-

Posts

3,266 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by JohnCh

-

I have a set, although I can only comment on appearance and weight as I'm still in the build stage. For my SV, Simon recommended digressive valving in front with 275 lb springs and standard valving with 150 lb progressive springs in the rear. They shipped with Hyperco springs though, which are blue. I forgot to weigh the fronts before installation, but the rear pair are 5lb 4.8 oz lighter than the factory 420R Bilsteins. -John

-

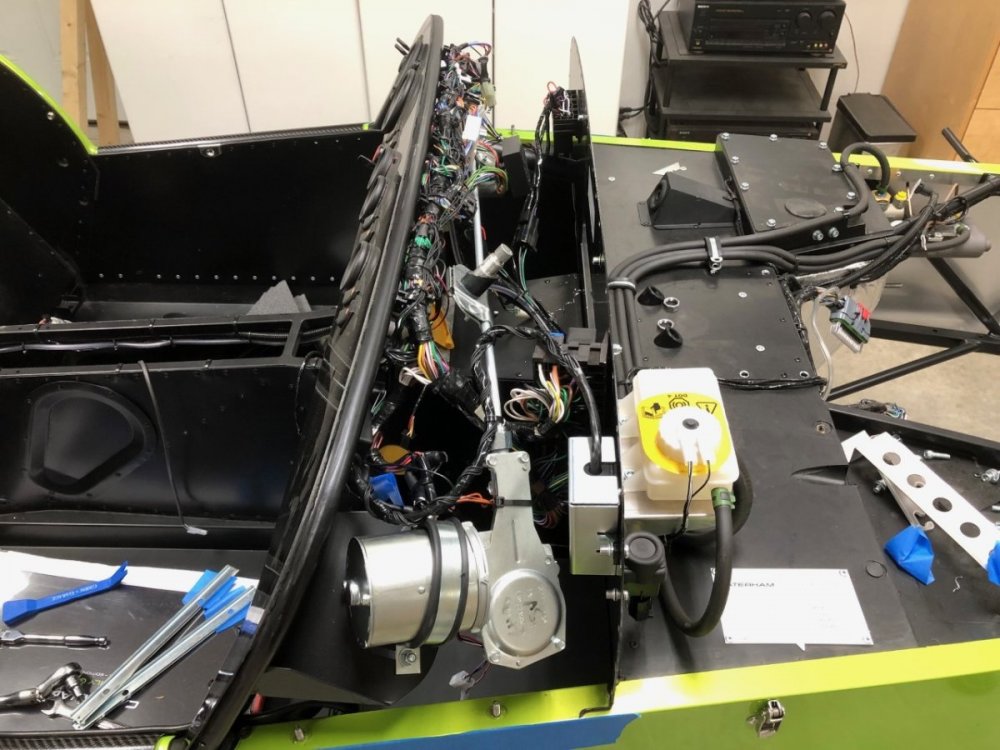

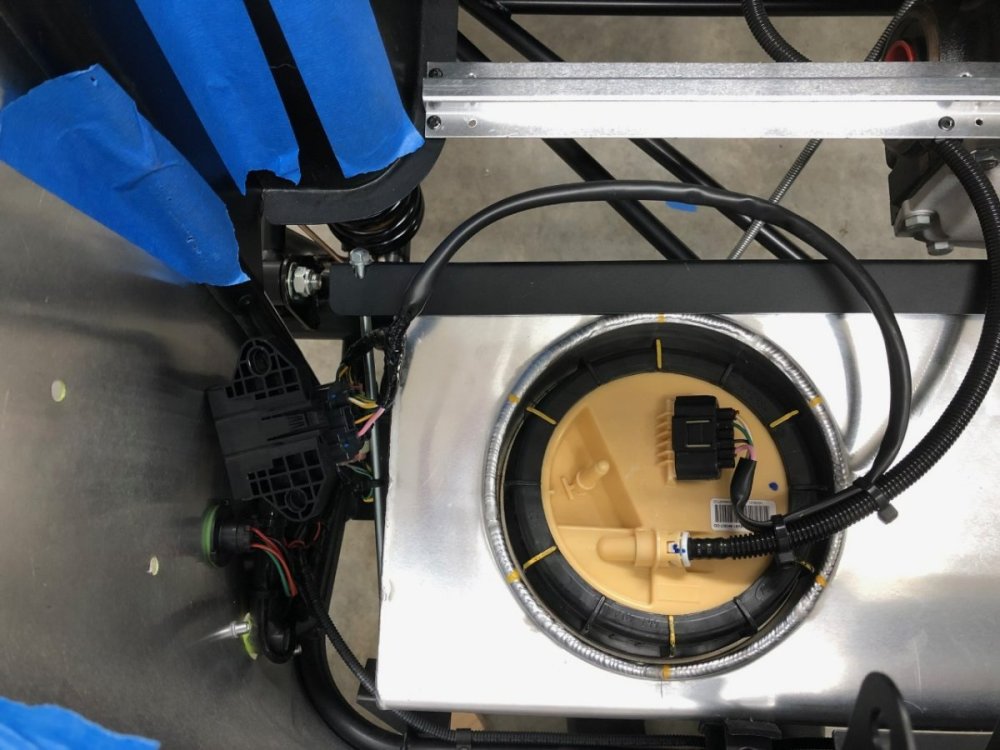

I've reached a point in the build where I need to get off my butt and start thinking through the fuel, dash, electrical, and wiring changes I'm making. Towards that end, I pulled the honeycomb to access the fuel tank area and also removed the in-tank pump. The original plan was to go with the combination of an external pump, Holley Hydramat, and capacitance fuel sender with low fuel warning light. I don't want to use the factory's returnless style system with ECU controlled fuel pump, as I prefer the tuning and troubleshooting simplicity of a return style system with adjustable pressure regulator. However, I may now opt to keep the factory in-tank pump, remove the PWM controller and run it flat out, then add the return run and regulator. I do want a low fuel warning light, since that has always come in handy on the Westfield, but I should be able to configure something based on the factory fuel sensor output to the AiM display. Looking at the available space for a cold air box, it was apparent that curved air horns would make better use of available space and enable longer inlet tract length. I fabbed up this curved extender that adds about 35mm of effective length and points the opening towards the horizon rather than the sky. I may tweak the design a bit before printing up a set, but it seems close. With the flywheel, clutch and pressure plate installed on the Esslinger, I decided to compare weights of the 2.4L to the 2.0L. Over the years, I've read weight differences between the 2.0L and 2.3L that ranged from 5-7kg. With both engines similarly dressed -- no alternator or starter -- but with the different intake systems, the delta was 5.0 kg. To verify scale accuracy, I weighed an object at 1.3 kg on my small scale then added that to the engine. The weight increased by 1.3 kg telling me that 5.0 kg difference is pretty accurate. One unknown in the weight comparison is how the 2.3L forged crank in the Esslinger differs in weight from the stock 2.3L crank. Not sure if it's lighter or heavier, and if it's just a kg or 2 different or if it's more dramatic. -John

-

I've been remiss in updating this thread. Rather than one really long post, I'll break this up into a couple. First, the rear suspension. Part of it is in place, but I need to sort out the reluctor rings for the traction control before the halfshafts can go in, which in turn are holding up the De Dion ears, hubs, and brakes installation. To make this a one-person job, I threw together a wooden cradle for my floor jack. Very stable and made that part of the job uneventful. A big discover during this stage of the build was the inaccuracy of the current Ikea manual. In their effort to make the manual better for visual learners, they opted to drop a lot of important text from the previous manuals. Apparently, Caterham thinks reading is hard. Consequently, things like mentioning the diff should be centered in the chassis based on measurements from specific spots which will likely result in different number of washers on either side of the diff, are no longer mentioned. Instead, the Ikea manual shows equal number of washers on either side implying better-than-actual chassis accuracy. There are a number of other times where the older manual comes through with important information, so my advice is to use both. Lining up the holes was fairly easy on the two bottom bolts, but the long top bolt was too misaligned to thread in with pressure. I really, really hate bashing a threaded fastener into place, but there was no other choice, so I pulled out the BFH and beat the bolt into submission. The De Dion, A-frame, shocks, and ARB were straightforward. I'm sure some of you are looking at the photo above and thinking to yourself "Nooo! You put the rear shocks in before the rollover bar!" That was intentional. Bruce Beachman is of the belief that the rollover bar should be the last thing to go in and since I may need to remove the fuel tank, which requires rollover bar removal, I opted to follow his advice. That means the rear shocks will come out at some point in the future. -John

-

Here's a lousy picture of mine. The grease nipple is located in the center of the photo. From what I've read, the cars are shipped with the u-joints pre-greased, but many consider it a good idea to top them up because...well, Caterham. 'Nuff said. -John

-

Thanks @papak, I contacted Tom over the weekend, who confirmed he still has those on hand. Although that remains an option, it looks like a modified oil filler cap will be all that's required.

-

Thanks Bartman, I hadn't seen the Westermann cap before, but it's similar to what I'll attempt later. The key difference is that rather than have the cap fully below the lip and requiring a tool to open, I think there is enough room to place a thin aluminum lid ~1-2mm thick on top of the cap, then bend the sides of the aluminum downward to give something for fingers to grab when opening. Thanks, John

-

Thanks @Bartman, that's along the lines of what I'm planning. Looking at the Ford factory oil filler cap yesterday, I saw some ways to modify it so that it only extends about 1-2mm over the lip, which will give me more than enough clearance. -John

-

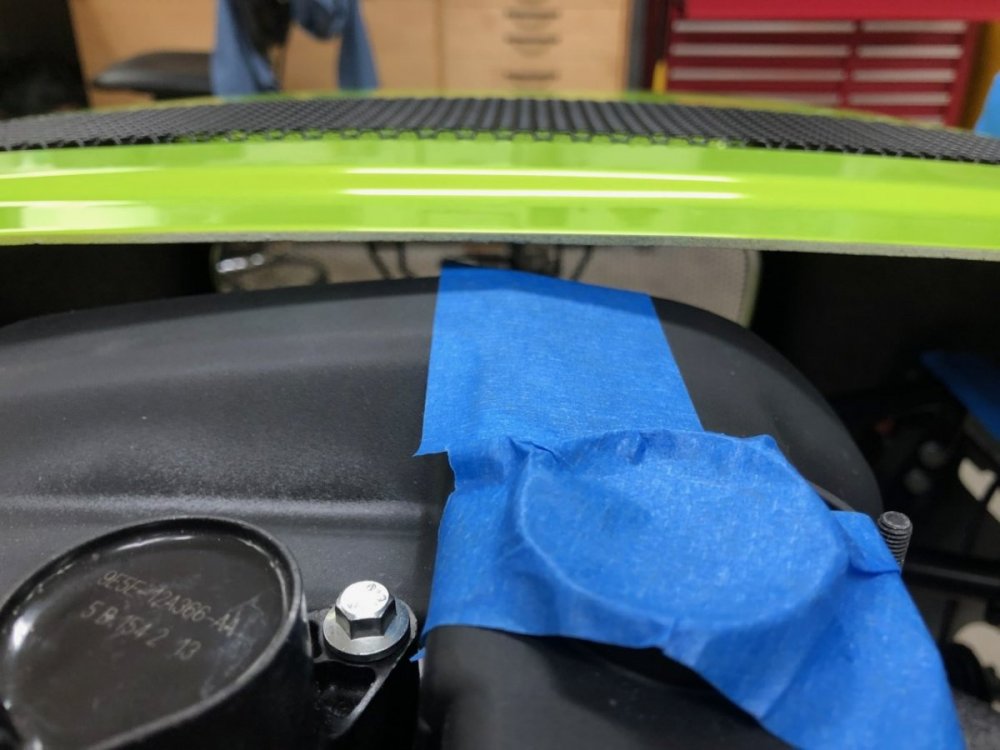

It occurred to me that the bonnet is pretty floppy, and the measurements taken earlier were without the nosecone in place, which might lift the front of the bonnet. Turns out it does. It appears that before any foam rubber is added to the nosecone lip that supports the bonnet, I've gained another 5mm. If I can replace the oil filler cap with a custom version that doesn't extend over the lip, or if it does, shave the lip down by that same thickness, I'll be fine as-is. -John

-

I took a look at the engine mounts yesterday with that thought in mind. It looks like 3mm could be shaved from the bottom of the arms that bolt to the block, and the rubber bobbins could potentially have another 5mm shaved from them. Not sure if that would be a good or bad idea, but then there is the trans mount which I have yet to examine. And with engine rocking, some buffer is desirable. I know there are other people out there running the 2.3L in an S3 without the shortened valve cover but not sure if they live with the occasional interference or if chassis-to -chassis differences and changes over the years contribute to the extra space. Can anyone comment? Thanks, John

-

Great suggestion @MV8. I forgot I bought an oscillating tool a few years ago to help with some corner sanding. After wrapping the engine in plastic to ensure no aluminum shavings would work their way into places they don't belong, the metal blade produced a clean, accurate cut. Photos below show the end result and the extra space created in the engine bay. The next attempt at the temporary install was much, much quicker. It looks like I'll need to shim out the right-hand engine mount from the block to get the engine mount to line up with the chassis holes, but it's only off by about one washer thickness, so should be straightforward. Less straightforward is engine to bonnet clearance. With the oil cap removed and the bonnet resting on that mating surface, the bonnet was sitting about 2mm above the side skin. It looks like a modified cam cover is in my future. Raceline sells one that will work height-wise, but their webpage states it's designed to be used with standard Ford coil pack and that coil-on-plugs can't be used. However, one of the three photos shows the cam cover installed in a car with COP in place, so clearly it can be done. Are there any other options out there? I seem to recall that Birkin has/had one? -John

-

Drilling out the side skin to clean up the holes was uneventful. With that blocker out of the way, I decided to try the temp engine install again after work. Based on everything I've read, installing the engine is tight in these cars, but I assumed that since I wasn't installing the engine/gearbox unit, and simply the long block, this would be easy. Just drop it straight down. Well...no. Doing it solo was a lot fiddlier than I expected. I couldn't just drop it down, but rather had to move the block fore and aft as I slowly lowered it down while simultaneously pandering to my paranoia about damaging my new car. Once the engine was roughly in place, and the RH mount could be reinstalled (otherwise, chassis tubes are in the way), I discovered it was impossible to get both engine mounts to align. With one side aligned, the other was always slightly out. It was close, but not close enough to force the issue. Surely, I was missing something? I kept at it, willing chassis tubes and the engine to occupy the same space at the same time but was unsuccessful. Then I had an epiphany. Well, more of a hypothesis that made me swear up a storm in anticipation of being proven correct. Caterham uses the Raceline dry sump system. To keep it simple, I bought the Raceline dry sump system for this engine. Raceline and I had many conversations about my project, and I obtained a lot of parts from them. i.e. they knew this was going in a 2022 420R SV. It turns out the front of the dry sump pan they provided extends out from either side of the block by about 35mm more than their pan fitted to the Caterham 420 engine. The extensions contain through-holes that appear to be engine mounts for a different installation. With that extra material in place, engine installation is a physics impossibility. Tomorrow, I break out a hacksaw and files. Tonight, I open a Guinness. Or two. Or... -John

-

Thanks @MV8 I missed that when digging through that version of the manual, but it is the size I initially bough. Bruce Beachman also got back to me quickly, confirming the size and that I will need to drill into the side skin. -John

-

I planned to do a temp install of the engine over lunch today to help me sort out available space for my non-standard items. Of course, Caterham forgot to include the bolts that attach the engine mounting bobbins to the chassis and the size is not listed in the various build manuals I have on hand. Based on the size of the holes in those mounts and the matching holes in the chassis, it looks like either M8 or 5/16". Opting for the former, and buying suitably sized fasteners, I discovered that when Caterham punched the hole in the bottom of the side skin for those fasteners, they drove up some of the aluminum skin several mm into the holes. This shrinks down the bottom of the hole to something that can only handle an M6 or 1/4" fastener. That seems too small for an engine mount. Can anyone confirm it the larger size is correct and if I'm supposed to drill out superfluous side skin material from underneath? The photo below is representative of all 4 holes. Thanks, John

-

Thanks @sltous! I wondered about those first and last holes. I didn't have an issue drilling out the rivets in those locations but did wonder if I could drill perpendicular-enough hole for the rivnut. -John

-

Are you looking for an actual cup holder, or a hydration solution when going on long drives? If the latter, consider something like this Camelbak. I have an older version that attaches behind the seat (put strap through shoulder harness cutouts or around the headrest.) G-forces don't create a mess, it stays out of the way, and it can be filled with ice to keep the beverage cold on very hot days. -John

-

Thanks @MV8 I'll keep that change in mind when I get to that part of the project. I have a lot of wiring to undo, redo, and replace before I even think about that part of the build.

-

If your wiring harness can't accommodate the DRL, you might be able to fabricate something simple with a relay. For my car, I plan to use a relay that feeds power from a switched 12v+ to the DRLs (low wattage LEDs), and when the running lights are on, that circuit energizes the coil, cuts that connection, and turns the DRLs off. This way the DRLs come on with the key but don't operate with the headlights on. From a wiring perspective, I'm thinking: 87a = switched 12v+ 87 = dead end 30 = 12v+ feed to DRL 86 = 12v+ from running lights 85 = ground Does anyone see any obvious flaws with this approach or have a better way to do it? Thanks, John

-

Congrats! One word of warning as you track your ship; if it's like my experience, it will disappear for several days at a time (4 days was the longest). Although that can be a bit concerning, it turns out it was just GPS/app issues, not a shipwreck or pirates. I'm sure you'll have the car soon. -John

-

Thanks @11Budlite that's a much better installation for access. Interesting that the fuse boxes are so different between our cars. I would expect the fuse count to be the same despite the three years and different engine spec but you have 26 fuses vs. 18 in mine. Some of that might be attributed to spares, but not all. I've been running a Ballistic EVO 2 in the Westfield for years. It's started the car after sitting overnight in mid 30F weather and can be picked up with a thumb and forefinger. What's not to like about that? Now that Ballistic is out of business, I'm debating between the AntiGravity and EarthX. Good to hear yours is working well. -John

-

Last night I had this same thought. I don't think room will be an issue given I won't have a heater box, I'll run a smaller Lithium battery, and I may not use the factory air filter setup. I'll check space availability once I figure out where things will fit with the revised dash layout and where I mount the ECU. Thanks Bruce. Absolutely no rush since I won't get to this for a while, but when you have time, I'd love to see it. -John

-

Thanks, I'll add those parts to the list.

-

Thanks to the help of a few people on the forum, I was finally able to remove the scuttle. See thread I linked to above for details if you tackle this yourself in the future. Since I was doing this solo and wasn't sure if the windscreen would attempt to tip backward once the 4 securing bolts were removed, I burned through a bunch of blue tape and had a razor blade handy to cut them when I attempted to lift it off. Worked flawlessly. Probably the only time I'll say that throughout the entire build. For some reason, the factory didn't trim the windscreen rubber on either side. I can take care of this now that the windscreen and stanchions are removed. Wow, that's a lot of wires to undo! I'm still waiting for my 620 dash wiring sub loom to arrive which will replace a chunk of them, and the AiM will receive signals from the ECU for all the gauges, so most of those wires will also go. CAN will make this much cleaner. With the scuttle removed, I'm left shaking my head at the fuse box. It seems that a contortionist will be required to reach several of those fuses. Once I understand how the cover is supposed to fit, I'll see if there is a way to reposition that for much easier access. The Westfield mounts them under the bonnet in front of the scuttle, which makes for much easier roadside fuse replacement. -John

-

I confirmed that with sufficient blue tape to prevent the windscreen from falling backward and protect the scuttle paint, removing the windscreen is indeed a one-person job. For anyone doing this in the future, items to remove are: 26 rivets at the front of the scuttle, plus 2 more on the sides 4 scuttle retaining nuts that attach the scuttle to the chassis tubes Windscreen wiper arm nuts Windscreen washer tube The two screws in the pair of tonneau snaps on the top center of the dash Wiring loom connection box secured by Velcro to the underside of the scuttle near the tonneau snaps Two heated screen wires located at either end of the windscreen. I was unable to remove the grommets, so resorted to cutting off the connectors. I'll probably replace them with bullet connectors that can slide through the grommet to make that process easier The windscreen with stanchions You will also need a lot of blue tape and a Guinness to steady your nerves. I'll add more pictures in my build thread. -John

-

Thanks @sltous, @11Budlite confirmed he also removes the windscreen first. I read in someone's blog they recommend three (no, not a typo) people be on hand to remove the windscreen. I might take a shot at doing it solo later today. I think I can stabilize things enough with tape and cardboard that if it proves problematic doing it myself, I can get the windscreen safely back into place without damage. Famous last words... -John

-

If an M4 rivnut will fit in that location, I'm going that route. The M4 button head diameter is the same as the rivet it replaces, so aesthetically it's a wash, and the M3 heads are a little too easy to strip in my experience. But then again, I'm a klutz. I removed all the other things holding the scuttle in place: heated screen wires, wiper nuts, washer tube, some electrical box velcro'd to the underside, etc. However, it appears removing it is a two-person job given the various bits that are in the way. It will either take a lot of simultaneous maneuvering from both sides, or the windscreen needs to come off so the scuttle can flex a bit to the sides and clear everything. I suspect some cars are easier in this regard given the hand-built nature. The Westfield, in contrast, is a one-person job. Unbolt everything and lift straight up. -John

.jpg.1b1c5589b65565f6b4974263ce8296bd.jpg)