Nick OTeen

Registered User-

Posts

223 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by Nick OTeen

-

WTB Ford Racing Alum Valve cover for cross flow

Nick OTeen replied to Vinman1's topic in Parts For Sale / Wanted

Here's another option: https://www.summitracing.com/parts/fms-302-137?seid=srese1&gclid=CjwKCAiAyPyQBhB6EiwAFUuaklXsMUfizDbqxO-rCyZZY0352cFyoROH0PFi6Kwr18WOVBCVIgZmehoCYw0QAvD_BwE -

WTB Ford Racing Alum Valve cover for cross flow

Nick OTeen replied to Vinman1's topic in Parts For Sale / Wanted

I have a polished aluminum valve cover that will fit, but it doesn't say "Ford Racing" (or anything else) on it. -

WTB Ford Racing Alum Valve cover for cross flow

Nick OTeen replied to Vinman1's topic in Parts For Sale / Wanted

https://wwwqa.performanceparts.ford.com/part/M-6582-16K -

One good source for LED lights for automotive use is here: https://www.superbrightleds.com/cat/tail-brake-turn/ One thing to keep in mind when replacing conventional incandescent turn signal bulbs with LED units is that most turn signal flasher units depend upon the electrical load provided by incandescent bulbs. Typical LED replacements don't provide a sufficient load which will cause the turn signal flasher to flash at a much faster rate. To overcome this will need to replace the flasher with one intended for use with LEDs. Some even provide an adjustment feature that allows you to dial in the flash rate you desire.

-

One of my race cars, which uses a PC680 (as does my Caterham 7) would quickly drain the battery while trying to start it. It turned out the bushings/bearings in the starter motor were worn which allowed the armature to be off-center. I had the starter rebuilt and afterward it spun like a champ and did not drain the battery.

-

I have carbon fiber stone guards that are covered with paint protection film on top of fiberglass fenders that are likewise covered with paint protection film that extends up to the top of each fender. Everything looks great.

-

New OEM LED tail light design.

Nick OTeen replied to KnifeySpoony's topic in General Sevens Discussion

While there is some slight resemblance, the lights on on the truck in the photo are not the ones Caterham is selling now. -

New OEM LED tail light design.

Nick OTeen replied to KnifeySpoony's topic in General Sevens Discussion

My set arrived from England yesterday morning. The name CATERHAM appears on the lens twice. One right side up and the other inverted. They look and feel to be very well made and the kit is impressively complete. I’m looking forward to installing them on my car. -

Quasi new 15” wheels and CR 500 tires for sale

Nick OTeen replied to SK400's topic in Parts For Sale / Wanted

Are all four wheels 6" in width, or is the set, by chance, 6" wide fronts and 8" wide rears? -

New OEM LED tail light design.

Nick OTeen replied to KnifeySpoony's topic in General Sevens Discussion

We will see how long it takes for them to arrive. The shipping seemed awfully steep, however, for such a small and light package; about the same as what I spent a couple of months ago having this pricey, but beautiful, and heavy, lump of iron shipped over from the UK: -

New OEM LED tail light design.

Nick OTeen replied to KnifeySpoony's topic in General Sevens Discussion

I like them. A big improvement over the standard-issue, box-o-lights that look like something found in the "Towing Accessories" section at your local auto parts store. The look to be well made and nicely engineered in terms of packaging and wiring. They're not cheap at roughly $530 delivered to the US, but I ordered a set and look forward to installing them on my car. -

Unusual take on a Caterham by an owner in Singapore

Nick OTeen replied to Vovchandr's topic in General Sevens Discussion

-

Highly recommended. Been there, bought that.

-

To answer your question, no, a hex bit (or Allen key) will not be suitable for removing a drain plug that has a square opening. While the standard drain plug on a T-9 transmission can be removed/installed with a 10mm hex tool, there is always the possibility that your plug got switched out some time in the past for a plug with a square opening. As such, you might try simply using a socket wrench with a 3/8" drive extension to remove the plug.

-

Caterham doesn't make any of its parts

Nick OTeen replied to Vovchandr's topic in General Sevens Discussion

Arch Motors, which is still in business, built pretty much every tube frame chassis for Lotus from the very beginning; including those for Lotus race cars up to and including the F1 chassis. For example, I'm currently restoring a 1962 Lotus 22 F-Jr. Its chassis was produced by Arch and still bears the stamped-in letters "AM" followed by a two digit number. Like all Arch tube frames, including the chassis of my 2005 Caterham, is beautifully brazed together rather than welded. Arch continued to make tube frames for Caterham up until at least 2005 before Caterham brought the chassis production in-house where they are welded rather than brazed. Arch Motors also produced all the aluminum body panels for Lotus 7s and, thereafter, Caterham 7s. -

+44 (0) 1322 625801

-

-

It will handle a quality 265GB memory card. As for external power, check out this video: [video=youtube;WzFk0HmUC-Y]

-

I'd be interested if that could be arranged.

-

They are on facebook. From the looks of things they do contract manufacturing of carbon fiber components for other companies. https://www.facebook.com/enishi.carbon/photos/a.2111815259131559/2126048934374858 Their facebook page also shows pictures of carbon fiber cycle wings, dash panels and noses for 7s.

-

Three KN ET19 16x7 wheels for Caterham

Nick OTeen replied to carguy1315's topic in Parts For Sale / Wanted

I bought one of these wheels to have around as a spare. At this price it was too good to pass up. It arrived Saturday and was, as described above, "excellent condition." -

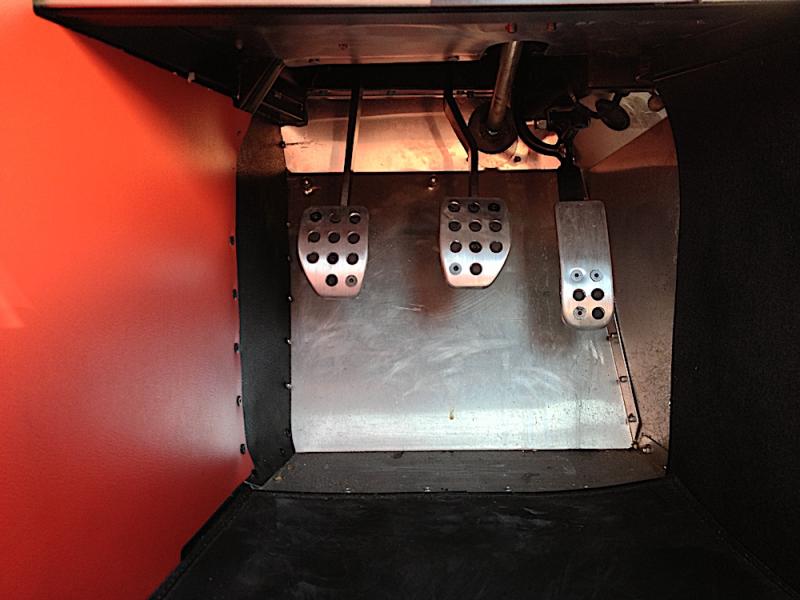

As I recall, I found those pedal overlays on eBay and they were relatively inexpensive. As you surmised, they are held in place by countersunk Allen screws. Reconturing the bends in the brake pedal required removing it and using a hydraulic press (along with using some metal bar stock scraps as dies) in a friend's auto repair shop. In all about a simple thirty minute process.

-

Regarding pedal setup to facilitate heel and toe work here's what I did. The first picture shows my Caterham's original pedal configuration. First off, the clutch and brake pedals were simply too small. You need more surface area than that provided by the little rubber pads, particularly on the brake pedal, to get a good feel and to be able to provide sufficient force. The other problem was the brake and throttle pedals being too far apart to allow heel and toe work. Additionally, the throttle pedal was a rather oddly-shaped thing. The solution was twofold. First was the addition of pedal "overlays" to address the lack of surface area. Second was to remove the brake pedal and, using a hydraulic press, redo the bends to bring it close to the throttle pedal. I should mention that, at least for me, "heel and toe" is something of a misnomer as I work the brake pedal with the ball of my left foot and the throttle pedal with the (right) side of the foot while my heel remains on the floor. The other, very important, element is to adjust the pedals such that when you are pressing hard on the brake pedal ends up on the same plane as the throttle pedal. This means under hard braking the ball of your foot is firmly on the brake while you blip the throttle with the outer edge of the foot.

-

You definitely should have a second throttle return spring, both as a safety measure and to give you more tactile feedback than what you are getting now from the single, existing spring.