-

Posts

3,266 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by JohnCh

-

Driving with no center console: reduced buffeting?

JohnCh replied to TurboWood's topic in General Tech

This is something I've been kicking around and plan to do some experimentation when the car is done. I remember reading somewhere many years ago that drilling a large hole (2-3") in the lower center portion of the windscreen dramatically reduces buffeting. From my own experience, very large wind deflectors make a huge difference, but at the expense of even more drag. Given what they can do in racing with aerodynamics by redirecting and speeding up/slowing down air to create high- and low-pressure zones in very specific spots, I suspect there is an opportunity for air management to make things more acceptable. i.e. use walls of air to change what's occurring rather than redirection by big pieces of Lexan. At some point, I'd love to tape strings of yarn all over the car, then attach a 360 deg camera to the roll bar and get a good look at what's happening. -John -

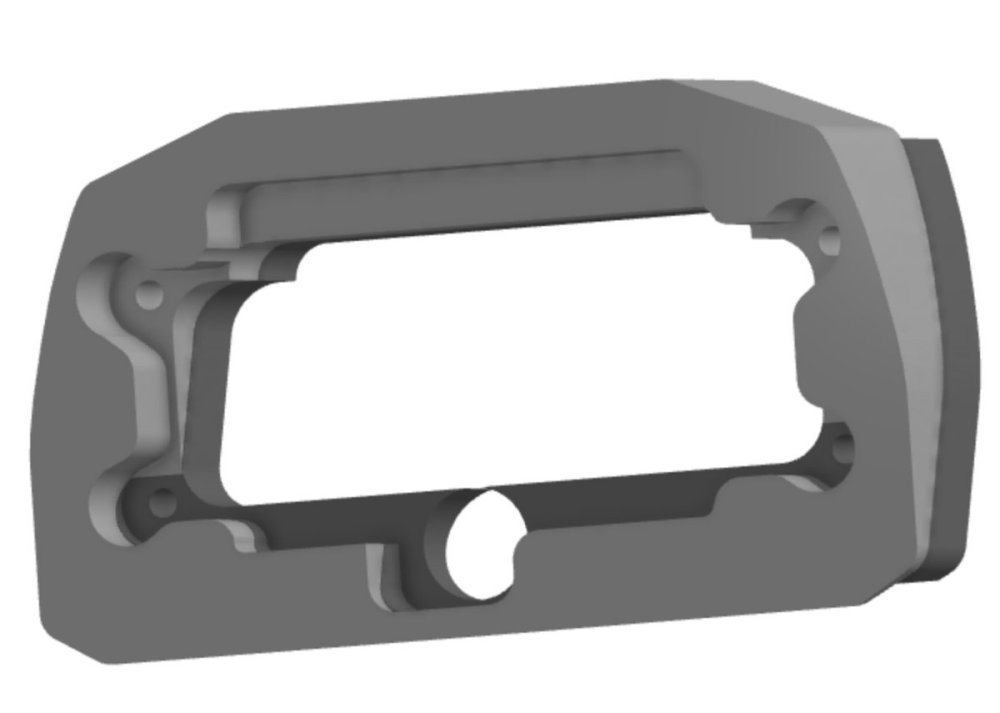

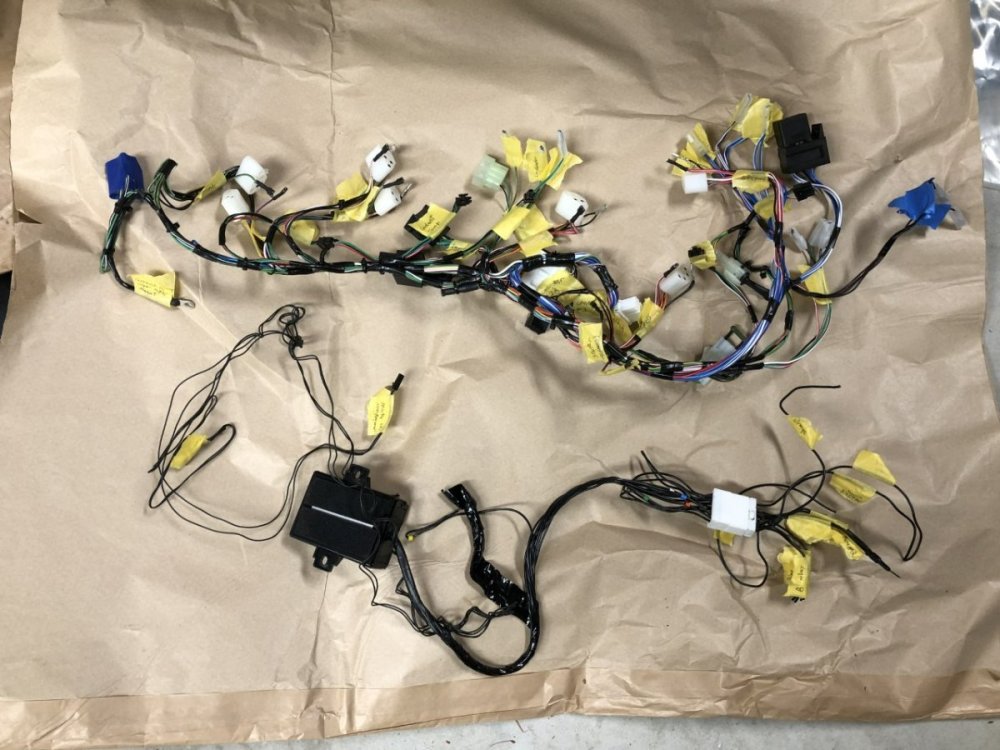

@sf4018, are you saying that without the pump control relay, the pump is fed by a constant 12v+ feed and runs even with the key off? I've had a change of plans and will no longer use the Emerald ECU and will instead use an unlocked MBE so this is something I'll need to address. I was under the impression from the factory that the stock pump can be run full time, so perhaps this is simply a setting in the software if the relay is not removed? Speaking of the ECU, as I dug into figuring out how to splice in the loom given it duplicates parts of the chassis harness (e.g. main and fuel relays), I realized this was a much bigger project with a high probability of creating head scratching problems down the road. None of the available wiring diagrams match my car and they are not particularly user-friendly for tracing by an amateur; or at least not compared to what I'm used to using. It seems there is a high probability of unintentionally orphaning a circuit and there will either need to be sufficient carnage to the chassis harness to make reverting to stock a nightmare, or I'll have tons of wires and two big connectors sitting in the engine bay if I try to keep it whole. Bottom line, it will look amateurish, which is not the look I'm going for. Just because I don't know what I'm doing, doesn't mean the car has to broadcast that fact whenever the bonnet is removed. In the interest of my time and what's left of my sanity, I've decided to leave the Emerald for a future upgrade, at which point I'll probably pull the harness and redo something with PDM control. This does mean I lose traction control, knock control, and switchable maps for now, but it also means finishing the rear suspension is no longer on hold due to the reluctor ring delays, and I won't need to deal with working out the sensor brackets and wire routing to the 4 corners. Given my speed, that's 4-6 weeks' time savings right there Thanks, I'm pleased with it. One surprise is how well the carbon fiber nylon filament complements the carbon dash. There is a grayish sheen to it that is a match for the grayish, shiny portion of the carbon fiber weave. It actually looks intentional from a design standpoint. Below is a screenshot from CAD that shows the parts. The AiM slips into the front of the lighter gray portion, and the darker gray is the back piece which is a little shorter to fit between the dash hoops. The carbon fiber dash is then sandwiched between the two. I know you do 3D printing. if you are interested in the source files, just let me know. -John

-

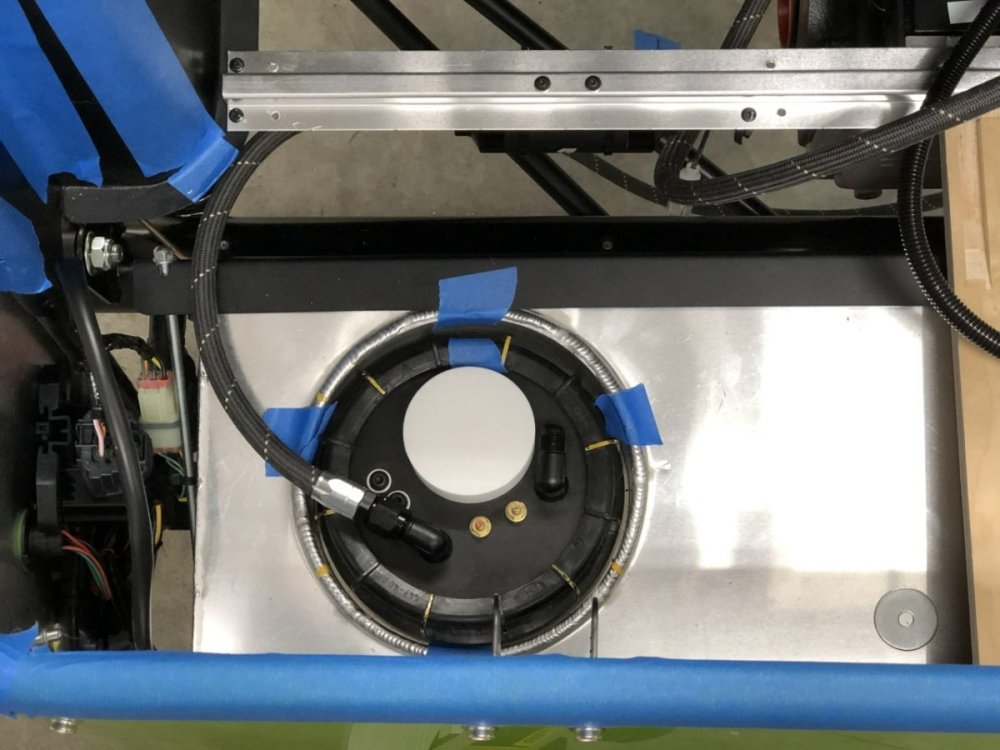

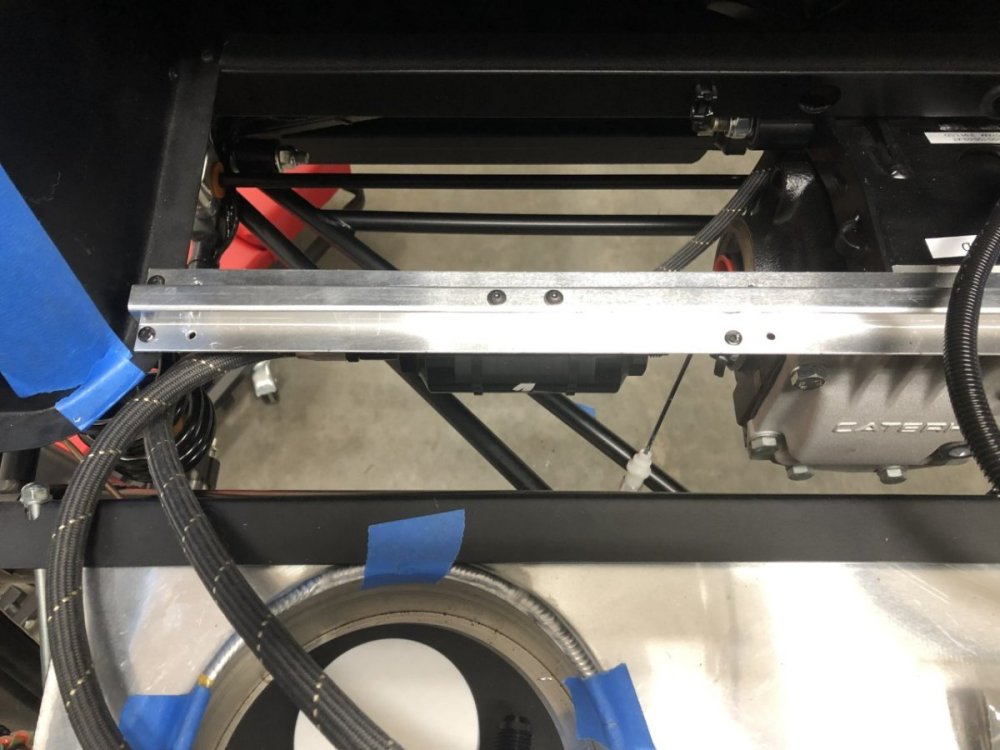

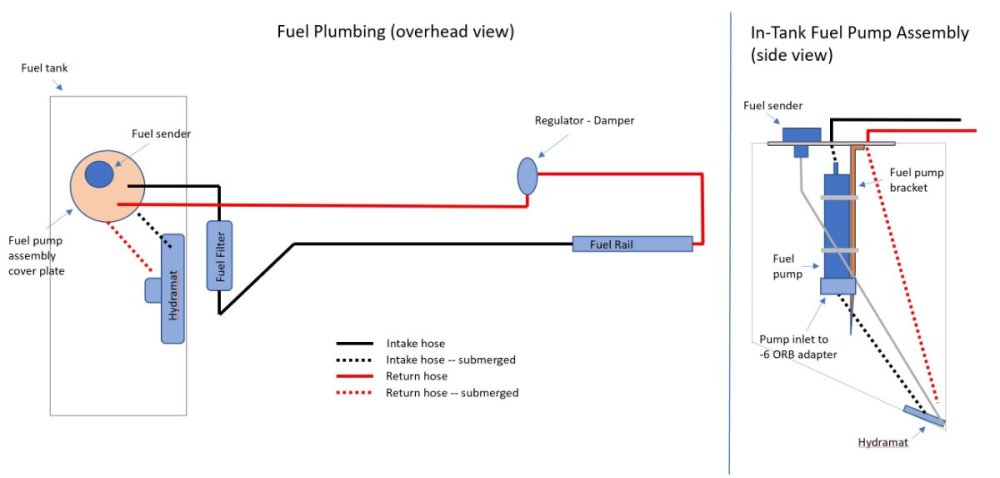

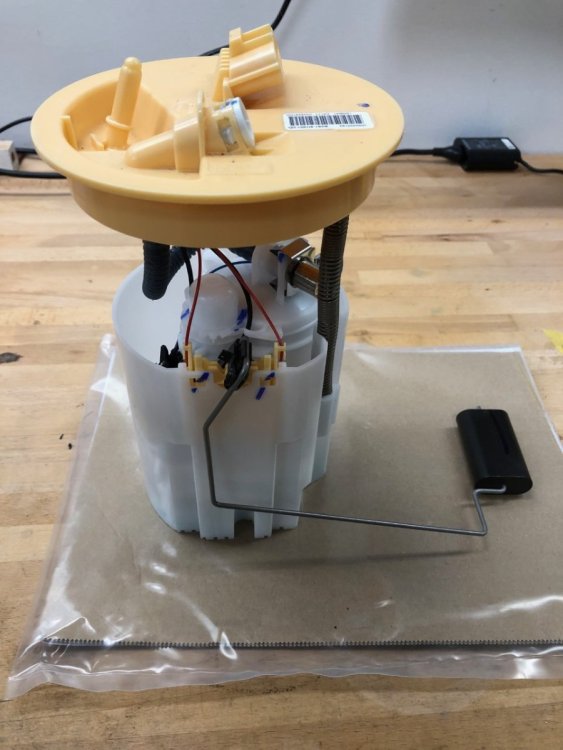

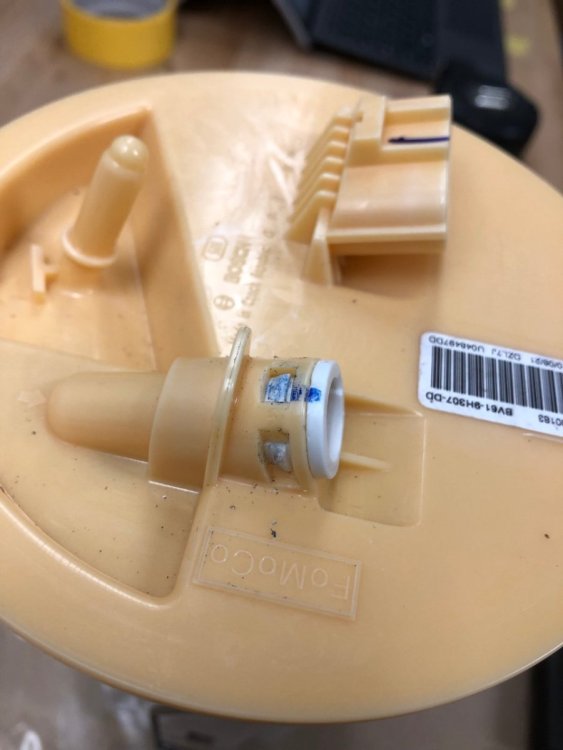

Next up, the fuel system. This isn't quite finished. I'm still waiting on a couple of fittings, but it's close enough to show pictures of in-progress work. The biggest challenge was fabricating a replacement fuel pump/sender/pre-pump filter assembly. As noted earlier in this thread, the stock setup doesn't allow the pump to reach the last gallon of fuel, uses a pump that is reportedly marginal for the power levels of this engine, has a sender that is more directional than accurate, and uses very small diameter hose. The replacement is a 3D printed lid, 255 lph pump, AN -6 fittings, capacitance fuel sender, and a Holley Hydramat. The fuel sender isn't here yet, but the white cylinder in the photo represents the head unit. A 1/2" diameter tube then extends into the tank at an angle, ending about 1/2" from the bottom front. Space in the tank is really tight and it took some fiddling to make all of this fit. Much time was spent experimenting with different fittings and how things were located on the lid to optimize available space. Unfortunately, I had to do this twice as my first attempt was made before fitting the Hydramat in the tank. When I did so, I discovered the tank has a baffle in the middle which forces the Hydramat closer to the fuel pump assembly than I anticipated. With the specific space constraints, this meant moving the pump from the right side of the lid to the left, then working out where the submersible hose and fuel sender tube would cross. Once the 90-degree fitting that attaches the Hydramat to the intake hose arrives, the fuel pump position on the aluminum bar can be finalized. I'll add a second hose clamp, cut the excess bar, and file some reliefs to help position the hose clamps. Then cut the hoses to length, add lock nuts and finish it up. I just hope it works One of the other shortcomings of the factory setup is a lack of a post pump filter. The sock that pulls the fuel to the pump operates as a pre-filter, but there is nothing between the pump and the injectors. To address this, I printed up a fuel filter holder that mounts the filter under the boot floor. It's out of the way but easy to access for maintenance. If one of the two missing fittings arrives tomorrow as planned, I should have the fuel plumbing 90% finished this weekend. That last 10% is the hose run from the front of the rail to the regulator/damper and requires that second missing fitting, which I don't expect until the end of next week. -John

-

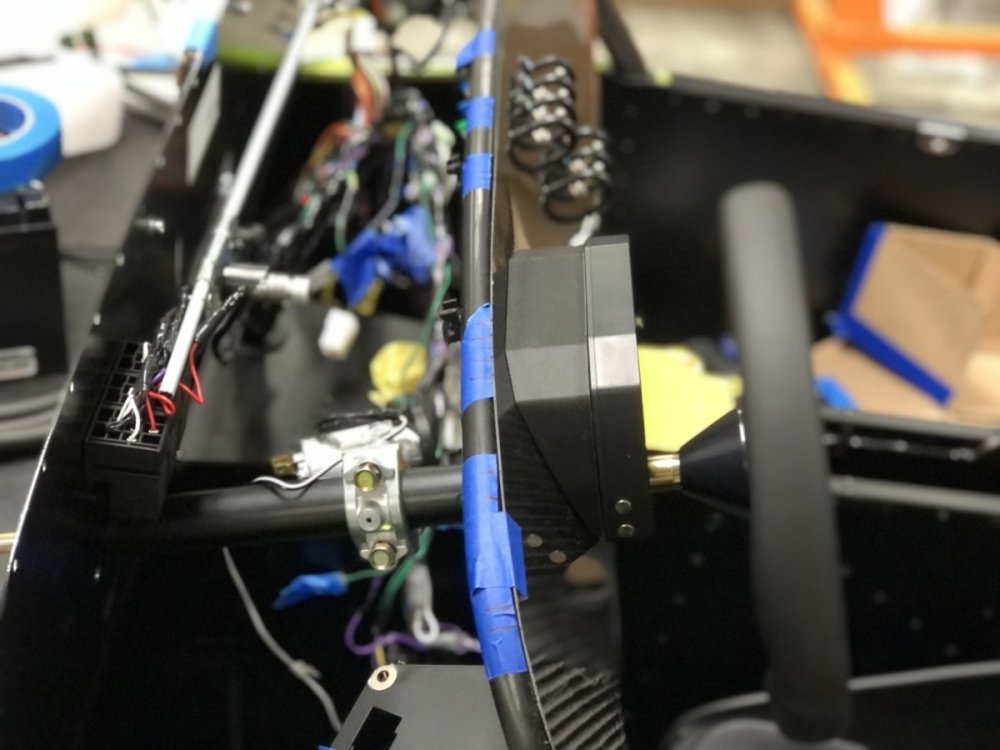

For the AiM display, rather than attach it so the screen is in the same plane as the dash where it's prone to severe glare on a sunny day, I designed a two-part bezel that tilts it forward a little over 20 degrees and doubles as a clamp to attach it to the dash. This positions the display directly at the driver rather than over their head. Because the seat and steering wheel are not orthogonal to the dash, the seat and wheel were temporarily installed and adjusted for me, then the display location was optimized so it is centered in the steering wheel when viewed from that position. This means the display looks a bit off center when viewed from anywhere other than the driver's seat. Still to come are the steering wheel mounted buttons and the hidden glove compartment which will mount in front of the gear lever. -John

-

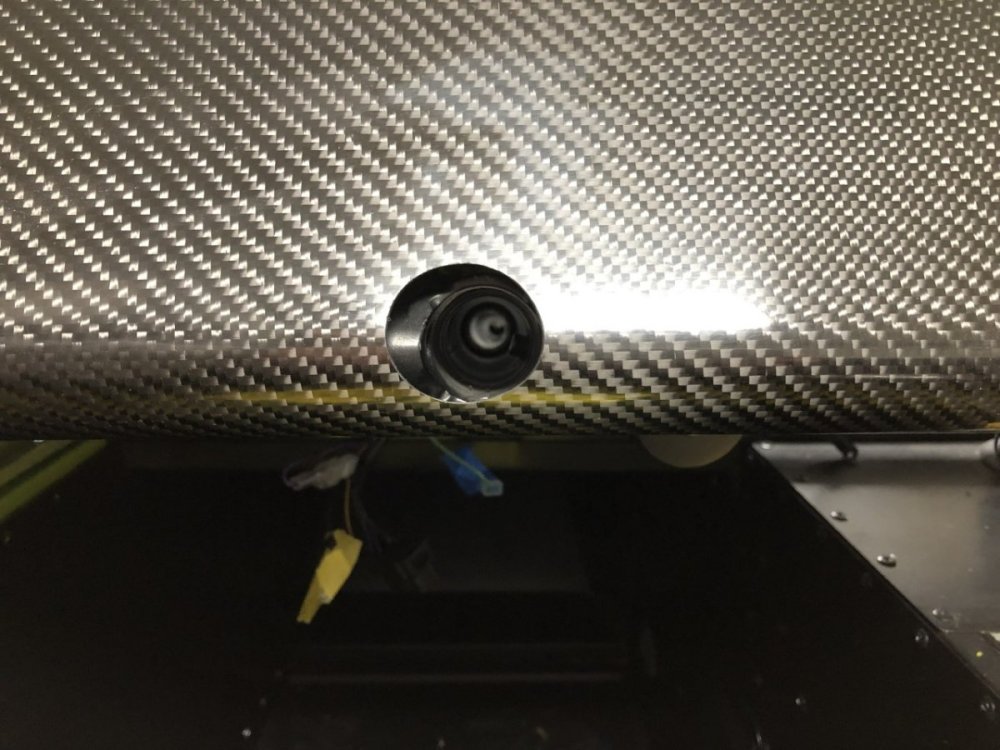

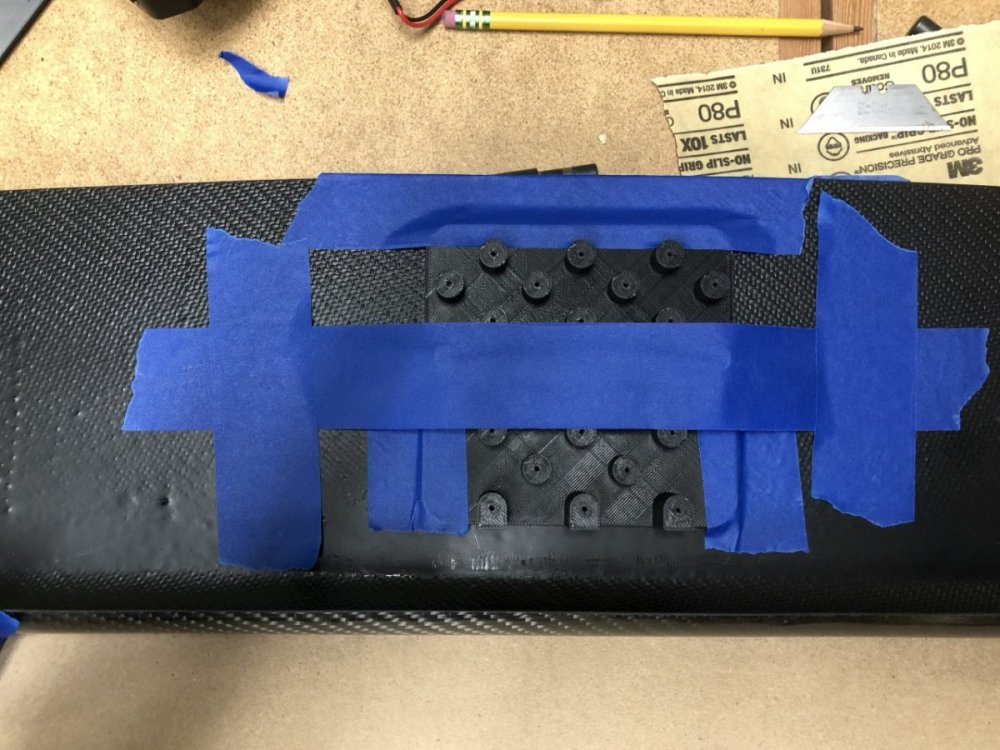

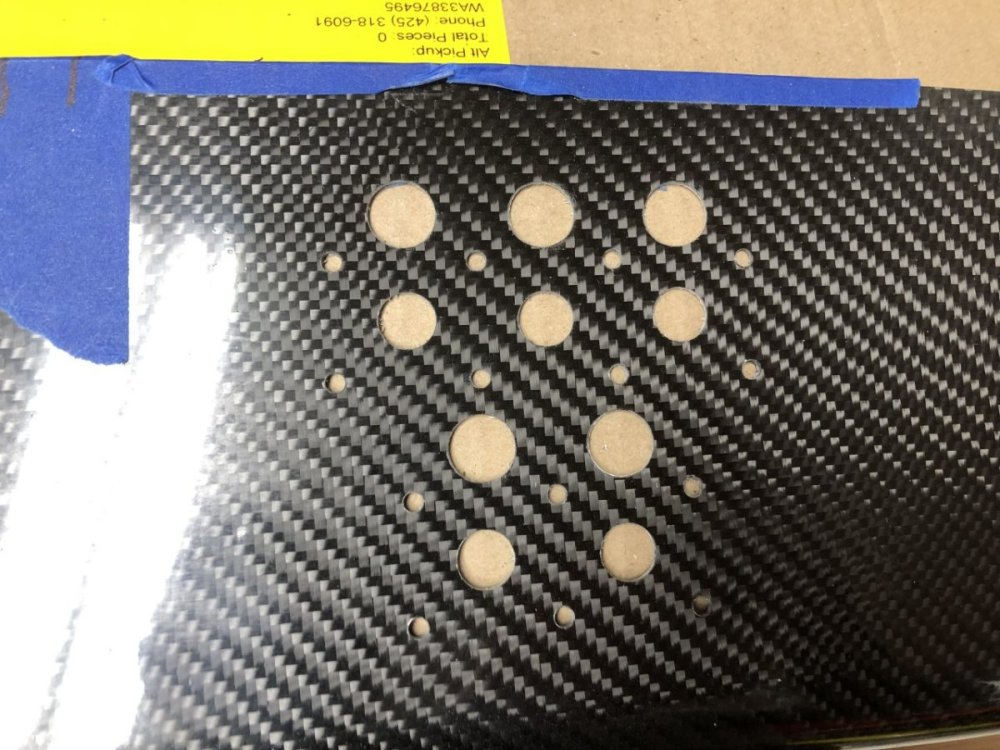

Time for a long overdue update. The past month has been marked by a lot of activity but not much in the way of results. Between shipping delays, incorrect parts, two snowstorms, one ice storm, one windstorm, power outages, and the flu, things have taken a lot longer than expected. This has been compounded by far too much head scratching on how to make everything fit. Every aspect of the Caterham is very tight compared to the Westfield. Things I assumed would be easy to fit based on the Westfield, are anything but on the Caterham. Because this update is long and picture heavy, I'll break this into a few posts. First up, the dash - part 1. Before working on the dash itself, this was a great opportunity to de-immobilize the car. With that out of the way, the 420 gauge and switch sub-loom was removed in preparation for the 620 replacement loom, which has been on order for….months. The immobilizer is the bottom loom in this photo. Although the blank dash Croc acquired from Westermann for CatKong was well made and fit without any fettling, the dash they sent me appears to have been made from a different mold. The quality is not to the level that I expected. The hole for the steering column is offset by 1/3", the shape was off and required removal of 1/8" - 3/16" of material around the shoulders of the dash so the scuttle would fit, there are few places where mold surface imperfections are visible when the light hits it just right, and the surface was scuffed. Some time with 80 grit sandpaper, a file, and a buffing wheel made things acceptable from a fit perspective, but the cosmetic issues still bother me. In some light, it looks great. In others, it looks old and a little worse for wear. To be fair, the stock dash also arrived with some scuffing, albeit, not as severe. I plan to leave it as-is for now, but prior to gluing it in place, I may remove the display and switch gear then tackle it again with a more aggressive polishing compound. If anyone has experience here, I'd love the advice. Cutting the holes for the switches was a little nerve-racking. First challenge was drilling the holes in precisely the right spots. To facilitate this, I printed a drill template sized for a 1/16" drill bit that placed the switchgear to the factory 620 spacing, and aligned everything correctly in the vertical plane when rested on the lower hoop. Second was the drilling method. The Internet experts have a lot of opinions: specialty spade bits, sharpen normal drill bits after every other hole, only used carbide bits, drill backwards, only get the size close, then finish with sandpaper, etc. Through a little trial and error on the small section of dash cut out for the AiM, I discovered that a stepped drill bit works great on carbon fiber. I used normal, unsharpened drill bits, increasing in size from 1/16" to 7/32" then switched to the stepped drill bit and prayed to multiple deities. To add a little more rigidity, a backing plate was printed out of carbon fiber impregnated nylon. This is a great material for car parts as the carbon fiber adds rigidity, and the nylon is chemically resistant, and can handle 160C temps. I'm using this material for the other 3D prints that are part of the build. -John

-

As long as we're talking about yellow Elans... I've lusted for an Elan since I was a kid and was finally able to scratch that itch 4 years ago. It's ridiculously narrow, immense fun, and shockingly competent for a car introduced nearly 60 years ago. The previous owner spent a bunch of money on a mechanical and interior refresh and various upgrades, including springs and shocks from Tony Thompson Racing in the UK, RD Enterprises header, small alternator, alloy fuel tank, Euro-style intake, bigger radiator, dual cooling fans and a few other items. I added a hollow front ARB from Kelvedon, Michelin XAS FF tires (very grippy), swapped the spare tire for a lightweight compressor and tire repair kit, gear reduction starter, a programmable 123 Ignition that had the curve set on the dyno, and spent a lot of time tweaking the rebuilt Stromberg's to improve throttle response. The car tips the scale a touch under 1500 lbs and never ceases to impress down a back road. -John

-

So, tell us a little about yourselves

JohnCh replied to slngsht's topic in General Sevens Discussion

I find a hybrid approach is best. Use a single thread to document the build and ask questions along the way. When you run into an issue that is more of a standalone problem not necessarily unique to you, and you aren't getting an answer in the thread, then it is useful to broaden the net with a new post and update your build thread with the answer or a link to that other thread. This way your build remains fully documented in a single thread, but when needed, you can get more eyeballs on the problem. That standalone thread may also be easier for others to find in the future via search if they are running into the same problem. -

So, tell us a little about yourselves

JohnCh replied to slngsht's topic in General Sevens Discussion

That sounds like a challenging project! Definitely start a thread in the Build section so we can follow along. Cheers, John -

I'm not sure what the situation was 10 years ago, but the current Michelin XAS tires are quite good. They come in both standard and FF (Formule France) versions, the latter of which Michelin refers to a competition compound and is what I run on my Elan. It's quite sticky and has exceeded all my expectations. Downsides are they require a tube and they are expensive. I've heard good things about the CN36. I'm looking forward to hearing your impressions in April. -John

-

Very cool! Did a little digging and apparently it was a Cobra-powered S3 run by Dan Morgan in 1966. @SevenAmerica, who knows all things Lotus 7, may know more. -John

-

As a reference, and absent an answer from someone who actually understands this stuff, Caterham fits -12 plumbing to the oil system. Granted these are longer runs to the dry sump tank and oil cooler, but I'd be hesitant to use something as small as -8. -John

-

Hmm. Roughly 320hp at the crank in a se7en. That should be...adequate? -John

-

Graham, as I recall you previously mentioned that head is capable of 275 whp with the right cams and throttle body. What's the goal?

-

Perhaps we've found your new avatar? -John

-

This followed me home yesterday

JohnCh replied to Smithengineered's topic in General Sevens Discussion

Glad you found a car so quickly! I'm looking forward to reading your impressions once you have a chance to put some miles on it. -John -

Bruce Beachman is a fan and has already put some of their parts on CatKong. So yes, the site has already been very bad for your wallet. For those who haven't seen their site, they do some very cool catch cans and also low profile, swiveling banjo fittings that can save the day when connecting to an ORB port and space is tight -John

-

I don't need one, but I like them and have always had them in my cars. Given I have no idea where I'll take this engine in the future, I like maintaining that flexibility. I've never had trouble with a one drifting but will keep the safety wire in mind if I do. The dial gauge that screws into the NPT port makes it easy to monitor.

-

The regulator-damper is an uncommon part made by Radium Engineering here in the PNW. My fuel rail does not have a damper, and while not strictly necessary, I view it as a nice to have. This part combines the adjustable regulator -- which I need as I'm eschewing ECU control of the pump -- and the damper into a single component that simplifies the plumbing. Overkill? More than likely, but so are most of the other things I'm doing to this car http://www.radiumauto.com/FPR-D-Fuel-Pressure-Regulator-Damper-P1716.aspx -John

-

My car's color is similar in how it changes color based on lighting conditions. I've yet to capture a photo that is close to reality. I can see why you call it Violently Violet, although Gaudy Grape is also accurate I sent you a PM about clicks to post. I think you may be unaware of some forum features and are taking the more scenic route. Cheers, John

-

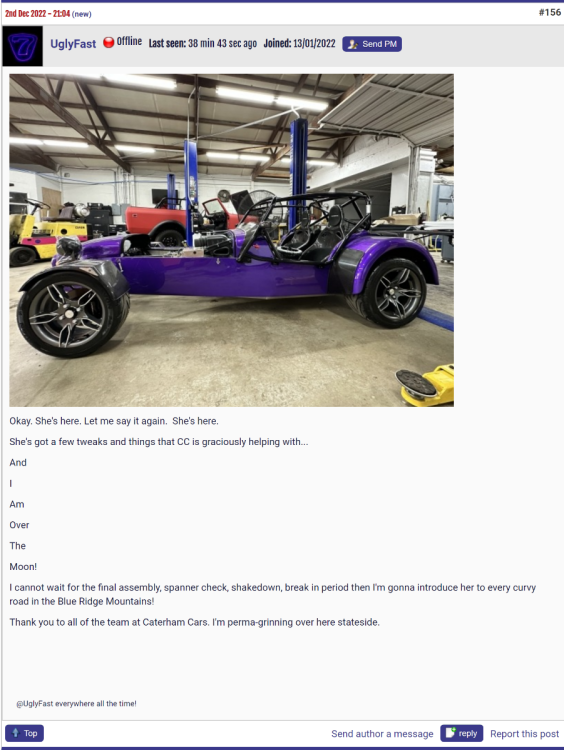

Hmm.... He teases us here on USA7s, but posts a photo of the car on BlatChat? Suddenly I don't feel so bad for making the prank call to customs a couple of weeks ago about contraband in his shipment -John

-

I'm tossing the factory line and replacing with AN -6 Goodridge 910 hose for both feed and return. The 910 is a smooth bore PTFE with an Aramid braid cover. It's lightweight and flexible. -John

-

I've finalized V1 of the fuel system. If it all fits together and I didn't make any mistakes, there won't be a V2...but we all know that's not gonna happen. Fingers crossed anyway. It seemed easier to start from scratch which resulted in the following design. Most of the parts are either already here or in transit. I should have a better sense over the next few days if V2 will be necessary. One open question is the lid for the fuel pump assembly. The stock part is 1/8" thick plastic with moldings on the surface for the various fittings. The replacement piece will either be cut from flat 1/8" Acetal sheet or 3D printed from Nylon. The material difference is down to availability. Acetal is the best gasoline and ethanol compatible option from the company that water jet cuts from a supplied file (Sendcutsend.com), whereas Nylon is the best if I 3D print it. Although my current printer can't handle that material, the new one arriving tomorrow is set up for it. Nylon is reputedly very tricky to print, but if I can make it work, it's preferred as I can redesign the lid a bit and improve some aspects. The Hydramat ensures the pump can access every last drop of fuel in the tank and acts as a pre-pump filter. Unlike Caterham, I'm also adding a post-pump filter that will mount in front of the tank and is accessible for maintenance via the plywood boot panel. For a fuel sensor, I'm using the same unit I have in the Westfield. It's a Centroid capacitance sensor with low fuel warning light output. I decided to splurge on the regulator and purchased the regulator-damper combo from Radium. Actual mounting location will likely be just in front of the pedal box or on top. I need to work out where the airbox will sit before making that decision. AN-6 line is used throughout, with the pump rated at 255 LPH. That means plenty of headroom should I later decide to add a lot more power so I can spin more often when attempting to drive in a straight line. -John

-

What about the cams? The stock pistons limit the amount of valve lift the engine can accommodate, which roughly equates to cams that cap out at about 210-220hp. It seems odd that the person wouldn't have fitted more aggressive cams to get into the >220hp range if they went through the effort of rods and pistons, unless the engine had an issue, and they were simply rebuilding with an eye towards the future. Without knowing the backstory, the lack of an oil pan and the price would be a bit of a red flag for me, and I would go into this assuming it would need at least a refresh. But at $1100 for a long block, if it works, it's a good deal and I wouldn't worry much about the resell price I mentioned earlier. As you know, you'll spend a lot more getting the engine and chassis ready for the swap. BTW you didn't mention ECU in your list above. Do you have an aftermarket ECU that can be reprogrammed for the Duratec? If not and you are running the Ford ECU used in many Zetec Caterhams, you should make sure that can be reused. Aftermarket ECUs aren't cheap. -John

-

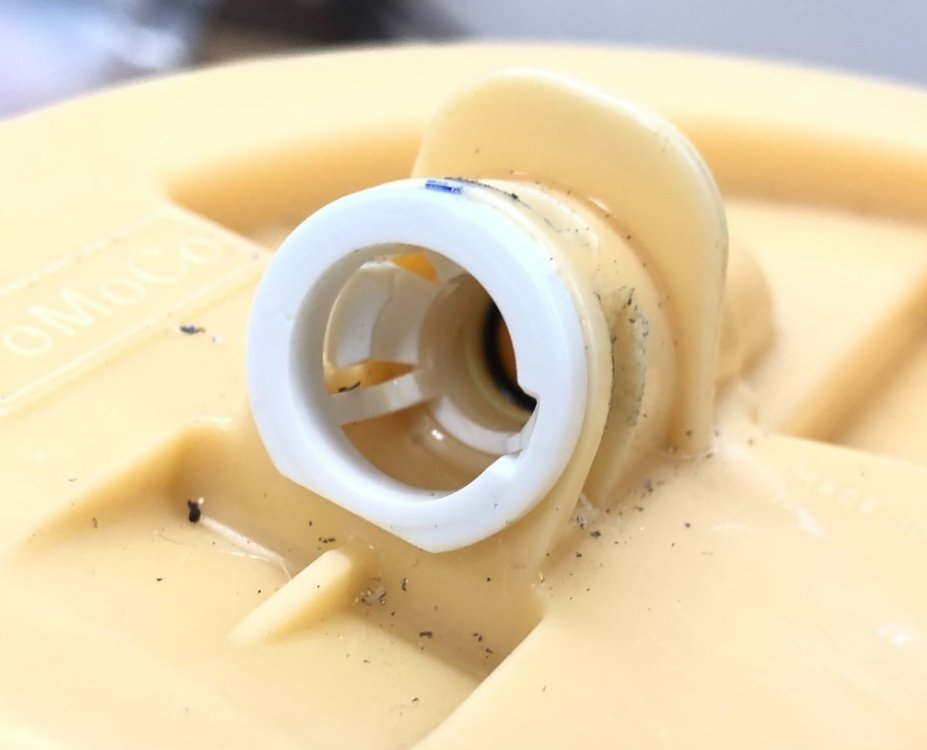

I dug into the fueling a little more yesterday. Removing the fuel line was maddening until I figured out that the three little tabs of the quick connector which hold it in place must be lifted away from a hidden ring around the outside of the fuel line and not pushed towards it as I had initially assumed. With that removed, the fuel pump assembly (FPA) was lifted out of the way for closer examination. Based on various measurements, it's pretty clear why so many people complain about the factory fuel level sensor accuracy and the actual tank capacity. The bottom of the tank slopes forward at about a 23 deg angle. The FPA mounting is also tilted forward but only about 8 deg. Because the bottom of the FPA must be in contact with the fuel for the pump to retrieve it, and because the tank floor slopes away so severely, there is about 0.9 gallons of fuel that it cannot touch. The fuel level sensor float -- or at least my float -- is set so that it's about 6mm below the bottom of the FPA when fully extended, meaning it's reading that some fuel is still in the tank when the fuel pump can no longer reach that available fuel. My current plans are to either modify the FPA so it will work with the Hydramat -- which will allow the pump to reach all available fuel -- and a capacitance sender or throw it away and start from scratch. I'm leaning towards the latter, as ultimately, I think it will be less frustrating and work better but need to do a little more research. -John

-

When you say forged 2.0L, what are the specs? The following parts are the same: Exhaust, bellhousing, clutch slave cylinder, engine mounts, starter, alternator & mounts. The intake ports are shaped differently and larger on the 2.5L head, so the intake won't fit. Dry sump is worth a call to Raceline who make the dry sump for Caterham. They list the 2.0L, 2.3L, and 2.5L dry sump separately and all at the same price. However, it's not clear to me if the pump or any fitting locations are actually different, or if this is simply done for marketing purposes; I didn't ask when placing my order. One thing to consider is optimal spec to minimize your losses when selling the 2.0L. If you pull the dry sump and oil pump (specific for the dry sump) you will need to buy a new oil pump and a wet sump. The latter isn't cheap. Given the price difference between the two (about $750 including pump) and the extra cachet the dry sump listing will have, it might not be worth removing the dry sump on that engine and instead selling it as-is. That's the process I'm following for my 420R engine that I'm putting up for sale in the near future. Note: if the 2.0L isn't using the Caterham/Raceline dry sump, you may also have to redo the oil lines as port locations and fittings may not work. -John