to Saudio's topic in General Sevens Discussion

I prefer to tell them the truth, which is pretty straight forward: It's a Caterham. Lotus made a car called the 7, then sold the rights to Caterham in the early 70's, who continue to produce it to this day. If they want to know more, you can add that they have evolved the car over the years to increase performance but have stayed true to the ethos of light weight. -John -

Does anyone know the Variohm Eurosensor part number for the oil pressure sensor Caterham fits to Sigma and Duratec cars? I need the specs to program an AiM display but unfortunately the sensor in my kit arrived with a damaged sticker that renders the part number unreadable. Thanks, John

-

So, tell us a little about yourselves

JohnCh replied to slngsht's topic in General Sevens Discussion

There was a forum member here several years ago who was also 6'6" and who fit in his SV with lowered floors. That doesn't mean you will fit or be comfortable, but it's certainly worth pursuing. Not everyone reads this thread (I know...it's shameful) so it might be worth starting a dedicated thread stating you are looking for an SV to try on for size in the Ohio area and indicate how far you are willing to travel. -John -

No apologies necessary! This has been a great conversation. Keeping it all in one place will simply improve discoverability for anyone having a similar issue in the future. -John

-

To avoid confusion, I moved the last few posts on the lifter issue to the dedicated thread on that topic: